Top 20 Production Worker Resume Objective Examples You Can Apply

If you are seeking to work as a production worker and are making a resume or CV to present to employers, the objective statement must be carefully crafted to get the recruiter’s attention and gain an interview.

This post will help you learn how to make a winning production worker objective for resume so your application can stand a better chance of success.

How to Write a Great Resume Objective for a Production Worker Position

Your production worker career objective will be effective if it presents what the recruiter needs for the position.

Recruiters generally publish the job description and requirements for the vacant production worker role to help interested persons for the job to know if they qualified for it or not.

If you have studied the job description and requirements and find yourself capable and qualified for the production worker job, you can then proceed to creating a really good objective statement by emphasizing you having major qualities, abilities, knowledge, and/or experience required for the position.

When an employer reads an objective statement in a resume that shows the owner has what is needed to effectively perform in the position, they are immediately interested in the person.

Therefore, you can be sure that the recruiter will find your resume for the production worker job attractive if it shows that you are competent to perform in the role and have what is required to produce exceptional performance on the job.

You will need some good examples of resume objectives for various production worker positions to help you learn how to make one for your resume or CV fast, so here they are:

Best 20 Production Worker Resume Objective Statements You Can Use

1. Experienced individual proficient in Mathematics and with GED. Interested in the position of Production Worker, to apply experience working with lathe and CNC equipment, as well as to apply strong assembling experience.

2. Highly motivated team player with eye for detail and a strong sense of urgency. Seeking for the position of Production Worker at ABC Technicals; coming with outstanding ability to do repetitive tasks and work outdoors and around moving mechanical equipment.

3. Team player with culinary expertise and ability to prepare high quality food following instructions. To obtain the position of Food Production Worker; bringing 2 years experience in preparing high volume foods in a fast-paced environment.

4. Meticulously detailed GED graduate with strong communication skill. Looking for employment as a Production Worker at XYZ Foods; to apply eyes for details in inspecting packaging materials for uniformity, and to complete packaging materials according to specification.

5. Energetic individual with High School Diploma and 1 year experience in a production setting, hopeful for the position of Production Helper in a fast-paced production setting where strong ability to stand for long hours and willing to work on any shift will be utilized.

6. Individual with physical dexterity, able to perform manual tasks for long periods. Looking to obtain the position of Industrial Production Worker at CBC, bringing strong computer skills, as well as expertise in operating hand and power tools.

7. Energetic individual highly skilled in the operation of robotics and a variety of production machines and tools used to coil, flatten, and attach fittings to parts specifications. Looking to obtain the position of Production Machine Operator at XYZ Resources to utilize machine skills in completing finished goods.

8. Forklift certified team player with strong understanding of process flow of documents, materials, and parts through the repair or manufacturing process and GED. Interested in a Production Worker position at CBC.

9. Talented individual with demonstrated track record of reliability and strong work ethic, seeking for the position of Conventional Machinist at CBC Inc. where strong ability to read and interpret blue prints and drawings, operate manual engine lathes, milling, and boring machines will be applied.

10. Service-oriented individual with keen eyes for detail and possessing GED desires to work in the position of Production Worker at XYZ Woods Inc.; coming with basic math skills and exceptional ability to read tape measure.

11. Individual with drive for result and a positive attitude. Looking to obtain a Production Worker position at MVA Company; bringing strong ability to record accurate, timely data on computer-based systems or manual logs, and 1 year production assembly work experience.

12. Highly flexible and experienced individual skilled in using hand and power tools, and able to follow standard work instructions. Seeking a Production Worker position to apply detail-orientation to support assembling processes with accuracy and efficiency.

13. To obtain a Production Worker position in a high volume and fast- paced organization, to utilize skills in operating manufacturing processing equipment and machines; adhering to all safety policies and procedures.

14. Energetic individual proficient in working with manufacturing equipment with profound ability to perform repeated tasks with accuracy. Interested in a Production Worker role at CBC Industries where 5 years of industrial experience and in-depth knowledge of safety measures and procedures will be utilized.

15. Exceptionally talented and skillful individual with ability to work in a team as well as in a fast paced work environment. Looking to obtain a Production Worker position at ABC Inc., bringing 5 years experience setting-up and operating processing and packaging machines in addition to exceptional skill in operating various power tools.

16. Certified safety professional with High School Diploma seeking the position of Production Worker at ABC Company, to apply high energy level, attention to detail, and outstanding ability to operate power tools and forklift in achieving departmental goals.

17. Individual with strong organizational ability and energy who is able to function excellently in a team as well as independently. Seeking employment at XYZ Inc. as a Production Worker. Also coming with computer and documentation skills, as well as strong knowledge of working with press crew.

18. Experienced individual with strong multi-tasking ability and High School Diploma. Interested in a Production Worker position at Mazi Tolls Inc. where basic math skills and experience running machines, reading factory orders, tape measures, gauges, and other test equipment will be maximally put to use.

19. Hopeful for a Production Worker position in a fast-paced environment, coming with basic math skills, computing skills, and basic mechanical knowledge to foster production processes. Also bringing 3 years experience in the corrugated industry.

20. Exceptionally creative baker with demonstrated ability to read, understand, and follow specifications seeks the job of a Production Worker at Mount Bakery, to utilize expertise in baking delicious pastries and cakes.

If you are writing a resume or CV for the position of a production worker, you need to make the objective statement very compelling to immediately attract the employer’s attention to read the rest of the resume.

Your chances of getting an interview from the recruiter will be enhanced if your career objective statement presents you as well suited for the production worker position that you are seeking.

This post will guide you to be able to make an effective resume objective statement for a production worker position.

Related Posts

This Site Uses Cookies

Privacy overview.

- Resume Builder

- Resume Templates

- Resume Formats

- Resume Examples

- Cover Letter Builder

- Cover Letter Templates

- Cover Letter Formats

- Cover Letter Examples

- Career Advice

- Interview Questions

- Resume Skills

- Resume Objectives

- Job Description

- Job Responsibilities

- FAQ’s

Production Worker Resume Examples

Are you looking for a job in production and wondering how to write a resume that stands out from the competition? Writing a great production worker resume can be challenging, as employers often have to sort through hundreds of resumes for each job opening. To help you craft a resume that stands out, this guide will provide tips on how to write a production worker resume, as well as provide a few examples. With the tips in this guide, you can create an impressive production worker resume that highlights your skills and experience.

If you didn’t find what you were looking for, be sure to check out our complete library of resume examples .

Start building your dream career today!

Create your professional resume in just 5 minutes with our easy-to-use resume builder!

