Flour Mill Business Plan

S B A P_ Business plan_V.01

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 1

M/s Shri * P.Ltd Survey No, , Andhra Pradesh.

WHEAT FLOUR MILL PROPOSAL FOR

TERM LOAN & WORKING CAPITAL ASSISTANCE

Business Plan

M/s Shri * Food Products

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 2

Business Plan COMPANY INFORMATION

S.No Particulars Details 01. Company M/s Shri * P.Ltd 02. Status Private limited company incorporated on * ROC, AP,

vide CIN No. *

03. Corporate Office Factory

04. Web Site 05. Management

06. Statutory Auditors

07. Finance Consultants

08. Bankers

09. Business Setting up a 120 TPD Wheat Roller Flour Mill & 30 TPD Chakki Atta Project

10. Industry Food Processing 11. Status SSI Unit in the field of Food Processing 12. Highlights Belongs to existing profit making Group in the business

of Flour trading and marketing. 13 Cost of the Project Project Cost: Rs 578.00 lakhs 14. Means of Finance Term Loan Rs 350.00 lakhs

Equity Capital Rs 228.00 lakhs Working Capital Rs 240.00 lakhs

15. Debt Equity ratio 1.54 : 1 16. DSCR 3.08 17. Payback period 3 years 18. Direct Employment 49 Personnel 19. Indirect Employment 50 20 Marketing Relationships Firm Commission agents net work in places 21. Break Even Capacity 35% 20. Technology Proven technology, promoters having experience

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 3

The Project M/s Shri * Pvt Ltd is a private limited company incorporated in Andhra Pradesh, India promoted by Mr. *2010. The promoters who have extensive experience in the Trading of Oil and Food Products have conceived the idea of encashing their trading experience and going in for Food Processing industry. The company is proposing to setup a Wheat Flour Mill of 120 Tons per day capacity along with a Atta Chakki Plant of 30 Tons per day processing unit at Survey No, * just about 10 Kms from Hyderabad.

The unit proposes to produce Wheat Products such as Atta, Maida, Chakki Atta, Ravva and Bran ( By product ) of 150 Tons per day ( 120 + 30 ) to cater to the needs of Whole Sale and Retail needs of South Indian Wheat Market. The required raw material is basically Wheat which is available in plenty from various parts of northern and western parts of India.

Processed wheat products are staple food items in India .Consumption and Demand for the products proposed for manufacturing by the company, is ever on increase due to increase in population, increase in per capita consumption owing to various factors such as rise in disposable income, increasing value of time, increasing demand for improved quality standard and hygiene of the products and non-economics of small-scale chakkis in wheat segment.

The Company has obtained on long lease, 2_Acres of industrial land in Nadigama Village, Patancheru Mandal, Medak district, for implementation of the Project. The land has been converted from agricultural area and is to be developed for setting up the production facilities

The total Investment of the project is estimated at Rs 578.00 Lacs which is proposed to be financed by the promoters as well as term loan from Banks in 1 : 1.54 ratio.

PPrroommootteerrss

M/S Shri * Agro Products Foods Products has been promoted by Mr. * .

• Mr.Kamal Kumar Mundada (Director)- S/o Late Sri Kishan Mundada started his career in the year 1991 after his school education. He entered the family business run by his father viz., M/s Mundada brokers who are commission agents for supply of crude edible oil to oil refineries till 2006. Currently the business is handled by his cousins. For a couple of years he assisted his young nephew who owns a proprietary concern ‘Anand Agencies’, distributors of wheat products viz., Atta, Chikki Atta, Maida etc. He gained rich experience assisting his nephew in the wheat products business. With this background, he started his own business in 2007viz., ‘Shubham Agro Industries’, a partnership firm to manufacture Chakki Atta at Kattedan industrial area. Presently the firm is clocking a turnover of Rs 6.00 Cr to Rs. 7.00 Cr per annum.

• Ashish Mundada S/o Sri Kamal Kumar Mundada after completing his graduation (B Tech in Electrical Engg) in the year 2006, started his career as a channel partner to market the products of Idea Cellular. He did this business for a period of 2 years and achieved a turnover of Rs 12 Cr each per year. He gave up this business and joined as a partner of ‘Shubham Agro Industries’.

• Share Holding Pattern:

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 4

S.No. Name of each Partner % equity contribution into the Project

01. Mr. Ashish Kumar Mundada 15.00% Director 02. Mr.Radha Kirshna Bajaj 25.00% Investor 03. Mr. Ashish Kumar Bung 12.50% Director 04. Mrs. Chandrakala Bung 5.00% Investor 05. Mr.Rohit Agarwal 17.50% Investor 06. Mrs.Indra Mundada 10.00% Director 07. Mr. Kamal Kishore Mundada 15.00% Director total 100.00%

Details of the Associate Concerns:

Name of the Concern

Activity Nature of Association

Annual Turnover

Financing Arrangements

Status of Account

Shubham Agro Industries

(Partnership firm)

Food Processing

Chakki Atta Mill

Sri Kamal Kumar Mundada-Director is a partner

Rs 7.00 Crores.

Nil Standard

The Products & The Process:

The Products proposed for manufacture are the different processed forms of Wheat grain and as such are different forms in which Wheat is consumed.

Roller Flour Mill Chakki Mill Maida 52% Chakki Atta 92%

Atta 15% Ravva 8% Bran 23% Bran 6% Wastage-loss 2% Wastage-loss 2% 100% 100%

(a) What is Maida?

Maida flour is finely-milled wheat flour variety which is used to make Indian breads such as paratha and naan. It is also used in Central Asian and Southeast Asian cuisine. Maida is a refined product of wheat. It is extracted from the inner white portion of the wheat after the outer brownish layer is removed. After the flour is ground in a flour mill, it is passed through a fine mesh (600 mesh per square inch) to obtain maida. Though sometimes referred to as "all-purpose flour" by Indian chefs, it more closely resembles cake flour or even pure starch. In India, maida flour is used to make pastries and other bakery items such as bread, biscuits and toast. Pastry flours available in United States may be used as a substitute for maida.

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 5

(b) What is Atta

Atta is the main ingredient of most varieties of Indian, Bangladeshi and Pakistani bread. It is a whole wheat-flour made from hard wheat grown across the Indian subcontinent. Flatbread made from atta, such as chapati, roti, naan and puri, are an integral part of Indian cuisine. Hard wheats have a high content of gluten (a protein composite that gives elasticity), as such, doughs made out of atta flour are strong and can be rolled out very thin. Atta is obtained from grinding complete wheat grains. It is creamy brown in colour and quite coarse compared to other types of flour. Since nothing is removed from true whole meal atta, all the constituents of the wheat grain are preserved. Atta available in market varies in its fibre content from very low to whole of natural fiber in wheat, around 12%.

(c) What is Ravva ? Husk removed wheat is ground to form rava, and used extensively in south Indian cuisine, such as in Karnataka and Tamilnadu, to make Rava dosa, Rava idli, upma, khichdi, and also sweets like Rava Ladoo and Rava halwa also known as Rava Kesari. There is another form of rava known as Chamba Rava, which is an extract of wheat flour. As this "Rava" is an extract of maida flour it is much finer. Rava may be described as the residues of milled material, after the flour is ground in a flour mill (Chakki). It is passed through a fine mesh till flour and rava are separated. Bombay Rava is used in Southern parts of India to make delicious dish called upma. It is also used as an additive in some Dosa items, especially the Rava Dosa. (d) What is Chakki atta ?

Atta is obtained from grinding complete wheat grains. It is creamy brown in color and quite coarse compared to other types of flour. Since nothing is removed from true whole meal atta, all the constituents of the wheat grain are preserved. Atta available in market varies in its fibre content from very low to whole of natural fibre in wheat, around 12%. Traditionally, atta is made by stone grinding, a process that imparts a characteristic aroma and taste to the bread. High bran content of true whole meal atta makes it a fiber-rich food. This may help to regulate blood sugar as well have other health benefits. The temperatures attained in a chakki produced by friction, are of the order of 110-125 deg C. At such high temperatures, the carotenes present in the bran tend to exude the characteristic roasty smell, and contribute to the sweetness of the atta. The various quality control parameters for the atta industry are Ash Content, Moisture Content, (f) What is Bran? Bran is the hard outer layer of grain and consists of combined aleurone and pericarp. Along with germ, it is an integral part of whole grains, and is often produced as a by-product of milling in the production of refined grains. When bran is removed from grains, the latter lose a portion of their nutritional value. Bran is present in and may be milled from any cereal grain, including rice, corn (maize), wheat, oats, barley and millet. Bran should not be confused with chaff, which is coarser scaly material surrounding the grain, but not forming part of the grain itself. Wheat bran is fed to horses in the form of a warm porridge or mash. Bran mash is considered an excellent way to get the horse to drink more water. It is also indicated for its laxative qualities. Bran is widely used as a major component in foods for cows, buffaloes, goats, rabbits, guinea pigs, etc. Bran is particularly rich in dietary fiber and essential fatty acids and contains significant quantities of starch, protein, vitamins and dietary minerals. Bran is often used to enrich breads (notably muffins) and breakfast cereals, especially for the benefit of those wishing to increase their intake of dietary fiber. Bran may also be used for pickling (nukazuke) as in the tsukemono of Japan. In Romania, fermented wheat bran is usually used when preparing sour soups, called borscht.

