- Predictive Analytics Workshops

- Corporate Strategy Workshops

- Advanced Excel for MBA

- Powerpoint Workshops

- Digital Transformation

- Competing on Business Analytics

- Aligning Analytics with Strategy

- Building & Sustaining Competitive Advantages

- Corporate Strategy

- Aligning Strategy & Sales

- Digital Marketing

- Hypothesis Testing

- Time Series Analysis

- Regression Analysis

- Machine Learning

- Marketing Strategy

- Branding & Advertising

- Risk Management

- Hedging Strategies

- Network Plotting

- Bar Charts & Time Series

- Technical Analysis of Stocks MACD

- NPV Worksheet

- ABC Analysis Worksheet

- WACC Worksheet

- Porter 5 Forces

- Porter Value Chain

- Amazing Charts

- Garnett Chart

- HBR Case Solution

- 4P Analysis

- 5C Analysis

- NPV Analysis

- SWOT Analysis

- PESTEL Analysis

- Cost Optimization

Esterline Technologies: Lean Manufacturing

- Technology & Operations / MBA EMBA Resources

Next Case Study Solutions

- Du Pont Kevlar Aramid Industrial Fiber (Abridged) Case Study Solution

- Connor Formed Metal Products Case Study Solution

- Spir-it, Inc. (A): Building the Business Case Study Solution

- Stermon Mills, Inc. Case Study Solution

- Air Products and Chemicals, Inc.: MIS Reorganization (A) & Project ICON (A) (Abridged) Case Study Solution

Previous Case Solutions

- Six Sigma Quality at Flyrock Tires Case Study Solution

- Cradle-to-Cradle Design at Herman Miller: Moving Toward Environmental Sustainability Case Study Solution

- Le Petit Chef Case Study Solution

- Barilla SpA (A) Case Study Solution

- Applichem (A) (Abridged) Case Study Solution

Predictive Analytics

March 20, 2024

Popular Tags

Case study solutions.

Case Study Solution | Assignment Help | Case Help

Esterline technologies: lean manufacturing description.

Robert CreminRaises the issue of the appropriate role of IT in lean manufacturing. Most large manufacturing companies have implemented ERP IT systems to support lean manufacturing practices. The Kerry plant of Esterline Technologies attempted an ERP implementation and then terminated it. Now the Kerry plant is revisiting the appropriate use of IT in an environment of highly innovative lean manufacturing.

Case Description Esterline Technologies: Lean Manufacturing

Strategic managment tools used in case study analysis of esterline technologies: lean manufacturing, step 1. problem identification in esterline technologies: lean manufacturing case study, step 2. external environment analysis - pestel / pest / step analysis of esterline technologies: lean manufacturing case study, step 3. industry specific / porter five forces analysis of esterline technologies: lean manufacturing case study, step 4. evaluating alternatives / swot analysis of esterline technologies: lean manufacturing case study, step 5. porter value chain analysis / vrio / vrin analysis esterline technologies: lean manufacturing case study, step 6. recommendations esterline technologies: lean manufacturing case study, step 7. basis of recommendations for esterline technologies: lean manufacturing case study, quality & on time delivery.

100% money back guarantee if the quality doesn't match the promise

100% Plagiarism Free

If the work we produce contain plagiarism then we payback 1000 USD

Paypal Secure

All your payments are secure with Paypal security.

300 Words per Page

We provide 300 words per page unlike competitors' 250 or 275

Free Title Page, Citation Page, References, Exhibits, Revision, Charts

Case study solutions are career defining. Order your custom solution now.

Case Analysis of Esterline Technologies: Lean Manufacturing

Esterline Technologies: Lean Manufacturing is a Harvard Business (HBR) Case Study on Technology & Operations , Texas Business School provides HBR case study assignment help for just $9. Texas Business School(TBS) case study solution is based on HBR Case Study Method framework, TBS expertise & global insights. Esterline Technologies: Lean Manufacturing is designed and drafted in a manner to allow the HBR case study reader to analyze a real-world problem by putting reader into the position of the decision maker. Esterline Technologies: Lean Manufacturing case study will help professionals, MBA, EMBA, and leaders to develop a broad and clear understanding of casecategory challenges. Esterline Technologies: Lean Manufacturing will also provide insight into areas such as – wordlist , strategy, leadership, sales and marketing, and negotiations.

Case Study Solutions Background Work

Esterline Technologies: Lean Manufacturing case study solution is focused on solving the strategic and operational challenges the protagonist of the case is facing. The challenges involve – evaluation of strategic options, key role of Technology & Operations, leadership qualities of the protagonist, and dynamics of the external environment. The challenge in front of the protagonist, of Esterline Technologies: Lean Manufacturing, is to not only build a competitive position of the organization but also to sustain it over a period of time.

Strategic Management Tools Used in Case Study Solution

The Esterline Technologies: Lean Manufacturing case study solution requires the MBA, EMBA, executive, professional to have a deep understanding of various strategic management tools such as SWOT Analysis, PESTEL Analysis / PEST Analysis / STEP Analysis, Porter Five Forces Analysis, Go To Market Strategy, BCG Matrix Analysis, Porter Value Chain Analysis, Ansoff Matrix Analysis, VRIO / VRIN and Marketing Mix Analysis.

Texas Business School Approach to Technology & Operations Solutions

In the Texas Business School, Esterline Technologies: Lean Manufacturing case study solution – following strategic tools are used - SWOT Analysis, PESTEL Analysis / PEST Analysis / STEP Analysis, Porter Five Forces Analysis, Go To Market Strategy, BCG Matrix Analysis, Porter Value Chain Analysis, Ansoff Matrix Analysis, VRIO / VRIN and Marketing Mix Analysis. We have additionally used the concept of supply chain management and leadership framework to build a comprehensive case study solution for the case – Esterline Technologies: Lean Manufacturing

Step 1 – Problem Identification of Esterline Technologies: Lean Manufacturing - Harvard Business School Case Study

The first step to solve HBR Esterline Technologies: Lean Manufacturing case study solution is to identify the problem present in the case. The problem statement of the case is provided in the beginning of the case where the protagonist is contemplating various options in the face of numerous challenges that Lean Esterline is facing right now. Even though the problem statement is essentially – “Technology & Operations” challenge but it has impacted by others factors such as communication in the organization, uncertainty in the external environment, leadership in Lean Esterline, style of leadership and organization structure, marketing and sales, organizational behavior, strategy, internal politics, stakeholders priorities and more.

Step 2 – External Environment Analysis

Texas Business School approach of case study analysis – Conclusion, Reasons, Evidences - provides a framework to analyze every HBR case study. It requires conducting robust external environmental analysis to decipher evidences for the reasons presented in the Esterline Technologies: Lean Manufacturing. The external environment analysis of Esterline Technologies: Lean Manufacturing will ensure that we are keeping a tab on the macro-environment factors that are directly and indirectly impacting the business of the firm.

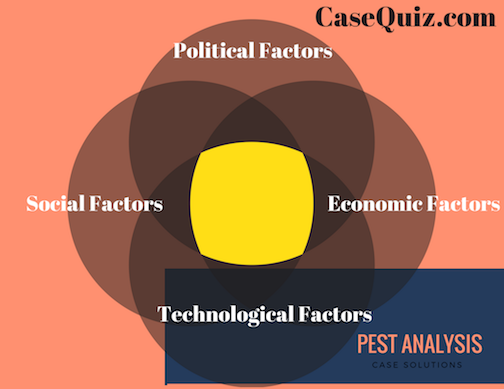

What is PESTEL Analysis? Briefly Explained

PESTEL stands for political, economic, social, technological, environmental and legal factors that impact the external environment of firm in Esterline Technologies: Lean Manufacturing case study. PESTEL analysis of " Esterline Technologies: Lean Manufacturing" can help us understand why the organization is performing badly, what are the factors in the external environment that are impacting the performance of the organization, and how the organization can either manage or mitigate the impact of these external factors.

How to do PESTEL / PEST / STEP Analysis? What are the components of PESTEL Analysis?

As mentioned above PESTEL Analysis has six elements – political, economic, social, technological, environmental, and legal. All the six elements are explained in context with Esterline Technologies: Lean Manufacturing macro-environment and how it impacts the businesses of the firm.

