- Get Involved

What is Engineering Design and the Engineering Design Process?

Engineering design is a process. It involves tools and ways of thinking that people can use in almost any situation. Each part of the process reveals information about the problem and possible solutions.

Engineering design is iterative. Engineers are expected to repeat the process. Steps like defining, planning, modeling, and testing, can be completed in different sequences to find the best possible solution.

Engineering design is problem-solving. It always has a purpose that is specific and known. It may involve experiments to better understand the problem (or a possible solution), but the goal of engineering design is always to solve a problem.

Engineering design is finding the best solution. Evaluation is an important part of the process. Solutions have different strengths and weaknesses and have to stay within the physical limits of available time, cost, tools, and resources. Engineers have to choose the solution that provides the most desired features with the fewest negatives. That’s why engineering is often called “design under constraint”.

Engineering design is an iterative process used to identify problems and develop and improve solutions.

The engineering design process can be extremely useful to any individual trying to solve a problem. But engineering design can be – and usually is – done in teams. Each team member brings different knowledge and experience to the process, which usually improves the results.

Can anybody do this?

Yes! One great thing about engineering design is that it relies on skills that anyone can do and can learn to do better with practice.

Different models of the engineering design process include different “steps”, but there are a few skills that anyone doing engineering design is likely to use - and most of these you are already familiar with. Here's a list:

- Ask questions

- Do research

- Draw/sketch

- Construct models or prototypes

- Conduct tests

- Evaluate results

- Present solutions

Professional engineers may work on problems that are bigger in scale and complexity, but the basic process for solving them is the same as the one you can use to solve everyday problems. The difference between planning a taco party and designing a city's water system is simply the amount of specialized knowledge and experience required to solve the problem.

Design and construct floating boom that will prevent an oil spill from reaching the beach and absorb as much oil as possible from a spill.

START TODAY

What if my idea fails?

Failure is okay .

In engineering design, failure is expected. It helps you find the best solutions before implementing them in the “real world”. Having a prototype fail is a GOOD thing, because that means you have learned something new about the problem and potential solutions.

What does the engineering design process look like?

The engineering design process is a remarkably flexible and useful way to look at many different kinds of problems. Here's a fun video that uses a the engineering design process to successfully solve what seems like a non-engineering problem.

