- Proceedings

Information

Journal of Energy and Natural Resources

- Processing Charges

Innovation in Exploration and Production: How Technology Is Changing the Oil and Gas Landscape

Ekrem Alagoz

R&D Department, Turkish Petroleum Corporation (TPAO), Ankara, Turkey

Yaser Alghawi

Harold Vance Department of Petroleum Engineering, Texas A&M University, College Station, United States

Muhammed Said Ergul

Petroleum and Natural Gas Engineering, Izmir Katip Celebi University, Izmir, Turkey

Add to Mendeley

This research paper examines the impact of technology on the oil and gas industry, specifically in the context of exploration and production. The purpose of the study is to analyze the innovative techniques being utilized and the challenges and limitations associated with technology adoption in the industry. The paper presents case studies of successful technology implementation and discusses the future of innovation in exploration and production. Technological advancements in the oil and gas industry have led to significant improvements in efficiency and cost savings. Innovative techniques such as 3D and 4D seismic imaging, unconventional oil and gas extraction, robotics and automation, data analytics and artificial intelligence, block chain technology, and digital twinning have revolutionized exploration and production processes. These technologies have enhanced decision-making, optimized operations, and reduced environmental impact. However, the industry faces challenges in adopting new technologies, including resistance to change, high costs, cybersecurity concerns, and technical limitations. Overcoming these challenges is crucial for the industry's long-term success and sustainability. The research concludes by emphasizing the need for continued innovation and technology adoption in the oil and gas industry. Future advancements in nanotechnology, machine learning, and augmented reality hold the potential for further transformative impacts. By addressing the challenges associated with technology adoption, the industry can strive towards a more sustainable and profitable future, meeting the growing global energy demand. Policymakers, industry stakeholders, and investors should stay informed about the latest trends and developments to make informed decisions and drive growth in the industry.

Oil and Gas Industry, Exploration and Production, Technology, Innovation, Environmental Impact

Ekrem Alagoz, Yaser Alghawi, Muhammed Said Ergul. (2023). Innovation in Exploration and Production: How Technology Is Changing the Oil and Gas Landscape. Journal of Energy and Natural Resources , 12 (3), 25-29. https://doi.org/10.11648/j.jenr.20231203.11

Ekrem Alagoz; Yaser Alghawi; Muhammed Said Ergul. Innovation in Exploration and Production: How Technology Is Changing the Oil and Gas Landscape. J. Energy Nat. Resour. 2023 , 12 (3), 25-29. doi: 10.11648/j.jenr.20231203.11

Ekrem Alagoz, Yaser Alghawi, Muhammed Said Ergul. Innovation in Exploration and Production: How Technology Is Changing the Oil and Gas Landscape. J Energy Nat Resour . 2023;12(3):25-29. doi: 10.11648/j.jenr.20231203.11

R&D Department, Turkish Petroleum Corporation (TPAO), Ankara, Turkey

Harold Vance Department of Petroleum Engineering, Texas A&M University, College Station, United States

Cite This Article

- Author Information

Verification Code/

The verification code is required.

Verification code is not valid.

Science Publishing Group (SciencePG) is an Open Access publisher, with more than 300 online, peer-reviewed journals covering a wide range of academic disciplines.

Learn More About SciencePG

- Special Issues

- AcademicEvents

- ScholarProfiles

- For Authors

- For Reviewers

- For Editors

- For Conference Organizers

- For Librarians

- Article Processing Charges

- Special Issues Guidelines

- Editorial Process

- Peer Review at SciencePG

- Open Access

- Ethical Guidelines

Important Link

- Manuscript Submission

- Propose a Special Issue

- Join the Editorial Board

- Become a Reviewer

Articles on Oil and gas exploration

Displaying all articles.

Whales stop singing and rock lobsters lose their balance: how seismic surveys can harm marine life

Ryan Day , University of Tasmania ; Jayson Semmens , University of Tasmania , and Robert McCauley , Curtin University

Oil drilling threatens the Okavango River Basin, putting water in Namibia and Botswana at risk

Surina Esterhuyse , University of the Free State

Underwater noise is a threat to marine life

Graeme Shannon , Bangor University

What are mud volcanoes?

Michael R. Hudec , The University of Texas at Austin

Opening 10 new oil and gas sites is a win for fossil fuel companies – but a staggering loss for the rest of Australia

Samantha Hepburn , Deakin University

Scott Morrison’s veto of a gas-drilling plan off Sydney was strange – but it should not be overturned

Planned seismic survey by Shell has kicked up a storm in South Africa. Here’s an explainer

Mia Wege , University of Pretoria ; Barend Erasmus , University of Pretoria ; Christel Dorothee Hansen , University of Pretoria ; Els Vermeulen , University of Pretoria ; James Roberts , University of Pretoria ; Jean Purdon , University of Pretoria , and Michael John Somers , University of Pretoria

We should ban all new oil and gas fields

David Waltham , Royal Holloway University of London

How fracking plans could affect shared water resources in southern Africa

The 2020 elections will determine which voices dominate public land debates

James R. Skillen , Calvin University

Trump greenlights drilling in the Arctic National Wildlife Refuge, but will oil companies show up?

Scott L. Montgomery , University of Washington

Why South Africa has a keen interest in extremist violence in northern Mozambique

Theo Neethling , University of the Free State

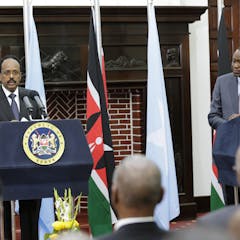

Western countries take sides in Kenya’s maritime row with Somalia

Patrick Muthengi Maluki , University of Nairobi

Methane emissions from oil and gas exploration are under-reported

Greg McDermid , University of Calgary and Maria Strack , University of Waterloo

A defeat on offshore drilling extends the Trump administration’s losing streak in court

Alejandro E. Camacho , University of California, Irvine and Robert Glicksman , George Washington University

The sage grouse isn’t just a bird – it’s a proxy for control of Western lands

John Freemuth , Boise State University

How media framing limits public debate about oil exploration

Sophie Bond , University of Otago ; Amanda Thomas , Te Herenga Waka — Victoria University of Wellington , and Gradon Diprose , Manaaki Whenua - Landcare Research

Related Topics

- Climate change

- Endangered species

- Fossil fuels

- Oil and gas industry

- Okavango Delta

- Peacebuilding

- Public lands

- Trump administration

- underwater noise pollution

Top contributors

Senior Lecturer Centre for Environmental Management, University of the Free State

Professor, Deakin Law School, Deakin University

Senior Lecturer, Institute of Diplomacy and International Studies, University of Nairobi

Lecturer in Zoology, Bangor University

Cecil D. Andrus Endowed Chair for Environment and Public Lands and University Distinguished Professor, Boise State University

Professor of Political Science, Department of Political Studies and Governance, University of the Free State

Professor of Law and Director, Center for Land Environment, and Natural Resources, University of California, Irvine

Associate Professor in Geography, University of Otago

Senior Lecturer in Environmental Studies, Te Herenga Waka — Victoria University of Wellington

Senior Researcher, Environmental Social Science, Manaaki Whenua - Landcare Research

Associate Professor of Environmental Studies, Calvin University

Professor, Department of Geography, University of Calgary

Professor of Environmental Law, George Washington University

Professor, Department of Geography and Environmental Management, University of Waterloo

Lecturer, University of Pretoria

- X (Twitter)

- Unfollow topic Follow topic

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

- We're Hiring!

- Help Center

OIL AND GAS EXPLORATION AND DRILLING

- Most Cited Papers

- Most Downloaded Papers

- Newest Papers

- Save to Library

- Procurement and Tendering Contracts Follow Following

- Construction contracts Follow Following

- International political economy of oil and gas Follow Following

- Oil Natural Gas Energy Geopolitics Follow Following

- Oil and Gas Drilling Engineering Follow Following

- Drilling and Well Engineering Follow Following

- Directional Drilling Follow Following

- Upstream Oil and Gas Follow Following

- Drilling Engineering Follow Following

- Oil and Gas Management Follow Following

Enter the email address you signed up with and we'll email you a reset link.

- Academia.edu Publishing

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Advanced Oil and Gas Exploration and Recovery Research Paper

Introduction, success in unconventional oil or gas exploration and recovery, economic benefits, environmental impact.