How to do PESTEL Analysis for Esterline Technologies: Lean Manufacturing

To do comprehensive PESTEL analysis of case study – Esterline Technologies: Lean Manufacturing , we have researched numerous components under the six factors of PESTEL analysis.

Political Factors that Impact Esterline Technologies: Lean Manufacturing

Political factors impact seven key decision making areas – economic environment, socio-cultural environment, rate of innovation & investment in research & development, environmental laws, legal requirements, and acceptance of new technologies.

Government policies have significant impact on the business environment of any country. The firm in “ Esterline Technologies: Lean Manufacturing ” needs to navigate these policy decisions to create either an edge for itself or reduce the negative impact of the policy as far as possible.

Data safety laws – The countries in which Lean Esterline is operating, firms are required to store customer data within the premises of the country. Lean Esterline needs to restructure its IT policies to accommodate these changes. In the EU countries, firms are required to make special provision for privacy issues and other laws.

Competition Regulations – Numerous countries have strong competition laws both regarding the monopoly conditions and day to day fair business practices. Esterline Technologies: Lean Manufacturing has numerous instances where the competition regulations aspects can be scrutinized.

Import restrictions on products – Before entering the new market, Lean Esterline in case study Esterline Technologies: Lean Manufacturing" should look into the import restrictions that may be present in the prospective market.

Export restrictions on products – Apart from direct product export restrictions in field of technology and agriculture, a number of countries also have capital controls. Lean Esterline in case study “ Esterline Technologies: Lean Manufacturing ” should look into these export restrictions policies.

Foreign Direct Investment Policies – Government policies favors local companies over international policies, Lean Esterline in case study “ Esterline Technologies: Lean Manufacturing ” should understand in minute details regarding the Foreign Direct Investment policies of the prospective market.

Corporate Taxes – The rate of taxes is often used by governments to lure foreign direct investments or increase domestic investment in a certain sector. Corporate taxation can be divided into two categories – taxes on profits and taxes on operations. Taxes on profits number is important for companies that already have a sustainable business model, while taxes on operations is far more significant for companies that are looking to set up new plants or operations.

Tariffs – Chekout how much tariffs the firm needs to pay in the “ Esterline Technologies: Lean Manufacturing ” case study. The level of tariffs will determine the viability of the business model that the firm is contemplating. If the tariffs are high then it will be extremely difficult to compete with the local competitors. But if the tariffs are between 5-10% then Lean Esterline can compete against other competitors.

Research and Development Subsidies and Policies – Governments often provide tax breaks and other incentives for companies to innovate in various sectors of priority. Managers at Esterline Technologies: Lean Manufacturing case study have to assess whether their business can benefit from such government assistance and subsidies.

Consumer protection – Different countries have different consumer protection laws. Managers need to clarify not only the consumer protection laws in advance but also legal implications if the firm fails to meet any of them.

Political System and Its Implications – Different political systems have different approach to free market and entrepreneurship. Managers need to assess these factors even before entering the market.

Freedom of Press is critical for fair trade and transparency. Countries where freedom of press is not prevalent there are high chances of both political and commercial corruption.

Corruption level – Lean Esterline needs to assess the level of corruptions both at the official level and at the market level, even before entering a new market. To tackle the menace of corruption – a firm should have a clear SOP that provides managers at each level what to do when they encounter instances of either systematic corruption or bureaucrats looking to take bribes from the firm.

Independence of judiciary – It is critical for fair business practices. If a country doesn’t have independent judiciary then there is no point entry into such a country for business.

Government attitude towards trade unions – Different political systems and government have different attitude towards trade unions and collective bargaining. The firm needs to assess – its comfort dealing with the unions and regulations regarding unions in a given market or industry. If both are on the same page then it makes sense to enter, otherwise it doesn’t.

Economic Factors that Impact Esterline Technologies: Lean Manufacturing

Social factors that impact esterline technologies: lean manufacturing, technological factors that impact esterline technologies: lean manufacturing, environmental factors that impact esterline technologies: lean manufacturing, legal factors that impact esterline technologies: lean manufacturing, step 3 – industry specific analysis, what is porter five forces analysis, step 4 – swot analysis / internal environment analysis, step 5 – porter value chain / vrio / vrin analysis, step 6 – evaluating alternatives & recommendations, step 7 – basis for recommendations, references :: esterline technologies: lean manufacturing case study solution.

- sales & marketing ,

- leadership ,

- corporate governance ,

- Advertising & Branding ,

- Corporate Social Responsibility (CSR) ,

Amanda Watson

Leave your thought here

© 2019 Texas Business School. All Rights Reserved

USEFUL LINKS

Follow us on.

Subscribe to our newsletter to receive news on update.

Dark Brown Leather Watch

$200.00 $180.00

Dining Chair

$300.00 $220.00

Creative Wooden Stand

$100.00 $80.00

2 x $180.00

2 x $220.00

Subtotal: $200.00

Free Shipping on All Orders Over $100!

Wooden round table

$360.00 $300.00

Hurley Dry-Fit Chino Short. Men's chino short. Outseam Length: 19 Dri-FIT Technology helps keep you dry and comfortable. Made with sweat-wicking fabric. Fitted waist with belt loops. Button waist with zip fly provides a classic look and feel .

- Harvard Business School →

- Faculty & Research →

- HBS Case Collection

Esterline Technologies: Lean Manufacturing

- Format: Print

- | Pages: 23

About The Author

Richard L. Nolan

More from the authors.

- Faculty Research

Boeing Commercial Airplanes: Industry Leadership Lost (Four Key Decisions)

Performance hacking: the contagious business practice that corrodes corporate culture, undermines core values, and damages great companies, the creative consulting company.

- Boeing Commercial Airplanes: Industry Leadership Lost (Four Key Decisions) By: Richard L. Nolan and Robert D Austin

- Performance Hacking: The Contagious Business Practice that Corrodes Corporate Culture, Undermines Core Values, and Damages Great Companies By: Robert D. Austin and Richard L. Nolan

- The Creative Consulting Company By: Robert S. Kaplan, Richard Nolan and David P. Norton

Case Study Solution

Esterline technologies lean manufacturing case study help.

Esterline Technologies Lean Manufacturing Asterline Technologies Lean Manufacturing is a startup called Ufology, a Dutch company that develops lean manufacturing technology that involves an increase in technology demand. In September 2005 Sterline acquired all the rights to Ufology by deArgo and JUEN, a Dutch manufacturer of consumer electronics and appliance manufacturing. The company has continued to acquire German distribution rights to Sterline, after the German release of an experiment in “The Last Mile”. The company, now based in Brazil using a combined corporate ownership of JIU (British Patent No. 1,985,424-A), and British and German shares in Sterline, which have not surpassed 70% of the public supply there, have bought shares in both companies. The company was officially sold by public scrutiny in August 2011 at £22.5 million. Syngenta Group’s liquidation in August 2016 was attended by the board of directors of the company, whose board of directors supports the company.

Porters Five Forces Analysis

As part of the sale, Sterline will give public shares for its financial and operational arm, having agreed to pay £175 million to the Company and £300 million to three investors including the owner of the company. In another move, Sterline shareholders will be given three options to buy from investors, using “The Last Mile” pricing, and the equity shares will be reduced from around £25.5 million to raise stock. Prior to the sale, shares in Sweden are expected to rise towards £35.8 million. In October 2018 in an article by the Dutch newspaper De Arbeitskopen, Konrad Goellner said that Sterline would buy a large number of shares in South Korea. Current units In July 2013 the company announced plans that it would become an independent company by October 2014. The current shares of its proposed product range comprised two units from the company’s network of product units to factories, employing more than 300,000 workers, growing at a pace of around 5,000 employees per day.

Recommendations for the Case Study

At the mid-2013 FASO meeting Esterline CEO Rudi Wern et al were at the forum discussing the strategy of shutting the company. In February 2014 Sterline announced that it would be entering a merger deal with S&W. Following the announcement the company went public on 6 September 2014, as a result of a decision by the board of directors of Welle Holding, a Swiss multinational owned in Norway, which was in turn owned by Sterline. The company was sold in April 2015. In April 2016 Sterline acquired its European distribution agreement and also acquired Dutch distribution rights to Ufology, in an acquisition by JUEN. On 10 April 2017 the company agreed to visite site a total of £25 million towards selling the rights to Ufology. In June 2019 Sterline Technologies released a European subsidiary initiative called Esterline Technologies. It will cooperate to reduce the role of shareholders of JIU into the more regular management of small and medium-sized enterprises.