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 6

Wheat & Wheat Products– The Staple Food:

• Wheat (Triticum spp) is a grass, originally from the Fertile Crescent region of the Near East, but now cultivated worldwide. In 2007 world production of wheat was 607 million tons, making it the third most-produced cereal after maize (784 million tons) and rice (651 million tons).

• Globally, wheat is the leading source of vegetable protein in human food, having a higher protein content than either maize (corn) or rice, the other major cereals. In terms of total production tonnages used for food, it is currently second to rice as the main human food crop, and ahead of maize, after allowing for maize's more extensive use in animal feeds.

• Wheat was a key factor enabling the emergence of city-based societies at the start of civilization because it was one of the first crops that could be easily cultivated on a large scale, and had the additional advantage of yielding a harvest that provides long-term storage of food.

• Wheat grain is a staple food used to make flour for leavened, flat and steamed breads, biscuits, cookies, cakes, breakfast cereal, pasta, noodles, and couscous and for fermentation to make beer, other alcoholic beverages, or bio fuel. Wheat is planted to a limited extent as a forage crop for livestock, and its straw can be used as a construction material for roofing thatch. The husk of the grain, separated when milling white flour, is bran.

• Wheat germ is the embryo portion of the wheat kernel. It is a concentrated source of vitamins, minerals, and protein, and is sustained by the larger, starch storage region of the kernel—the endosperm.

• Raw wheat can be ground into flour or - using hard durum wheat only, can be ground into semolina; germinated and dried creating malt; crushed or cut into cracked wheat; parboiled (or steamed), dried, crushed and de-branned into bulgur also known as groats.

• If the raw wheat is broken into parts at the mill, as is usually done, the outer husk or bran can be used several ways. Wheat is a major ingredient in such foods as bread, porridge, crackers, biscuits, Muesli, pancakes, pies, pastries, cakes, cookies, muffins, rolls, doughnuts, gravy, boza (a fermented beverage), and breakfast cereals (e.g., Wheatena, Cream of Wheat, Shredded Wheat, and Wheaties).

• 100 grams of hard red winter wheat contain about 12.6 grams of protein, 1.5 grams of total fat, 71 grams of carbohydrate (by difference), 12.2 grams of dietary fiber, and 3.2 mg of iron (17% of the daily requirement); the same weight of hard red spring wheat contains about 15.4 grams of protein, 1.9 grams of total fat, 68 grams of carbohydrate (by difference), 12.2 grams of dietary fiber, and 3.6 mg of iron (20% of the daily requirement).

• Much of the carbohydrate fraction of wheat is starch. Wheat starch is an important commercial product of wheat, but second in economic value to wheat gluten. The principal parts of wheat flour are gluten and starch. These can be separated in a kind of home experiment, by mixing flour and water to form a small ball of dough, and kneading it gently

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 7

while rinsing it in a bowl of water. The starch falls out of the dough and sinks to the bottom of the bowl, leaving behind a ball of gluten.

Background of Wheat in India

Wheat is a major food staple in India, and is crucial to India’s food economy and security. With wheat production of 75 to 85 million tons annually and a large demand, India’s wheat economy is now the second largest in the world. The marketed surplus from the production has also been rising and it is estimated that about 60-70 percent of the production now comes to the market (India, Directorate of Economic and Statistics 2010).

• Maida and Atta are required for daily human consumption directly, or indirectly by way of bread, biscuits, sweets, cakes, confectioneries etc. However bran is the byproduct produced in the process of manufacturing wheat products is used for making cattle feed.

• Major portion of atta is used for making Roti, part of daily staple diet in India. A part of atta is also used for biscuits.

• Maida is mainly used for bread, biscuit, cakes, cookies sweets, confectionaries etc. and Bread is popular snack food for lower middle-income group name as ‘Pav’. Premium range of the bread is popular breakfast item among middle and upper income group in urban areas

• Suji is used for daily human consumption in various forms and specially used for infant foods

TThhee PPrroodduuccttiioonn PPrroocceessss:: TTeecchhnnoollooggyy

The processing of Wheat is done through running wheat in a roller system and the technology is very conventional and time tested. Details of the processing together with a flow chart are available else where in this report. Market for Wheat Products: The Food Processing Industry:

India is the world's second largest producer of food next to China, and has the potential of being the biggest with the food and agricultural sector. The processing food segment accounts for USD 29.4 billion, in a total estimated food market of about USD 91.7 billion. The food processing industry is one of the largest industries in India. It currently ranks fifth in terms of production, consumption, export and growth prospects.

The Government of India has identified the Food Processing Industry sector as a high priority area. It has given a number of fiscal reliefs and incentives to encourage commercialization and value addition to agricultural produce. As per a study conducted by McKinsey and Confederation of Indian Industry (CII), the turnover of the total food market is approximately USD 69.4 billion out of which value-added food products comprise USD 22.2 billion.

The total food production in India is likely to double in the next ten years and there is an opportunity for large investments in food and food processing technologies, skills and equipment. Godrej Foods, Reliance, Namdhari, ITC, Nestle, Ruchi Soya Industries, Tata Coffee, Tata Tea, RPG group, Subhiksha are major players. The Indian food processing industry is primarily export oriented. India’s geographical situation gives it the unique advantage of connectivity to Europe, the Middle East, Japan, Singapore, Thailand, Malaysia and Korea. One such example indicating India’s location advantage is the value of trade in agriculture and processed food between India and Gulf region.

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 8

Macro-Scene- Wheat Products:

Wheat is a cereal grain grown and consumed worldwide. Wheat is more popular than any other cereal grain use in baked goods. Its popularity stems from the gluten that forms when flour is mixed with water. Without gluten, raised bread is hard to imagine. Wheat is also preferred because of its mild, nutty flavor. Both the factors account for wheat being the most widely grown cereal grain in the world. Today, thousands of varieties of wheat are grown throughout the world, most requiring fertile soil and a temperate climate. Major wheat growing countries include China, India, France, and Russia. Recent projections by the International Food Policy research Institute (IFPRI) indicate that, by 2020, two-thirds of the world’s wheat consumption will occur in developing countries, where wheat imports are estimated to double by 2020.

As noted earlier in this report, wheat demand worldwide is calculated to rise by 40% from 1993 to 2020 to reach 775 million tons. The expected increase in demand is partly motivated by population growth but also results from substitution out of rice and coarse grain cereals as incomes rise and populations become increasingly based in urban areas. (Source: Multi Commodity Exchange of India Limited) .

Growth in packaged Atta industry is driven by four factors viz. (i) Rise in disposable income, (ii) Value of Time, (iii) Demand for improved quality and hygiene and (iv) Economic / Non Economy of small scale Chakkis. However, the current position of wheat availability is very comfortable and this is reflected by overflowing wheat stocks with the Food Corporation of India Therefore, with the easy availability of wheat for the next few years, increasing urbanization, and rising income levels, the demand for the flour milling industry is expected to grow rapidly in the future.

• The size of the Indian urban food market is estimated at Rs 350,000 Crore. The domestic market for processed food is huge and fast growing. The retail boom will create a huge demand for the food-processing sector in the coming years. Little wonder that 2007 has been designated the Year of Food Technology.

• The private sector is yet to realize its full potential in the food-retailing sector, as the market is still to explore. Though, it has now started discovering the money there is to be made in the urban food retailing market. Urban centers have the potential of development process. But they do not produce food as they lack agricultural land; on contrary the rural areas do. In that sense, the urban areas provide an assured market for the food produced by farmers. The urban food marketing system thus assumes considerable importance for both feeding the urban population and helping farmers.

• There are certain distinct characteristics of urban food demand. The urban population generally has a higher purchasing power. The rising average income is leading to greater demand for high-value processed food. A considerable number of urban women work, creating a demand for heat-and-serve foods.