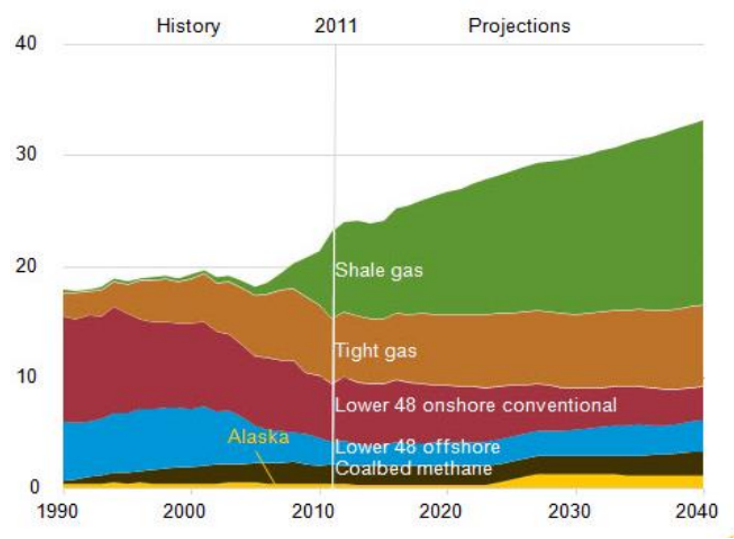

A new revolution is dawning: the unconventional oil and gas revolution, which has created a huge economic impact. In particular, this will impact the broader economy, increase the U.S. gross domestic product (GDP), address the country’s unemployment problem and add more revenues to the country’s coffers. Because of the vast demand for conventional oil and gas, the United States has long embarked on oil exploration and in these past few years the country has experienced the increased availability of shale energy. Many Americans have to learn the nature and benefits of shale energy but researchers and the government, in particular, know that this form of unconventional energy will address the large energy demand and the benefits will expand to all the 50 states.

The GDP contribution of unconventional oil and gas (UOG) reached $284 billion in 2012, with upstream operations accounting to $238 billion, and an additional midstream and downstream operations of $39 billion ( IHS , 2013). Midstream refers to initial activities encompassing transport from sea to land to pipelines; whereas, downstream refers to converting the natural gas liquids into consumer products which involves refining, processing or upgrading ( IHS , 2013)

. A United States study reveals that the total unconventional oil and gas (UOG) produced in the Lower 48 states reached $63 billion for the federal, state, and local tax revenues in 2012, and by 2020 this could reach $113 billion (Hausman & Kellogg, 2015). The higher unconventional energy production, which Hausman and Kellogg (2015) described as supply boom, was triggered by technological development in extraction. Horizontal drilling applied with hydraulic fracturing is an innovation that allows easy and low-cost extraction.

The Energy Information Administration reports that in the U.S. alone, investigators and engineers have pinpointed at least 2,203 trillion cubic feet of gas reserve, enough for the country to survive for 93 years, as estimated by policy makers based on current rates of consumption (Sprague, 2015). Trapped in shale rock in the U.S. are estimated 2,431 billion barrels of what scientists call wet natural gas, while in the Niobrara shale rock, there are about 4.1 billion barrels (Sprague, 2015). In Colorado, there is an estimated 20,666 billion barrels of gas reserve. Colorado is the forerunner of oil and gas development in the West (Noel as cited in Sprague, 2015).

OUG exploration can drill 1 to 2 miles below the earth’s surface, taking out oil and gas through steam injection, added with chemicals to create ruptures on rock formations (Jemielita et al., 2015). First, engineers use remote sensing technique and apply spectral measurements and chemical tests to retrieve oil and gas information and data. Scientists also use and analyze high-resolution images in order to get the most reliable information about oil and gas (Song, Yang, Zhen, & Li, 2014).

Since 2006, the United States has been successful in shale gas production, particularly in Texas, which has the predominant Barnett Shale. This has encouraged shale gas recovery technologies for firms to hasten their shale development activity. The combination of two technologies – horizontal and hydraulic drilling – generated less costly shale gas production and stimulated growth (Kharabah, 2014).

Conventional reservoirs are smaller than unconventional ones but the unconventional reservoirs have larger oil or gas in place and difficult to develop. Unconventional reservoirs need high technology and are much more costly to develop. International gas companies are continuously searching for unconventional gas reservoirs in order to meet the huge demand. The resource triangle for conventional and unconventional reservoirs is shown in figure 1.

Shale refers to a type of clay or mud that can easily split into layers and have transformed into rocks by way of geological circumstance. Shale formations function as source rocks and seals for conventional reservoirs. Gas gets out from the source rock to sandstone or carbonate reservoirs, in which gas is trapped in the sandstone forming a gas reservoir. Shale gas reservoir is considered extremely organic with a permeability ranging from 0.1 mD to 10-7 mD (Siripatrachai & Ertekin as cited in Kharabah, 2014). Natural gas and oil are found in permeable sandstones, shale rocks, and coal foundation (Jemielita et al., 2015).

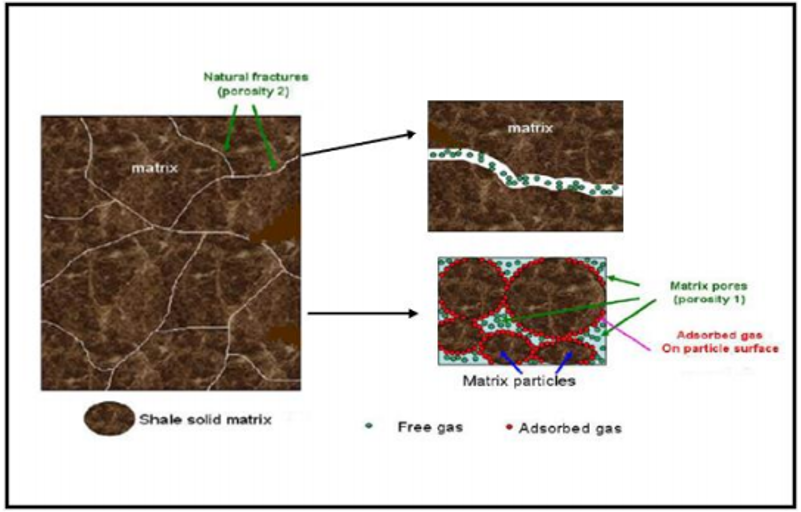

Gas deposit has been categorized by scientists as: free gas, which is predominant in pores and has low permeability; free gas, which has higher permeability; and the last is adsorbed gas predominant on the shale’s surface. Adsorbed gas can be primarily characterized by two parameters: Langmuir Volume (V L ) and Langmuir Pressure (P L ). Methane is the gas produced in shale, but there can also be wet gas. This is shown in figure 2.

Horizontal drilling is the conventional method of drilling shale gas. Horizontal drilling is done after a vertical one wherein the drill penetrates the “kickoff point,” proceeds to a curve to reach the “entry point” in the reservoir. The bottom hole is then located. This method helps to infiltrate a maximum distance of gas-bearing rock and a maximum number of vertical rock formations (Jemielita et al., 2015).

Horizontal wells are more recommended than vertical ones, particularly when drilling in a Marcellus shale reservoir. In this kind of reservoir, the natural fractures are vertical and when a vertical well is drilled, very few vertical fractures are intersected. In a horizontal well, many vertical fractures are intersected (Kharabah, 2014), which is considered productive as the well can get as much gas to be brought to the surface as possible. Horizontal wells are very costly: an average newly drilled horizontal well costs about 1.5 to 2.5 times more than a vertical well (Joshi as cited in Kharabah, 2014); but the productive benefits for a horizontal well exceed those of the vertical well.

Hydraulic fractures

Hydraulic fractures are created in the reservoir to allow free flow of oil or gas. There are two types of these, which can be determined by the direction of the stress field (vertical or normal to the horizontal minimum stress) in generated formation. If the horizontal well is drilled parallel to the minimum horizontal stress, it is expected that the fractures created will be perpendicular to the horizontal well, thereby, creating a transverse well, while the other limiting case can be generated if a horizontal well is drilled perpendicular to the minimum horizontal stress, creating a longitudinal fracture (Sprague, 2015).

Hydraulic fracturing uses a combination of water and chemical, others include sand, in retrieving oil and gas deposited in the shale rock (EIA as cited in Sprague, 2015), On the other hand, longitudinal fractured wells are enormously effective in high permeability reservoirs, but in Marcellus shale reservoirs, engineers use transverse fractured horizontal well for productivity instead of longitudinal fractured horizontal well (Kharabah, 2014)

. At a depth of 1,000 to 4,000 feet, steel casings are pushed to the bottom of the shale to prevent water from mixing with the oil or gas. The casing and the wellbore are separated with cement. When everything is in place, drilling proceeds until it reaches 6,000 to 10,000 feet where the oil and gas can be extracted from the shale reservoir (The Groundwater Protection Council as cited in Sprague, 2013).

After recovery, natural gas requires fewer processing steps before it is consumer ready. Eighty percent of natural gas used in America is produced domestically; but the country imports over 50% of its needed oil from other countries (American Gas Association as cited in Stoekl, 2012). Oil will be cheap because of the law of supply and demand, coupled with more unconventional oil and gas recovery. This is not to mention the increased oil production (Stoekl, 2012).

Unconventional energy transforms local energies in the U.S., providing jobs and leveling oil prices for the common American consumers (Stoekl, 2012). There has been an annual increase of U.S. GDP since 2012 due to midstream and upstream operations ( IHS , 2013). The sector has provided 2.1 million jobs to Americans and expatriates, with 377,000 of the jobs coming from midstream and downstream operations ( IHS, 2013). Upstream activity also contributed trillions of dollars to government revenue. U.S. net trade from unconventional energy will reach $22 billion and it will be at a higher level in 2022. States which do not have major unconventional energy activity can provide at least 500,000 laborers through diverse energy-related businesses ( IHS , 2013).