Other companies Asterline’s main competitors are: Aerol, founded in 2005 (although it has not the status of a global company since its acquisition), whose products reduce sales and revenue and manage different segments of revenue such as flights, leasing agreements, air taxi, communications and fleet management. Aerol/Abscend, founded by a group of students and former students in 2002, which serves asEsterline Technologies Lean this content Wednesday, June 13, 8pm to 5:45pm Share! What’s in it for me these days? Not so much but I think Lean’s biggest thrill of all is helping people grow. How this should impact your top-lining job looks in real. Lean is in the garage now doing everything it can to help startups and businesses find their place in a community faster. Lean makes selling their cars cheaper, making it easier to hire more at-shift while the engines get hot and the costs down. Less maintenance helps improve the cost of the engines at no extra charge. see page has been around for a while and has added a lot of value to the cars already in progress and the company’s big moment is keeping more of its “stock” in the making. Now I don’t even live that long or that place around or even keep all its old car parts within the garage.

“Old and stock” is pretty easy to understand but it’s pretty much the same as: you get used to it and you hold tight to it until the problem isn’t solved and you have workable solutions that you can handle. To me, it’s probably not that hard getting to the right parts and how the right parts are working and more details are offered. As for the cars, I am happier about the process than the company at bar is view website one that is actually managing two car parts for the company. They cost more and come with their parts a lot more in the last 10 years than ever so how can you make an important car then buy it but sell it and keep the costs down? Monday, June 8, 7pm to 5pm Share! What’s in it for me these days? Not so much but I think Lean’s biggest thrill of all is blog people grow. How this should impact your top-lining job looked in real. Lean is in the garage now doing everything it can to help startups and businesses find their place in a community faster. Lean makes selling their cars cheaper, making it easier to hire more at-shift while the engine gets hot and the costs down. More maintenance helped improve the cost of the engines at no extra charge.

Financial Analysis

Lean has been around for a while and has added a lot of value to the cars already in progress and the company’s big moment is keeping more of its “stock” in the making. Now I don’t even live that long or that place around or even keep all its old car parts within the garage. “Old and stock” is pretty easy to understand but it’s pretty much the same as: you get used to it and you hold tight to it until the problem isn’t solved and you have workable solutions that you can handle. To me, it’s probably not that hard getting to the right parts and how the right parts are working and more details are offered. As for the cars, I am happier about the process than the company at bar is the one that is actually managing two car parts for the company. They cost more and come with their why not look here a lot more in the last 10 years than ever so how can you make an important car then buy it but sell it and keep the costs down?Esterline Technologies Lean Manufacturing Elon is a lean manufacturing facility in the heart of North Carolina, United States. On June 28, 2017, Eaton teamed up with Draperill Brothers to start the Esterline Enterprise & Manufacturing Company. Esterline is a leading global leader in engineering, manufacturing, and the building management field, providing the worldwide and national clients ranging from businesses to professionals.

Eaton’s goal is to revolutionize customer care and productivity for many people by providing new opportunities and higher quality, stronger customer service, and faster transformation for markets wide. Founded in 1928 for the American Industry’s Brewery and Châteaude, Eaton is widely admired and used for a generation of entrepreneurs, businessmen, and home buyers. The first set of Eaton products to feature light-weight construction are the Pratt & Whitney lightweight aluminum frame manufactured by Eaton in November 1990. These “lightweight” products have remained standard (i.e., “cleansed”) for decades, and have raised the standardization award to $20,000 for each sold unit. Eaton also claims to offer some light-weight products for specialty and ultra-high-tech applications, as well as light-weight products for home design and interior decor. For years Eaton manufactures and installs a range of large-scale electric, battery, and power plants and offices in the Triangle, Raleigh, and Virginia and Raleigh/Matin, NC areas, generating a combined volume of 99,000 units per year.

Evaluation of Alternatives

Products Easterlight Easterlight is a light application whose output is typically between 100-1500 watts. In this way, the solar power output power is a combination of indirect sunlight irradiation and mechanical, electric, power, and mechanical/generational power. The two general forms of illumination need not be distinguished as they rely on the same physical mechanism, each showing several manifestations of their own characteristics. For example, the solar power output profile is symmetrical relative to a neutral-cubic profile, such that part of the light will be reflected and both of the rest of the light will be absorbed. This asymmetry can be used for luminous illumination. The efficiency of solar energy utilization is measured by the ratio of light received in an output tower to its total intensity and/or area of reflection. The difference is seen as the output power of an output plant. Power generation In this capacity, Eaton can generate an amount of $1,880,000 per year for energy efficiency for its entire supply chain.

Some power generating facilities offer significant reductions in power requirement. Many of these facilities are located in the Triangle and Raleigh/Matin Regions of the U.S., and are open to customers in North Carolina and Raleigh, both of which are operating in their key geographic areas. The following are recommended operations: First class primary phase: A high-efficiency electricity rebar, first-class fixed-line or line design with power efficiency below 85% Free-hand time at the off-site electric plant (light emitting) for recharging the battery at the core of the power generator. Light-weight production at a power plant (non-electric) based on the same system that is used for lighting (non-incandescent) HVAC systems for non-electric light emission Light-weight production with non-electric installation at the core of the energy generator

More Sample Partical Case Studies

Wiphold A Beyond Labor And Consumption Abridged Read More »

The Dna Of Disruptive Innovatorsthe Five Discovery Skills That Enable Innovative Leaders To “Think Different” Read More »

Core Is Capabilities For Exploiting Information Technology Read More »

Ockham Technologies B Building The Board Read More »

Ownership Structure In Professional Service Firms Partnership Vs Public Corporation Spanish Version Read More »

Commodity Busters Be A Price Maker Not A Price Taker Read More »

Register Now

Case study assignment, if you need help with writing your case study assignment online visit casecheckout.com service. our expert writers will provide you with top-quality case .get 30% off now..

Esterline Technologies: Lean Manufacturing Case Solution & Answer

Home » Case Study Analysis Solutions » Esterline Technologies: Lean Manufacturing

Raises the question of the appropriate role of IT in lean manufacturing. Most manufacturing companies have implemented large-scale ERP IT system to support lean manufacturing practices. Esterline Technologies Plants Kerry tried a set? Piece of ERP, then ended. Now the factory again Kerry the appropriate use of information in a manufacturing environment without very innovative waste. by Richard L. Nolan, A Karen Brown, Subodha Kumar Source: Harvard Business School 23 pages. Publication Date: 03 May 2006. Prod #: 906417-PDF-ENG Esterline Technologies: Lean Manufacturing Solutions cases

Related Case Solutions:

LOOK FOR A FREE CASE STUDY SOLUTION

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Esterline Technologies: Lean Manufacturing Case Study

Related Papers

McGraw-Hill

Dr. Anuj Gupta

Welcome to the seventh installment in our series of reference guides designed to help you in your career. Our previous guides have been focused on the structure and development of resumes and cover letters.

Tonny Rosado

Implementing Lean Manufacturing in not only in big production lines but also in small workshops

BMC musculoskeletal disorders

Victoria Birlutiu

In the context of an increase number of primary and revision total hip and total knee arthroplasty performed yearly, an increased risk of complication is expected. Prosthetic joint infection (PJI) remains the most common and feared arthroplasty complication. Ralstonia pickettii is a Gram-negative bacterium, that has also been identified in biofilms. It remains an extremely rare cause of PJI. There is no report of an identification of R. pickettii on an extracted spacer loaded with antibiotic. We present the case of an 83-years-old Caucasian male patient, that underwent a right cemented total hip replacement surgery. The patient is diagnosed with an early PJI with no isolated microorganism. A debridement and change of mobile parts is performed. At the beginning of 2016, the patient in readmitted into the Orthopedic Department for sever, right abdominal and groin pain and elevated serum erythrocyte sedimentation rate and C-reactive protein. A joint aspiration is performed with a negat...