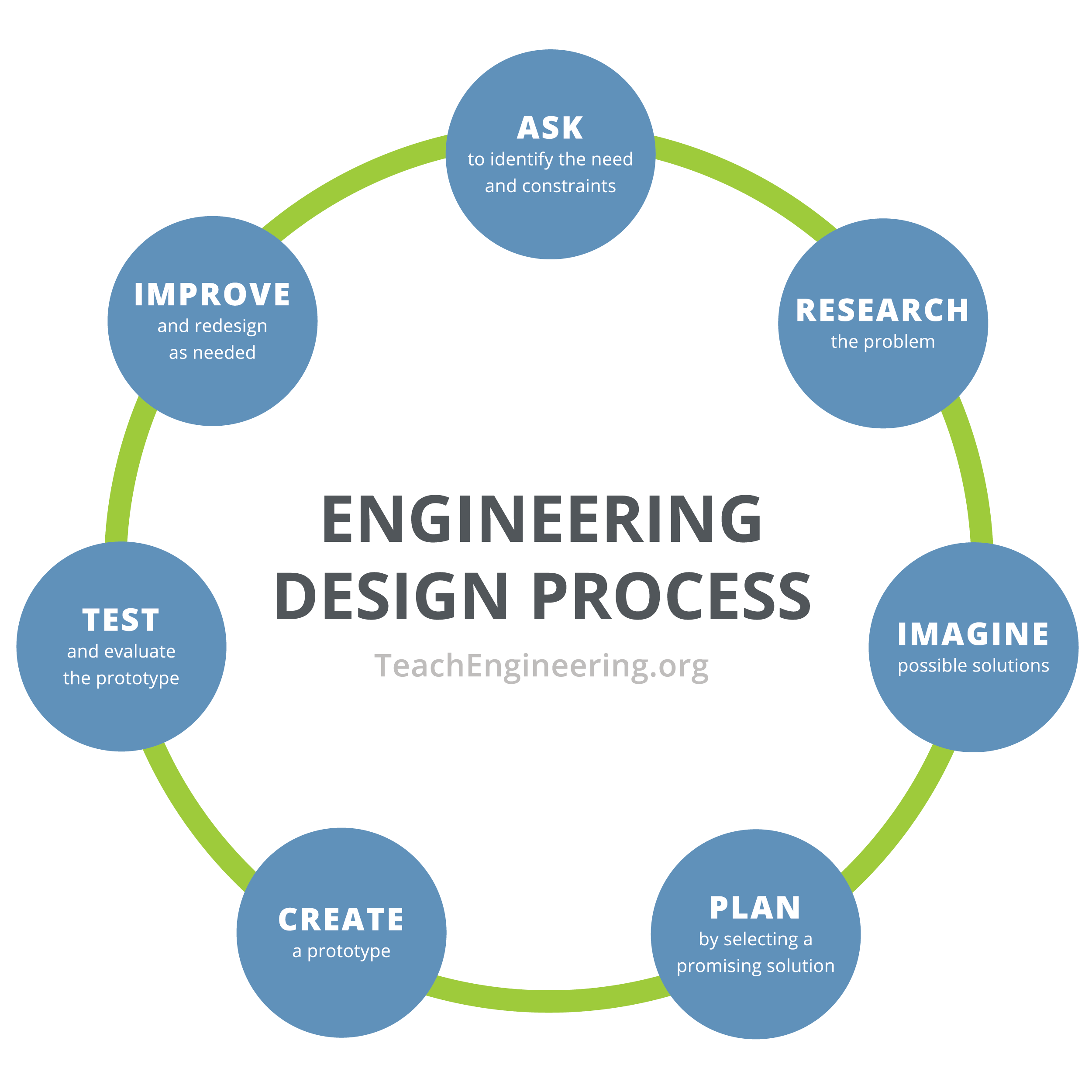

This example shows a number of different steps, but not everyone approaches the design process the same way. That's okay. There are actually several different models used to teach and talk about engineering design. Here are a couple of others that are pretty simple:

Notice that neither of these models has a specific start or end point. Designers often jump around between steps.

INDUSTRIAL TRAINER

Learn Professional

- Facebook Page

Engineering Design: An Overview of the Engineering Design Process and Best Practices

Table of Contents

Engineering Design

Introduction Engineering design is the process of creating solutions to problems through the application of scientific, mathematical, and engineering principles. Engineering design is a critical aspect of any successful project, whether it be a product, system, or infrastructure. The engineering design process is a systematic approach to problem-solving that involves a series of steps and best practices. This blog post will provide an overview of the engineering design process and best practices for designing products, systems, and infrastructure.

Engineering Design Domains

The Engineering Design Process is a series of steps that engineers undertake to elaborate a solution of a problem.

Product Design Product design is the general process of creation of new products and services.

Mechanical Design Mechanical engineering design is an engineering procedure aimed at designing parts, components, products, or systems of a mechanical nature while applying engineering physics and mathematics principles with materials science.

Electrical Design Electrical design is the process of planning, creating, testing or supervising the development and installation of electrical equipment, such as electrical components, schematics, lighting equipment, power systems, power distribution, fire and life safety systems, electronic components, voice and data telecommunications infrastructure.

Industrial Design Industrial design is the practice of designing products for mass production.

Civil Design Civil engineering design is a professional engineering discipline that deals with the design, dimensioning, and engineering of buildings and structural members, ensuring they to withstand different types of loads and forces applied to those members.

Architectural Design Architectural design is a concept that focuses on components or elements of a structure translating the non-physical design problem into the physical building product.

Software Design Software design is the practice of creating a specification of a software artifact, intended to accomplish goals, by means of planning a software solution including considerations of functional components, layers, algorithms, interfaces, integration, data, and security.