Yergin, IHS executive, says that the unconventional energy revolution has created impact in the entire United States, including those states which are not involved in oil production, with the largest economic contribution provided by Texas and Pennsylvania. However, New York and Illinois have assumed roles of producing goods and services relevant to the supply chain. The unconventional energy producing states have contributed approximately 1.3 million jobs ( IHS , 2013). John Larson, IHS vice president, indicated that the UOG revolution will have a wider impact on the US economy.

Energy-intensive firms using chemicals, including the food sector, are putting a portion of their capital for energy operations due to decreased domestic prices. It has been forecasted that energy-intensive sub-sectors, particularly those involved in iron and steel production, chemicals like resin and synthetics, including those used in agriculture, will surpass the entire US industrial economy ( IHS , 2013).

The chemical industry is one of the greatest beneficiaries of the shale gas boom. U.S.-based chemical companies use natural gas-based feedstocks such as ethane to produce raw materials for a wide range of products including plastics, films, and adhesives (Huh, 2013). It is projected that after 2030 the chemical industry would become the fastest growing industry. Additionally, there has been a dramatic increase in U.S. chemical exports recently, and this is correlated with increasing oil-to-gas ratio.

Since natural gas burns cleaner than other fossil fuels, many companies and municipalities are deploying fleets of natural gas-powered cars, trucks and buses in attempt to reduce emissions. Clean Energy Fuels Corporation in the U.S. is rapidly developing a coast-to-coast network of compressed natural gas (CNG) filling stations. An 18-wheeler running on CNG can haul cargo to nearly every major city across the U.S. (Huh, 2013).

However, there are environmental ramifications in the UOG exploration and recovery. While unconventional energy is mostly organic, it can still have environmental impact, particularly in the drilling and recovery activities. Compared with wind and solar energy, which do not need the long process of extraction, unconventional energy extraction affects the ecosystem. The presence of multiple stressors has a negative environmental effect. Unconventional energy development has been criticized as an environmental stressor as it could affect stream sedimentation and the aquatic ecosystem around UOG development (Entrekin et al., 2015).

Entrekin et al. (2015) argue that unconventional energy exploration and recovery from shale rock can negatively affect rivers and streams through water withdrawals, land changes, and other changes in the ecosystem. However, they also indicate that the extent of environmental damage, such as the negative impact on the stream ecosystem, is still unknown. As described earlier, shale is mud that transforms into rock through geological circumstance; shale holds a large reservoir of oil and gas, believed to be present in 41 countries around the world, holding as much as 7,299 trillion cubic feet of natural gas and hundreds of billions of barrels of oil (US DOE/EIA as cited in Entrekin et al., 2015).

Activities like infrastructure installations, drilling and fracturing, water use and waste management can disturb aquatic communities and provide ecological impact. Infrastructure activities include construction of roads and bridges, pipelines, which can affect underlying communities and small-scale farming. Water flows which sustain natural habitats will be altered (Entrekin et al., 2015). There is also the fear of environmental accident that might cause chemical contamination or leaking wastewater storage systems, liquid-truck or train accidents, pipeline leakages, and so forth. Lack of empirical studies on the environmental impact of UOG has exacerbated fears of environmental groups, especially since UOG development has been remarkably fast due to the increased demand of oil and gas.

At present, there are five shale plays in the United States which supply as much as 80 percent of shale gas in the country. Notable among these shale plays is the Appalachian basin and the Williston basin, but development in other areas is rapidly increasing, such as those in Pennsylvania and West Virginia. UOG extraction in New York and the Delaware River Basin has been placed on hold due to suggestion by some groups that more research should first be conducted (Entrekin et al., 2015).

In measuring the environmental effects of human activities, researchers used the vulnerability metric or threat index, which focuses on agriculture, urbanization, and mining. Vulnerability refers to exposure of the ecosystem to environmental stressors, which can be anthropogenic, construction of roads, bridges and other infrastructure, and the natural sensitivity of the ecosystem. Ecosystems are considered most vulnerable if they have “the most natural sensitivity and exposure to natural stressors” (Entrekin et al., 2015).

The US economy can gain much from refining of crude oil and natural gas liquids production. Rich gas has to be transported to processing plans, be “cleaned” of residue, transported to the NGL fractionator, and then sold to refiners or retailers. The process adds value to the product and creates more economic activity ( IHS , 2013).

In addition to the industries that directly take in natural gas as their feedstocks or as fuels to generate electricity, there are those that will benefit from low cost of natural gas. Many energy-intensive industries such as aluminum, steel, glass, cement, etc. are gaining global competitiveness from a significant reduction in operating costs due to cheap energy. Similarly, residential and commercial customers will benefit from lower costs of power, heating and fuel. Savings from lower gas prices will amount to $926 annually in disposable household income, and these savings would increase to nearly $2,000 per household (Huh, 2013).

This will most likely stimulate consumption, and the effects could be similar to a sizable tax or interest rate cut. Nonetheless, little growth in terms of natural gas demand is expected to come directly from the residential and commercial sectors; some conversions from oil heating to gas are underway in the Northeast, but as the population shifts to warmer regions where electricity dominates the space heating market, it is likely that less gas will be used for heating and more gas will be used to generate electricity for space heating and air conditioning. Some heating-related gas demand shows up as power sector demand for gas (Huh, 2013).

Despite the economic benefits, the U.S. should consider the environmental impact and conduct more empirical studies on the relationship of UOG and the aquatic ecology.

Entrekin et al. (2015) have noted that there is a relatively small but increasing literature exposing the relationship between UOG extraction and recovery and “the ecology of aquatic ecosystems” (p. 3-28). The geological shape, soil composition, and vegetation can change water, sedimentation, and the movement around the ecological system in areas where there is UOG development. As a whole, the natural environmental conditions, along with prevailing stressors, will certainly affect aquatic communities around these man-made activities.

Entrekin, S., Maloney, K., Kapo, K., Walters, A., Evans-White, M., & Klemow, K. (2015). Stream vulnerability to widespread and emergent stressors: A focus on unconventional oil and gas. Plos One , 10 (9), 1-28. Web.

Hausman, C., & Kellogg, R. (2015). Welfare and distributional implications of shale gas. Brookings Papers on Economic Activity , 1 (1), 1-45. Web.

Huh, H. (2013). Sustainable development of shale gas and gas-to-propylene (Master of Engineering thesis, Albert Nerken School of Engineering, New York). Web.

IHS: America’s new energy future: The unconventional oil and gas revolution and the US economy. (2013). Web.

Jemielita, T., Gerton, G., Neidell, M., Chillrud, S., Yan, B., Stute, M.,…Panettieri, R. (2015). Unconventional gas and oil drilling is associated with increased hospital utilization rates. Plos One , 10 (7). Web.

Kharabah, A. (2014). Estimating ultimate gas recovery from unconventional gas reservoir (Doctoral thesis, West Virginia University, Virginia). Web.

Song, X., Yang, F., Zhen, H., & Li, X. (2014). Synergistic analysis and correlative study on remote sensing and chemical exploration data for oil-gas exploration. International Journal for Remote Sensing , 25(21), 4675-4684. Web.

Sprague, C. (2015). The nexus of farming and energy: Navigating social tensions at the intersection of sustainable agriculture and unconventional oil and gas drilling (Master of Arts thesis, Colorado State University). Web.

Stoekl, A. (2012). Unconventional oil and the gift of the undulating peak. Imaginations Journal, 3 (2), 35-45. Web.

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2024, January 29). Advanced Oil and Gas Exploration and Recovery. https://ivypanda.com/essays/advanced-oil-and-gas-exploration-and-recovery/

"Advanced Oil and Gas Exploration and Recovery." IvyPanda , 29 Jan. 2024, ivypanda.com/essays/advanced-oil-and-gas-exploration-and-recovery/.

IvyPanda . (2024) 'Advanced Oil and Gas Exploration and Recovery'. 29 January.

IvyPanda . 2024. "Advanced Oil and Gas Exploration and Recovery." January 29, 2024. https://ivypanda.com/essays/advanced-oil-and-gas-exploration-and-recovery/.

1. IvyPanda . "Advanced Oil and Gas Exploration and Recovery." January 29, 2024. https://ivypanda.com/essays/advanced-oil-and-gas-exploration-and-recovery/.

Bibliography

IvyPanda . "Advanced Oil and Gas Exploration and Recovery." January 29, 2024. https://ivypanda.com/essays/advanced-oil-and-gas-exploration-and-recovery/.