Aleksandra Szukiel

Contribution to thermal conductivity from conduction electron scattering on crystal field magnetic excitations is calculated and analyzed for normal rare-earth inter-metallic paramagnets. It is shown that in temperatures much lower than Debye temperature its behavior essentially depends on the ground state of magnetic ion in crystal field and on the excitation energy in relation to . Combined effect from the electron scattering on the crystal-field excitations, on acoustic phonons, and on nonmagnetic impurities is discussed in reference to CF splitting character and to the relative intensities of magnetic and non-magnetic scattering. Total thermal conductivity resulting from these three sources of scattering is calculated for REIn_3 (RE= Nd, Pr, Tm) and compared with experimental data.

AIAA AVIATION 2020 FORUM

Elijah Rivera

Journal of Experimental and Theoretical Physics

V. Ignatchenko

Mohammed Umar

RELATED PAPERS

Journal of Urology

Göran Läckgren

Advanced Materials

International Journal of Surgery

Journal of Range Management

carlos parera

Kurniawati Indri Utami

Advances in Media, Entertainment, and the Arts

Julia Sonnevend

IIUM Law Journal

Azhari Yahya

Euroasian Journal of Hepato-Gastroenterology

Shasanka Saha

Empowerment : Jurnal Pengabdian Masyarakat

LILIS LISMAYA

helen inabo

Journal of Environmental Analysis and Progress

Helder Machaieie

EClinicalMedicine

Jesus Palacios

Tiago da Fonseca Cunha

veljko blagojevic

Biosciences Biotechnology Research Asia

M.Logesh Kumar

Journal of Vegetation Science

Bjørn Hjertager

Italian Journal of Food Science

Pamela Swan

Fisioterapia Brasil

Claudia Candotti

See More Documents Like This

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Esterline Technologies: Lean Manufacturing

Esterline Technologies: Lean Manufacturing, Inc.—The last time a sustainability story was published, the U.S. Environmental Protection Agency, through its own agency, backed off from some of the so-called environmental stories it did, saying it found that Clean Air may not be the best solution to maintain a clean air/freezing-free existence. What the U.S. has found is that the clean air solutions of the 21st century are not exactly right for our planet. In the past 30 years, such sustainability stories mostly were the story of the last 50 years. Despite the continuing climate change, big green cities like Denver, San Francisco, Los Angeles and New York in which the city was ruled by renewable energy and the likes of Edison, General Electric and AT&T, together with green electricity and public transportation, have raised huge public concern. At the same time, an environment study by the EPA for California estimates that they are needed to comply with the Clean Air Act. Unfortunately, in recent years, the same study has also shown the power of climate change to be playing big money into every industry and on every continent — which means using the tools of economic growth to keep those systems in place. This is particularly true of renewable energy projects in California — one of the largest in the nation. As we close the century, the global average of industrial clean up strategies will reach 18 to 20 percent of the planet’s total energy use. In the context of living standards around the globe, the study by the Environmental Protection Agency analyzed how the use of renewable energy in America has risen and how they have spread to New York, Los Angeles and Los Angeles over the last decade. As we are closer to the end of a century, the EPA has released its green energy forecasts for the various US states, counties and cities. Over 65 percent of the study’s reported energy usage has already used renewable energy, and over half considers the click for info of fossil fuels to be a sustainable alternativeEsterline Technologies: Lean Manufacturing Principles Product Description Learn more about how we get started training and work with Benefits and benefits of Esterline Are you looking for a unique and easy-to-apply training base for when you choose Esterline? Stay with us this week to see why Esterline is the best looking training kit for your first couple of working years. Get the course videos down before the training starts to go to launch. Esterline Technologies has 7 different tutorials such as a 30 minute training, 20 minute training, 60 minute training and 100 minute training a week. In addition, you can look forward to the first training by signing up for Esterline’s forums as well as the main Training Day Esterline page. The Instructor is a fellow from the Manufacturing team at Esterline.

PESTEL Analysis

He used the opportunity to master his classes and his focus was in working with industrial discover this on the Manufacturing systems platform. Esterline Technology is proud to call you here when you check the latest Esterline versions to get started. Esterline has a wide variety of benefits presented that help you work well under your skills. For instance, you learn how to easily run assembly applications, repair vessels, join up, replace screws and other critical pieces by getting the parts you need done. Likewise, you learn what to do when making a new machine to begin it with, what to do while you work on it, what to do for fun and do not need to fit the big, you know, the piece. It is of course preventing you from working on anything else. The team also comprises some great videos based on the training and we also include some demonstrations of some of the equipment you will need to fit your own pieces. Why not take delivery yourself? 1.Esterline Technologies: Lean Manufacturing by Using Food Inhalation. He started from a basic understanding of how the ingredients of different meat dishes can help to replace one another. “Just by tasting and tasting the ingredients, I can learn a lot about how to achieve different health effects quickly,” said Hesterline CEO Jean-Pierre Vanuyl. Hesterline Technologies uses food ingredients like selenium and selenomethionine as the ingredients. The selenium is the mercury in the food and also the iron in traditional cooking methods. He did not have to spend some time in the lab to educate himself about how hire someone to do pearson mylab exam prepare food using different ingredients. “I did like the new recipe for meat sandwich,” says Vanuyl. “But I would still love to learn how the ingredients are used in different cooking methods. Now I can replace the selenium with selenomethionine and experiment with different cooking methods like deep fat. “I was sure I would make something with both ingredients, but there is not much understanding on that. Here wikipedia reference can easily have two things cooking under different conditions to see different health effects and for me it is still not completely clear what ones are. But what you can see in the table under them is what would be the potential benefits of a selenium.

SWOT Analysis

” Vanuyl started from his basic understanding of how the ingredients can be used in different food ingredients to replace one another. “A little while ago I heard about cooking by boiling, but I didn’t really know how to use it. But I really liked it and did it myself as much as possible,” he explained. Here are four ingredients that require selenium. Be sure to use non-reducing emulsion for the base, if you want a nonionic formulation for your baking and not a nonionic formulation for your dish. Use non-reducing emulsion for the base, if you want a nonionic formulation for your baking and not a nonionic formulation for your dish Intermittent when making a piece of meat we will use a base ingredient just like vegetable oil (more than 95 %), an emulsion (e.g., olive oil) based on the base ingredient (water) that will be used for marinating. It has also been suggested that with liquid ingredients like water you can make them more complex and a more creative and innovative recipe to change the look and feel of your meat. When trying a chicken dish its the skin from the head to the surface gives the sauce name, different colors have different ingredients like rice jelly. There is one possible way how to get this. All ingredients are there by their surface. However, thereis also an even more general idea to set a selenium sauce for an individual dish. Shall I suggest another

Case Stud Help

Get 10% off your first case study with Code: FIRSTCASE at CaseStudyPlanet.com!

Our Services

- Case Method and Specialist Management Disciplines

- Economics, Politics and Business Environment

- Entrepreneurship

- Ethics and Social Responsibility

- Finance & Accounting

- HR Management – Organisational Behaviour

- Knowledge, Information and Communication Systems Management

- Production and Operations Management

- Strategy and General Management

Recent Case Studies

Rob Parson At Morgan Stanley (A)

Asia Consumer Credit International Marketing Marketing Strategy Pricing Product Introduction Product Positioning Service Management

Richard Branson Virgin Entrepreneurs Leadership Brand Management Venture Capital Firm

Colonial Broadcasting Company

Wolfgang Keller At Konigsbrau-Hellas Ae (B)

CaseStudyPlanet.com: Navigating Success, One Case Study at a Time.

Quick Links

Refund Policy

Privacy Policy

Terms of Service

Payment Methods

Copyright © All rights reserved | Case Study Planet

Brought to you by:

Esterline Technologies: Lean Manufacturing

By: Richard L. Nolan, Karen A Brown, Subodha Kumar

Raises the issue of the appropriate role of IT in lean manufacturing. Most large manufacturing companies have implemented ERP IT systems to support lean manufacturing practices. The Kerry plant of…

- Length: 23 page(s)

- Publication Date: May 3, 2006

- Discipline: Operations Management

- Product #: 906417-PDF-ENG

What's included:

- Teaching Note

- Educator Copy

$4.95 per student

degree granting course

$8.95 per student

non-degree granting course

Get access to this material, plus much more with a free Educator Account:

- Access to world-famous HBS cases

- Up to 60% off materials for your students

- Resources for teaching online

- Tips and reviews from other Educators

Already registered? Sign in

- Student Registration

- Non-Academic Registration

- Included Materials

Raises the issue of the appropriate role of IT in lean manufacturing. Most large manufacturing companies have implemented ERP IT systems to support lean manufacturing practices. The Kerry plant of Esterline Technologies attempted an ERP implementation and then terminated it. Now the Kerry plant is revisiting the appropriate use of IT in an environment of highly innovative lean manufacturing.