• The urban population density is high and this demands a chain or a network of retail outlets. Indian food retailing is poised for a quantum leap. Not only are newer names set to dot the retail landscape but also such new formats, as hyper-and super-markets are to emerge.

• The key drivers for increased demand in value-added processed food products are: a) growth in consumer class; b) change in lifestyle characterized by expanding urban population, increased number of nuclear and dual-income families; c) change in attitudes and tastes with increasing modernization and to a lesser extent westernization of tastes,particularly, of the youth; d) low penetration rates; and e) ability to offset seasonal supply-and-demand effects in fresh products.

Technical Feasibility:

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 9

DETAILS OF THE PROJECT / INFRASTRUCTURE / CAPASITIES & PRODUCTION

AA.. PPrroodduucctt CCaappaacciittiieess // RRaaww mmaatteerriiaallss

The 8 Body Roller Flour Mill & 4 Chakki Atta Plant, Machinery, Buildings and other Infrastructure designed (as per details given below) to produce the following capacities. Wheat Roller Flour Mill & Atta Chakki Plant capacities & proposed utilized capacities:

Particulars 2011-12 2012-13 2013-14 2014-15 2015-16 MT/ PA MT/ PA MT/ PA MT/ PA MT/ PA Capacity of Roller Flour Mill Plant ( 120 TPD ) 39600 39600 39600 39600 39600 Capacity of Chakki Atta Plant ( 30 TPD ) 9900 9900 9900 9900 9900 Operating Capacity % 50% 55% 60% 65% 70% Production Roller flour Mill products * 14850 21780 23760 25740 27720 Production Atta Chakki 3713 5445 5940 6435 6930

B. Land & Location of the project The 120 TPD Roller Flour Mill plant along with 30 TPD Chakki Atta Plant is proposed to be located in 2_Acres of leased land ( long term registered lease for a period of 12 years) at Survey No,31/A, Nadigama Village, Patancheru Mandal, Medak district, Andhra Pradesh just about 10 Kms from Hyderabad. Patancheru also known as Patan Choru, is a census town and mandal headquarters in Medak district located about 10 km from Hyderabad on the Hyderabad-Sholapur highway.

The location has excellent approach roads, water resource and proximity to Power. The area being on the State highway logistically is ideal to locate the unit. The area has all the infrastructure facilities such as adequate power, skilled labor, transportation facilities for locating the plant. Thus the unit is located in a ideal location. The land development include leveling of 2 acres, providing 20 and 12 feet roads in the eastern and southern sides respectively for bulk movement of cargo and staff vehicles and building a Compound wall. The total cost of development is estimated at Rs 1.94 lakhs. (C) Factory buildings

The Company is proposing to build 24356 sq feet of factory RCC buildings to host plant machinery and other facilities as per the food grade standards and to host the utilities such as power / water / security / steam etc. The drawings and building outlay are ready for execution. The factory consists of processing and storage facilities. Processing is carried out in three stages – Storage, Cleaning, Milling, Grinding, packaging, hosting of utilities, Administration and general structure. All these facilities are provided in two buildings constructed as per FPO norms, the second building would have central partition dividing the storage space and processing space. Administrative, security, toilets and rest rooms are provided as per the requirement. The total cost of buildings is estimated at Rs 92.64 lakhs

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 10

(G) Plant and Machinery & Process Technology:

Total cost of machinery is estimated, at Rs.232 lac’s based on quotations received from various vendors, details of which are as under:

a) Cleaning (Preparatory) Section: Wheat procured, contains many impurities like sand, metal pieces, dirt and gunny pieces. The process of the cleaning is primary sieving for the removal of large size impurities, brushing for removal of dust attached to the surface of grain, removal of metal impurities. The machinery required for the cleaning section mainly consist of drum sieve, classifier, magnets separator etc. Cleaned wheat is stored in silos for conditioning before milling.

b) Milling Section: The three major parts of wheat are Bran, Germ and the Endosperm. The bran and germ is separated as it affects the baking quality of the flour. The Roller Mill Process is a gradual reduction process where bran and its parts are broken down in succession of relatively gentle grinding stage. Grinding is done in Roller Mill with a pair of rolls mounted in parallel alignment that can be adjusted to do precision grinding. At each grinding stage products consist of mixture of coarse, medium and fine particles including the portion of the flour that are separated by sifting of material following each grinding stage. The produce is then sieved in plan shifters. Pneumatic lifts are used to feed in at the top and passes from the sieves to sieves by gravity flow. The machines required in Milling Section mainly consist of Roller Mills, Plan Shifters, Bran Finishers, Reverse Jet Filters, Dampener, Pneumatic lifts etc.

c) Others: Roller Flour Mill will be fully automated and will have various other equipments such as Elevators, Cyclones, Air lock, Conveying System, Screening System, Dust Collection equipments etc.

d)The miscellaneous fixed assets include furniture, jeep, weigh bridge office machines & equipment, fire-fighting equipment, testing equipment, & transformer including HT (High Tension) line.

Manufacturing Process & Technology: The technology for food processing industry is not complicated and mostly related to engineering. Good qualified and experienced team of management exposed to running hi-tech plants, is sure to have an edge over the competitors. The machinery suppliers extend all the necessary technical supports such as installation and upkeep.

Cleaning (preparatory) Section: The wheat contains many impurities like sand, metal pieces, dirt and gunny pieces. Wheat is cleaned before processing to remove coarse impurities like stones, chafe, stitching threads, woods, straws, dust etc. Conveyors, Elevator, Drum Sieve, Reel Machine, Separator with aspirators, magnet, etc. are used in pre-cleaning which improves the storability of the wheat.

Storage Silos: Cleaned wheat is stored in silos for the continuous process and making a proper blend of wheat according to the requirement as needed for the end product mix.

First Cleaning: pre cleaned wheat is further processed to remove foreign ingredients that not only reduces the yield but also affects the taste and colour of the finished goods. Auto weigher, flow balancer, Dry de-stoner, intensive dampener, magnets are used in process and wheat is tempered at this stage.

In take & pre cleaning

Storage Silo

First Cleaning

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 11

Second Cleaning: By absorption of water at 1st cleaning stage cellulose layer of wheat expand, crack and get partly loose which is further tempered to have constant moisture using Intensive Dampner, Flow Balancer, Scourer, Volumetric Measure, Automatic Water Doser for smooth milling. Grinding: For getting good extraction Gradual Reduction System of break is used to separate the bran and endosperm. This breaking of wheat separating bran and endosperm is a mechanical process done by passing the wheat through Rolls running at different speed to produce a cutting and shearing action. Apart from Rolls Disc, Beat and impact Detachers are used besides the elevators to move the product from one roll to another

Purification: Semolina and Middling produced at grinding stage are separated from bran by air in Purifier Machines whereby a composite fractions composed of endosperm with adhering bran are also separated.

Bran Finisher: Whatever flour remain in bran is cleaned using bran finisher and the remaining bran is packed.

Packaging: Since the process is of Gradual Reduction therefore at each stage end products are produced and sent pneumatically after sieving using Bolting Cloth in service Machines and the finished product are packed for delivery in market

((HH)) EEnnvviirroonnmmeennttaall IImmppaacctt This project is environmental friendly. Government of India has classified this in Green Category of industries. The factory is situated adjacent to main road leading to National High Way and there is no threat to traffic congestion. There is no dwelling close to the factory. The noise from the factory is very minimal. The factory has a potential to employ the locals as the process involves huge man power. The expertise of the locals can also be used to the benefit of the unit as most of the villagers are farmers. The presence of this environmental friendly unit would certainly help improve the locality as service oriented facilities are bound to come up because of the manpower employed.

(I) POLLUTION ABATEMENT Solid Wastes: The solid waste generated is only bran which is saleable and has commercial applications. Liquid effluent: Nil, Air Pollution: There is no production of any obnoxious gases any where in the process. Licenses & Regulatory permissions: The Company has obtained the necessary approvals/permissions/licenses from the various authorities as listed hereunder:

S.No. Item of Approval/License /Permission

01 SSI Registration Received 02 Power Feasibility Under process 03 Environment Under process 04 VAT Registration Received 05 Factory Inspector Under process 06 Panchayat License Received 07 Estimates / Quotations Received

Second Cleaning

Grinding

Purification

Bran Finisher

Packaging

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 12

Resources Raw Material:

The basic raw material is Wheat and it is the largest produced grain in India next to Rice. International Scenario of Wheat Producing Regions

Major wheat growing countries include China, India, France, and Russia. Worldwide wheat is grown in Asia, Africa, Europe and America. On basis of area maximum acreage comes from India that accounts for 13% of total world average, followed by EU, Russia, China, USA, Australia, Canada and Kazhakastan. Total average is around 217 million hectare, which keeps fluctuating between 210 million hectare to 230 million hectare in general.