- Growing role of Shale Gas

- Economic Analysis of Shale Gas

- Hydraulic Fracking for Natural Gas Extraction in Pennsylvania

- Shale Inc. Code of Ethics

- Utica and Marcellus Shales' Reservoir Development

- The Environmental Impacts of Exploratory Drilling

- Shale Oil Threat in Gulf Corporation Council

- The Advantages of Hydraulic fracturing for the Global Economy

- Hydraulic Fracturing and Its Environmental Impacts

- Environmental Biology: Hydraulic Fracturing Technology

- Carbon Cycle and Its Key Stages

- Water and Soil Resources Issues in the Middle East

- The Discovery of Oil Reserves in South Sudan

- Oil Drilling Project Monitoring and Control

- Water Cycle and Environmental Factors

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- v.8(11); 2022 Nov

Research advances of microbial enhanced oil recovery

a University of Chinese Academy of Sciences, China

b Institute of Porous Flow and Fluid Mechanics, University of Chinese Academy of Sciences, China

d State Key Laboratory of Enhanced Oil Recovery, China

Jianlong Xiu

c PetroChina Research Institute of Petroleum Exploration and Development, China

Lixin Huang

Yuandong ma, associated data.

Data will be made available on request.

Microbial enhanced oil recovery (MEOR), characterized with the virtues of low cost and environmental protection, reflects the prevalent belief in environmental protection, and is attracting the attention of more researchers. Nonetheless, with the prolonged slump in global oil prices, how to further reduce the cost of MEOR has become a key factor in its development. This paper described the recent development of MEOR technology in terms of mechanisms, mathematical models, and field application, meanwhile the novel technologies of MEOR such as genetically engineered microbial enhanced oil recovery (GEMEOR) and enzyme enhanced oil recovery (EEOR) were introduced. The paper proposed three possible methods to decrease the cost of MEOR: using inexpensive nutrients as substrates, applying a mixture of chemical and biological agents, and utilizing crude microbial products. Additionally, in order to reduce the uncertainty in the practical application of MEOR technology, it is essential to refine the reservoir screening criteria and establish a sound mathematical model of MEOR. Eventually, the paper proposes to combine genetic engineering technology and microbial hybrid culture technology to build a microbial consortium with excellent oil displacement efficiency and better environmental adaptability. This may be a vital part of the future research on MEOR technology, which will play a major role in improving its economic efficiency and practicality.

- • Mechanisms of microbial enhanced oil recovery.

- • The novel technology of microbial enhanced oil recovery.

- • Field trails of microbial enhanced oil recovery.

Microbial enhanced oil recovery; MEOR mechanisms; Biosurfactants; Biopolymers, Field trials.

1. Introduction

Traditional oil recovery technology consists of two stages: primary and secondary oil recovery ( Hadia et al., 2019 ). Primary oil recovery is the use of formation pressure to extract oil and gas from the reservoirs, with a 5–10% recovery rate of the original oil in place. In the stage of secondary oil recovery, people increase the reservoir pressure by injecting gas or water into the reservoir to replenish elastic energy for the rock and fluid in the formation, with the recovery rate ranging from 10% to 40% of the original oil in place ( Hadia et al., 2019 ; Patel et al., 2015 ). However, more than 60% of crude oil remains trapped even though the reservoir has been tapped twice by traditional oil recovery technology ( Wang et al., 2022 ; Niu et al., 2020 ). The tertiary oil recovery technology uses various physical, chemical and biological techniques to improve reservoir seepage characteristics and residual oil mobility, triggering the improvement of oil recovery ( Haq et al., 2020 ). Gas enhanced oil recovery (GEOR) and chemical enhanced oil recovery (CEOR) are popular methods of enhanced recovery in tertiary oil recovery technology ( Hadia et al., 2019 ; Massarweh and Abushaikha, 2021 ). However, they are both cost-effective and high-risk technologies, and even contain toxic chemicals potentially damaging the environment and human health. In recent years, with the global oil price depression, how to extract crude oil economically and efficiently has become a hot topic ( Safdel et al., 2017 ).

Microbial enhanced oil recovery (MEOR) attracts broad attention with the advantages of environment-friendliness and low-cost ( Wu et al., 2022 ). Microbial enhanced oil recovery (MEOR) is one of the tertiary oil recovery approaches which uses ex-situ/in-situ microorganisms and their metabolites like biopolymers, biosurfactants, bio-enzymes, biogases, solvents, and biogenic acids to modify the flow characteristics of residual oil in the reservoirs to enhance oil recovery ( Niu et al., 2020 ; Patel et al., 2015 ). However, it has not been widely used in the petroleum industry due to the complexity of its mechanism and the uncontrollable reservoir environment. Meanwhile, its success has been inconsistent, even in some field trials of enhanced oil recovery (EOR). Therefore, it is necessary to summarize and analyze the research of MEOR technology in recent years to reduce the additional risk cost caused by its uncontrollable factors. This paper reviewed MEOR technology from three aspects: mechanisms, mathematical model, and field application. Moreover, two novel technologies of MEOR, including genetically engineered microbial enhanced oil recovery (GEMEOR) and enzyme enhanced oil recovery (EEOR), are introduced. In the paper, we analyzed the research on microbial enhanced recovery in recent years and proposed possible solutions on how to further reduce the cost of MEOR and enhance microbial flooding efficiency.

2. MEOR mechanisms

MEOR is usually achieved via the interaction of microbial metabolites with reservoirs, which mainly includes increasing swept volume and enhancing oil displacement efficiency ( Wang et al., 2019 ). The mechanisms of MEOR based on microbial metabolites can be classified into the following parts: (1) Biosurfactants are mainly used to reduce the oil/water interfacial tension, modify the porous media wettability, emulsify residual oil, and improve the migration ability of bacteria ( Hajibagheri et al., 2017 ; Zhang et al., 2022 ); (2) Biopolymers and microorganisms plug the high-permeability porous media selectively, beyond which the biopolymers are also used as tackifiers to increase the aqueous phase viscosity ( Elshafie et al., 2017 ; Gao, 2018 ; Qi et al., 2018 ); (3) Biogases, solvents and biogenic acids can dissolve the carbonate rocks in oil reservoirs, making it easier for water to enter the pores of rocks and contact with the residual oil. Meanwhile, the gas produced by some of the dissolved carbonate rocks can increase the reservoir pressure ( Rathi et al., 2018 ); (4) The microorganisms in reservoirs live on the crude oil as carbon source, which can degrade the long-chain saturated hydrocarbons, reduce the viscosity and improve the fluidity of crude oil ( Tao et al., 2017 ). Particularly, the first two mechanisms are believed to have the greatest effect on improving oil recovery ( Patel et al., 2015 ). Figure 1 illustrated the mechanisms of microbial metabolites in the process of MEOR.

The role of microbial products in the process of MEOR.

2.1. Role of biosurfactants

Biosurfactants contain hydrophilic and hydrophobic groups which are a kind of amphiphilic compounds ( Alvarez Yela et al., 2016 ). In oil reservoirs, the hydrophilic and hydrophobic groups of biosurfactants will be soluble in aqueous phase and oil phase respectively. As shown in Figure 1 , This unique property can eliminate the repulsive force between oil and water, change the wettability and emulsify crude oil. Compared with the chemical surfactants, the advantages of biosurfactants are exhibited as biodegradability, low toxicity, and excellent stability ( Cameotra and Makkar, 2004 ). Biosurfactants can be roughly classified into six categories, including the lipopeptides, glycolipids, phospholipids, fatty acids, polymeric surfactants, and particulate biosurfactants ( Geetha et al., 2018 ). Some of them, such as lipopeptides and glycolipids, have been widely used to enhance the oil recovery ( Dhanarajan et al., 2017 ). As of now, a variety of microorganisms have been identified as the producing surfactant, including Bacillus , Pseudomonas , Saccharomyces , Rhodococcus and Acinetobacter . Table 1 provides the details about biosurfactants classification and producing microbes.

Table 1

Biosurfactants classification and producing microbes.

Biosurfactants exhibit the ability to reduce oil-water interfacial tension and emulsify crude oil, which have been shown to be closely related to their molecular mass. Low-molecular-weight biosurfactants, for example, the surfactin, can reduce the oil-water interfacial tension and change the wettability ( Alvarez et al., 2020 ; Varjani and Upasani, 2019 ). While biosurfactants with high molecular weight, such as emulsan, perform well at emulsifying ( Asfora Sarubbo et al., 2006 ; Tao et al., 2020 ). Furthermore, studies have shown that the concentration of biosurfactant can affect its function on crude oil as well. When the biosurfactants are at a low concentration, they tend to disperse the crude oil into minor particles to improve the utilization of crude oil by microorganisms. On the contrary, when the biosurfactants are at a high concentration, the hydrophobic groups of them tend to form micelles with crude oil and stabilize ( Sharma and Pandey, 2020 ). Therefore, the concentration of biosurfactants should be configured according to the actual demand.