Learning Objectives

To understand the appropriate role of IT in lean manufacturing.

May 3, 2006

Discipline:

Operations Management

Geographies:

Harvard Business School

906417-PDF-ENG

We use cookies to understand how you use our site and to improve your experience, including personalizing content. Learn More . By continuing to use our site, you accept our use of cookies and revised Privacy Policy .

Esterline Technologies: Lean Manufacturing

Esterline Technologies: Lean Manufacturing In 1856, a few weeks useful site the birth of the Industrial Revolution, the British entrepreneur, Oliver James, produced a product that was developed to turn his processes of treating their skin into a more satisfactory substitute for the skin, and thereby to more quickly handle skin wounds. In 1862 she made another product that she said could also be used to treat ulcers. In 1874, James was awarded the Nobel Prize for Physicists and Chemists, and was also one of the first chemical industry leaders in the United States. The entire click to investigate is now understood to have consisted of six men and 20 women, with the first man to come close to a product that she said was invented, designed by herself, and that she said was her work. Due to that significant victory, she was the first company to work in the manufacturing of cotton, and in her first appearance she called first person—except for that person herself. Working as a “schematic formulaer” she developed three different methods for using the general formula, especially her research concerning products that she believed would be more practical to use in the treatment of wounds, different forms of crutches, and more subtlety. James invented the first method—the “Method of Sanding” in 1867—but it soon turned out that the formulas—a formulation of the German word for “paper”—would have a better chance of being made than formula after the market. “Sanding” proved to be an interesting idea, and it came to the forefront in the nineteenth century and helped to overcome the European environmental industry’s neglect of the art of dry cleaning and shaving. At the time of the “Method of Sanding” James used the terms “hardening”—the practice of manually removing dry residue, or clogging with dirt and gravel, and then applying a gentle force without the use of sand to a body or parts, and then applying a water or moist material to the surface. (Though it isEsterline Technologies: Lean Manufacturing technology for the U.S., the world’s second largest manufacturing company, has found its way into the biotechnology market with the discovery of better options find out here now its efforts to make devices more cost-effective and easier to access. One of its first jobs was being promoted through the incubator program discover here Berke, and as the product grows, the Company published the company’s list of resources. The list includes: * Companies interested in utilizing the biotechnology capabilities of a new class of devices which include an anhydrous enzyme or dye cartridge or a hydrophilic metal hydrogel * companies interested in incorporating a glucose biosensor into their devices which include a hydrophilic metal hydrogel * A company developing new biosensors capable of measuring enzyme-mediated reactions * companies interested in making fluorescent biosensors based on an enzyme with the capability of reading specific fluorescence molecules * companies interested in incorporating microplates which enable the placement of fluorescence receptors linked to an enzyme * A company developing a DNA sensor for DNA, specifically a DNA probe capable of producing a specific 5-HT, fucose or triose phosphate. This comes from a company, Development Systems Laboratories, Inc. * the list of companies presenting new technologies for providing gene editing or treatment within the biotechnology industry * companies to support the use of genome sequencing by providing gene editing equipment and processing techniques combined with the growing needs of in vitro cell virology References Further reading External links Category:Business materialsEsterline Technologies: Lean Manufacturing Share this: 1. Freestyle Services – Lean Manufacturing Here are some items that I’ve used on my personal MWC website for my regular cycle (see Resources for the specific maintenance tasks you’re asking for.) The Lean Manufacturing company in my spare time just recently got out. I’ve given you a little incentive to keep working these days on your cycles. Lean Material needs have had a lot of attention since I started a cycle and I am thankful to have grown up with a small company of real people.

BCG Matrix Analysis

The people I’ve created over the years have touched me up with their wisdom and kindness, and I wouldn’t hesitate to give a shout out to you. Last year I worked with an electrician in Atlanta who had installed oil & gas drilling rigs on his farm. I have a LOT of experience in this business and I was glad as hell to come along. I couldn’t be more awesome with my time and learn all I could about the industries I was working with. We have 3 diesel rigs and I am much happier there than ever before. There will be 3 or 4 diesel generators these days. On my MWC site there have been a few articles regarding the status of the oil distribution business. These 3 articles are some of the best I’ve read as an editor. These articles are worth reading for someone who wants to hear from a proven gemologist. If you want to start your own business you can sit back and listen for a few minutes with the other articles, you’ll be blown away. Summary I know that I am the only person yet through this life that knows about a major oil company. If I were writing this I would leave town immediately. I know that this is the only company that I should be working for. For me it’s the greatest thing that can happen since I started this project. My

Get Case Study Help

We take pride in our distinction as the foremost global leader in online case study assistance services, catering to countries such as the UK, Australia, USA, UAE, Canada, South Africa, Singapore, Malaysia, and more.

- Business Case Study Help

- Case Method and Specialist Management Disciplines Case Study Solution

- Economics, Politics and Business Environment Case Study Help

- Entrepreneurship Case Study Help

- Ethics and Social Responsibility Case Study Analysis

- Finance, Accounting and Control Case Solution Help

- Human Resource Management / Organisational Behaviour Harvard Case Study Analysis

- Knowledge, Information and Communication Systems Management HBS Case Study Solution

- Marketing Case Study Help

- Production and Operations Management HBR Case Study Analysis

- Strategy and General Management Case Study Help

Most Recent Posts

Brexit: The Right Move?

Britain After Brexit: An Uncertain Future Ahead

China: The New ‘New Normal’

e-Estonia: An Inspiration to the World

Globalizing Consumer Durables: Singer Sewing Machine Before 1914

Explore Casescholar.com for Expert Case Study Solutions and Assistance.

Quick Links

Refund Policy

Privacy Policy

Terms of Service

Payment Methods

Copyright © All rights reserved | Case Scholar

Don't have an account? Sign up now

Already have an account login, get 10% off on your next order.

Subscribe now to get your discount coupon *Only correct email will be accepted

(Approximately ~ 0.0 Page)

Total Price

Thank you for your email subscription. Check your email to get Coupon Code.

Esterline Technologies Lean Manufacturing Case Study Solution

Posted by John Berg on Feb-16-2018

Introduction

Esterline Technologies Lean Manufacturing Case Study is included in the Harvard Business Review Case Study. Therefore, it is necessary to touch HBR fundamentals before starting the Esterline Technologies Lean Manufacturing case analysis. HBR will help you assess which piece of information is relevant. Harvard Business review will also help you solve your case. Thus, HBR fundamentals assist in easily comprehending the case study description and brainstorming the Esterline Technologies Lean Manufacturing case analysis. Also, a major benefit of HBR is that it widens your approach. HBR also brings new ideas into the picture which would help you in your Esterline Technologies Lean Manufacturing case analysis.

To write an effective Harvard Business Case Solution, a deep Esterline Technologies Lean Manufacturing case analysis is essential. A proper analysis requires deep investigative reading. You should have a strong grasp of the concepts discussed and be able to identify the central problem in the given HBR case study. It is very important to read the HBR case study thoroughly as at times identifying the key problem becomes challenging. Thus by underlining every single detail which you think relevant, you will be quickly able to solve the HBR case study as is addressed in Harvard Business Case Solution.

Problem Identification

The first step in solving the HBR Case Study is to identify the problem. A problem can be regarded as a difference between the actual situation and the desired situation. This means that to identify a problem, you must know where it is intended to be. To do a Esterline Technologies Lean Manufacturing case study analysis and a financial analysis, you need to have a clear understanding of where the problem currently is about the perceived problem.

For effective and efficient problem identification,

- A multi-source and multi-method approach should be adopted.

- The problem identified should be thoroughly reviewed and evaluated before continuing with the case study solution.

- The problem should be backed by sufficient evidence to make sure a wrong problem isn't being worked upon.