(Source: Multi Commodity Exchange of India Limited) World Wheat Production

World production of wheat hovers around 585 million tons. Maximum contribution comes from European Union, which comprises 25 countries followed, by China, India, and United states.

(000 Tonnes) Countries 2000-01 2001-02 2002-03 2003-04EU-25 124,197 113,553 124,483 106,615China 99,640 93,873 90,290 86,490 India 76,369 69,680 71,810 65,100 United States 60,641 53,001 43,705 63,814Russia 34,450 46,900 50,550 34,100Australia 22,18 24,299 10,132 26,231Canada 26,519 20,568 16,198 23,552World Total 581,377 580,930 566,963 552,828

(Source: USDA)

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 13

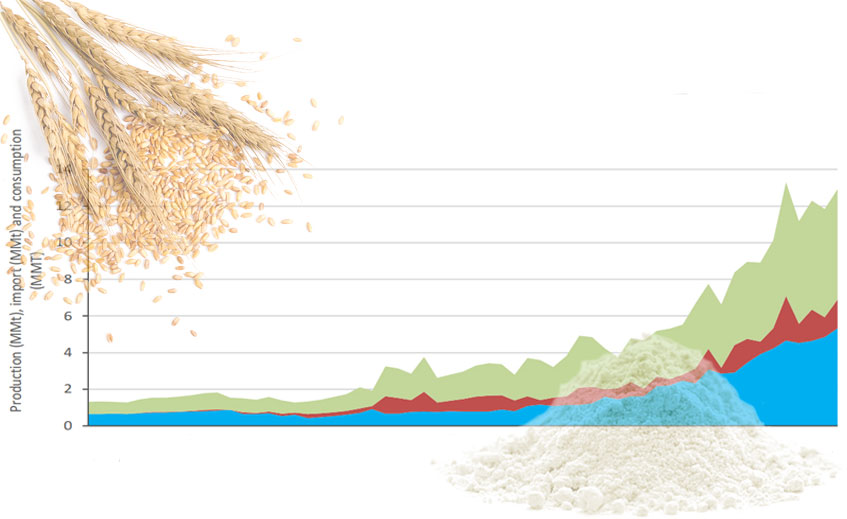

World wheat consumption is consistently growing. Long-term trend supports the fact that is evident from above chart. Wheat being one of the major staple foods all across the world demand seems to remain strong owing to increasing population. Two major consuming countries of wheat are EU, China, India, Russia, USA and Pakistan.

Wheat has made the largest contribution to the growth of food grain production in India. This is shown by the growth rates: wheat production has grown at a much faster pace compared to other food grains. During 1974 – 2010, when total food grain production grew at an annual rate of 3.68 per cent, wheat production grew at 5.36 per cent. Even in the last decade, wheat production is showing the fastest growth. The growth in wheat production has come from increase in yield as well as expansion of area. The increase in area sown has come at the expense of coarse cereals and pulses area, and from an increase in cropping intensity through multiple cropping. WHEAT ALL INDIA PRODUCTION IN MILLION TONS – 1974 - 2010

WHEAT - ALL INDIA PRODUCTION

MILLION TONNES

ACTUAL PRODUCTION PRODUCTION TREND

Nationally about 18 per cent of the net cropped area is planted to wheat. Figure 1 shows the shares of different states in the national wheat production. Uttar Pradesh (U.P.) contributes the largest share with 36 per cent of production, followed by Punjab with 19 per cent and Haryana with 11 per cent. These three northern states together contribute two-thirds of the production of wheat. These are followed by Madhya Pradesh (M.P.) 11 per cent, Rajasthan 10 per cent, Bihar 6 per cent and Gujarat 3 per cent. All the rest contribute only 4 per cent. As expected, the major wheat growing states are all in the north.

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 14

Figure 1: Distribution of Wheat Production across States

Gujarat 3% Rest of India 4%

BBiihhaarr 66%% RRaajjaasstthhaann 1100%% UUPP 3366%% MMPP 1111%%

PPuunnjjaabb 1199%% Haryana 11%

Source: Based on data from India, Directorate of Economics and Statistics 2010 Another feature of wheat production is that the wheat yields vary substantially across the states, as shown above. Punjab and Haryana show the highest yields of 3853 and 3660 kg/ha, respectively. These are followed, after a significant gap, by Rajasthan, U.P. and Gujarat with 2500, 2498 and 2373 kg/ha respectively – which are close to the national average of 2583 kg/ha. Bihar and M.P. follow with much lower yields of 1999 and 1625 kg/ha, respectively. These yields can be compared with 2907 kg/ha in USA, 1907 kg/ha in Australia, 1029 kg/ha in Russia, 3667 kg/ha in China and 7603 kg/ha in France (FAO 1998). CROP CALENDER OF WHEAT IN INDIAN MAJOR WHEAR GROWING STATES

State Sowing Harvesting Assam Nov(B) - Dec(M) Mar(B)-Apr(E) Bihar Nov(M)-Dec(E) Mar(M)-Apr(E) Gujarat Oct(B)-Nov(E) Feb(B)-Mar(E) Haryana Oct(E)-Dec(B) Apr(M)-Apr(E) Himachal Pradesh Oct(B)-Nov(E) Apr(M)-Jun(E) Jammu & Kashmir Oct(B)-Dec(E) May(B)-May(E) Karnataka Oct(B)-Dec(E) Jan(B)-Feb(E) Madhya Pradesh Oct(M)-Dec(E) Feb(M)-Apr(E Maharashtra Oct(B)-Dec(E Feb(B)-Mar(E) Orissa Oct-Nov Mar-Apr Punjab Oct(B)-Nov(E) Apr(B)-May(E Rajasthan Nov(B)-Dec(E) Mar(B)-May(E) Uttar Pradesh Oct(B)-Jan(M) Apr(B)-Apr(M) West Bengal Nov(B)-Dec(E) Mar(B)-Apr(E All India Oct-Dec Feb-Jun

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 15

Procurement of Wheat will be made from Western and Northern parts of India through use of Commission agents and commission net work. With abundant availability through production and a well oiled distribution system, the procurement of the Raw Material does not pose any problem.

Simplified Outline of the Marketing System of Wheat in India

(D) Power & Fuel

Power requirement of the Roller Flour Mill plant is estimated at 500 KVA and is proposed to be obtained from the local Power grid. The Power received at 33 KV would be stepped down to 415 volts by means of transformer located in the main step-down sub-station (MSDS) and would be fed into the low tension switch board located in MSDS. One diesel-generating power set of 250 KVA rating at 430V, 50 Hz is proposed as a standby to meet the emergency power requirement of vital units of the plant requiring uninterrupted power supply in case of power cuts. The total cost of Power from APCPDCL is estimated at Rs 15.00 lakhs along with HT cabling, internal wiring, switches and internal lighting is estimated at Rs 16.74 lakhs.

(E) Water Requirements

The Flour mill Plant would require water for cleaning, washing of about 10,000 liters of water on a continuous basis. The unit has a 3” bore well along with storage tanks above the ground in the supply network to take care of the make up water requirement. In addition to the above around 1000 liters of water is required for human consumption and sanitation.

(F) Project Implementation Schedule:

The unit is proposing to complete the entire implementation of the project in 6 months time. The company has already purchased required land, completed all the legal formalities, identified and ordered equipment, and have completed finalizing commission agent network all over India to sell the entire production on a continuous basis.

Farmers - SOURCE

Primary Market Commission Agents

Whole Sellers

Processors / Flour Mills F C I Urban Whole Sellers

State Civil Supply Flour Mills Retail Shops

Fair Price Shops Consumers – END

CONSUMPTION

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 16

The project implementation is proposed to be as per the following chart.

• The project is proposed to be executed for commercial production by June 2011 • The company had already started construction of the factory • The machineries are being finalized. • Thus for the projected FY 2011 the results comprise of 6 months operation only.

ACTIVITY DEC JAN FEB 11 MAR 11 APRIL 11 MAY !! JUNE 11

YEAR Land Purchase

Land Development Civil Works Machinery Order Receipt of machinery Electrical works & Power Erection of machinery Trial Production Commercial Production

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 17

CAPEX & PROJECT FINANCIALS The total CAPEX, Means of finance & the projected repayment capabilities of the company are depicted below for having an understanding about the company’s potential for implementing the project and repayment of the loans.