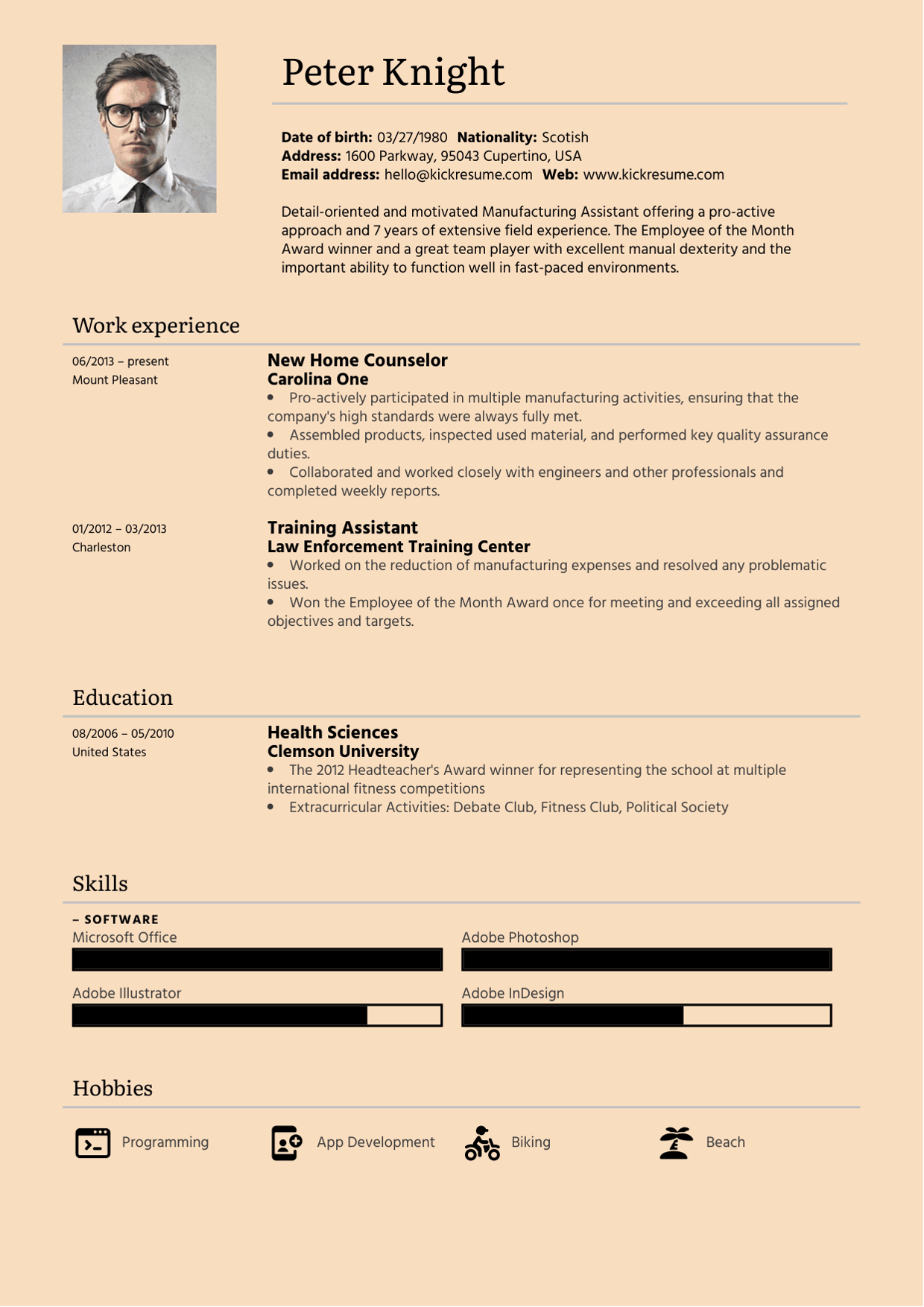

Production Worker

123 Main Street | Anytown, USA 99999 | Phone: (123) 456-7890 | Email: [email protected]

Highly motivated and flexible production worker with 4+ years of experience in manufacturing and assembly line work. Solid track record of thorough and accurate work performance. Skilled in operating machinery and tools, working as part of a team, and adhering to production goals. Proven ability to quickly learn new processes and procedures. Focused on producing quality products and providing excellent customer service.

Core Skills :

- Machine operation

- Problem solving

- Quality assurance

- Attention to detail

- Time management

Professional Experience : Production Worker | ABC Manufacturing | 2017 – Present

- Assemble and package products according to instructions

- Operate machinery and tools in accordance with safety procedures

- Monitor production line to ensure quality and efficiency

- Pack products in boxes and wrap with protective material

- Communicate with other staff members to maintain a steady workflow

Production Assistant | XYZ Manufacturing | 2015 – 2017

- Assisted in the production of automotive parts

- Performed quality control checks on all products

- Monitored and maintained inventory levels

- Worked with other production workers to meet production goals

- Provided support to supervisors and other staff members

Education : High School Diploma | Any High School | 2014 – 2015

Create My Resume

Build a professional resume in just minutes for free.

Production Worker Resume with No Experience

Recent graduate with no experience looking to make a career as a Production Worker. Reliable, hardworking, and possess excellent problem- solving skills. Proficient in computers and eager to learn new technologies.

- Excellent problem- solving skills

- Ability to work in a fast- paced environment

- Quick learner

- Proficient in computer software

- Strong organizational skills

- Great communicator

Responsibilities

- Assemble products in a timely manner

- Operate and maintain production machinery

- Follow safety procedures and company policies

- Monitor production process and make appropriate adjustments

- Keep the work area clean and organized

- Report any issues to the supervisor

- Assist with the training of new team members

Experience 0 Years

Level Junior

Education Bachelor’s

Production Worker Resume with 2 Years of Experience

Hardworking and dedicated production worker with more than 2 years of experience in a manufacturing setting. Experienced in all aspects of production, from operating and maintaining basic machinery to packaging and shipping finished products. Skilled in adhering to safety protocols and ensuring production procedures are followed. Possesses excellent communication, problem- solving and organizational skills.

- High- speed production experience

- Quality assurance & control

- Processing and packaging experience

- Assembly line operations

- Maintenance and repair

- Safety protocols

- Organizational skills

Responsibilities :

- Performing duties on the assembly line with speed and accuracy

- Inspecting finished products for quality assurance

- Checking for any defects and rectifying them before reaching the customer

- Ensuring production is done in a safe and efficient manner

- Repairing and maintaining assembly line machinery

- Carrying out installation and set up of new machinery

- Operating and monitoring production machinery

- Packaging and labeling finished goods according to instructions

- Maintaining a clean and orderly production area

Experience 2+ Years

Production Worker Resume with 5 Years of Experience

Diligent Production Worker with 5 years of experience in an industrial setting. Experienced in coordinating with management, maintaining production standards, and working collaboratively with other members of the production team. Proven track record of adhering to safety protocols, optimizing efficiency, and delivering high- quality products.

- Production Line Assembly

- Quality Assurance

- Machine Operation

- Continuous Improvement

- Inventory Management

- Safety Protocols

- Time Management

- Troubleshooting

- Assembled product on a production line using proper assembly techniques.

- Ensured product quality by conducting inspections and tests, and following quality assurance procedures.

- Operated a variety of machines such as drills, presses and saws to complete assembly processes.

- Monitored production efficiency and identified opportunities for continuous improvement in processes.

- Managed inventory of production materials and supplies and maintained accurate records.

- Adhered to safety protocols and enforced company policies and guidelines at all times.

- Managed time efficiently and maintained a high standard of work during every shift.

- Troubleshot issues on the production line and offered solutions to minimize any downtime.

Experience 5+ Years

Level Senior

Production Worker Resume with 7 Years of Experience

Hardworking and reliable Production Worker with 7 years of experience in operating production line machinery, assembling products and operating forklifts. Proven ability to work in a fast- paced environment and meet production deadlines. Skilled in troubleshooting and problem solving. Looking for a permanent position in a production or manufacturing company.

- Excellent work ethic

- Problem solving skills

- Physical strength

- Production line machinery operation

- Forklift operation

- Operating production line machinery and completing production processes

- Assembling products according to process instructions

- Loading raw materials and unloading finished products

- Performing routine maintenance and troubleshooting on production line equipment

- Identifying quality issues and notifying supervisor

- Operating forklifts to load and unload materials

- Maintaining a clean and organized workspace

Experience 7+ Years

Production Worker Resume with 10 Years of Experience

Highly motivated and experienced Production Worker with 10 years of experience in the manufacturing field. A self- starter with excellent organizational and problem- solving skills, able to work independently or as part of a team in fast- paced environments. Demonstrated success in achieving production goals, meeting tight deadlines, and ensuring quality control standards.

- Knowledge of manufacturing processes

- Ability to work independently and as part of a team

- Experience with quality control standards

- Operating machines and equipment to produce components according to company specifications

- Performing regular maintenance and safety checks on machines and equipment

- Inspecting components for defects and ensuring quality control

- Tracking production output and maintaining accurate records

- Troubleshooting any problems that arise during production

- Maintaining a clean and safe working environment

- Collaborating with supervisors, managers, and other personnel to ensure production goals are met

- Performing other duties as assigned.

Experience 10+ Years

Level Senior Manager

Education Master’s

Production Worker Resume with 15 Years of Experience

Highly experienced Production Worker with over 15 years of extensive experience in the manufacturing and industrial industries. Extensive knowledge of production practices, warehouse operations, and quality control. A tireless worker who effectively performs tasks in a timely and efficient manner. Proven ability to work with a wide variety of production machinery, tools, and equipment. Possesses excellent communication and problem- solving skillsand can quickly adapt to new and changing environments.