Popular Engineering Design Software

Here are some examples of popular software tools used in different areas of engineering:

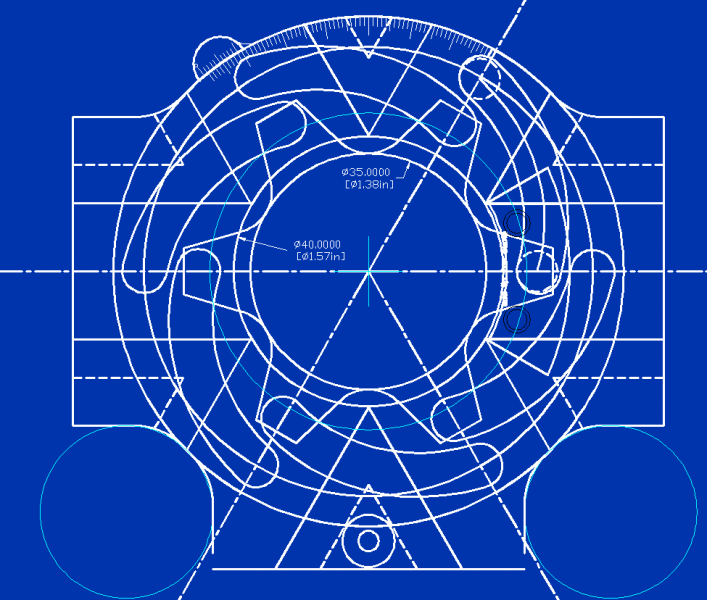

- Computer-Aided Design (CAD) Software: CAD software is used for creating 2D and 3D models of products, structures, and machines. Popular CAD software tools include AutoCAD, SolidWorks, CATIA, Pro/Engineer, and Inventor.

- Finite Element Analysis (FEA) Software: FEA software is used to simulate and analyze the behavior of structures and materials under different loads and conditions. Popular FEA software tools include ANSYS, Abaqus, COMSOL, and Nastran.

- Computational Fluid Dynamics (CFD) Software: CFD software is used to simulate and analyze the behavior of fluids and gases in different environments. Popular CFD software tools include ANSYS Fluent, STAR-CCM+, and OpenFOAM.

- Electronic Design Automation (EDA) Software: EDA software is used for designing and simulating electronic circuits and systems. Popular EDA software tools include Cadence, Mentor Graphics, and Altium Designer.

- Geographic Information System (GIS) Software: GIS software is used for creating and analyzing maps and geographic data. Popular GIS software tools include ArcGIS, QGIS, and Google Earth.

- Project Management Software: Project management software is used for planning and tracking engineering projects. Popular project management software tools include Microsoft Project, Asana, Trello, and Jira.

The Engineering Design Process

The engineering design process is a systematic approach to problem-solving that involves a series of steps. The steps are as follows:

Define the Problem

The first step in the engineering design process is to define the problem. This involves understanding the problem, its scope, and the requirements of the project. The problem should be well-defined, measurable, and achievable.

Gather Information

The second step is to gather information. This involves researching the problem, collecting data, and understanding the constraints of the project. The information gathered should be used to develop a thorough understanding of the problem.

Generate Concepts

The third step is to generate concepts. This involves brainstorming, sketching, and exploring different ideas. The goal is to generate as many ideas as possible.

Evaluate Concepts

The fourth step is to evaluate the concepts. This involves selecting the most promising ideas and assessing their feasibility. The evaluation should take into account technical feasibility, economic viability, and market potential.

Develop a Solution

The fifth step is to develop a solution. This involves creating a detailed design that takes into account all the requirements of the project. The design should be technically sound, economically viable, and meet the needs of the market.

Test and Refine

The sixth step is to test and refine the solution. This involves building a prototype and testing it to ensure that it meets the requirements of the project. The prototype should be refined until it meets all the requirements.