Project Cost Rs lacs Loan % Loan (a) Land on lease (b) Land, Development Anex1 1.94 0.00% 0.00 (c ) Buildings and construction Anex 1 132.37 70.00% 92.64 (d) Plant, Machinery & Utilities Anex 2 309.29 75.00% 231.97 (e) Electricity Deposit 15.00 0.00% 0.00 (f) Power Connectivity / Cables / Pole's 10.00 75.00% 7.50 (g) Preop Exp) Anex 3 14.14 50.00% 7.07 (h) Office and other misc equipment Anex 4 2.00 75.00% 1.50 (i) Contingencies 3.00% 13.25 75.00% 9.94 (j) Working Capital Margin 25% 80.00 0.00% 0.00

Total Project Cost 578.00 350.62

Projected Performance/Financial Indicators:

S.No Particulars 2011-12 2012-13 2013-14 2014-15 2015-16 2016-17

1 Domestic Sales(Gross) 2992.75 4513.46 4917.32 5327.75 5738.19 5746.08 2 Export Sales 0.00 0.00 0.00 0.00 0.00 0.00 3 Net Sales 2992.75 4513.46 4917.32 5327.75 5738.19 5746.08

% rise/fall (-) in net sales 50.81 8.95 8.35 7.70 7.85

4 Operating Profit 184.92 294.65 324.60 354.74 388.79 387.24 5 Profit Before tax 124.38 219.40 259.15 299.09 342.94 349.96 6 PBT/ Sales (%) 4.16% 4.86% 5.27% 5.61% 5.98% 6.09% 7 Profit After Tax 90.70 154.32 179.81 205.89 235.03 238.68 8 Cash Accrual 137.39 201.01 226.50 252.58 281.73 285.37 9 Paid Up Capital 228.00 228.00 228.00 228.00 228.00 228.00

10 TNW 318.70 473.02 652.83 858.71 1093.74 1332.43 11 Adjusted TNW 304.56 458.88 638.69 844.57 1079.60 1318.29 12 TOL/TNW (times) 1.89 1.13 0.71 0.47 0.30 0.21 13 Adjusted TOL/TNW 1.97 1.16 0.73 0.47 0.31 0.21 14 NWC 110.75 241.75 398.26 580.84 1095.44 1095.44 15 Current Ratio 1.33 1.71 2.16 2.67 3.44 4.92

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 18

Other Ratios 2011-12 2012-13 2013-14 2014-15 2015-16 2016-17 1 Operating Cost/ sales % 6.18% 6.53% 6.60% 6.66% 6.78% 6.74% 2 Net Sales /TTA (times) 3.30 4.55 4.45 4.28 4.06 3.60 3 PBDIT 8.03 21.68 48.07 66.35 66.35 66.35

EFFICIENCY RATIOS As on 31st March Particulars 2011-12 2012-13 2013-14 2014-15 2015-16 2016-17

1 Net Sales/ Total Tangible ( times ) 3.30 4.55 4.45 4.28 4.06 3.60 2 PBT/ Total Tangible Assets (%) 13.73% 22.10% 23.45% 24.04% 24.29% 21.90% 3 Operating Cost to sales (%) 6.18% 6.53% 6.60% 6.66% 6.78% 6.74% 4 Bank Finance/ Ct. Assets (%) 53.39% 41.17% 32.33% 25.87% 17.45% 17.45% 5 Inventory+ Receivables to net 53 45 47 47 47 47 6 PBDIT 231.61 341.34 371.29 401.43 435.48 433.93

RISK RATING RELATED RATIOS S.No Particulars 2011-12 2012-13 2013-14 2014-15 2015-16 2016-17

1 Current Ratio 1.33 1.71 2.16 2.67 3.44 4.92 2 TOL/TNW (times) 1.89 1.13 0.71 0.47 0.30 0.21 3 PBDIT/Interest (times) 3.83 4.54 5.67 7.21 9.50 11.64 4 PAT/Net Sales (%) 3.03% 3.42% 3.66% 3.86% 4.10% 4.15% 5 ROCE (%) (PBDIT/TA) 25.18% 33.91% 33.17% 31.91% 30.54% 26.92% 6 INV+REC./Sales (days) 53 45 47 47 47 47

SECURITY MARGIN % S.No Particulars 2011-12 2012-13 2013-14 2014-15 2015-16 2016-17

1 Written Down Value 441.30 394.61 347.92 301.23 254.54 207.85 2 Loan Outstanding 332.50 262.50 192.50 122.50 52.50 0.00 3 Margin 108.80 132.11 155.42 178.73 202.04 207.85 4 Security Margin % 24.66% 33.48% 44.67% 59.33% 79.37% 100.00%

Movement of TNW

Particulars 2011 2012 2013 2014 2015 2015 Opening balance 0.00 304.56 458.88 638.69 844.58 1079.61 Add. i Profit/(-)Loss after Tax 90.70 154.32 179.81 205.89 235.03 238.68 ii Increase in Capital 228.00 iii Dec./(-) Inc.in Intangible Assets -14.14 iv Inc../(-) \ Dec.in Reserves 0.00 v. Increase in Quasi Equity 0.00 Less : Dividend 0.00

TNW 304.56 458.88 638.69 844.58 1079.61 1318.29

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 19

Credit Limits – Existing and Proposed

Assessment of WC facilities:

Particulars 2011-12 2012-13 2013-14 2014-15 2015-16 2016-17 Raw Material : a) Indigenous 71.92 73.02 79.66 86.30 92.94 92.94 Months 0.25 0.23 0.23 0.23 0.23 0.23 Stock in Process 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Finished Goods 76.37 77.27 84.17 91.08 97.98 98.03 Months 0.26 0.23 0.23 0.23 0.23 0.23 Other Spares : a) Indigenous 7.00 8.00 9.00 10.00 10.00 10.00 Months 12 13 13 13 12 12 Receivables : a) Domestic 277.11 403.67 455.31 493.31 531.31 532.04 Months 0.83 1.07 1.11 1.11 1.11 1.11 Receivables 277.11 403.67 455.31 493.31 531.31 532.04 Months 0.83 1.07 1.11 1.11 1.11 1.11 S. Creditors 28.77 31.21 34.05 36.89 39.72 39.72 Months 0.10 0.10 0.10 0.10 0.10 0.10 Other Creditors 70.00 70.00 70.00 70.00 52.50 0.00 Other Current Assets 17.12 21.00 114.17 247.03 410.05 642.15

Assessed Bank Finance:

Particulars 2011-12 2012-13 2013-14 2014-15 2015-16 2016-17

Total CA 449.52 582.96 742.31 927.72 1142.29 1375.16

Other CL 98.77 101.21 104.05 106.88 92.22 39.72

Working Capital Gap 350.75 481.75 638.26 820.84 1050.07 1335.44

Net Working Capital 110.75 241.75 398.26 580.84 810.07 1095.44

Assessed Bank Finance 240.00 240.00 240.00 240.00 240.00 240.00

NWC to TCA (%) 24.64% 41.47% 53.65% 62.61% 70.92% 79.66%

Bank Finance to TCA % 53.39% 41.17% 32.33% 25.87% 21.01% 17.45%

S. Cr. To TCA (%) 6.40% 5.35% 4.59% 3.98% 3.48% 2.89%

Other CL to TCA (%) 15.57% 12.01% 9.43% 7.55% 4.60% 0.00%

Inv. To Net sales (days) 14 13 13 13 13 13

Rec. to gross sales (days) 25 33 34 34 34 34

S. Cr. To purchases (days) 3 3 3 3 3 3

Credit Limits (Proposed): (Rs. in lacs) Limits State Bank of Hyderabad % Total Cons/

MBA CC 240.00 100% Nil TL 350.00 100% Nil Total FB Limits 590.00 100% Nil

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 20

Present Proposal with State Bank of Hyderabad

Facility Present Limit Proposed Limit CC limit (Hypothecation of Receivables) Nil Rs 240.00 Lacs Term Loan Nii Rs 350.00 Lacs Securities 40% collateral security apart from primary assets Repayment of Term loans.

• The Project implementation has commenced and is proposed to be completed for commercial production by June 2011.

• The term loan is thus proposed to be repayable in 5 years i.e 60 monthly installments along

with interest with a initial holiday of 12 months. i.e first 6 months for project implementation and the balance 6 months for stabilizing the cash flows.