- Production and Manufacturing Processes

- Quality Control

- Warehouse Operations

- Equipment Maintenance

- Safety Practices

- Problem- solving

- Interpersonal Communication

- Operated production machines and equipment to ensure accurate and efficient output according to specifications.

- Monitored and inspected production processes to ensure they are completed in accordance with established standards and regulations.

- Performed regular maintenance and repairs on production machines and equipment.

- Ensured that all safety protocols and practices were followed.

- Assisted in the loading, unloading, and storing of production materials and products.

- Coordinated with other production workers to share information, discuss progress, and ensure deadlines are met.

- Inspected finished products for quality and accuracy.

- Maintained accurate and up- to- date records of production processes and materials used.

Experience 15+ Years

Level Director

In addition to this, be sure to check out our resume templates , resume formats , cover letter examples , job description , and career advice pages for more helpful tips and advice.

What should be included in a Production Worker resume?

A Production Worker resume should include the following:

- Professional Summary: A brief overview of your qualifications and experience as a Production Worker.

- Education: Include any relevant degrees, certifications, and/or diploma programs you have completed.

- Work Experience: List any previous jobs as a Production Worker, including the total number of years of experience and any specific tasks or duties that you have held.

- Skills: List any skills that are relevant to the position, such as machine operation and maintenance, problem-solving, and team collaboration.

- Other: Any additional qualifications or experience not related to the position, such as additional languages, technical certifications, or volunteer experience.

What is a good summary for a Production Worker resume?

A production worker resume should include a short but informative summary that highlights the candidate’s qualifications and experience. The summary should be tailored to the specific role and emphasize any production experience and skills directly related to the position. It should also reflect the candidate’s ability to work in a team environment, flexibility, and attention to detail. By including the most important qualifications, employers can quickly determine if the candidate is a good fit for the position.

The summary should be concise and include the candidate’s most relevant qualifications. For example, a production worker seeking a job in a manufacturing plant might include: “Experienced production worker with 5+ years of experience handling assembly line operations in a fast-paced environment. Skilled in troubleshooting processes, meeting tight deadlines, and working as part of a team.”

This summary gives a potential employer a snapshot of the candidate’s experience and qualifications and provides them with enough information to determine if the candidate is a good fit for the position. It also shows that the candidate has the required knowledge and experience to succeed in a production role.

What is a good objective for a Production Worker resume?

A production worker helps to ensure the efficient functioning of production operations. If you are applying for a production worker role, it is essential to have an effective objective statement on your resume to grab the attention of the hiring manager.

A good objective for a production worker resume should highlight your main skills and relevant experience that make you an ideal candidate for the job. Here are a few tips to help you write an effective objective statement:

- Showcase your experience in production operations: Highlight your experience in production operations and include any relevant certifications or qualifications that make you an ideal candidate for the job.

- Highlight any awards or recognition received: Include any awards or recognition received for your production work. This will demonstrate your commitment and dedication to the job.

- Demonstrate your organizational skills: Showcase your organizational skills and ability to plan and coordinate production activities. This will demonstrate your ability to manage the production operations efficiently.

- Mention your ability to work in a team: Highlight your team-working skills and ability to work in a fast-paced environment. This will show that you are an ideal candidate for the job.

By following these tips to write an effective objective for a production worker resume, you will be able to effectively present your skills, qualifications, and experience to the hiring manager.

How do you list Production Worker skills on a resume?

When drafting a resume for a Production Worker, it is important to list skills relevant to the position. Proven production experience, organizational abilities, and knowledge of safety regulations are all essential skills, and should be included in your resume.

The following is a list of Production Worker skills that you may want to include on your resume:

- Experience working on a fast-paced production line

- Ability to read and follow detailed instructions

- Knowledge of safety regulations and procedures

- Organizational skills and the ability to prioritize tasks

- Mechanical aptitude and experience with hand and power tools

- Ability to identify defects in products and materials

- Detail-oriented with the ability to complete tasks accurately

- Proven troubleshooting and problem-solving skills

- Experience with quality control processes

- Excellent communication skills

- Proficient in using computers and other technology

- Ability to lift heavy objects and stand for extended periods of time

What skills should I put on my resume for Production Worker?

When applying for a production worker job, it’s important to highlight the skills you have that make you an ideal candidate. Depending on the company, these skills may vary, but there are some foundational skills that are required for almost any production worker position.

- Mechanical Skills: Production workers must have a basic understanding of machines and how they work. They should be able to troubleshoot and repair machinery, as well as understand how to use tools and equipment safely.

- Quality Control: Production workers must be able to inspect their own work for quality assurance. This requires them to have a keen eye for detail and to be able to spot mistakes and errors quickly.

- Time Management: As a production worker, you must be able to manage your time wisely and be able to work efficiently. You should be able to work quickly and accurately while maintaining a safe work environment.

- Teamwork: Working in a production environment usually involves working alongside other people. This means that you must be able to communicate effectively and work together in order to achieve a common goal.

- Adaptability: Production work is often unpredictable and can change quickly, so you must be able to adapt to different situations and changing conditions. You should also be able to learn new skills and processes quickly and efficiently.

By highlighting these core skills on your resume, you will be able to demonstrate to potential employers that you are a qualified applicant for the production worker job.

Key takeaways for an Production Worker resume

When you are creating a resume as a Production Worker, it is important to make sure that it contains all the information that potential employers will be looking for. To make sure that your Production Worker resume stands out from the crowd, here are some key takeaways to help you make your resume as effective as possible:

- Showcase your skills: Make sure to emphasize your skills and abilities as a Production Worker. List out the production processes you have experience with, your knowledge of industry equipment, and any additional knowledge you have such as health and safety regulations.

- Emphasize your experience: Include the number of years of experience you have as a Production Worker, as well as any relevant experience from other positions or industries. This will demonstrate to potential employers that you possess the required skills and knowledge to perform the job.

- Include certifications: If you have any certifications or licenses related to Production Work, make sure to include them on your resume. This will show potential employers that you have taken the extra steps to ensure you have the necessary skills and knowledge to perform the job.

- List accomplishments: Recruiters often look for evidence that an individual has performed well in their previous positions. List any awards, promotions, or accomplishments that you have achieved during your time as a Production Worker to demonstrate your success.

- Use keywords: Keywords are essential when it comes to resumes in any industry. When creating your Production Worker resume, be sure to include keywords related to the production industry, such as “manufacturing”, “assembly line” and “machine operator”. This will help ensure that recruiters can easily find your resume in searches.

By following these key takeaways, you will be able to create a Production Worker resume that stands out from the crowd and gives potential employers all the necessary information to determine if you are the right candidate for the job.

Let us help you build your Resume!

Make your resume more organized and attractive with our Resume Builder

- Production worker objectives and summaries

Production worker Objectives and summaries

20 Production worker objectives and summaries found

A well-written objective or summary on your resume can be the difference between getting rejected, or getting invited for an interview. Copy any of these Production worker objective or summary examples, and use it as inspiration for your own resume. All examples are written by certified resume experts, and free for personal use.

Learn more about: objective vs. summary

Factory worker

Summary examples.

Experienced and systematic factory worker with physical stamina and endurance capable of performing multiple tasks while sustaining proficiency of the given job by supporting technology manufacturing needs. A reliable and focused factory worker with prior experience in manufacturing assembly, testing, inspection, materials, and equipment. A worker with good technical abilities and the capacity to acquire new concepts easily by implementing them within the time limit.

Passionate individual driven by a desire to grow and excel in the production industry as a factory worker with over 5 years of experience operating, monitoring, and maintaining assembly machinery in the field of electronics. Proven history in optimizing productivity, developing talented teams, coaching high-potential staff for upward mobility, and streamlining processes and workflow for measurable results.