In practical EOR applications, biosurfactants are usually used at concentrations above their critical micellar concentration (CMC) values to achieve excellent emulsification of crude oil. Some studies indicate that the CMC of biosurfactants is obviously lower than that of chemical surfactants. This means that we can use much smaller amounts of biosurfactants than chemical surfactants to achieve the desired effect ( Hadia et al., 2019 ). Nevertheless, high production cost still partly limits the application of biosurfactants. Therefore, it is urgent to reduce the production cost of biosurfactants. This paper summarized three possible methods. Firstly, the most promising approach is to use the abundant and cheap agro residue as the primary substances. Such as molasses, corn steep liquor and rice mill polishing residue played well in the production of biosurfactants ( Al-Bahry et al., 2013 ; Gurjar and Sengupta, 2015 ). The mixture of biosurfactants and chemical surfactants is another potential method to reduce the cost in MEOR. Studies have shown that mixing biosurfactant with a green non-ionic surfactant is a practical approach to enhance oil recovery ( Haq et al., 2020 ). The third method for reducing costs is to directly extract the biosurfactants from nature. In oil reservoirs with bacteria that produce surfactant, researchers believe there is probably a large amount of biosurfactants. Ethylenediamine (EDA) is used to extract biosurfactants (such as anionic surfactants) from crude oil into the aqueous phase, resulting in a cationic surfactant complex with surface tension (ST) reduced to 48 mN/m ( Nasiri and Biria, 2020 ).

In general, biosurfactants exhibit excellent application prospect in enhancing oil recovery. But at present, how to further reduce the cost of obtaining and using biosurfactants have become particularly important. The three possible implementation methods proposed in this paper: the application of cheap substrates to produce biosurfactants, the use of a mix of biosurfactants and chemical surfactants, and the extraction of the surfactants from nature. This may make biosurfactants exhibit better practicality and applicability in MEOR.

2.2. Role of biopolymers and biomass

Biopolymers and biomass have been used in the MEOR field mainly for plugging of high-permeability zones and realizing permeability modification ( Sen, 2008 ). Compared with synthetic polymers, biopolymers exhibit excellent stability, even in conditions of high temperature, hyper salinity and high shear rate ( Couto et al., 2019 ). Besides, biopolymers have no pollution and the rejectamenta could be broken down by microorganisms ( Zhao et al., 2018 ).

The actual reservoirs are mostly heterogeneous. Fluids enter the high-permeability zones easily, but it is hard to immerge low-permeability zones and move the residue oil. In the MEOR process, the microorganisms and nutrients that produce polymers will flow into the high permeability areas with the fluid. Biopolymers and bacteria clump together through continuous metabolic reproduction to block areas with high permeability, improving the efficiency of water drive sweep ( Patel et al., 2015 ). Moreover, studies have shown that the extracellular polysaccharides produced by bacteria protect them from drying and predation, as well as increasing the adhesion of bacteria, so this type of bacteria has a better plugging effect than others ( Sen, 2008 ). In addition, the plugging efficiency of biomass is related to the permeability of reservoirs and the radius of throats. The pore throat radius of reservoir is generally larger and the plugging ability of bacteria is weaker. With low permeability, the sieving effect becomes more prominent when the pore throat radius equals the diameter of the bacteria, and the sealing efficiency of the bacteria for the reservoir increases significantly ( Bi et al., 2016 ; Sen, 2008 ).

In addition, biopolymers are often used as thickeners to enhance crude oil recovery by increasing the viscosity of the aqueous phase and expanding the sweep efficiency ( Jang et al., 2015 ). Such polymers usually exhibit typical pseudoplasticity besides excellent stability in the reservoir environment. In the near-well zone, the polymer solution flows fast, with high shear rate and low viscosity, which contributes to promoting deeper into the reservoir. As the polymer solution moves away from the injection side, the shear rate decreases and the viscosity increases, which facilitates the repulsion of the remaining oil.

Xanthan gum, as a common biopolymer, has been widely used in petroleum, cosmetic and pharmaceutical fields due to its special molecular structure ( Palaniraj and Jayaraman, 2011 ). It is a polymeric extracellular polysaccharide produced by Xanthomonas , whose cellulose backbone consists of five monosaccharides (two glucose units, two mannose units and one glucuronide unit), to form a pentasaccharide repeating unit ( Xu et al., 2014 ; Ramos de Souza et al., 2022 ). Compared with synthetic polymer hydrolyzed polyacrylamide, xanthan gum shows a better resistance to the heat and salt but processes a slightly higher cost ( Jang et al., 2015 ; Rellegadla et al., 2017 ). Except xanthan gum, many kinds of biopolymers have been used in petroleum filed as well. Table 2 listed some biopolymers and their producing bacteria with potential applications in the field of MEOR. Others, such as Rhizobium viscosum CECT 908, produced a biopolymer which was found to maintain excellent stability even at high shear rates, temperatures, and salinities ( Couto et al., 2019 ). In the oil recovery tests of heavy crude oil, the R. viscosum biopolymer exhibits better performance than xanthan gum, the former can achieve a recovery rate of 25.7%, while the latter is less than 20%. Moreover, other studies have shown that the combination of biopolymer and biosurfactant flooding is better than their single use in enhancing oil recovery ( Ji et al., 2022 ). For example, the combination of Enterobacter cloacae (biopolymer-producing strain) and Pseudomonas aeruginosa (biosurfactant-producing strain) were used to profile control and flooding, the oil recovery up to 17.4%, as against to 10.4% and 7.9% for them, respectively, when used alone ( Bi et al., 2019 ). This provides a sound idea on the follow-up polymer drive studies.

Table 2

Biopolymers used in MEOR with their producing microbes.

Most of the current research on novel microbial polymers remains in the laboratory stage, except the Xanthan gum. This is mainly due to its production difficulty and high production cost. In view of this, in the follow-up research work, we should simplify its production process as much as possible and reduce its production cost. Moreover, the mixed use of biopolymers with other oil displacement reagents is also a promising research direction.

2.3. Role of biogases, biogenic acids and solvents

Biogases, organic solvents and acids produced by microbial metabolism play a vital role in microbial recovery enhancement technologies. Gases are metabolized by microorganisms, such as carbon dioxide, nitrogen and methane, which can increase formation pressure in the reservoir ( Niu et al., 2020 ). Besides, the gas dissolved in the crude oil may swell the volume of the crude oil, reduce the viscosity of the crude oil and improve the flow properties. Microorganisms produced acids and organic solvents, such as acetic acid, propionic acid, butyric acid, ethanol, acetone, butanol and isopropanol, which can dissolve the carbonate rocks in the reservoir, thus increasing the porosity and permeability of the reservoir ( Sen, 2008 ; Al-Sulaimani et al., 2011 ). In addition, biogas, organic solvents, and acids, which metabolite in the process of microbial enhanced oil recovery, usually have certain synergistic effects. Researchers enriched the thermophilic anaerobic bacteria from heavy oil samples, which proved that metabolites produced by native microorganisms, such as carbon dioxide, ethanol, acetic acid and biosurfactants exhibit the ability to improve heavy oil recovery in carbonate porous media, and the oil recovery was up to 12% ( Castorena-Cortés et al., 2012 ). Rathi et al. enriched methanogenic bacteria from high-temperature reservoirs, which can produce methane (8.08 mmol/L), carbon dioxide (4.25 mmol/L) and volatile fatty acids (1957.11 mg/L), recover 8.3% of crude oil in the core of sandstone filling ( Rathi et al., 2018 ).

Overall, the utilization of biogas, organic solvents, and acids generated by microbial metabolism are mainly tend to inject cheap nutrients into the reservoir and activate endogenous microorganisms to improve the recovery of depleted reservoirs.

2.4. Biodegradation

In the petroleum industry, microbial degradation commonly used to storage tanks cleaning, wellhead wax cleaning and wax prevention, or to enhance recovery of dead reservoirs. During microbial degradation, the bacteria can degrade long chain hydrocarbons to short linear alkanes of crude oil, which essentially change the physicochemical properties of crude oil, especially the viscosity, and improve the fluidity of residual oil, thus the oil becomes easier to be cleaned or extracted ( Muthukumar et al., 2022 ). Crude oil, on the other hand, is usually categorized into four major groups: saturated hydrocarbons, aromatic hydrocarbons, asphaltenes and resins ( Varjani, 2017 ). Different microorganisms can degrade different components of crude oil. The simpler compounds in crude oil can be degraded by various microorganisms, but complex compounds (e like PAHs, asphaltenes and resins) can be degraded by few microorganisms. For example, the Bacillus , Pseudomonas , Rhodococcus , Immunobacterium , and Saccharomyces can effectively degrade the saturated and monoaromatic hydrocarbons of crude oil, and a few Rhodococcus , Mycobacterium , Pseudomonas , and Mycobacterium contribute to the degradation of the complex compounds in crude oil.

Therefore, to adequately degrade the components of the residual oil, the idea of using microbial consortium to degrade crude oil was initiated. The researchers constructed a mixed consortium of microorganisms with Rhodococcus erythropolis , Serratia proteamaculans , Alcaligenes sp., and Rhizobium sp., and the consortium consumed 85.26% of the crude oil within 15 days, with significantly higher consumption efficiency than that of individual strains, which confirmed the feasibility of the concept ( Xia et al., 2019 ).