Implement the Solution

The final step is to implement the solution. This involves producing the product, system, or infrastructure and bringing it to market. The implementation should be done in a way that ensures that the product, system, or infrastructure meets all the requirements of the project.

Best Practices for Designing Products

- Understand the User : It is important to understand the user when designing products, systems, and infrastructure. This involves understanding their needs, wants, and limitations. The design should be created with the user in mind and should meet their needs.

- Consider Sustainability : Sustainability should be considered when designing products, systems, and infrastructure. This involves designing products, systems, and infrastructure that are environmentally friendly and have a minimal impact on the environment.

- Use High-Quality Materials: High-quality materials should be used when designing products, systems, and infrastructure. This ensures that the product, system, or infrastructure is durable and long-lasting.

- Test and Validate: Testing and validating the design is critical to ensure that it meets the requirements of the project. This involves testing the design in a controlled environment and validating it against the requirements of the project.

- Use Simulation and Modeling: Simulation and modeling can be used to test the design and ensure that it meets the requirements of the project. This involves creating a virtual model of the product, system, or infrastructure and simulating its performance.

- Consider Safety and Reliability : Safety and reliability should be considered when designing products, systems, and infrastructure.

- Optimize Cost and Performance: Cost and performance should be optimized when designing products, systems, and infrastructure. This involves finding the balance between the cost of the design and its performance.

- Collaboration and Communication: Collaboration and communication are essential when designing products, systems, and infrastructure. This involves working with other members of the team to ensure that the design meets the requirements of the project and is feasible.

- Use Design Standards and Regulations : Design standards and regulations should be followed when designing products, systems, and infrastructure. This ensures that the design meets the required safety, quality, and performance standards.

- Continuous Improvement: Continuous improvement should be a part of the design process. This involves evaluating the design, gathering feedback, and making changes to improve its performance and meet the requirements of the project.

- Examples of Engineering: Design Engineering design is used in a wide range of industries and applications. Here are some examples of engineering design in action:

- Automotive Design: Automotive design involves the creation of vehicles that are safe, reliable, and efficient. The design process includes developing the body, chassis, engine, and transmission.

- Aerospace Design : Aerospace design involves the creation of aircraft, spacecraft, and satellites. The design process includes developing the aerodynamics, propulsion, and control systems.

- Civil Engineering Design : Civil engineering design involves the creation of infrastructure such as buildings, bridges, and roads. The design process includes developing structural, mechanical, and electrical systems.

- Consumer Product Design : Consumer product design involves the creation of products such as electronics, appliances, and furniture. The design process includes developing the product’s aesthetics, ergonomics, and usability.

- Environmental Engineering Design : Environmental engineering design involves the creation of systems and infrastructure that protect the environment. The design process includes developing waste management systems, water treatment systems, and renewable energy systems.

Conclusion Engineering design is a critical aspect of any successful project. The engineering design process provides a systematic approach to problem-solving, and best practices should be followed when designing products, systems, and infrastructure. Understanding the user, considering sustainability, using high-quality materials, testing and validating the design, using simulation and modeling, considering safety and reliability, optimizing cost and performance, collaborating and communicating, following design standards and regulations, and continuous improvement are all essential when designing products, systems, and infrastructure. Examples of engineering design can be seen in industries such as automotive design, aerospace design, civil engineering design, consumer product design, and environmental engineering design. By following the engineering design process and best practices, engineering design can create innovative and effective solutions to complex problems.

Useful Links:

- Productivity Tools

- Quality Tools

- Process optimization Tools

- Lean Manufacturing Tools

- How to Apply for MNC Jobs

What is engineering design?

Engineering design is the process of creating a solution to a problem or need using engineering principles and techniques. It involves the systematic application of scientific and mathematical principles to design a product, system, or infrastructure that meets specific requirements and satisfies the needs of the user.

What are the steps of the engineering design process?

The engineering design process typically involves the following steps: Define the problem Research and gather information Develop possible solutions Select the best solution Create a prototype or model Test and evaluate the prototype Refine and improve the design Finalize the design and prepare it for production

What are some best practices for engineering design?