Two years of progressive experience in manufacturing as a factory worker within the automotive industry. Possesses a deep understanding of electrical, mechanical, and pneumatic machinery. Great team worker with high attention to detail to ensure safety. Disciplined self-starter who is relied upon to get the job done no matter what the challenge. Bilingual: Fluent in English and Spanish.

Objective examples

A trained and hardworking factory worker with over 4 years of experience and the ability to work long hours seeks a position in a factory to amplify the business's growth by utilizing knowledge and training for positive contributions to the organization in a challenging environment.

Highly motivated and hard-working individual seeking a position as a Factory Worker. Looking to expand my 2+ years of experience and further develop my skills within technical manufacturing, and to bring deep knowledge of electrical, mechanical, and pneumatic machinery.

Production worker

Reliable and service-focused production worker with prior experience in manufacturing assembly, quality management, and materials and machinery. Committed and diligent worker who can do teamwork and produce high-quality work effectively. A competent expert with strong leadership qualities and a problem-solving mindset to lead teams for the execution of orders and on-time delivery. Leverages exceptional collaboration and cooperation to achieve personal and professional goals.

Talented and focused production worker with experience in maintaining a clean assembly line, handling reliable stock levels, and shipments of finished products. A skilled worker with expertise in the operation of the plant, daily production management, and inventory control. Passionate, meticulous, and good organizational skills to adapt to a range of projects while guaranteeing proper functioning and excellent quality.

Proficient and dedicated production worker experienced in handling tidy production line machinery and equipment, managing accurate inventory levels, and shipping finished products. A skilled worker with expertise in machine operation and production line & warehouse management. Possesses team spirit, attention to detail, and strong organization skills to cater bundle of tasks by ensuring smooth functioning and high quality.

Energetic and competent Production Worker with 5 years of experience operating machinery, assembling goods, and monitoring production processes at an automobile parts company. Recognized for being dependable and detail-oriented in support of the company’s production goals and initiatives.

An accomplished production worker with 4+ years of experience in handling manufacturing assembly lines and inventory management systems seeks a position in a factory or production plant to utilize the learned skillset for timely delivery of orders and business growth.

Assembly line worker

Highly committed, intelligent, and hard-working recent college graduate with over 2 years of manufacturing experience in assembly and production. Strong attention to detail, skilled in interpreting complex instructions, quality assurance processes, fusing, cutting, and measuring tools. Possesses mechanical, technical, dexterity, hand-eye coordination, physical stamina, and strength. Ensures assigned workspace is kept clean and safe before and after shifts.

Highly motivated individual with 2+ years of experience as an assembly line worker fabricating and joining small electronics in the automotive industry. Naturally inquisitive, organized, and detail-oriented. Able and willing to take direction and assume new responsibilities as necessary. Excellent interpersonal skills with great verbal and written communication. Builds positive relationships with coworkers with diverse cultural backgrounds.

Dynamic and dedicated Assembly Line Worker with 6 years of experience producing electronic components for medical equipment. Qualified in blueprint interpretation, component installations, pneumatic tools use, and final assembly processes. Recognized as a dependable team player who relates and works cooperatively with diverse groups of people. Exceptional time management, safety management, attention to detail, problem-solving, and crisis management skills.

Over two years of experience as an assembly line worker bringing exceptional work ethic and a positive attitude that encourages team productivity. Seeking a position to expand knowledge of assembly and production, quality assurance, and tools and machinery.

Results-oriented, innovative professional seeking an assembly line worker position at a medical technology company to support operational growth by utilizing in-depth knowledge of technology and electronics. Brings exceptional team-oriented and dedicated work ethic to increase productivity.

Accomplished professional in assembling finished products with knowledge of blueprint interpretation, tools experience, and quality control standards. Demonstrates a history of working as an assembler with expertise in functioning calibration and production control software. Focuses on keeping a clean workspace, types of machinery, and tools and leverages the excellent talent and attention to detail to ensure safety, efficacy, and quality results.

Two years of experience as a manufacturing assembler for an international tech company based in Silicon Valley. Great attention to detail, time management, and dexterity skills. Able to assess situations and problem solve in fast-paced and high-stress situations. Responsible and willing to learn new skills and face challenges head-on. Recognized by supervisors as a “go-to” professional.

Proactive and results-oriented professional with over 6 years of experience as an assembler specializing in quality control and product development. Extensive knowledge of schematics, blueprints, and machinery contributes to exceptional output. Quick learner and problem solver while dealing with new systems and concepts. Provides leadership in team environments to galvanize productivity and promote mutual success and growth for an organization.

A young professional seeking to obtain an Assembler position with a tech company that will benefit from in-depth knowledge of electronics, design collaboration, and creative solutions in the assembly process to improve the efficiency and safety of an organization.

A result-oriented assembler, having six years of expertise in interpreting blueprints, handling pneumatic tools, and managing the final assembly seeks a role in a reputed organization to ensure accurate mechanical assembly and quality assurance controls.

- Easy step-by-step builder

- Professional templates

- Try for free!

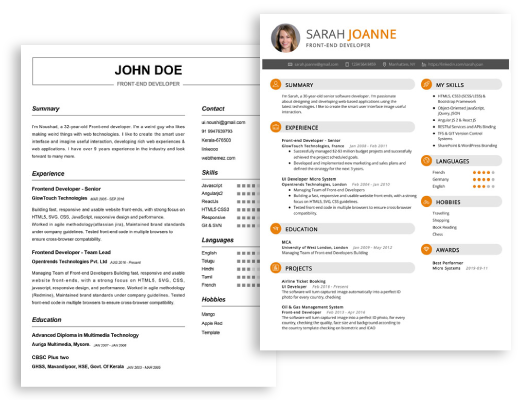

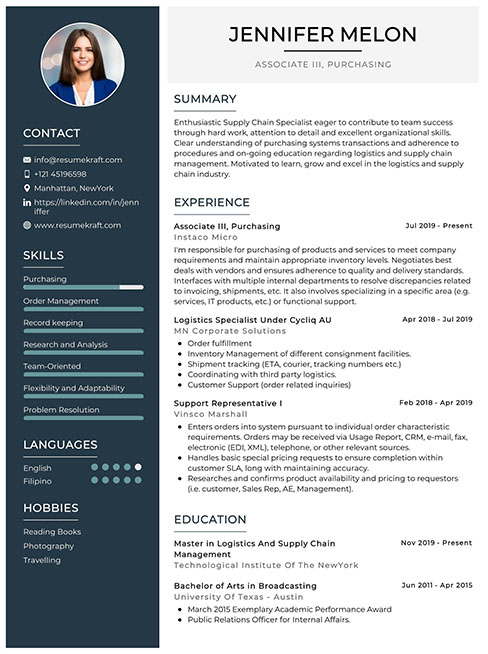

Professional resume templates

Make a resume that wins you interviews! Choose one of these professionally-designed resume templates and follow 3 easy steps to complete.

Create a perfect resume in a few minutes

- Field-tested resume templates created by experts

- Powered by Resume.io

- Try now for free!

Free resume templates

- Free for personal use

- Direct download as a Microsoft Word document

- Created by a CPRW certified resume expert

- Optimized for applicant tracking system (ATS) screening

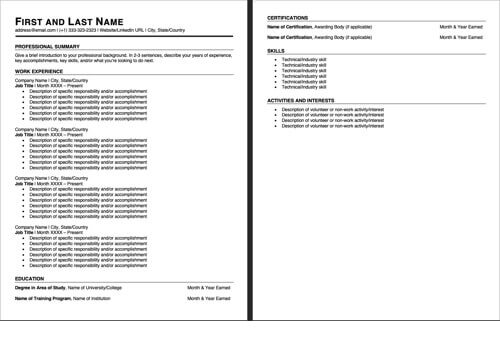

Choosing a correct resume format and template

Resume template

Download our American style resume template. Chronological resume format. Download a functional resume template .

Learn more about the differences between a resume and a CV .

CV template

Download our British/European style cv template. Similar to a resume but more commonly used in Europe, Asia and Africa.