PROJECTED OPERATIONAL RESULTS Detailed data on operational expenses and profits for the forthcoming 6 years of projected operations have been worked out and given in the statement annexed. While working out estimates, prices of inputs and selling prices of outputs have been kept at constant rates assuming that any increase in inputs cost would be effect by proportionate increase in the selling price. Marginal increase has been provided in other operational cost to cover effects of possible inflation. CASH GENERATION & REPAYMENT SCHEDULE Based on the estimates of cash generation from the operations and considerations the need to retain certain funds for meeting any other contingent situations, plans for repayment of the loan has been worked out and enclosed as annexes. By the end of the third year the company shall be self sufficient to meet the enhanced working capital limits /or /for expansion or diversification PROJECTED CASH FLOWS A projected cash flow statement of the company at the end of the projected 6 years of working has been drawn up and given in the statement enclosed. The pictures emerges from a glance of the date, spread for the 6 years i.e. Increasing levels of reserve accumulation and decreasing borrowings on the one hand and increasing levels of current assets on the other with comparatively very less amount blocked in fixed capital. The data also reveals a comparatively high ratio of equity to debt depicting a growing strong capital base of the unit over loan funds in the business.

Matrix Consulting_ 101, Durga apartments, Rajbhavan Road, Hyderabad 0 9989 040404 21

CONCLUDING REMARKS

From the foregoing detailed analysis of the proposal towards Term loan and working capital finance for Shri * Pvt Ltd it can be concluded that the Company has been extremely careful and selective in preparing its business program. It has drawn up the scheme after adequately studying Wheat and Wheal products market in india. The plans have been made in such a way that the salability of the market could be almost assured with least marketing cost. The firm has already made a committed commission agents network in place thus the sale is firmly committed.

TECHNO ECONOMICAL ASPECTS

The Group are well experienced in procuring Wheat and trading in Wheat based products for the last 5 years. The core founders are qualified and experienced persons and posses all required technical know-how in selling their products and commercial expertise to run the business of a day to day basis.. The founders would be on full time occupation with the company. A suitable and broad based marketing network is already available which could be taken expanded further if found necessary to achieve for proposed sales targets.

FINANCIAL ASPECTS

The Capital investment proposed is comparatively low and the founders have necessary resources to bring in and organize the proposed capital. The financial assistance sought from Bank is well within normal of lending. The projected operational results show reasonable profit generation by the unit to enable it to meet its debt servicing obligations. A considerable part of cash generation is also proposed to be ploughed back every year to supplement future working capital requirement. Thus the venture is a thoroughly well planned organization and is a sound and viable proposition.

SMEDA Flour Mill

Maize mill wheat flour mill hongdefa machinery tony 008618330112982

Wheat Flour Mill Business Plan Presentation

Dangote Flour Mill annual report 2011

China manufacturer maize mill wheat flour mill

Engineering

Flour Mill Manufacturer in India

Rathore & Company, New Delhi, Flour Mill

Indian Flour Mill Final (1)

The Need Of Using Flour Mill for Top Quality Flour

Dangote flour mill annual report 2015

Investor Relations

Flour mill design

production on kisaan flour mill, jammu

Sulluoglu flour mill catalogue

Roller Flour Mill (Atta, Maida & Suji) - Market Survey cum ... Flour Mill... · 2 Introduction Roller Flour mill serve the purpose of processing wheat to convert it into flour. The

Roller Flour Mill Project Report

Taflan Flour Mill Products Catalogue

Dangote flour mill annual report 2014

- About Us Company Profile Certification Honor Social Responsibility Foreign Public Welfare Staff Skill Improvement Blood Donation Teaching Assistants Donation To Elderly Donation Epidemic Donation Video Group Culture

- Products Wheat Flour Milling Plant Maize Flour Milling Plant Single Machine

- Exhibition 2024

- Competitiveness

Keywords: Muti-story Flour Milling Plant , Single Flour Milling Plant

- Company Profile

- Certification

- Foreign Public Welfare

- Staff Skill Improvement

- Blood Donation

- Teaching Assistants Donation

- To Elderly Donation

- Epidemic Donation

- Group Culture

Wheat Flour Milling Plant

Maize Flour Milling Plant

Single Machine

Flour Mill Business Plan with Costs

Although there are many flour mills in the market, the high demand for various types of flour makes it still profitable to start a flour business by establishing small and medium-sized flour mills.

Start Your Flour Mill Bussiness with PINGLE Now!

Many people are interested in starting a flour mill business. However, they have no idea about the detailed steps and expected costs of setting up a flour mill. And they are curious about how much money a flour mill, say on a small scale, can make in a year. Here, Pingle , a China leading flour mills manufacturer, provides the information you may need, such as a business plan for a wheat flour mill. If you are interested in starting your own wheat/atta flour mill business , or other grain flour business, like cassava flour milling, please contact us for FREE quotation on both small-scale or large-scale flour mill machinery.

Contact PINGLE for a professional maize milling business plan pdf

Types of flour milling operations

In general, there are two types of flour mills: small scale and large scale. The choice between small or large scale should be made with due consideration to your specific situation. Below we will analyze small flour mills and large flour mills for your consideration.

Small Business Flour Mills

First of all, small flour mill machinery requires little capital, but the profit margin is relatively small. It works well in two modes, one charging a certain amount of money for milling and the other for producing flour. Therefore, the small flour mill business is very flexible and you can adjust the production according to the market demand. Also the whole operation is relatively easy and simple and can be used by almost all adults.

Start Your Flour Mills From Small Business Now!

Through advanced mill technology and highly automatic mill solutions, we can reduce production costs and ensure you obtain higher profits in the production and operation process.

Innovate flour mill technology, through the development and upgrade of key equipment such as electric or hammer mills, equipped with precise processing control to ensure stable flour quality and meet different flour technology standards.

Committed to sustainable development, our flour machinery adopts environmentally friendly designs to minimize energy consumption, help you achieve sustainable production, and save electricity to the greatest extent.

Success stories speak for themselves, we have provided innovative flour solutions to numerous customers around the world, bringing a reliable reference to your business. Here are some of our construction cases

To improve production efficiency, our equipment can meet the needs of small, medium and large flour mills. Especially in African markets such as Uganda and Kenya, these small flour machinery are very popular. At the same time, the intelligent and automated functions of flour machinery will greatly improve your production speed and efficiency.

Choose a reliable partner. We are a leading company in the field of flour processing, winning the trust of our customers with our excellent R&D capabilities and service levels.

Large Flour Mills

Due to the complex flour making process and advanced flour making machinery, a large investment in a large flour mill project is inevitable. However, due to the high demand for wheat flour around the world, especially in some regions such as India, Egypt, Algeria, Italy, Brazil, etc., the profits are substantial in most cases. Large flour mills allow for automated and continuous flour production, from raw material to packaged flour.

PINGLE Flour Mills Project

Cost of setting up a flour mill

The cost of a flour mill varies greatly due to different production capacities. If you are setting up a small mill flour mill, the cost will be much cheaper than a medium or large flour mill. Setting up a flour mill can require a lot of capital, so if you don't have enough money but don't want to miss out on a profitable endeavor, you can seek help from a bank loan or just find a reliable partner flour milling business who is passionate about flour mills.

Typically, mini flour mills cost $2,500 to $3,000. small flour mill plants will cost $3,500 to $5,000. However, for large flour mills, the cost is certainly high. For example, a large flour mill with automatic wheat mill machinery may cost $19,000 to $1,448,000. However, this price is for reference only and the cost of a specific flour mill will depend on the specific conditions and equipment selection!

Custom Flour Mill Business Plan

How do I start a flour mill? The following will talk about the basic factors that should be considered when deciding to get started.

1. Getting financial support

Any business needs financial support before it can start. How much does it cost to buy a flour mill ? Will you need a loan or just put all your money into this business. For estimating the amount, it is better to have a better understanding of the local market as well as the global market where the flour mill business is profitable.

2. Obtaining a flour milling license

Getting a license from the government or registering your plant with the local government is also important for the success of your flour milling business. Ensuring that every policy and flour production process complies with local rules and regulations is an essential requirement for a flour mill.

3. Finding the right plant location

The right plant location is very important for a flour milling business. The right plant location should have easy access to raw materials and the delivery and transportation of final packaged flour. Once the location is determined, it's time to get out of the flour milling plant's coverage area. In general, a complete flour mill plant layout should include an area for storing raw materials, an area for the flour milling machine, and an area for the flour packing area.

4. Buying a flour mill

When the above conditions are in place, it is time to consider how and where to obtain flour machinery. The selection of a flour mill is closely related to capacity, investment cost, flour making process, raw materials, etc. Therefore, it cannot be done overnight. Therefore, it cannot be done overnight. Time needs to be taken to select the most reliable flour machinery supplier, which helps avoid many unexpected problems in flour mill installation and operation and reduces machinery purchase costs.