Some best practices for engineering design include: Understanding the user’s needs and requirements Considering sustainability and the environmental impact of the design Using high-quality materials and components Testing and validating the design through simulations and prototypes Considering safety and reliability in the design Optimizing cost and performance Collaborating and communicating effectively with team members and stakeholders Following design standards and regulations Continuously improving and refining the design.

What are some examples of engineering design in action?

Engineering design can be seen in a variety of industries and applications, including: Automotive design Aerospace design Civil engineering design Consumer product design Environmental engineering design.

Why is engineering design important?

Engineering design is important because it allows engineers to create innovative and effective solutions to complex problems. By following a systematic design process and using best practices, engineers can create products, systems, and infrastructure that meet specific needs and requirements, while also being safe, reliable, and cost-effective. Effective engineering design can also have a positive impact on society and the environment.

Share this:

- Click to share on Facebook (Opens in new window)

- Click to share on Twitter (Opens in new window)

- Click to share on WhatsApp (Opens in new window)

- Click to share on LinkedIn (Opens in new window)

- Click to share on Pinterest (Opens in new window)

- Click to share on Telegram (Opens in new window)

- Click to print (Opens in new window)

- Click to email a link to a friend (Opens in new window)

Enter your active email address to subscribe to this blog and receive notifications of new updates by email.

Email Address

Recent Posts

- Best Practices Industrial Asset Management

- Techniques for materials handling and transporting

- Techniques for fostering innovation and entrepreneurship

- Best Practices for Professional Development

- Apply MNC Jobs

- Financial Management

- Industrial Trainer

- Lean Manufacturing

- Personality development

- Process Optimization

Best Practice

3G PRINCIPLE 3K PRINCIPLE 3M PRINCIPLE 3R 4M PRINCIPLE Avoid These Common Mistakes on a Job Interview Benefits of Kaizen Business Analysis capacity management Continual improvement Cybersecurity Cycle Time daily work management Examples gemba gembutsu genjitsu Industrial Trainer KAIZEN Kaizen continuous improvement Kaizen principles Kanban Lead Time Lean meaning Muda Mura Muri Objectives philosophy Process Process Analysis Quality Circle R&D RECYCLE Reduce Research and Development REUSE Rockwell hardness Significance Six Sigma Supply Chain Optimization The Secret of Standardization The Toyota 3M Model Total Productive Maintenance What is Capacity Management?

The Engineering Design Process

The engineering design process is a series of steps that engineers use to create solutions to problems. It is a structured approach to problem-solving that involves identifying a problem, defining the problem, generating potential solutions, evaluating those solutions, selecting the best solution, and implementing and testing that solution. The engineering design process is iterative, meaning that engineers often repeat some or all of the steps several times to refine their solution. It is a critical component of the field of engineering, as it allows engineers to solve complex problems and create new products and technologies. Effective use of the engineering design process requires a strong understanding of engineering principles, scientific methods, and mathematical analysis.

The engineering design process involves making a series of decisions. Each decision must be carefully considered and justified based on various factors such as function, safety, cost, and feasibility. Throughout the process, engineers must weigh the benefits and drawbacks of different options and choose the best course of action based on their knowledge, experience, and the available resources. Justifying decisions is an essential part of the design process as it helps to ensure that the final product meets the required specifications and functions as intended. By justifying each decision, engineers can also communicate their thought process to others involved in the project, such as clients, stakeholders, or team members, and gain their trust and support.

The engineering design process is nearly always iterative in nature. Retracing steps and going back to a previous decision is a common occurrence in the engineering design process. As new information is gathered or unforeseen challenges arise, engineers may realize that an earlier decision was not the best one. In such cases, it is important to reevaluate the decision, consider alternative options, and make a new decision based on the updated information. This process of reiteration and adjustment is a fundamental part of the design process, as it allows engineers to continually improve and refine their designs until they meet the desired specifications. Accepting that retracing steps is sometimes necessary can be challenging, but it is essential to maintain a flexible mindset and be willing to adapt as new information comes to light. By doing so, engineers can ensure that they are producing the best possible outcome for their project.