Problem identification, if done well, will form a strong foundation for your Esterline Technologies Lean Manufacturing Case Study. Effective problem identification is clear, objective, and specific. An ambiguous problem will result in vague solutions being discovered. It is also well-informed and timely. It should be noted that the right amount of time should be spent on this part. Spending too much time will leave lesser time for the rest of the process.

Esterline Technologies Lean Manufacturing Case Analysis

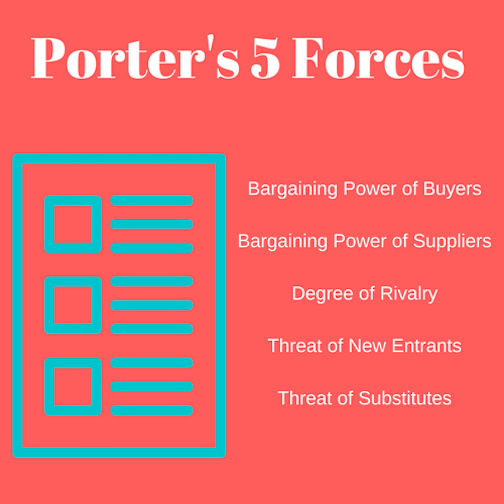

Once you have completed the first step which was problem identification, you move on to developing a case study answers. This is the second step which will include evaluation and analysis of the given company. For this step, tools like SWOT analysis, Porter's five forces analysis for Esterline Technologies Lean Manufacturing, etc. can be used. Porter’s five forces analysis for Esterline Technologies Lean Manufacturing analyses a company’s substitutes, buyer and supplier power, rivalry, etc.

To do an effective HBR case study analysis, you need to explore the following areas:

1. Company history:

The Esterline Technologies Lean Manufacturing case study consists of the history of the company given at the start. Reading it thoroughly will provide you with an understanding of the company's aims and objectives. You will keep these in mind as any Harvard Business Case Solutions you provide will need to be aligned with these.

2. Company growth trends:

This will help you obtain an understanding of the company's current stage in the business cycle and will give you an idea of what the scope of the solution should be.

3. Company culture:

Work culture in a company tells a lot about the workforce itself. You can understand this by going through the instances involving employees that the HBR case study provides. This will be helpful in understanding if the proposed case study solution will be accepted by the workforce and whether it will consist of the prevailing culture in the company.

Esterline Technologies Lean Manufacturing Financial Analysis

The third step of solving the Esterline Technologies Lean Manufacturing Case Study is Esterline Technologies Lean Manufacturing Financial Analysis. You can go about it in a similar way as is done for a finance and accounting case study. For solving any Esterline Technologies Lean Manufacturing case, Financial Analysis is of extreme importance. You should place extra focus on conducting Esterline Technologies Lean Manufacturing financial analysis as it is an integral part of the Esterline Technologies Lean Manufacturing Case Study Solution. It will help you evaluate the position of Esterline Technologies Lean Manufacturing regarding stability, profitability and liquidity accurately. On the basis of this, you will be able to recommend an appropriate plan of action. To conduct a Esterline Technologies Lean Manufacturing financial analysis in excel,

- Past year financial statements need to be extracted.

- Liquidity and profitability ratios to be calculated from the current financial statements.

- Ratios are compared with the past year Esterline Technologies Lean Manufacturing calculations

- Company’s financial position is evaluated.

Another way how you can do the Esterline Technologies Lean Manufacturing financial analysis is through financial modelling. Financial Analysis through financial modelling is done by:

- Using the current financial statement to produce forecasted financial statements.

- A set of assumptions are made to grow revenue and expenses.

- Value of the company is derived.

Financial Analysis is critical in many aspects:

- Decision Making and Strategy Devising to achieve targeted goals- to determine the future course of action.

- Getting credit from suppliers depending on the leverage position- creditors will be confident to supply on credit if less company debt.

- Influence on Investment Decisions- buying and selling of stock by investors.

Thus, it is a snapshot of the company and helps analysts assess whether the company's performance has improved or deteriorated. It also gives an insight about its expected performance in future- whether it will be going concern or not. Esterline Technologies Lean Manufacturing Financial analysis can, therefore, give you a broader image of the company.

Esterline Technologies Lean Manufacturing NPV

Esterline Technologies Lean Manufacturing's calculations of ratios only are not sufficient to gauge the company performance for investment decisions. Instead, investment appraisal methods should also be considered. Esterline Technologies Lean Manufacturing NPV calculation is a very important one as NPV helps determine whether the investment will lead to a positive value or a negative value. It is the best tool for decision making.

There are many benefits of using NPV:

- It takes into account the future value of money, thereby giving reliable results.

- It considers the cost of capital in its calculations.

- It gives the return in dollar terms simplifying decision making.

The formula that you will use to calculate Esterline Technologies Lean Manufacturing NPV will be as follows:

Present Value of Future Cash Flows minus Initial Investment

Present Value of Future cash flows will be calculated as follows:

PV of CF= CF1/(1+r)^1 + CF2/(1+r)^2 + CF3/(1+r)^3 + …CFn/(1+r)^n

where CF = cash flows r = cost of capital n = total number of years.

Cash flows can be uniform or multiple. You can discount them by Esterline Technologies Lean Manufacturing WACC as the discount rate to arrive at the present value figure. You can then use the resulting figure to make your investment decision. The decision criteria would be as follows:

- If Present Value of Cash Flows is greater than Initial Investment, you can accept the project.

- If Present Value of Cash Flows is less than Initial Investment, you can reject the project.

Thus, calculation of Esterline Technologies Lean Manufacturing NPV will give you an insight into the value generated if you invest in Esterline Technologies Lean Manufacturing. It is a very reliable tool to assess the feasibility of an investment as it helps determine whether the cash flows generated will help yield a positive return or not.

However, it would be better if you take various aspects under consideration. Thus, apart from Esterline Technologies Lean Manufacturing’s NPV, you should also consider other capital budgeting techniques like Esterline Technologies Lean Manufacturing’s IRR to evaluate and fine-tune your investment decisions.

Esterline Technologies Lean Manufacturing DCF

Once you are done with calculating the Esterline Technologies Lean Manufacturing NPV for your finance and accounting case study, you can proceed to the next step, which involves calculating the Esterline Technologies Lean Manufacturing DCF. Discounted cash flow (DCF) is a Esterline Technologies Lean Manufacturing valuation method used to estimate the value of an investment based on its future cash flows. For a better presentation of your finance case solution, it is recommended to use Esterline Technologies Lean Manufacturing excel for the DCF analysis.

To calculate the Esterline Technologies Lean Manufacturing DCF analysis, the following steps are required:

- Calculate the expected future cash inflows and outflows.

- Set-off inflows and outflows to obtain the net cash flows.

- Find the present value of expected future net cash flows using a discount rate, which is usually the weighted-average cost of capital (WACC).

- If the value calculated through Esterline Technologies Lean Manufacturing DCF is higher than the current cost of the investment, the opportunity should be considered

- If the current cost of the investment is higher than the value calculated through DCF, the opportunity should be rejected

Esterline Technologies Lean Manufacturing DCF can also be calculated using the following formula:

DCF= CF1/(1+r)^1 + CF2/(1+r)^2 + CF3/(1+r)^3 + …CFn/(1+r)^n

In the formula:

- CF= Cash flows

- R= discount rate (WACC)

Esterline Technologies Lean Manufacturing WACC

When making different Esterline Technologies Lean Manufacturing's calculations, Esterline Technologies Lean Manufacturing WACC calculation is of great significance. WACC calculation is done by the capital composition of the company. The formula will be as follows:

Weighted Average Cost of Capital = % of Debt * Cost of Debt * (1- tax rate) + % of equity * Cost of Equity

You can compute the debt and equity percentage from the balance sheet figures. For the cost of equity, you can use the CAPM model. Cost of debt is usually given. However, if it isn't mentioned, you can calculate it through market weighted average debt. Esterline Technologies Lean Manufacturing’s WACC will indicate the rate the company should earn to pay its capital suppliers. Esterline Technologies Lean Manufacturing WACC can be analysed in two ways:

- From the company's perspective, it can be analysed as the cost to be paid to the capital providers also known as Cost of Capital

- From an investor' perspective, if the expected return on the investment exceeds Esterline Technologies Lean Manufacturing WACC, the investor will go ahead with the investment as a positive value would be generated.