Download cv-template.docx 29.34 KB

Resume Builder

- Resume Experts

- Search Jobs

- Search for Talent

- Employer Branding

- Outplacement

- Resume Samples

- Installation and Maintenance and Repair

Production Worker Resume Samples

The guide to resume tailoring.

Guide the recruiter to the conclusion that you are the best candidate for the production worker job. It’s actually very simple. Tailor your resume by picking relevant responsibilities from the examples below and then add your accomplishments. This way, you can position yourself in the best way to get hired.

Craft your perfect resume by picking job responsibilities written by professional recruiters

Pick from the thousands of curated job responsibilities used by the leading companies, tailor your resume & cover letter with wording that best fits for each job you apply.

Create a Resume in Minutes with Professional Resume Templates

- Make adjustments to manage the ink distribution

- Makes recommendations and may assist in designing and manufacturing racks and fixtures used in painting processes in addition to areas for improvement

- May assist with rework on assemblies and/or systems as a result of testing

- Clean, oil, and make minor adjustments or repairs to machinery and equipment

- Providing regular employees relief from extended work schedules, vacations, and other time off request

- Performs quality testing as defined in the work instructions

- Perform work tasks such as loading product into machines, inspect product, package finished product and stack product onto pallets

- Set up and break down the work station

- May assist in the preparation of food products (mixing, baking, etc.)

- Practices and complies with all company policies and procedures including safety and work rules, etc

- Practices and complies with all company policies including safety and work rules, etc

- May assist in packaging of food products

- Maintains excellent customer service and positive attitude towards guest, customers, clients, co-workers, etc

- Performs routine tasks using standard procedures and equipment

- Assist Supervisor in auditing work stations to ensure SOPS are being followed

- Oversees the daily department production activities and facilitates departmental workflow

- Work with various departments to meet production targets

- Clean and perform routine maintenance on equipment for standard operation following preventative maintenance guidelines and using approved tools

- Serves as safety model, promote a high level of safety awareness, continuous improvement and safety practices

- Lead workforce by orienting, training,; enforcing safety policies and procedures

- This is a working Lead position

- Assuring seaming table is clean at all times, sweeping floor around, under, and between seamer table, checking dust collector, vacuuming the seaming table

- Basic safety knowledge

- Excellent Attention-to-Detail

- Able to work outside in variable weather conditions

- Ability to perform basic math calculations and unit of measure conversions

- Demonstrated ability to grasp and maintain the knowledge of using computers to obtain specifications and production operation information

- Ability to learn and adapt quickly to changes

- Basic knowledge of diagrams and schematics – know how to follow and read

- Be detailed orientated with good communication and interpersonal skills

- Ability to work quickly and efficiently under pressure

15 Production Worker resume templates

Read our complete resume writing guides

How to tailor your resume, how to make a resume, how to mention achievements, work experience in resume, 50+ skills to put on a resume, how and why put hobbies, top 22 fonts for your resume, 50 best resume tips, 200+ action words to use, internship resume, killer resume summary, write a resume objective, what to put on a resume, how long should a resume be, the best resume format, how to list education, cv vs. resume: the difference, include contact information, resume format pdf vs word, how to write a student resume, production worker resume examples & samples.

- Operating equipment to insert

- Sorting and bundling newspapers

- Counting bundles in preparation of loading onto delivery trucks and transporting newspapers from machinery to delivery trucks

Production Worker Lead Resume Examples & Samples

- SHIPPING-EXPORTING EXPERIENCE

- FORK TRUCK CERTIFICATION

- COMPUTER LITERATE

- MICROSOFT OFFICE EXPERIENCE,

- INFORMATION ENTRY INTO EXPORT PORTAL

- Rework product as necessary

- Comply with Good Manufacturing Practices

- Comply with all Safety Policies and Procedures

- Comply with all Coca-Cola Quality System procedures

- Training of new associates

- Fill in on any lines when needed

- Ability to read, write, speak, and comprehend English

- Ability to hand stack cases of product from floor to over-head weighing up to 35 pounds repetitively up to 8 hours

- Ability to push and pull force of 80lbs

- Ability to stand and walk for extended periods of time in temperature extremes on a daily basis up to 12 hours

Truesdale Production Worker Line Resume Examples & Samples

- Supply line with raw materials as needed

- Move product, filled containers and raw materials to proper storage

- Forklift operations/inspections

- Ability to understand, record, and communicate system problems and solutions

- Move and lift material weighing 50 pounds to distances of 10 feet or more, floor to waist

- Any other duties as assigned to ensure the effectiveness, efficiency, and quality of products, processes and work environment

Truesdale Seasonal Production Worker Resume Examples & Samples

- Record inspection requirements and data on provided forms

- Load packaged goods onto trailers

- Clean and sanitize equipment, floors, windows, outdoor grounds, or any other areas as needed

Production Worker Seasonal Resume Examples & Samples

- Operate equipment through proper program controls

- Ability to work extended hours, weekends and holidays

- Ability to squat and bend over at the waist

- Operates production equipment as outlined in work instructions using judgment to correct problems, with authority to stop production when equipment, safety or product quality is in jeopardy

- Operates equipment at rates that meet productivity goals

- Moves and prepares raw material as required

- Performs routine maintenance and repair work on equipment and assists maintenance as required

- Interacts with supervision on mechanical and quality discrepancies

- Observes all company rules and regulations

- Keeps work area neat, clean and orderly

- Maintains accurate and complete labor, productivity and scrap records

- Performs basic equipment changeovers as required

- Properly labels all products produced

- Provides excellent service for and maintains communication with internal customers at all times

- Promotes the culture of Total Quality and strives for continuous improvement

- May require handling hazardous waste

- May be assigned other miscellaneous duties (including training) by department supervision/leadership

- Minimum one (1) year of manufacturing experience

Packing & Molding Production Worker Resume Examples & Samples

- Communicate with packers from the previous shift to determine if there are any problems on the packing portion of the line

- Operate packaging equipment to fill, label, stack and stretch wrap product containers

- Monitor packaging equipment performance; make adjustments to equipment as necessary

- Record and review production data as required on log sheets

- Contact supervisor or lead person in the event of any problems with the lines, product quality, or critical control points

- Perform product and packaging change-overs as scheduled

- Restock boxes, skids, and liners for next shift and current shift as needed

- Clean work areas and equipment as assigned or scheduled

- Must obtain forklift/pallet handling equipment certification, and use forklift/pallet handling equipment to move product or packaging materials as required

- Maintain all production areas in a neat and clean condition

- Properly account for any product rework

- Comply with all GMP, safety, sanitation and any other plant rules as established by the company

- Perform other duties as assigned by the Packaging and Molding Supervisor

Regular General Production Worker Resume Examples & Samples

- Keep up with various rates of production speeds

- Work cooperatively with other employees and supervisors

- Regular and consistent attendance

- Ability to work in a variety of body positions; bending, stooping, standing and the ability to have coordinated movements of pulling, pushing, grasping, reaching, and bilateral arm movements

- Ability to perform multi-step assembly tasks on a product while moving with an assembly line

- Ability to move 30 lbs. unaccompanied

- Prolonged periods of standing

- Ability to work on any shift

- Ability to follow directions

- Reliable Transportation

- Rudimentary English

- Please do not reapply if you have applied in the last 90 day’s **

- Performing cleanup on various production and packaging related equipment

- Training and assisting in all areas of production and packaging as required

- Following all company Safety Rules and Good Manufacturing Practices (GMP)

- Effective communication, interpersonal and organizational skills

- Demonstrated knowledge of behavior based safety systems

- Responsible for the trimming, rehydrating, and papering of all lettuce items needed for the day’s shipping, as stated on the par level sheets

- Responsible for lidding all strawberries and cherry tomatoes needed for shipping as stated in the par level sheets

- Perform other duties as requested by management

- Pallet Jack and Fork lift Experience preferred

- Sort, inspect, clean, paint, label and refill empty cylinders

- Ensure the consistent quality of cylinders are being processed

- Manually move cylinders from pallet jacks to a roller conveyer system

- Load filled cylinders onto pallets and then load onto empty trailers for next day’s shipments