While there is no one-size-fits-all approach to the engineering design process, a typical process often includes the following steps:

- Define the problem : The first step in the design process is to clearly define the problem you are trying to solve. This involves understanding the needs and requirements of the user or customer, identifying any constraints or limitations, and setting specific goals and objectives.

- Conduct research : Once the problem has been defined, engineers typically conduct research to gain a deeper understanding of the problem and potential solutions. This may involve reviewing existing products or technologies, conducting experiments, or gathering data through surveys or other methods.

- Develop potential solutions : Using the information gathered during the research phase, engineers develop a range of potential solutions to the problem. This may involve brainstorming, sketching, or creating computer models of different designs.

- Evaluate potential solutions : Engineers then evaluate each potential solution based on a set of criteria, such as cost, performance, safety, and ease of use. This may involve creating prototypes, conducting simulations, or performing experiments to test each design.

- Select the best solution : After evaluating each potential solution, engineers select the best design to move forward with. This may involve combining different elements of different designs or modifying a design to better meet the requirements of the problem.

- Implement and test the solution : Once a design has been selected, engineers implement and test the solution. This may involve building a prototype, performing additional simulations or experiments, or conducting user testing to ensure that the solution meets the needs of the user or customer.

- Iterate and improve : The engineering design process is iterative, meaning that engineers often repeat some or all of these steps several times to refine their solution. This may involve making changes to the design based on user feedback or additional testing, or identifying new problems that need to be addressed.

Engineering Design Assumptions

Design Methodologies

Risk Mitigation through Design

Design Perspicuity

Engineering design – example projects.

Concurrent Design

FMEA - Failure Modes and Effects Analysis

Engineering design - example projects.

Engineering Design Explained: Process and Steps

- April 19, 2024

The engineering design process is arguably the cornerstone of product development projects, be it small-scale customized products or hi-tech industrial equipment. It provides engineers with clear guidelines on how to plan projects and track their progress. In this article, we will discuss the engineering design cycle and process in detail.

What is Engineering Design?

Let us begin with an overview of what is engineering design. A simple definition would be the application of engineering techniques and principles to solve a design problem creatively and systematically.

As it may seem, even our simple definition is a bit of a handful. For this reason, designers divide the whole process into various engineering design process steps, which adds clarity and structure to their work.

The engineering design cycle starts at the ideation stage and sees the product through from prototype to production , at which point it is ready to enter the market.

Engineering Design Process

The upcoming sections dive deeper into each stage of the process.

Problem Definition

Problem definition is the first, and arguably the most important, among engineering design process steps. At this stage, the engineering team sits down with product stakeholders, which includes people like investors, production managers, and the sales team.

The requirements of the product design are discussed in detail and the expectations of the entire group are clearly understood. This includes high-level targets like product functionality, aesthetic requirements, budgetary constraints, material limitations, product quality, etc.

The problem definition provides a framework for designers to base their work on. Goals are set for subsequent steps in the engineering design cycle accordingly, and it is common to revisit the problem statement if issues arise.

In the research phase of the engineering design process, engineers carry out an in-depth study of the project. This phase involves a thorough investigation to understand the problem from various sources like academic literature reviews, design consultations, and engineering design principles.

This research gives designers specific insight into the problem and sets the stage for informed decision-making. At the end of this process, the designers are well aware of the problems they may encounter and the positives they can utilize.

Design Requirements

Once the research phase is complete, engineers can define design requirements by translating their insights into specific criteria. These criteria are technical, specific, and measurable.

In a common engineering design process example, these requirements include targets like product weight, volume, useful life, user safety, and manufacturing costs.

Feasibility Study

Next comes the feasibility phase. It is a critical phase in the engineering design process that focuses on evaluating the real-world practicality and viability of potential solutions. Engineers weigh their ideas against constraints coming from technical, environmental, financial, and legal aspects.