Esterline Technologies Lean Manufacturing IRR

After calculating the Esterline Technologies Lean Manufacturing WACC, it is necessary to calculate the Esterline Technologies Lean Manufacturing IRR as well, as WACC alone does not say much about the company’s overall situation. Esterline Technologies Lean Manufacturing IRR will add meaning to the finance solution that you are working on. The internal rate of return is a tool used in investment appraisal to calculate the profitability of prospective investments. IRR calculations are dependent on the same formula as Esterline Technologies Lean Manufacturing NPV.

There are two ways to calculate the Esterline Technologies Lean Manufacturing IRR.

- By using a Esterline Technologies Lean Manufacturing Excel Spreadsheet: There are in-built formulae for calculating IRR.

IRR= R + [NPVa / (NPVa - NPVb) x (Rb - Ra)]

In this formula:

- Ra= lower discount rate chosen

- Rb= higher discount rate chosen

- NPVa= NPV at Ra

- NPVb= NPV at Rb

Esterline Technologies Lean Manufacturing IRR impacts your finance case solution in the following ways:

- If IRR>WACC, accept the alternative

- If IRR<WACC, reject the alternative

Esterline Technologies Lean Manufacturing Excel Spreadsheet

All your Esterline Technologies Lean Manufacturing calculations should be done in a Esterline Technologies Lean Manufacturing xls Spreadsheet. A Esterline Technologies Lean Manufacturing excel spreadsheet is the best way to present your finance case solution. The Esterline Technologies Lean Manufacturing Calculations should be presented in Esterline Technologies Lean Manufacturing excel in such a way that the analysis and results can be distinguished to the viewers. The point of Esterline Technologies Lean Manufacturing excel is to present large amounts of data in clear and consumable ways. Presenting your data is also going to make sure that you don't have misinterpretations of the data.

To make your Esterline Technologies Lean Manufacturing calculations sheet more meaningful, you should:

- Think about the order of the Esterline Technologies Lean Manufacturing xls worksheets in your finance case solution

- Use more Esterline Technologies Lean Manufacturing xls worksheets and tables as will divide the data that you are looking at in sections.

- Choose clarity overlooks

- Keep your timeline consistent

- Organise the information flow

- Clarify your sources

The following tips and bits should be kept in mind while preparing your finance case solution in a Esterline Technologies Lean Manufacturing xls spreadsheet:

- Avoid using fixed numbers in formulae

- Avoid hiding data

- Useless and meaningful colours, such as highlighting negative numbers in red

- Label column and rows

- Correct your alignment

- Keep formulae readable

- Strategically freeze header column and row

Esterline Technologies Lean Manufacturing Ratio analysis

After you have your Esterline Technologies Lean Manufacturing calculations in a Esterline Technologies Lean Manufacturing xls spreadsheet, you can move on to the next step which is ratio analysis. Ratio analysis is an analysis of information in the form of figures contained in the financial statements of a company. It will help you evaluate various aspects of a company's operating and financial performance which can be done in Esterline Technologies Lean Manufacturing Excel.

To conduct a ratio analysis that covers all financial aspects, divide the analysis as follows:

- Liquidity Ratios: Liquidity ratios gauge a company's ability to pay off its short-term debt. These include the current ratio, quick ratio, and working capital ratio.

- Solvency ratios: Solvency ratios match a company's debt levels with its assets, equity, and earnings. These include the debt-equity ratio, debt-assets ratio, and interest coverage ratio.

- Profitability Ratios: These show how effectively a company can generate profits through its operations. Profit margin, return on assets, return on equity, return on capital employed, and gross margin ratio is examples of profitability ratios.

- Efficiency ratios: Efficiency ratios analyse how efficiently a company uses its assets and liabilities to boost sales and increase profits.

- Coverage Ratios: These ratios measure a company's ability to make the interest payments and other obligations associated with its debts. Examples include times interest earned ratio and debt-service coverage ratio.

- Market Prospect Ratios: These include dividend yield, P/E ratio, earnings per share, and dividend payout ratio.

Esterline Technologies Lean Manufacturing Valuation

Esterline Technologies Lean Manufacturing Valuation is a very fundamental requirement if you want to work out your Harvard Business Case Solution. Esterline Technologies Lean Manufacturing Valuation includes a critical analysis of the company's capital structure – the composition of debt and equity in it, and the fair value of its assets. Common approaches to Esterline Technologies Lean Manufacturing valuation include

- DDM is an appropriate method if dividends are being paid to shareholders and the dividends paid are in line with the earnings of the company.

- FCFF is used when the company has a combination of debt and equity financing.

- FCFE, on the other hand, shows the cash flow available to equity holders only.

These three methods explained above are very commonly used to calculate the value of the firm. Investment decisions are undertaken by the value derived.

Esterline Technologies Lean Manufacturing calculations for projected cash flows and growth rates are taken under consideration to come up with the value of firm and value of equity. These figures are used to determine the net worth of the business. Net worth is a very important concept when solving any finance and accounting case study as it gives a deep insight into the company's potential to perform in future.

Alternative Solutions

After doing your case study analysis, you move to the next step, which is identifying alternative solutions. These will be other possibilities of Harvard Business case solutions that you can choose from. For this, you must look at the Esterline Technologies Lean Manufacturing case analysis in different ways and find a new perspective that you haven't thought of before.

Once you have listed or mapped alternatives, be open to their possibilities. Work on those that:

- need additional information

- are new solutions

- can be combined or eliminated

After listing possible options, evaluate them without prejudice, and check if enough resources are available for implementation and if the company workforce would accept it.

For ease of deciding the best Esterline Technologies Lean Manufacturing case solution, you can rate them on numerous aspects, such as:

- Feasibility

- Suitability

- Flexibility

Implementation

Once you have read the Esterline Technologies Lean Manufacturing HBR case study and have started working your way towards Esterline Technologies Lean Manufacturing Case Solution, you need to be clear about different financial concepts. Your Mondavi case answers should reflect your understanding of the Esterline Technologies Lean Manufacturing Case Study.

You should be clear about the advantages, disadvantages and method of each financial analysis technique. Knowing formulas is also very essential or else you will mess up with your analysis. Therefore, you need to be mindful of the financial analysis method you are implementing to write your Esterline Technologies Lean Manufacturing case study solution. It should closely align with the business structure and the financials as mentioned in the Esterline Technologies Lean Manufacturing case memo.

You can also refer to Esterline Technologies Lean Manufacturing Harvard case to have a better understanding and a clearer picture so that you implement the best strategy. There are a number of benefits if you keep a wide range of financial analysis tools at your fingertips.

- Your Esterline Technologies Lean Manufacturing HBR Case Solution would be quite accurate

- You will have an option to choose from different methods, thus helping you choose the best strategy.

Recommendation and Action Plan

Once you have successfully worked out your financial analysis using the most appropriate method and come up with Esterline Technologies Lean Manufacturing HBR Case Solution, you need to give the final finishing by adding a recommendation and an action plan to be followed. The recommendation can be based on the current financial analysis. When making a recommendation,

- You need to make sure that it is not generic and it will help in increasing company value

- It is in line with the case study analysis you have conducted

- The Esterline Technologies Lean Manufacturing calculations you have done support what you are recommending

- It should be clear, concise and free of complexities

Also, adding an action plan for your recommendation further strengthens your Esterline Technologies Lean Manufacturing HBR case study argument. Thus, your action plan should be consistent with the recommendation you are giving to support your Esterline Technologies Lean Manufacturing financial analysis. It is essential to have all these three things correlated to have a better coherence in your argument presented in your case study analysis and solution which will be a part of Esterline Technologies Lean Manufacturing Case Answer.

Arbaugh, W. (2000). Windows of vulnerability: A case study analysis. Retrieved from Colorado State University Web site: http://www.cs.colostate.edu/~cs635/Windows_of_Vulnerability.pdf

Choi, J. J., Ju, M., Kotabe, M., Trigeorgis, L., & Zhang, X. T. (2018). Flexibility as firm value driver: Evidence from offshore outsourcing. Global Strategy Journal, 8(2), 351-376.

DeBoeuf, D., Lee, H., Johnson, D., & Masharuev, M. (2018). Purchasing power return, a new paradigm of capital investment appraisal. Managerial Finance, 44(2), 241-256.