Besides the use of microbial consortia to degrade diverse crude oil components, mutually beneficial symbiotic relationships may exist between individual members of the consortium. During the degradation of petroleum hydrocarbons, some bacteria showed the ability to degrade metabolites accumulated by other members, alleviating the inhibitory effect of metabolites on the degradation ability of such bacteria, which consequently improved the degradation efficiency ( Sun et al., 2021 ; Zhong et al., 2011 ). For instance, the consortium containing Rhodococcus sp. WB9 and Mycobacterium sp. WY10 showed relatively high phenanthrene-degradation efficiency. It was because that strain WB9 degraded phenanthrene to produce 1-hydroxy-2-naphthoic acid which suppressed its degrading activity of phenanthrene, but strain WY10 could degrade 1-hydroxy-2-naphthoic acid and the 1-hydroxy-2-naphthoic acid repression on phenanthrene degradation when strain WB9 was relieved ( Sun et al., 2021 ). Furthermore, the researchers found that metabolites produced by the microorganisms also promoted the degradation of other members in the consortium. For instance, when the biosurfactant produced by yeast Pseudozyma sp. was added to Pseudomonas putida , the degradation of crude oil by the bacteria showed considerable improvement, especially for alkanes (C10–C24) increasing about 46% ( Sajna et al., 2015 ). This may be explained by the fact that biosurfactants modulate the content of cell surface proteins and change the hydrophobicity of cell membranes, which makes it easier for cells to adhere to hydrocarbons, hence improving the degradation of crude oil by microorganisms ( Sharma and Pandey, 2020 ).

As a conclusion, the microbial consortium combined with the characteristics of each member cleverly is technically challenging, yet shows promising potential for applications on tank cleaning, wellhead wax cleaning and wax prevention, or for improving the recovery of depleted reservoirs.

Currently, the microorganisms used in oil recovery possess limitations, although they have their specific properties ( Niu et al., 2020 , Tatar, 2018 ). The microorganisms commonly used in MEOR are almost screened from endogenous microbes of reservoirs. These natural microorganisms are more or less defective, like poor salt tolerance or temperature resistance. With the development of genetic engineering technology, rapid progress has been made in genetically engineered microbial enhanced oil recovery (GEMEOR) technology. GEMEOR mainly uses genetic recombination, protoplast fusion and mutagenesis to create oil microorganisms with excellent performance. For example, Enterobacter cloacae can produce water-insoluble biopolymer at the optimum temperature of 30 °C. Protoplast fusion of Enterobacter cloacae and thermophilic Geobacillus strain can construct high-temperature resistant polymeric engineering bacteria, which can produce extracellular polysaccharide at 45 °C and perform well in core displacement experiment, with an improvement oil recovery by 11.3% ( Sun et al., 2013 ). As another example the new strain FA-2 was constructed by protoplast fusion using Bacillus mojavensis which can produce lipopeptide under aerobic conditions and Pseudomonas stutzeri which can grow rapidly under anaerobic conditions. This novel strain showed excellent adaptability, and produced up to 382 mg/L of lipopeptides under extreme conditions (anaerobic conditions, pH 4.5–10.0 and salinity up to 100 g/L) ( Liang et al., 2017 ). In addition, special functional strains can be constructed by gene knockout technology. For example, the fructose-1,6-diphosphatase (FBP) encoding gene in Enterobacter was knocked out to construct a new strain that can produce cellulose under specific conditions. Scanning electron microscopy showed that the new strain produced bacterial cellulose using glucose instead of glycerol as the sole carbon source. Bacterial concentration and cellulose production at different locations in core experiments showed that the plugging position of new strain was better than the original strain. Moreover, enhanced oil recovery by the new strain was 12.09%, 3.86% higher than the original strain ( Gao et al., 2020 ).

The current research on GEMEOR remains focused on the construction of functional strains with good performance in the laboratory, but lacks practical field application. Therefore, in the subsequent research, we need to construct functional bacteria that can be applied to the target reservoirs for the better field test.

Enzyme, produced by viable cells, is a kind of organic substances with catalytic activity and high selectivity. Enzyme enhanced oil recovery (EEOR) is a new method of microbial enhanced oil recovery in recent years. In the early oil and gas industry, enzymes were mainly used for hydrocarbon desulfurization and polymer pretreatment ( Patel et al., 2015 ). It was later shown that enzymes produced by microorganisms have the resemblance with biosurfactants, which can change rock wettability and reduce oil-water interfacial tension ( Rahayyem et al., 2019 ). In addition, bio-enzyme can break down the heavy components of crude oil, such as asphaltenes and paraffins, into lower molecular weight components, to reduce the viscosity and fluidity ( Parthipan et al., 2017 ). The most common bio-enzymes used in EEOR are proteinases, dehydrogenases, esterase and lipases, etc ( Rahayyem et al., 2019 ). In practical application, enzymes are usually mixed with other enzymes or surfactants. For example, bio-enzyme DGE mainly consists of protease, ethanol dehydrogenase and xylanase. Studies show that bio-enzyme DGE possesses the ability of reducing oil-water interfacial tension and changing the rock wettability. Meanwhile, the high interfacial activity qualified by DGE solution has a certain emulsification effect on crude oil during EEOR process, improves oil-water phase flow ratio and increases the oil drive efficiency ( Daoshan et al., 2009 ). EEOR technology is now better applied in field trials, such as China, Myanmar, United Arab Emirates, etc ( Rahayyem et al., 2019 ). Huff and puff test was conducted in the west oilfield of Dagang, China, by injecting enzyme solution with a mass fraction of 6%. The pilot achieved positive results, with daily oil increase of 6.49 t in the well group, water content decreased of 14.7%, and input production ratio over 1:7 ( Feng et al., 2008 ). In addition, it has been shown that the alternate use of conventional MEOR technology and EEOR can significantly improve the recovery of crude oil ( Gao et al., 2017 ).

EEOR is a microbial oil recovery technology with great potential, but still has many shortcomings. Screening and designing cost-effective enzyme-producing strains, selecting inexpensive formulations and shortening the production cycle are effective measurements to promote the development of EEOR technology. In addition, some factors need to be considered in the field test study, such as preventing enzyme degradation, improving emulsion formation, and reducing enzyme loss in the reservoir.

5. Numerical modeling of MEOR

MEOR is a comprehensive technology that integrates multiple disciplines of petroleum geology, biological porous flow and interface physical chemistry. The complex theory basis contributes to much uncertainty in practical applications. In order to accurately predict the production trend of the reservoir during microbial enhanced recovery, optimize the field plan, reduce the implementation risk and achieve economic and efficient extraction. Since the late 1980s, many researchers have conducted numerical simulation studies of MEOR based on the mechanism of MEOR action ( Yao et al., 2012 ; Sivasankar and Suresh Kumar, 2019 ; Wang et al., 2019 ; Chakraborty et al., 2020 ). So far, some distinctive MEOR mathematical models have been formed ( Table 3 ). The contents covered the transport of oil, water, microorganisms, nutrients, and metabolites in the reservoir, the growth and death of microorganisms, nutrient consumption, product generation, and the effects of different products on the physical properties of the reservoir and crude oil.

Table 3

The mathematical models used for MEOR.

Islam model, Change model and Zhang model are the most classical models in numerical modeling of MEOR, which described the various physical and chemical activities and the variations of reservoir characteristics in details. The Islam model is based on the transport of microorganisms and nutrients in the formation along with the kinetics of microbial growth, which considers the metabolism of microorganisms in the reservoir, the blockage of the reservoir by transport, and the change in the physical properties of the oil phase ( Islam, 1990 ). Change model is based on the black oil model, which covers all the activities of microorganisms and nutrients in the reservoir and provides sound reference value ( Chang et al., 1991 ). The Zhang model, on the other hand, is developed from the Islam model based on two limiting nutrient Monod equations and considers the effect of microbial adsorption on the pore surface of reservoirs ( Xu et al., 1992 ).

Since then, many researchers have improved the above model and established numerical models of MEOR considering more comprehensively and more closely to the real reservoir environment. For instance, in order to simulate endogenous microbial enhanced oil recovery (EMEOR) process researchers have established a mathematical model of EMEOR by taking carbon and oxygen sources as nutrient sources to control microbial growth and considering the effects of microbial action on parameters such as porosity, permeability, viscosity, and surface tension. The optimal nutrient injection concentration, injection concentration, gas-liquid ratio, injection period and other parameters of the target block were calculated by the model and then compared with the experimental data in field to verify the reliability of simulation results ( Yao et al., 2012 ). To explore the role of microorganisms in real reservoir on enhanced oil recovery, the researchers established a mathematical model of microbial oil recovery with competition mechanism of dual bacteria to analyze the effect of dual bacteria competitive growth and product interaction on enhanced oil recovery ( Wang et al., 2019 ). It is shown that the double-bacterial competition model is more appropriate to the actual reservoir and has better accuracy when compared with the single-bacterial model. In addition to the competition among microorganisms, the complex reservoir environment is an extreme challenge for the growth of microorganisms. The researchers studied the effects of reservoir temperature, mineralization, and pH on microbial enhancement of recovery by building the corresponding mathematical models and obtained the following conclusions: (1) reservoir temperature and seepage velocity have a combined effect in oil recovery; (2) The injection water with a salinity closed to the optimum for microbial growth can significantly improve the oil displacement efficiency; (3) When changing the reservoir pH from high acid to low base (pH 5–8), the biosurfactants have the best effect on reducing the interfacial tension, which can significantly increase the oil driving efficiency ( Sivasankar and Suresh Kumar, 2017 , Sivasankar and Suresh Kumar, 2018 , Sivasankar and Suresh Kumar, 2019 ).