In doing so, designers develop a broader understanding of the project beyond the core design aspects. Moreover, they can identify potential risks, challenges, and technologies that can help them define a practical way forward.

What’s more, ensuring project feasibility is usually critical to securing funding from investors too.

Concept Generation

Feasible projects enter the concept generation phase. This is an intensive brainstorming stage where the design team pitches ideas for different design concepts. The focus is on creativity and problem-solving, where team members are encouraged to find all possible solutions to the problem at hand.

Intensive brainstorming generally leads to a pool of potential design concepts that the team can then move ahead with.

After this initial stage, however, design engineers have idea-specific discussions to sift out poor ideas and direct their focus on concepts worth exploring further. It is an important phase in the engineering design process as low potential ideas are filtered out and the team gains clarity and direction regarding their approach.

Initial Design

After finalizing a concept to go ahead with, designers now need to get their hands dirty. The initial design stage is all about creating rough outlines or initial drafts of the proposed solution, with a focus on key features and design requirements.

Moreover, such designs are also a good way to communicate your design intent and ideas to non-engineering teams. This is an important aspect of engineering design as cross-team communication is necessary for ensuring progress and transparency in the process.

Such initial designs serve as a starting point for further refinement in upcoming stages.

Optimize Design and Engineering Drawing

By the end of the initial design stage, designers have generally gone through a lengthy process of elimination to pinpoint the exact design they want to move forward with. However, at this point in the engineering design process, the initial design is still far from a functioning design.

Therefore, the detailed design and optimization stage bridges the gap between conceptual and functional design. First, the initial design will add requisite details. Dimensions are finalized, materials are chosen, tolerances are determined, and assembly setup/constraints are defined. These are hardcore mechanical design activities that ensure the functionality and safety of an engineering design.

Engineers use engineering drawings to consolidate and communicate all this information within and across teams. After design, an optimization study may also be performed. This is a good design and engineering practice. It aims to maximize the performance of the product by finding the best configuration of design inputs (dimensions, orientation, engineering fits, etc.).

Prototype Development and Testing

The prototype development and testing phase focuses on transforming the product design into a working, tangible form. In this stage of the engineering design process, various rapid prototyping methods like 3D printing or CNC machining are utilized to manufacture working prototypes of the design.

After production, engineers use rigorous testing to identify flaws and areas for improvement. Tests may include failure testing, fatigue testing, overloading, etc. All these tests aim to simulate the real working environment of the product and to verify whether the design can work efficiently in those conditions or not.

This phase is usually very iterative as each cycle of testing reveals new issues that require rework on the design. The movement from conceptual design to final design takes time and patience on the design team’s end.

Moreover, this phase in the engineering design cycle also includes an in-depth design for manufacturing study. This analysis focuses on fine-tuning the design to ensure compatibility with manufacturing processes. For example, sharp internal corners may be rounded for convenient CNC machining.

By the end of the time-consuming prototype development and testing phase, the design is completely ready to go into batch production.

The final phase in the engineering design process is production. After this stage, the team launches the product in the market and it gets into the hands of end-users. Therefore, it is a critical stage as mistakes are not affordable and the stakes are high.

In the context of engineering design, the design team forwards its work to the production department. The production team then prepares a manufacturing plan based on factors like deadlines, chosen manufacturing processes, DFM analysis, quality and quantity requirements, and material availability.

For example, if the product quantity is low, the production team focuses on low-volume production methods like CNC machining or vacuum casting rather than injection molding or die casting.

After manufacturing, the products pass through a quality check system where requirements like dimensional and form tolerances, surface quality, and heat treatments are verified.

Most companies work with a pre-defined quality threshold. For example, a company operating on 6-Sigma levels must make sure that there are less than 3.4 defects per million opportunities. Such requirements help maintain manufacturing quality.

Finally, the production team packages the products and delivers them to the supply chain department.

This point marks the end of the engineering design cycle.