- Maintain the appearance of the yard and production facility

- Demonstrate a high commitment to safety and follows company safety procedures and policies

- 1-3 years of production/manufacturing experience

- Experience operating a forklift and ability to be forklift certified

- Physical ability to lift up to 50lbs in each hand repeatedly throughout the day

- Ability to follow processes, procedures, and instructions

- Ability to function effectively as a member of a production team

- Be able to stand 8-10 hours per day

- First line inspection of product quality

- Ongoing inspection of product quality

- Reporting to the supervisor any defects in product or malfunctioning of equipment

- Complete the necessary paperwork to record daily production totals for production reporting

- Removing all parts from the mold before cycling the press

- Efficiently running the molding machine and the related products associated to the molding process per the work instructions

- Sort parts on automatic molding machines per related work instruction for product being molded and assembled or decorated

- Learn to run and inspect new products

- Follow cleaning procedures

- Follow established company policies

- Follow all established health and safety policies

- Communicate with supervisors and other department personnel

- Assist as necessary in any molding related activities

- Knowledge of GMP

- Machine operation experience in a production environment preferred

- Dependability and ability to adapt to change are essential

- Ability to read, write and communicate in English

- High School Diploma/GED

Food Service Production Worker Resume Examples & Samples

- Fundamentals Reads and follows recipes and is able to extend recipes using conversion charts to increase/decrease portions

- Reads and follows production sheets to gather all food items needed for each meal and to produce the correct number of servings of cold food items for each meal

- Practices safe food handling methods according to HAACP and infection control standards

- Covers, labels, dates and stores food in a proper manner according to guidelines

- Able to operate all necessary equipment in the production of foods

- Food Preparation Prepares cold food for all meals according to recipes

- Monitors and maintains correct appearance, temperature and flavor of all items produced

- Organizes the timing of all production work to keep up with needs

- Replenishes all cold foods in a timely manner to cafeteria, trayline, doctor's lounge and catering functions

- Preps all items for the following day's meals

- Completes all food station set up for meal service 15 minutes prior to cafeteria and trayline start times

- Prepares functions according to catering sheets

- Trayline Accurately sets up trayline with correct food and utensils

- Maintains accurate portion sizes and appearance of food on trays

- Cleaning and Sanitizing Responsibilities

- Maintains a clean and orderly work environment that meets the safety and sanitation requirements of the department as well as those of local, state and federal agencies

- Communications Accepts assigned duties in a cooperative manner

- CCHS ORGANIZTION-WIDE COMPETENCY ASSESSMENT REQUIREMENTS

- All employees are expected to meet the standards of performance outlined in the Organization-Wide Competencies listed below as applied to the position

- Customer Service Orientation includes attitude, behavior, interpersonal skills, and problem solving that enable an employee to respond to internal and external customer needs and expectations in a positive manner

- Adaptability includes teamwork, flexibility needed to fulfill job responsibilities, adapting to changes in work environment and accepting supervisory feedback

- Efficiency and Effectiveness includes quantity and quality if desired work, as well as organization skills necessary to perform successfully

- Essential Job requirements includes adherence to all relevant policies, procedures, and guidelines affecting the work environment, as well as maintenance of required competencies and communications skills

- Managerial Responsibilities (if applicable) includes overall accountability for assigned workgroup relative to operational goals, personal requirements, and budgetary constraints

- As an organization, all employees with patient contact are expected to demonstrate competencies, specific to their job duties, for the following patient population categories: Elderly, Children, Cardiac, Neuro, Surgical, Impaired (Hearing/Visual), Cultural, Age

- NOTE: The above stated duties are intended to outline those functions typically performed by individuals assigned to this classification

- This description of duties is not intended to be all inclusive or to limit the discretionary authority of supervisors to assign other tasks of similar nature or level of responsibility

- One to two years of food service production experience preferred

- Must perform a diverse range of tasks related to operating a variety of manufacturing equipment utilized in the production of various products (i.e. opening, closing, mixing, filling, loading, inserting parts, capping products, tightening lids, sealing bags, etc.)

- Moves freely around machine to assure all working mechanisms are operating properly and reach all necessary parts in machine to make adjustments, minor repairs, set-up, changeovers, etc

- Must be capable of standing at workstation for extended periods of time (8 hours or more) operating equipment or packaging products while closely monitoring and visually inspecting products and process

- Associate may work in a filling or packaging area, inspecting product, filling cartons, bags, or containers with products, applying labels, stamping product identification numbers, expiration dates, making boxes and placing product into final package

- Must be consistently able to produce error-free paperwork and check the paperwork of others

- Required to read scales in order to weigh raw materials, final products, etc. in order to assure a consistent high quality product

- May use statistical process control and automated software and hardware to monitor quality

- Must read and follow all safety and quality procedures which may include wearing protective equipment (PPE), smocks, hairnets etc., as well as read and follow all written formulation procedures, standard operating procedures and good manufacturing practices

- Must be capable of operating all material handling equipment such as hand jacks, powered jacks, etc

- Responsible for properly reporting production units, job numbers and labor hours

- Must also meet and/or exceed all quantity and quality standards set in department

- May provide basic training for new employees and/or contingent employees

- Insures compliance with QA, GMP, SOP, FDA, 5 S, and labor standards

- Responsible for maintaining cleanliness of equipment and work area

- Associate will be innovative, knowledgeable and intensely committed to ensure that every product and service we supply conforms to FDA and Quality System Regulations as well as ISO 13485/MDD Standards

- Ability to read and interpret documents such as safety rules, operating and maintenance instructions, and procedure manuals, written in English

- Ability to add, subtract, multiply, and divide in all units of measure using whole numbers, common fractions, metric measurement and decimals. Ability to compute rate, ratio, and percent

- Ability to apply commonsense understanding to carry out instructions furnished in written, oral, or diagram form. Ability to deal with problems involving several concrete variables in standardized situations

- Associate must be very detail oriented

- Associate may be cross-trained to perform other duties within the department or as needed

Shift General Production Worker Resume Examples & Samples

- Must display safe work practices and habits

- Must be able to perform work at different workstations and various departments as production needs require

- Load raw product/materials onto a moving conveyor system and unload finished product from a moving conveyor system

- Cut shelving to various lengths as directed ad stack shelving onto pallets

- Ability to perform minor preventative maintenance and cleaning as directed

- Operate cartoning equipment and vacuum assisted lifting devices

- Must demonstrate the ability to perform all required tasks in the Roller Welder department

- Must demonstrate the ability perform all required tasks in the Epoxy Paintline department

- Must demonstrate the ability perform all required tasks in the Coater department

- Follows the available Job Instruction Breakdowns (JIBs) and all on the job training for all tasks

- Handles materials to and from the production line

- Perform material handling duties on a forklift or primer mover if certified

- Utilizes special handling equipment to aid in movement or positioning of materials

- Counts, identifies, and weighs materials as required

- Must maintains good housekeeping of their assigned area

- Must maintain specific quality standards by performing all checks as required by the quality sampling procedures

- Must seek to attain acceptable production rates and pursue continuous improvement

- Completes all necessary paperwork and computer input as requested

- Uses common hand tools, gauges, measuring devices, pallet jacks, and other handling equipment to perform job function

- Reads, understands, and responds to instruction

- Ability to record and maintain all production and quality documentation

- Must be able to understand & complete basic math equations

- Expected to become skilled at identifying product names, codes, labels, ID numbers and associated components

- Performs running adjustments, performs minor preventative maintenance on equipment, completes standard setups/changeovers on equipment(only when required and approved by the department supervisor)

- Ability to work in a team environment & maintain regular attendance

- Must be able to work overtime as business need dictates

- Adhere to all plant policies and procedures

- Perform various manual tasks and learn operational responsibilities in the corrugator, converting and/or shipping areas

- Perform basic industrial housekeeping duties

- Perform essential care and condition monitoring of operating equipment

- Operate mobile equipment such as forklifts may be required

- Previous manufacturing experience is an asset

- Prior manufacturing experience in a GMP environment a plus (food manufacturing, pharmaceutical, manufacturing, etc.)