Usually, the focus of mathematical models is different in different reservoir environments, leading to differences in composition, diffusion, adsorption, migration mechanism and so on. In general, the establishment of mathematical model is a process of continuous improvement, only for closer to the real reservoir environment, to provide a certain reference basis for actual production.

6. Field application

6.1. screening criteria.

The reservoir environment plays a decisive role in the effectiveness of MEOR, such as reservoir temperature, pressure, mineralization, pH, permeability, porosity, and crude oil viscosity. Temperature of the reservoir is the most important element, which shows a considerable influence on the growth and metabolism of microorganisms. Extremely low or high temperatures will cause slow growth or even death of microorganisms, thus affecting the synthesis of microbial products. Pressure is an extremely important parameter in the MEOR process, and excessive pressure will affect the growth of microorganisms. Variable pressure also leads to changes in the solubility of reservoir gas, resulting in changes in crude oil viscosity and potentially affecting oil displacement efficiency. The high mineralization is in addition to affecting the growth of microorganisms, it also tends to form precipitation with other substances and cause blocking ( Gao, 2018 ). Besides affecting the metabolic activity of microorganisms, pH also affects the performance of biosurfactants. A low pH will lead to aggregation and sedimentation of biosurfactants, which is commonly used in experiments for the crude purification of surfactants produced by microorganisms ( Pereira et al., 2013 ; Safdel et al., 2017 ). Permeability and porosity of the reservoir affect microbial transport, the smaller the pore radius, the greater the resistance in the process of microbial migration ( Sen, 2008 ). Due to the wide variation in technology and reservoir conditions in different countries and regions, the criteria used to screen reservoirs for MEOR technology considerably differ. Table 4 lists reservoir screening criteria including the Institute of Reservoir Research, the US Department of Energy and CNPC.

Table 4

Reservoir screening criteria for MEOR.

6.2. Field trials

Since Beckman first proposed the idea of MEOR in 1926, many researchers have conducted specific studies on it. In particular, the oil crisis of the 1970s greatly stimulated the desire of oil workers for cheap and efficient means of exploitation. MEOR technology has developed rapidly and numerous field trials have been conducted. According to application, the process of MEOR can be classified into four categories: microbial flooding recovery (MFR), microbial selective plugging recovery (MSPR), cyclic microbial recovery (CMR), and microbial wax removal (MWR). Table 5 lists the features and limitations of four commonly-used microbial oil recovery techniques and together with two novel technologies, GEMEOR and EEOR. Table 6 lists some field tests of MEOR in various countries, including the technical tools, microorganisms and nutrients used.

Table 5

The features of different MEOR technologies.

Table 6

The field trials of MEOR around the world.

In 1954, the first field test of microbial enhanced oil recovery was conducted in Arkansas, USA ( Ghadimi and Ardjmand, 2006 ). In 1992, researchers conducted field tests in Oklahoma to determine whether microorganisms preferentially seal high permeability zones to improve water drive efficiency. The results of the test indicated that large-scale injection of readily metabolizable carbohydrates would not adversely affect ongoing operations in the field, but would alter existing flow patterns and reduce propagation rates within the test area ( Coates et al., 1993 ). Similarly in Oklahoma, researchers injected microbes and molasses into wells from a centralized injection station and increased oil production by 19.6% from 1990 to 1993 ( Bryant et al., 1994 ). In 2007, endogenous microbial flooding was carried out in California. The researchers injected amount of nutrient mixture into the reservoir to activate the original microorganisms in the reservoir. The test results showed a positive increase of 6% in crude oil recovery ( Zahner et al., 2010 ). In addition, a field test of endogenous microbial flooding in Texas has shown that microbial flooding technology may be used in reservoirs with permeability below 50 mD ( Akintunji et al., 2012 ).

In China, many field trials have been conducted in recent years, involving oil fields such as Daqing, Xinjiang, Dagang, Shengli, North China, etc., and all achieved positive results ( Gao, 2018 ). Microbial huff and puff and microbial enhanced water flooding tests have been carried out successively in Daqing Oilfield. The cumulative oil increase of microbial huff and puff test was 9175.5 t, and the cumulative oil increase of microbial enhanced water flooding over 5800 t, confirming the feasibility of microbial oil recovery technology in Daqing permeable reservoirs ( Guo et al., 2007 ). Besides, some studies have shown that microbial oil recovery technology also has a positive effect on the extraction of heavy oil. The researchers combined the screened viscosity-reducing microorganisms for heavy oil with reservoir endogenous microorganisms and found that the wax and asphaltene content of the produced oil could be effectively reduced and the average daily production of the wells increased significantly ( Sun et al., 2017 ). Usually, it is difficult to effectively recover the reservoir after polymer drive, while researchers conducted microbial modification tests on this type of reservoir and found that with the injection of bacteria, the water content of the extracted fluid decreased significantly and the recovery was enhanced ( Jun et al., 2007 ).

In Russia, it was used to enhance oil recovery by activating microbial colonies in the reservoir. Microorganisms producing organic acids, surfactants, carbonic acid, and methane were discovered during the test, which resulted in a cumulative oil increase of 41,080 t in the Romashkino field ( Ivanov et al., 1993 ). In Argentina, parthenogenic anaerobic microorganisms that degrade hydrocarbons have been successfully used to enhance crude oil recovery, with an increase in short-chain hydrocarbons and enhancement mobility of crude oil in the test ( Strappa et al., 2004 ). In Canada, microbial treatment of less economical and idle wells yielded positive results and effectively extended the life of these wells ( Town et al., 2010 ). In Indonesia, researchers used molasses and commercial fertilizers to activate microbes in reservoirs, increasing crude oil production by about 1750 barrels. It was found that the abundance of total aerobic bacteria in the reservoir increased 10,000 times, the abundance of anaerobic bacteria increased 10 times, and the abundance of hydrocarbon degrading bacteria increased 1000 times after nutrient injection. The increase in the number of beneficial microorganisms reduced the oil-water interfacial tension by about 47 % and the viscosity by about 24 % ( Ariadji et al., 2017 , 2019 ). Microbial enzymatic oil recovery experiments were conducted in Mann Field, Myanmar. Testers injected 2 % of the bio-enzyme concentrate into two test wells, resulting in an increase of 2166 barrels ( Ott et al., 2011 ). Additionally, in Azerbaijan, Malaysia, Romania, Peru and other countries, MEOR field tests showed positive results ( Bybee and Karen, 2006 ; Ghazali et al., 2001 ; Ibragimov et al., 2015 ; Ibrahim et al., 2004 ; Lazar et al., 1999 ; Maure et al., 2005 ; Sabut et al., 2003 ).

7. Conclusions and outlooks

As global oil prices have prolonged slump in recent years, it is urgent to decrease the cost of MEOR further in order to seek better returns. Compared with other three recovery techniques, the microbial oil recovery technology takes advantage of relatively inexpensive, environment-friendly, and pollution-free. This paper reviewed abundant field trials, which confirmed the superiority and feasibility of MEOR technology. But meanwhile, some factors still strict the widespread application of MEOR technology, including the intricacy of the MEOR process, the unstable success rate, the low product yield and the low oil recovery. Therefore, future research work should focus on solving these urgent problems. The first issue is the cost of microbial products. Through the study of relevant literature, this paper summarizes the following possible methods to reduce the cost: (1) Using abundant and cheap agro residue or industrial waste as a substrate for bacterial growth whenever possible; (2) Using biological products in combination with chemical products; (3) Using crude microbial products whenever possible, eliminating the cost of expensive purification. The next issue is that the complex reservoir environment has a great impact on microbial growth and the success rate of microbial displacement technology. Therefore, before microbial flooding, it is necessary to structure a more systematic reservoir screening criteria, analyze the reservoir characteristics and microbial diversity of each well systematically, and establish the corresponding mathematical model of MEOR. At the same time, it is also feasible to construct strains with outstanding tolerance to harsh reservoir environment by genetic engineering technology. Moreover, the application of genetic engineering technology and microbial consortium construction technology may be a breakthrough for microbial oil recovery in the future. The former enables the creation of functional oil recovery bacteria with excellent performance, while the latter creates perfect microbial consortia. The combination of both may enhance the practicality of MEOR technology.

Declarations

Author contribution statement.

All authors listed have significantly contributed to the development and the writing of this article.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Declaration of interests statement.