5. Operator training and safety education

For most flour mills, flour production should have several operators or workers . Systematic training and safety education for workers and operators is one of the most important elements to start the operation of a flour mill. They must not only be proficient with the equipment and machinery, but also know how to add flour ingredients. Most suppliers of four-mill machinery offer training programs and courses to their customers to help them get into the flour industry quickly and avoid many typical operating mistakes.

6. Flour milling business marketing strategy development

How to get the final produced flour directly to the customer is also a difficult task for the flour mill investor. If the local flour market is not very competitive, then don't worry, the final flour product will sell very well. Some markets such as Nigeria, India, Pakistan, Uganda, Chile, Australia, Algeria, Ethiopia, etc. are very popular to start a flour milling business due to high demand and low competition.

7. Supply chain management:

Develop a robust supply chain management strategy to ensure a stable and reliable supply of corn raw materials. Build relationships with trusted suppliers and explore options for sourcing corn locally to minimize transportation costs and shorten delivery times.

8. Product Diversification:

Consider diversifying your products beyond basic cornmeal to cater to different market segments and consumer preferences. Explore opportunities to produce value-added corn products such as fortified flours, cornmeal blends or specialty flours to expand your market reach and revenue streams. Pingle's equipment can help you produce different types of powder.

9. Sustainable Practices:

Employ sustainable practices in corn milling operations to minimize environmental impact and promote long-term sustainability. Explore options for energy efficiency, waste reduction and water conservation to align your business with environmental stewardship principles and meet the growing demand for sustainable products. Pinle can help you upgrade and maintain your machinery and equipment, create the most efficient production equipment, and reduce waste during grinding.

When you are planning to start a flour mill business by setting up a flour mill, you can refer to the above tips and steps for a complete and viable flour business plan. Pingle can provide customized flour mill business plans to start a flour mill business easily. If you still have a lot of confusion, please contact us for more detailed information, we have built many flour mill projects around the world. We are sure that some of our experience is just what you are looking for!

Pingle's flour machines for business have gained popularity in various countries like Zambia, India, Uganda, Kenya, and Nigeria. We offer comprehensive services, including on-site installation, commissioning, and after-sales support. Whether you're starting a maize mill business or expanding an existing one, our maize milling business plan pdf provides valuable guidance. Contact us today to kickstart your flour mill project and benefit from our expertise and assistance.

VIEW MORE PINGLE Provided Flour Mill Business Plan Project

VIEW MORE PINGLE Flour Mill Plant

VIEW MORE PINGLE Flour Mill SERVICE

- Flour Milling Machine

- Maize Flour Milling Machine

- Wheat Flour Milling Machine

How to Start a Flour Mill Business – Complete Guide

A flour mill is an easy business to start. You can start this business in both city and rural areas. Furthermore, a flour mill offers a wide range of manufacturing opportunities for entrepreneurs.

Table of Contents

What is a Flour Mill Business?

A flour mill business involves the processing of wheat and other grains to produce flour, a fundamental ingredient in various food products. The primary objective of a flour mill is to transform raw wheat kernels into flour through milling processes.

How a Flour Mill Works

Here are key aspects of a flour mill business:

Raw Material Processing

Flour mills source raw materials, mainly wheat, from agricultural regions. The quality of wheat is crucial for producing high-quality flour. The Milling Process starts with the cleaning and conditioning of Raw wheat. It undergoes cleaning to remove impurities and conditioning to optimize moisture content.

Milling Machines

The cleaned wheat is then milled using specialized machinery to separate the bran, germ, and endosperm. This process results in different types of flour, including whole wheat flour and refined flour. Flour mills implement quality control measures by conducting laboratory tests on the flour produced. This includes assessments of protein content, moisture levels, and other factors.

Packaging and Distribution

Packaging: The processed flour is packaged in various quantities, from small consumer packages to bulk packaging for industrial clients. Flour mills distribute their products through various channels, including wholesalers, retailers, and, in some cases, directly to consumers.

Market Segmentation

Flour mills may produce different varieties of flour, such as all-purpose flour, whole wheat flour, speciality flour, and even organic or gluten-free options. It caters to diverse markets, including households, bakeries, food manufacturers, and industrial users.

Regulatory Compliance

Flour mills must comply with local and national regulations related to food safety and quality. This involves obtaining the necessary licenses and certifications. Maintaining high hygiene standards throughout the milling process is essential for regulatory compliance.

Technological Innovation

Flour mills often invest in advanced milling machinery to improve efficiency and product quality. Some mills incorporate automation to streamline processes and reduce labour requirements.

Business Models

Flour mills may adopt various business models, such as traditional milling, speciality flour production, organic flour milling, or industrial-scale milling.

Market Trends

Adaptation: Flour mills monitor market trends and adapt their processes to meet changing consumer preferences. This may include producing gluten-free products or emphasizing sustainable and organic practices.

Supply Chain Management

Flour mills establish reliable supply chains for wheat, often collaborating with farmers or agricultural cooperatives. Efficient logistics are crucial for timely sourcing of raw materials and distribution of finished products.

Is the Flour Business Profitable

Flour remains a staple in various food products, contributing to consistent consumer demand. Data from market research indicates sustained consumer interest in home baking and cooking, driving flour consumption. According to a report by Statista, the global flour market was valued at approximately $245 billion in 2020. The market is projected to witness a compound annual growth rate (CAGR) of around 3.7% from 2021 to 2028.

15 Steps to Start a Flour Mill Business

Starting a flour mill business can be a rewarding venture, providing a staple product that is in constant demand. Here’s a step-by-step guide to help you navigate the process of establishing a successful flour milling business:

1. Conduct Market Research

Identify the target market by determining the demand for flour in your target market. Consider factors such as population size, dietary habits, and the presence of competitors.

2. Select your Niche

Below we list down the Most Profitable Flour Mill Business Ideas:

- Bran: The bran is the skin of the grains. Also, bran is used as a dietary fibre.

- Cornflour: Cornflour is an essential item in the food processing industry. Corn milling or maize milling is a highly profitable business. However, you must establish the mill in a location where you can source the corn easily.

- Gram Flour: The most common name for gram flour is besan. And the product has a great demand in our country.

- Sooji: Sooji is another trendy grocery item in our country. You can produce sooji from the same manufacturing unit.

- Wheat Flour (Atta): Atta is one of the most essential items for the domestic kitchen.

- Wheat Flour (Maida): Maida has comparatively more demand than atta.

3. Select the Business Model

The business models of flour mills can vary based on factors such as scale, target market, and value proposition. Here are several common business models adopted by flour mills:

⇒ Traditional Flour Milling Model

Traditional flour mills follow a conventional model of sourcing wheat, milling it into flour, and distributing the product to local markets.

⇒ Specialty Flour Milling Model

Speciality flour mills focus on producing unique and high-quality flours tailored to specific consumer preferences or dietary requirements.

⇒ Organic Flour Milling Model

Organic flour mills exclusively source and process organic wheat, catering to the growing demand for organic and sustainable food products.

⇒ Industrial Flour Milling Model

Industrial flour mills operate on a large scale, producing massive quantities of flour for commercial and industrial use.

⇒ Vertical Integration Model

Flour mills employing vertical integration control various stages of the supply chain, from wheat cultivation to retail distribution.

⇒ Direct-to-Consumer Model

Flour mills adopting a direct-to-consumer model sell their products directly to end consumers through online platforms, farmer’s markets, or on-site stores.

⇒ Contract Milling Model

Contract milling involves milling wheat on behalf of other businesses, allowing them to focus on their core activities.

⇒ Export-Oriented Model

Flour mills following this model focus on exporting their products to international markets, capitalizing on global demand.

⇒ Cooperative Flour Milling Model

Cooperative flour mills are owned and operated by a group of farmers or community members who share in the management and profits.

Read: Home Based Manufacturing Business Ideas

4. Create a Business Plan

Clearly outline your business goals, including the scale of production, target market, and financial projections. Conduct a thorough cost analysis covering equipment, raw materials, labour, and operational expenses.

5. Choose a Suitable Location

Select a location close to wheat-producing regions to minimize transportation costs. Ensure access to essential infrastructure, including water and electricity.

6. Obtain Necessary Licenses and Permits:

You need to understand and comply with local and national regulations governing flour milling. Obtain the necessary licenses and permits required to operate a flour mill.

Here we put a list of basic requirements.

- First of all, determine the form of the organization and register your business with ROC.

- Apply for the Trade License from the local municipal authority.

- Furthermore, apply for Udyog Aadhaar MSME Online Registration

- Apply for FSSAI registration.

- You have to apply for AGMARK .

- Apply for BIS certification

- Check the tax liabilities.

- This business doesn’t demand any pollution clearance. However, check it with the State Pollution Control Board of your area.

- Apply for the GST registration number.