- Ability to successfully complete a criminal background & drug screens

- Ability to walk & stand between 8-12 hours/day

- Ability to work in a fast paced manufacturing environment

- Ability to work mandatory overtime including weekends as required

- Ability to work multiple shifts a plus

- Ability to read, write, speak and understand English

- Regular use of hands, wrists & forearms

- Ability to multi-task in a fast paced, team oriented environment

- Technical education and familiarity with electronic instruments preferred

- Familiarity with standard warehouse and manufacturing processes

- Clean and maintain measuring instruments and test equipment; treat and inspect/test parts (e.g., routed and deburring operations) per applicable work instructions

- Communicate information to others about project status, updates, specific instructions, etc. and review item status in MRP and ensure item is logged/closed out based on its current status

- Document nonconformance and dispositions using nonconformance forms

- Measure and inspect dimensions of products to verify conformance to specifications, using measuring instruments such as rulers, calipers, gauges, or micrometers (as required)

- Clean and organize the immediate work area

- Interpret and follow blueprints for proper production task completion

- May be required to obtain certification as necessary per function requirements

- Requires verbal and written communication skills. The position also requires the ability to follow work instructions/order within area of responsibility

- The laborer will occasionally bend, stoop, squat and climb heights, but never crawl. They will frequently crouch kneel, balance and frequently reach above the shoulder level and frequently push and pull

- The employee will frequently carry up to 10 to 34 pounds and a little less frequently 35-50 pounds. They will carry 51-100 pounds occasionally. Working in the Cable Tray, two production workers may carry a 200 pound ladder together occasionally

- The employee is required to frequently lift 10 -34 pounds and a little less frequently 35-50 pounds. They will occasionally carry 51-100 pounds. Again, in the Cable Tray business, two production workers may carry a 200 pound ladder together

- It is not required to operate any equipment that is operated by a foot pedal. The repetitive action of simple grasping, and firm grasping is required, however fine manipulating is not used

- The employee works around moving machinery, but is not required to operate it. There are NO unprotected heights to work in and the only change in temperature is created by the opening of a dock door

- No relocation is being offered for this position. Only candidates residing within a 50 mile radius of Highland, IL will be considered

- Experience working in a manufacturing environment

- Responsible for following Job Safety Analysis guidelines to ensure safety

- Maintain good hand and eye coordination

- Work rapidly in order to maintain production requirements

- Perform job according to job expectations and as outlined in the standard work document

- Assist in training other production workers

- Keep area clean and wood off floor

- Perform other assigned tasks as needed

- At least 1 year of consistent employment (same employer) within the last 3 years

- Must be reliable

- Prior manufacturing experience

- Set up machinery ensuring all production materials are available

- Available to work weekends and overtime

- High school diploma or general equivalency diploma (GED)

- Must have 3 years experience working in a fast pace manufacturing environment or 3 years experience working in a fast pace operations food service environment

- Commitment to ADM’s goal of achieving a zero injury culture; understand and follow company safety procedures

- Exhibit regular and prompt attendance

- Able to meet physical requirements of the position including, but not limited to: prolonged periods of standing and sitting, working in confined spaces and from heights, bending, kneeling, climbing stairs and ladders, working in a variety of conditions (heat, cold, dust, etc), lift up to 55 lbs unassisted

- Willing to work overtime, weekends, holidays, swing/rotating shifts if needed

- Demonstrate initiative to work independently while flexible enough to work in team setting when needed

- Exhibit a professional image at all times; maintain a positive and respectful attitude

- Knowledge of pumps, blend tanks, boilers and silo's would be helpful, mechanical ability needed

- Previous experience operating a computer is preferred

- $15.65/hourly

- Monday thru Friday

- Production workers must be able to understand instructions whether they are written or verbal, and follow said instructions

- Complete work with accuracy and efficiency

- �Adhere to all safety policies and procedures

- The nature of all production positions is repetitive motions for extended periods of time

- One year of production experience or similar in carpentry or fast paced, detail-oriented environment is preferred

- Ability to read/write/communicate in English

- Prolonged standing and repetitive motions, bending, stooping, pushing and pulling

- Frequent lifting up to 60 lbs

- Overtime is required, including weekends

- Adhere to safe work practices

- Clean and maintain measuring instruments and test equipment. Analyze and interpret blueprints, manuals and other materials to determine specifications, inspection and testing procedures and conduct tests and inspection by following applicable work instructions

- Document nonconformance and dispositions using nonconformance forms and identify and recommend corrective actions, as necessary

- Develop and approve inspection techniques. (In Duarte, this would not apply.) Measure and inspect dimensions of products to verify conformance to specifications, using measuring instruments such as rulers, calipers, gauges, or micrometers

- Member in Deburring proficiently performs tasks such as wash deburred hardware; remove sharp edges and excess material from hardware using necessary tools, such as files, scrapers, picks, and rubber tools; perform visual inspection of deburred hardware, looking for missed burrs and edges or damages; post clean hardware per applicable work instructions; deburr hardware with simple geometry and minimal critical features (e.g., .001 max. corner breaks, cylindricity; tight diametrical tolerances); deburr hardware with a limited number of features; buff and polish deburred hardware

- Members in Light Assembly (i.e. Heli-coils, Lee plugs, bushings, and Lee jets) proficiently perform 5 processes related to light assembly. (Does not apply to Duarte)

- Perform preventative maintenance to ensure machines and equipment run smoothly and notify supervisors of production or machine problems

- Knowledge of and the ability to use equipment used in the deburring process such as files, scrappers, air motors, media blasting machines, and power washers (for Deburring member) and the ability to use a variety of basic hand tools (e.g., wrenches, hammers, screwdrivers, scrappers, box cutters). The ability to read, interpret and use the information presented in drawings, diagrams and blueprints to determine appropriate activities, tools, and next steps in the production process

- Knowledge of and the ability to perform various light assembly processes, including STI installation, heat and freeze processing, Lee plug assembly, bonding, pressure wash, swaging, flagging, leak test, arbor press, hydraulic press, etc. (for Light Assembly member)

- Knowledge of navigation and use of the WISE system for modules relevant to area of responsibility

- Knowledge of nonconformance procedures and processes when parts fail inspection. This includes knowledge of systems required to log and track failed inspections and associated documentation within area of responsibility

- Knowledge of part special handling guidelines and specifications. This includes researching part handling instructions using facility databases or work orders and following the handling procedures required

- The knowledge of and ability to identify products. This includes the ability to use stamping machines, including inputting specifications into the machine and operation of user controls. This also includes the ability to use electrolytic etch and laser marking

- Knowledge of the Six Sigma processes and the ability to apply Six Sigma principles to production process for continual improvement and operational effectiveness

- Knowledge of lean manufacturing techniques (e.g., continuous improvement, waste minimization, pull processing) to drive improvements in customer value and the ability to integrate the techniques into current production processes

- The ability to write effectively, to read and understand work documents and to communicate information clearly to coworkers and supervisor. The position also involves the ability to mentor and provide guidance to members through instruction and personal example. The position also requires the ability to provide training to other members in specific job skills

- The ability to accomplish a task with concern for all the areas involved, including the ability to notice minute inconsistencies/faults in parts, and the ability to know when a decision needs to be made and having the readiness to make timely, sound decisions. This includes recognizing when outside advice is needed and committing to action, even in uncertain situations

- The ability to write effectively, to read and understand work documents, to communicate information clearly to coworkers and supervisors, and the ability to listen attentively and comprehend key pieces of spoken information and the ability to instruct others on the specific activities used in a production process. This includes demonstrating and explaining the activities on the job

- Member in Deburring proficiently performs tasks such as wash deburred hardware; remove sharp edges and excess material from hardware using necessary tools, perform visual inspection of deburred hardware, looking for missed burrs and edges or damages; post clean hardware per applicable work instructions; deburr hardware with simple geometry and minimal critical features (e.g., .001 max. corner breaks, cylindricity, tight tolerances); deburr hardware with a limited number of features; buff and polish deburred hardware