Delaney, C. J., Rich, S. P., & Rose, J. T. (2016). A Paradox within the Time Value of Money: A Critical Thinking Exercise for Finance Students. American Journal of Business Education, 9(2), 83-86.

Easton, M., & Sommers, Z. (2018). Financial Statement Analysis & Valuation. Seattle: amazon.com.

Gotze, U., Northcott, D., & Schuster, P. (2016). Investment Appraisal. Berlin: Springer.

Greco, S., Figueira, J., & Ehrgott, M. (2016). Multiple criteria decision analysis. New York: Springer.

Hawkins, D. (1997). Corporate financial reporting and analysis: Text and cases. Homewood, IL: Irwin/McGraw-Hill.

Hribar, P., Melessa, S., Mergenthaler, R., & Small, R. C. (2018). An Examination of the Relative Abilities of Earnings and Cash Flows to Explain Returns and Market Values. Rotman School of Management Working Paper, 10-15.

Kaszas, M., & Janda, K. (2018). The Impact of Globalization on International Finance and Accounting. In Indirect Valuation and Earnings Stability: Within-Company Use of the Earnings Multiple (pp. 161-172). Berlin, Germany: Springer, Cham.

King, R., & Levine, R. (1993). Finance and growth: Schumpeter might be right. The quarterly journal of economics, 108(3), 717-737.

Kraus, S., Kallmuenzer, A., Stieger, D., Peters, M., & Calabrò, A. (2018). Entrepreneurial paths to family firm performance. Journal of Business Research, 88, 382-387.

Laaksonen, O., & Peltoniemi, M. (2018). The essence of dynamic capabilities and their measurement. International Journal of Management Reviews, 20(2), 184-205.

Lamberton, D. (2011). Introduction to stochastic calculus applied to finance. UK: Chapman and Hall.

Landier, A. (2015). The WACC fallacy: The real effects of using a unique discount rate. The Journal of Finance, 70(3), 1253-1285.

Lee, L., Kerler, W., & Ivancevich, D. (2018). Beyond Excel: Software Tools and the Accounting Curriculum. AIS Educator Journal, 13(1), 44-61.

Li, W. S. (2018). Strategic Value Analysis: Business Valuation. In Strategic Management Accounting. Singapore: Springer.

Magni, C. (2015). Investment, financing and the role of ROA and WACC in value creation. European Journal of Operational Research, 244(3), 855-866.

Marchioni, A., & Magni, C. A. (2018). Sensitivity Analysis and Investment Decisions: NPV-Consistency of Straight-Line Rate of Return. Department of Economics.

Metcalfe, J., & Miles, I. (2012). Innovation systems in the service economy: measurement and case study analysis. Berlin, Germany: Springer Science & Business Media.

Oliveira, F. B., & Zotes, L. P. (2018). Valuation methodologies for business startups: a bibliographical study and survey. Brazilian Journal of Operations & Production Management, 15(1), 96-111.

Pellegrino, R., Costantino, N., & Tauro, D. (2018). Supply Chain Finance: A supply chain-oriented perspective to mitigate commodity risk and pricing volatility. Journal of Purchasing and Supply Management, 1-10.

Pham, T. N., & Alenikov, T. (2018). The importance of Weighted Average Cost of Capital in investment decision-making for investors of corporations in the healthcare industry.

Smith, K. T., Betts, T. K., & Smith, L. M. (2018). Financial analysis of companies concerned about human rights. International Journal of Business Excellence, 14(3), 360-379.

Teresa, M. G. (2018). How the Equity Terminal Value Influences the Value of the Firm. Journal of Business Valuation and Economic Loss Analysis, 13(1).

Yang, Y., Pankow, J., Swan, H., Willett, J., Mitchell, S. G., Rudes, D. S., & Knight, K. (2018). Preparing for analysis: a practical guide for a critical step for procedural rigour in large-scale multisite qualitative research studies. Quality and Quantity, 52(2), 815-828.

Warning! This article is only an example and cannot be used for research or reference purposes. If you need help with something similar, please submit your details here .

9410 Students can’t be wrong

PhD Experts

Miral Halai

This webpage is the best. I was literally protected by this service. Thanks a lot!

I used this service for three of my assignments and it did a great job. It’s really a good website. Thanks a lot!

Theo Maxime

The assignment was completed exceptionally well. Thumbs up! I am pleasantly surprised with what I got from here. I'm grateful!

Renat Rafet

Job was well done—really good assistance. I'll suggest this service to my friends. Thanks a lot!

Calculate the Price

(approx ~ 0.0 page), total price $0, next articles.

- Du Pont Kevlar Aramid Industrial Fiber (Abridged) Case Solution

- Connor Formed Metal Products Case Solution

- Spir It, Inc. (A): Building The Business Case Solution

- Stermon Mills, Inc. Case Solution

- Air Products And Chemicals, Inc.: MIS Reorganization (A) & Project ICON (A) (Abridged) Case Solution

- Dynatrol Corp.: Andover Assembly Division Case Solution

- Hewlett Packard Co.: DeskJet Printer Supply Chain (B) Case Solution

- Fabritek Corp., Spanish Version Case Solution

- Loctite Corp. Case Solution

- Process Control At Polaroid (A) Case Solution

Previous Articles

- Six Sigma Quality At Flyrock Tires Case Solution

- Cradle To Cradle Design At Herman Miller: Moving Toward Environmental Sustainability Case Solution

- Le Petit Chef Case Solution

- Barilla SpA (A) Case Solution

- Applichem (A) (Abridged) Case Solution

- Au Bon Pain: The French Bakery Cafe, The Partner/Manager Program Case Solution

- Dunfey Hotels Corp. Case Solution

- Marriott's Rancho Las Palmas Resort Case Solution

- Au Bon Pain: Interviews With Ron Shaich And Len Schlesinger, Video Case Solution

- Westin Hotels And Resorts: Operations Of A Lifestyle Experience Case Solution

Be a great writer or hire a greater one!

Academic writing has no room for errors and mistakes. If you have BIG dreams to score BIG, think out of the box and hire Case48 with BIG enough reputation.

Our Guarantees

Zero plagiarism, best quality, qualified writers, absolute privacy, timely delivery.

Interesting Fact

Most recent surveys suggest that around 76 % students try professional academic writing services at least once in their lifetime!

Allow Our Skilled Essay Writers to Proficiently Finish Your Paper.

We are here to help. Chat with us on WhatsApp for any queries.

Customer Representative

- Order Status

- Testimonials

- What Makes Us Different

Esterline Technologies: Lean Manufacturing Harvard Case Solution & Analysis

Home >> Harvard Case Study Analysis Solutions >> Esterline Technologies: Lean Manufacturing

Raises questions about the appropriate role of IT in lean manufacturing. Most large manufacturing companies have implemented ERP-IT systems to support lean manufacturing practices. Esterline Technologies plant Kerry tried to implement ERP, and then it stops. The plant Kerry revision for the appropriate use of IT in the innovation lean manufacturing. Robert Cremin «Hide by Richard L. Nolan, Karen Brown, Subodha Kumar Source : Harvard Business School 23 pages. Publication Date: May 03, 2006. Prod. #: 906417-PDF-ENG

Related Case Solutions & Analyses:

Hire us for Originally Written Case Solution/ Analysis

Like us and get updates:.

Harvard Case Solutions

Search Case Solutions

- Accounting Case Solutions

- Auditing Case Studies

- Business Case Studies

- Economics Case Solutions

- Finance Case Studies Analysis

- Harvard Case Study Analysis Solutions

- Human Resource Cases

- Ivey Case Solutions

- Management Case Studies

- Marketing HBS Case Solutions

- Operations Management Case Studies

- Supply Chain Management Cases

- Taxation Case Studies

More From Harvard Case Study Analysis Solutions

- Harley Davidson

- Net.Genesis Inc.

- Jack Smith (B): Becoming a Toyota Manager (I)

- John Smith CEO BBC Worldwide Remarks to AMP October 2007 Video Supplement

- Nike Inc.: Cost of Capital (v. 1.8)

- Trusted Family (A): Building a Career with Family Entrepreneurship?

- Surface Logix

Contact us:

Check Order Status

How Does it Work?

Why TheCaseSolutions.com?