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

- Al-Adasani A., Bai B. Soc. Pet. Eng. J.; 2010. Recent developments and updated screening criteria of enhanced oil recovery techniques. (International Oil and Gas Conference and Exhibition in China). [ Google Scholar ]

- Akintunji A.A., Sheehy A., Marcotte B.W.G., Govreau B.R. Soc. Pet. Eng. J.; 2012. A Texas MEOR application shows outstanding production improvement due to oil release effects on relative permeability. (SPE Improved Oil Recovery Symposium). [ Google Scholar ]

- Al-Bahry S.N., Al-Wahaibi Y.M., Elshafie A.E., Al-Bemani A.S., Joshi S.J., Al-Makhmari H.S., Al-Sulaimani H.S. Biosurfactant production by Bacillus subtilis B20 using date molasses and its possible application in enhanced oil recovery. Int. Biodeterior. Biodegrad. 2013; 81 :141–146. [ Google Scholar ]

- Al-Sulaimani H., Joshi S., Al-Wahaibi Y., Al-Bahry S., Elshafie A., Al-Bemani A. Microbial biotechnology for enhancing oil recovery: current developments and future prospects. Biotechnol. Bioinf. Bioeng. 2011; 1 (2):147–158. [ Google Scholar ]

- Alvarez V.M., Guimarães C.R., Jurelevicius D., de Castilho L.V.A., de Sousa J.S., da Mota F.F., Freire D.M.G., Seldin L. Microbial enhanced oil recovery potential of surfactin-producing Bacillus Subtilis AB2.0. Fuel. 2020; 272 :117730. [ Google Scholar ]

- Alvarez Yela A.C., Tibaquirá Martínez M.A., Rangel Piñeros G.A., López V.C., Villamizar S.H., Núñez Vélez V.L., Abraham W.-R., Vives Flórez M.J., González Barrios A.F. A comparison between conventional Pseudomonas aeruginosa rhamnolipids and Escherichia coli transmembrane proteins for oil recovery enhancing. Int. Biodeterior. Biodegrad. 2016; 112 :59–65. [ Google Scholar ]

- Amezcua-Vega C., Poggi-Varaldo H.M., Esparza-Garcia F., Rios-Leal E., Rodriguez-Vazquez R. Effect of culture conditions on fatty acids composition of a biosurfactant produced by Candida ingens and changes of surface tension of culture media. Bioresour. Technol. 2007; 98 (1):237–240. [ PubMed ] [ Google Scholar ]

- Ariadji T., Astuti D.I., Aditiawati P., Purwasena I.A., Persada G.P., Soeparmono M.R., Amirudin N.H., Ananggadipa A.A., Sasongko S.Y., Abqory M.H. Soc. Pet. Eng. J.; 2017. Microbial huff and puff project at Mangunjaya field wells: the first. (SPE Asia Pacific Oil and Gas Conference and Exhibition). [ Google Scholar ]

- Ariadji T., Astuti D.I., Priharto N., Ananggadipa A.A., Persada G.P., Subiantoro E., Erwanto P.E., Abqory M.H. Soc. Pet. Eng. J.; 2019. Field implementation of nutrient huff and puff in Bentayan field, South Sumatera: towards a low-cost EOR. (SPE/IATMI Asia Pacific Oil and Gas Conference and Exhibition). [ Google Scholar ]

- Asfora Sarubbo L., Moura De Luna J., De Campos-Takaki G.M. Production and stability studies of the bioemulsifier obtained from a new strain of Candida glabrata UCP 1002. Electron. J. Biotechnol. 2006; 9 (4):400–406. [ Google Scholar ]

- Aurepatipan N., Champreda V., Kanokratana P., Chitov T., Bovonsombut S. Assessment of bacterial communities and activities of thermotolerant enzymes produced by bacteria indigenous to oil-bearing sandstone cores for potential application in Enhanced Oil Recovery. J. Petrol. Sci. Eng. 2018; 163 :295–302. [ Google Scholar ]

- Bi Y.Q., Yu L., Huang L.X., Ma T., Xiu J.L., Yi L.N. Microscopic profile control mechanism and potential application of the biopolymer-producing strain FY-07 for microbial enhanced oil recovery. Petrol. Sci. Technol. 2016; 34 (24):1952–1957. [ Google Scholar ]

- Bi Y., Xiu J., Ma T. Application potential analysis of enhanced oil recovery by biopolymer-producing bacteria and biosurfactant-producing bacteria compound flooding. Appl. Sci. 2019; 9 (23):5119. [ Google Scholar ]

- Bryant R.S. MEOR screening criteria fit 27% of U. S. oil reservoirs. Oil Gas J. 1991; 89 (15):56–59. [ Google Scholar ]

- Bryant R.S., Stepp A.K., Bertus K.M., Burchfield T.E. Soc. Pet. Eng. J.; 1994. Dennis M microbial enhanced waterflooding field tests. (SPE/DOE Improved Oil Recovery Symposium). [ Google Scholar ]

- Bybee, Karen MEOR in Northwest Peru. J. Petrol. Technol. 2006; 58 (1):48–49. [ Google Scholar ]

- Cameotra S.S., Makkar R.S. Recent applications of biosurfactants as biological and immunological molecules. Curr. Opin. Microbiol. 2004; 7 (3):262–266. [ PubMed ] [ Google Scholar ]

- Castillo N.A., Valdez A.L., Farina J.I. Microbial production of scleroglucan and downstream processing. Front. Microbiol. 2015; 6 :1106. [ PMC free article ] [ PubMed ] [ Google Scholar ]

- Castorena-Cortés G., Zapata-Peñasco I., Roldán-Carrillo T., Reyes-Avila J., Mayol-Castillo M., Román-Vargas S., Olguín-Lora P. Evaluation of indigenous anaerobic microorganisms from Mexican carbonate reservoirs with potential MEOR application. J. Petrol. Sci. Eng. 2012; 81 :86–93. [ Google Scholar ]

- Chakraborty S., Govindarajan S.K., Gummadi S.N. Influence of crucial reservoir properties and microbial kinetic parameters on enhanced oil recovery by microbial flooding under nonisothermal conditions: mathematical modelling and numerical simulation. J. Petrol. Sci. Eng. 2020 [ Google Scholar ]

- Chang M.M., Chung F.T.H., Bryant R.S., Gao H.W., Burchfield T.E. Soc. Pet. Eng. J; 1991. Modeling and laboratory investigation of microbial transport phenomena in porous media. (SPE Annual Technical Conference and Exhibition). SPE 22845-MS. [ Google Scholar ]

- Coates J.D., Chisholm J.L., Knapp R.M., McInerney M.J., Menzie D.E., Bhupathiraju V.K. In: Premuzic E.T., Woodhead A., editors. vol. 39. Elsevier; 1993. Microbially enhanced oil recovery field pilot, Payne county, Oklahoma; pp. 197–205. (Developments in Petroleum Science). [ Google Scholar ]

- Couto M.R., Gudina E.J., Ferreira D., Teixeira J.A., Rodrigues L.R. The biopolymer produced by Rhizobium viscosum CECT 908 is a promising agent for application in microbial enhanced oil recovery. Nat. Biotechnol. 2019; 49 :144–150. [ PubMed ] [ Google Scholar ]

- Daoshan L., Mingyi S., Fangtian N.J.P.G., Efficiency R. Research on pilot test of biologic-enzyme enhanced oil recovery in Gangxi oil reservoir of Dagang Oilfield. Pet. Geo. Rec. Eff. 2009 [ Google Scholar ]

- Datta P., Tiwari P., Pandey L.M. Isolation and characterization of biosurfactant producing and oil degrading Bacillus subtilis MG495086 from formation water of Assam oil reservoir and its suitability for enhanced oil recovery. Bioresour. Technol. 2018; 270 :439–448. [ PubMed ] [ Google Scholar ]

- Datta P., Tiwari P., Pandey L.M. Oil washing proficiency of biosurfactant produced by isolated Bacillus tequilensis MK 729017 from Assam reservoir soil. J. Petrol. Sci. Eng. 2020; 195 [ Google Scholar ]

- Dhanarajan G., Rangarajan V., Bandi C., Dixit A., Das S., Ale K., Sen R. Biosurfactant-biopolymer driven microbial enhanced oil recovery (MEOR) and its optimization by an ANN-GA hybrid technique. J. Biotechnol. 2017; 256 :46–56. [ PubMed ] [ Google Scholar ]

- Dogan I., Pagilla K.R., Webster D.A., Stark B.C. Expression of Vitreoscilla hemoglobin in Gordonia amarae enhances biosurfactant production. J. Ind. Microbiol. Biotechnol. 2006; 33 (8):693–700. [ PubMed ] [ Google Scholar ]

- Elshafie A., Joshi S., Al-Wahaibi Y., Al-Bahry S., Al-Bemani A., Al-Hashmi A., Al-Mandhari M. Soc. Pet. Eng. J.; 2017. Isolation and characterization of biopolymer producing Omani Aureobasidium pullulans strains and its potential applications in microbial enhanced oil recovery. (SPE Oil and Gas India Conference and Exhibition). [ Google Scholar ]

- Elshafie A.E., Joshi S.J., Al-Wahaibi Y.M., Al-Bemani A.S., Al-Bahry S.N., Al-Maqbali D., Banat I.M. Sophorolipids production by Candida bombicola ATCC 22214 and its potential application in microbial enhanced oil recovery. Front. Microbiol. 2015; 6 :1324. [ PMC free article ] [ PubMed ] [ Google Scholar ]