7. Secure Funding

Determine the initial investment required for land, equipment, and working capital. Consider loans, grants, or partnerships to secure the necessary funds.

8. Flour Mill Business Plant Setup & Machinery

First of all, you have to secure a location for manufacturing operations. Check the available transportation facility, electricity, water, semi-skilled manpower, and drainage facility. For setting up a small-scale unit with the entire product range, you will need to have 3000 Sq Ft built-up areas at least.

Related: Things To Consider in Selecting Factory Location

Here are some basic requirements for plant & machinery:

- Bucket elevator

- Reel machine (3 segments)

- Rotary separator with aspiration channel

- Scourer machine with aspiration channel

- Intensive dampener

- Indent cylinder

- Screw conveyor

- V-Groove, Pulleys, Couplings, V-Belts, etc

- Weighing scale

- Dust cyclone

- L.P fan for cleaning

- Roller Mill body

- Roll Grooving & spindle cutting

- Supper cyclone

9. Set Up the Milling Unit

Design an efficient layout for the milling unit, considering workflow and safety. Set up and install the milling equipment, ensuring proper calibration and maintenance.

10. Quality Control Measures

Implement regular testing procedures to ensure the quality of the flour produced. Adhere to strict hygiene standards in the milling process to meet regulatory requirements.

11. Employ Skilled Workforce

Hire experienced millers for operating machinery, quality control, and overall production management. Conduct training programs to enhance the skills of your workforce.

12. Develop Distribution Channels

Build relationships with distributors, wholesalers, and retailers for efficient distribution. Consider export options to expand your market reach.

13. Implement Marketing Strategies

Develop a strong brand identity for your flour. Highlight any unique qualities or milling processes. Utilize online platforms to create awareness and reach a wider audience.

14. Monitor Wheat Market Trends

Keep abreast of wheat market trends, including price fluctuations and supply-demand dynamics. Implement strategies to manage risks associated with market volatility.

15. Build Relationships with Suppliers

Negotiate favourable contracts with wheat suppliers to ensure a steady and cost-effective supply. Work closely with suppliers to maintain consistent quality standards.

Related: Questions To Ask Before Starting a Manufacturing Business

Frequently Asked Questions

What is the cost of setting up a flour mill.

The flour milling business generally demands two different types of investments. One is a fixed capital investment. It includes land (if you purchase the land), building, machinery, registration, and licensing fees. If you start the business with a rental premise then fixed capital includes the security deposit amount for the area of land.

Another is the working capital investment. It includes raw materials, staffing, rent, transportation, marketing, distribution, and administration costs. There are different types of small business loan-providing companies in our country. Loan providers also offer various customized schemes for your specific requirements.

Related: Best Small Business Loans in India

4. What is the profit margin of flour mills?

You can earn an inspiring profit margin from a flour milling business. However, the percentage of profit depends on several aspects. To enhance the profit, you will need to reduce the production cost.

Also, you must consider enhancing the sales volume and penetrating new areas. Remember, you will only expect a good profit when you sell the product as a brand.

What Types of Flour Can Be Produced by a Flour Mill?

Flour mills can produce various types of flour, including all-purpose flour, whole wheat flour, speciality flour (such as gluten-free or organic), and customized blends based on consumer preferences.

What are the Key Factors Influencing Flour Business Profitability?

Key factors include market demand, product diversification, operational efficiency, raw material costs, and adherence to quality and safety standards.

What are the Market Trends in the Flour Industry?

Market trends include increased demand for speciality and organic flour, the rise of e-commerce and direct-to-consumer sales, and a focus on healthier flour options.

Can Flour Mills Export Their Products?

Yes, flour mills often explore export opportunities. Understanding international trade regulations, market demand, and quality standards is essential for successful exports.

What Certifications are Important for Flour Mills?

Answer: Certifications such as ISO 9001 (Quality Management), ISO 22000 (Food Safety Management), and relevant organic certifications contribute to ensuring quality and compliance with industry standards.

What Challenges Might Flour Mill Businesses Face?

Challenges can include fluctuating raw material costs, market competition, regulatory changes, and the need for ongoing investments in technology and quality control.

Next What Business Research Team

The Editorial Staff at NextWhatBusiness is a team of Business Consultants having years of experience in small and medium-scale businesses.

Flour Mill Business Plan: Key Cost Factors You Need to Consider

Although there are many flour milling plants in the market, but the high demand for various flours makes it still profitable to start flour milling business through setting up small scale or medium scale flour mill factory.

Many people are interested in starting flour mill business. However, they have no ideas about the detailed steps and perspective cost of flour mill factory setup. And they are also curious about how much money can a flour mill, like a small scale, make per year . Here, ABC Machinery offers the information you may be needed, like wheat flour mill business plan. (You may also like: Flour Mill Plant Cost >>)

Flour Milling Business Types

Generally, flour milling business has two types small scale or large scale. Choosing small scale or large scale should fully take your specific conditions into consideration. Here we will analyze the small scale flour mill and large scale flour mill plant for your consideration.

Flour Mill Machine for Small Business

Firstly, the small scale flour mill machinery requires small amount of money, but the profit margin is relatively small. It works greatly in two models, one is to charge a certain amount for milling grains, the other is to produce flour mill. So, small scale flour mill business is flexible, you can adjust your production based on the market needs. In addition, the whole operations are relatively easy and simple, so almost all the adult can use it.

Large Scale Flour Mill Plant

It is inevitable that large scale flour mill project requires heavy investment since the complicated flour milling process and advanced flour milling machinery. However, the profits are decent in most cases since there are large demand of wheat flour around the world, especially in some regions, such as India, Egypt, Algeria, Italy, Brazil, etc. Large scale flour mill plant can achieve automatic and continuous flour production, from raw materials to packaged flour.

Cost of Setting up Flour Mill Factory

The cost for a flour mill factory varies a lot due to the different production capacity. If you are going to set up a small scale factory flour mill, the cost will be a much cheaper than medium scale or large scale flour mill plant. Setting up flour mill plant may require large amount, so if you doesn’t have enough money but won’t want miss the profitable endeavors, you can search helps of bank loans or just to find out a reliable partner who is also enthusiastic about the flour milling business.

Typically, the F6FC mini flour mill machine will cost $2,500 ~ $3,000 . The M6FX mini flour mill factory will cost $3,500 ~ $5,000 . However, for the large scale flour mill factory, the cost definitely high. For example, the large scale flour mill plant equiped with automatic wheat mill machinery may cost $19,000 ~ $1,448,000 . But, this price is just for a references, the exact cos of the flour mill factory plant should based on the exact conditions and equipment selections!

M6FX Mini Flour Mill Machine Working Video

If you are interested in starting your own wheat/atta flour mill business, or other grain flour business, like cassava flour milling, please contact us for FREE quotation on both small scale or large scale flour mill machinery.

Custom-made Flour Mill Business Plan

- Get Financial Support

Any business will need financial support before starting. How much money is required to have the flour milling machine ? Is it needed to take out loans or just put all your money into this business. For the estimate amount, it is better to have a better understanding about local market as well as global market of profit in flour mill business. (Read more: Get the Policy Loan for Your Business >>)

- Find Right Factory Location

A right factory location is very important for the flour milling business. The right factory location should have convenient transportation that is easily for the access of raw materials and delivery and shipping of final packed flour. After the location is decided, it it time to get out the covering area of the flour processing plant . In general, a complete flour mill plant layout should include the area for storage of raw materials , area for flour milling machines , area for flour packaging .

- Get Licence for Flour Milling

Getting the licence from the government or registering your factory in local administration is also important for the success of the flour milling business . It is the basic requirements for a flour milling factory to ensure every policy and flour production process are compliant with the local regulation and legislation.

- Purchase Flour Milling Machine

When above mentioned conditions are ready, it is time to think about how and where to get the flour milling machinery . The selection of flour milling machines are closely connected with the capacity, the investment cost, the flour milling process, the raw materials and more . Therefore, it can’t be done overnight. It needs to take time to choose the most reliable flour milling machinery supplier, which can help to avoid many unexpected problems in the installation and operation of the flour milling factory and lower the cost of machinery purchases. (Read more: Wheat Flour Machine Suppliers >>)

- Operator Training and Safety Education

For most flour mill factory, there should be have several operators or workers for flour production . The systematic training and safety education for the workers and operators are very important one the flour mill factory starts running . They not only should to have a good command of the equipment and machinery, but also need to know how to flour ingredients additions. Most four mill machinery supplier will offer the training plan and course for their customers to help them quickly enters the flour industry and avoid many typical operational mistakes.

- Make Marketing Strategy for flour Milling Business