- Member in Light Assembly shall proficiently perform5 of the following processes: STI installation, heat and freeze processing, part marking, Lee plug assembly, bonding, PIND testing; applying Molykote, performing pressure wash/flush, operating air oven, swaging, flaring; loctite (bonding), leak testing, general assembly, riveting, staking; operating arbor press, hydraulic press, spring checker, gauge lap, hand lap, center lap and deburring

- The ability to accurately provide the information requested on specific forms, reports, and logs. This includes generating or transcribing appropriate words, numbers, or symbols to complete written or computerized forms, reports, or logs

- The ability to define, diagnose, and resolve problems. This includes seeking, logically examining, and interpreting information from different sources to determine a problem's cause and developing a course of action to resolve the problem and to prevent its reoccurrence. This also includes the ability to acquire and apply new knowledge and skills and the ability to integrate knowledge of current resources and constraints, priorities and manufacturing processes to determine the benefits and costs associated with key decisions

- Knowledge of the Six Sigma processes and the ability to apply Six Sigma principles to production process for continual improvement and operational effectiveness, preferred

- At least 3 years of related work experience

Flavor Production Worker Resume Examples & Samples

- Previous manufacturing experience is preferred

- Must be able to work on weekends when needed to complete customer orders that are scheduled

- Ability to lift (50) lbs without difficulty

- Ability to weigh ingredients accurately utilizing a floor scale, flow meter and load cell

Production Worker, Effingham Resume Examples & Samples

- Operate forklift and power scrubbers

- Work the bagging line

- Record product codes/lot numbers

- Load and unload trucks for customers

- Assess inventory to ensure proper delivery to customers

- Scanning, cutting, and emptying packages to fill mixers

- Must be available to work different shifts, overtime, and weekends, as needed

Bakery Production Worker Resume Examples & Samples

- Filler Machine: Employee stands on a platform at conveyor which is approximately 40 inches in height and using both hands alternately slides forward repetitively one product with each hand into positions on the filler machine. If the employee works on right side of filler machine first rotation, then the next rotation the employee will work on the left side of the filler machine

- Feeding the Wrapper: Employee may sit or stand at conveyor approximately 37 to 39 inches in height and using both hands alternately slides in repetitively one product with each hand into positions on a moving conveyor. Employee also reaches above shoulder level to retrieve product from shuck-out bin to feed into wrapper machine

- Box Marker: Employee may sit or stand at 36 inch table making boxes out of pre-cut cardboard by folding the sides into box formation. Then while standing, the employee will stack completed boxes one at a time in a stack ranging from floor level to 5 to 6 ft. tall

- Sliding in or Picking up Product: Employee stands at conveyor approximately 37 to 39 inches in height and using both hands repetitively picks up one product in each hand or using both hands slides-in product simultaneously into boxes that are moving along a conveyor. Employee also reaches at shoulder level to discard product in bins as needed to retrieve production from bins to place into boxes as needed

- Box Dropper and Poking Down Product: The employee may stand or sit at a conveyor which is approximately 37 to 39 inches in height. The employee opens a box by “flicking” the wrist using a downward motion and repetitively places the box on the conveyor in front of the employee. The Employee watches the product move along conveyor and if necessary “pokes down” product that are not placed in box properly

- Tying bags of Product: Employee stands at a table approximately 36 inches high between conveyors. The employee repetitively grasps filled bags of product, weighing 24 to 26 ounces, as the bad moves off the conveyor onto the table. With one hand the employee holds the top of the filled bag closed, while twirling the bottom of the filled bag with the other hand in order to secure the filled bag. The employee then pushes top of bag into the tying machine in order to tie each bag. Next, the employee places tied bag onto the next conveyor to be transported to the casing-up station

- Casing-up Product: This job consists of picking up tied bags of product one at a time repetitively, weighing 24 to 26 ounces each, and placing tied bags into box until six(6) bags are in the box. Next, the employee pushes filled box onto the next conveyor which transports box through the tape machine

- Stacking Product: This job consists of stacking repetitively filled boxes of product one at a time, weighing up to approximately 10 pounds each, onto floor pallet in a cube structure to be shrink wrapped. The stack ranges from floor level to approximately 5 to 6 feet high

- Housekeeping: Clean-up occurs at the end of every shift most every day. Clean-up occurs: (1) intermittently during shift as needed (if the line shuts down because of equipment failure or supply error), (2) during change-over and (3) at the end of the production week

- Range of Motion: Range of motion requires forward 12 to 24 inches repetitively and reaching above shoulder level repetitively. Bending, stooping, twisting, and repetitive motion required

- Ensures that all internal and external food safety and quality policies and procedures are followed

- Performs other duties as assigned by supervision

- Observe all safety procedures

- Take responsibility for producing high quality product in each step of production

- Maintain clean work area

- Observe and follow all Good Manufacturing Practices

- Must possess a High School Diploma / GED

- Must be able to read and write English

- Must be flexible to work any shift (1st, 2nd, and 3rd). Must be available to work weekends, holidays and overtime as scheduled

- Previous manufacturing experience is desirable

- Previous food manufacturing experience is highly desirable

- Experience with Safe Quality Food (SQF) practices is desirable

- Experience with Total Productive Maintenance (TPM) is desirable

- Experience with Autonomous Maintenance (AM) is desirable

- Experience with Kaizen or other Continuous Improvement methodology is desirable

- Focus on maintaining excellent quality

- Ability to follow directions well

- Ability to work independently within a team environment

- Close attention to detail

- Compound as required by production demand by following shop floor precisely as instructed to do so by shop floor papers

- Responsible for safe operation of fork lift and all material handling equipment within the work area

- Maintain a safe working environment, utilize appropriate safety equipment and proactively improve the safety culture of the department

- Maintain processing area and equipment in a clean, sanitary and presentable condition; adhere to Good Manufacturing Practices and exemplary housekeeping standards

- Ability and willingness to work as part of a team to solve problems, develop procedures, and recommend improvements

- Electronic or electro-mechanical assembly operations on assemblies or sub-assemblies

- Set-up, calibration, testing and troubleshooting of circuits, components, instruments and mechanical assemblies

- Manufacturing equipment operation. Weigh, measure and check raw materials to ensure that batches manufactured contain proper ingredients in proper quantities

- Performs incoming, raw material and final mfg inspection and/or audits of quality control programs

- Set up, mix, receive, store and deliver and dispense production chemicals

- Assists with routine repair and retest products

- Assists with in-process tests (such as hardness, weight, variation, pH and moisture content) to ensure that batches meet specifications

- Assists in resolving routine manufacturing related problems affecting daily operations

- May provide general guidance to others and train lower level employees

- Frequent inter-organizational and external contacts

- Electromechanical assembly experience

- Computer Skills Including Microsoft Office

- 5+ years experience

- Lean Manufacturing

- FDA exposure

- Above high school diploma

- Mechanical / Electrical engineering related skill and experience preferred

- Willing to work hard and learn more techniques

- Strong communication skill

- Microsoft Office (Word, Excel, PowerPoint)

- No disabilities related work in production line

Composites Production Worker Resume Examples & Samples

- Performs plastic fabrication tasks, such as molding, laminating, oven-curing, trimming, and finish work

- Performs mechanical assembly tasks and machine routing and drilling operations

- May spray paint subassemblies

- Works with epoxies, resins, and other chemical compounds, mixing according to specified formulas

- Checks tolerances to ensure that fabricated parts meet drawing requirements

- Performs routine testing, such as pressure testing, resistance testing, and torque testing

- Cleans work area and tooling

Production Worker Operator Resume Examples & Samples

- Operate production equipment in a timely and efficient manner in order to produce quality product

- Maintain pallet supply for palletizer

- Cover breaks for all production workers

- Responsible for overall maintenance of the auto and manual packing lines and surrounding work area, including starting and stopping of packaging equipment

- Packaging finished goods with appropriate labels, lot codes, manufacturing dates, and expiration dates

- Frequently responsible for appropriately stacking product on pallets or racks

- Frequently responsible for appropriately completing department related paperwork