Important Skills to Master for Engineering Design

Engineering design is a growing field with a lot of scope for young professionals. It is constantly evolving and absorbing related disciplines into its large body of knowledge, underpinning the fact that design engineers need to stay up to date with contemporary technology to stay competitive.

While the development of the engineering design cycle is a broad topic, we will highlight some of its core skills for design engineers.

Engineering Knowledge

The first and foremost requirement to become a talented design engineer is to acquire engineering knowledge. This includes having a strong grasp of topics like machine design, thermal and fluid systems, manufacturing, and CAD. This list can go on, but we highlight some of the main topics for a basic overview.

Of course, depending on the designer’s specific industry, the knowledge requirements can change. It is good practice to identify your interests early on and start developing yourself in those specific skills to get a head start.

Creative Problem Solving

Design is all about finding creative solutions to complex problems. A design engineer must have the creative ability to come up with novel solutions to engineering problems. Additionally, these solutions should also be in line with the set design requirements and must obey design standards.

As you may imagine, it can get tough to think of ideas that are not only new and creative but also practical from an engineering perspective. Therefore, aspiring design engineers should put themselves through design projects to polish their skills and become good at their job.

Communication and Teamwork

The engineering design process is not simple, as we have seen. One person can rarely handle all the workload alone. Therefore, it is common to work in a team of technical and non-technical people while working on an engineering design project.

Therefore, one of the most important skills to have as engineers and manufacturers is communication and teamwork. If you are a good collaborator, you can carry your team very well. Team members contribute their share of the workload, complement each other’s capabilities, and maintain respectfulness.

Similarly, communication is a key skill to possess in teamwork. There are numerous situations where ineffective communication can cause problems. For example, not being able to communicate quality requirements to the production department can have serious consequences in the form of failed products.

Engineering Design and Design for Manufacturing

In this last section, we would like to touch upon the topic of engineering design and design for manufacturing. Both are highly interlinked fields that work together to make a product successful.

The engineering design process was fully explained in the previous sections. As we saw, it has numerous engineering design process steps and clearly defined roles for design engineers at each step.

Design for manufacturing, in simple words, is a specialized field that focuses on making a design convenient to manufacture. This is done by altering the design in such a way that its functionality remains unaffected, but it gets cheaper and quicker to produce.

A common example of DFM analysis is the usage of filleted internal corners, removal of deep and narrow slots, and avoiding thin walls in CNC machining to ensure better surface quality and minimal tool wear. This does not change anything about product utility, but it drastically decreases part rejections, cycle times, and material wastage.

WayKen Supports Your Engineering Design - From Prototype to Production

Engineering designs optimize for manufacturing feasibility and efficiency, minimize potential production challenges, and reduce lead times and costs. As a professional rapid manufacturing company , WayKen enhances the engineering design process by offering advanced production and manufacturing solutions to meet specific needs. With WayKen’s support, you can identify and address potential production issues early on, ensuring smoother transitions from design to production.

The engineering design process is surely an outstanding methodology for working with design problems. The various engineering design process steps make the entire process very systematic and easy to follow, helping design teams organize their work in a better way.

Why is prototyping important in the engineering design cycle?

Prototyping is crucial for validating the engineering design before it goes into full-time production. Due to the complex nature of engineering design projects, mistakes are expected to occur. The prototyping stage sifts out such design flaws and allows designers to improve the design over iterations.

What tools are used for engineering design?

Engineering design utilizes numerous tools like CAD, CAE, FEM, machine learning, life cycle analysis, etc. The exact choice of engineering tools depends on the engineering design process step and the nature of the project.

How to find the right manufacturer for engineering design?

Some of the factors you should consider while choosing a manufacturer for engineering design include manufacturing capabilities, quality of service, cost, material availability, and customer service.

- +86-19129903236

- [email protected]

- Contact Us on Skype

- Penglongpan Hi-tech Park, Dafu Rd, ShenZhen, China.

- +86 755 2373 1920

- [email protected]

Capabilities

- CNC Machining

- CNC Aluminum

- Clear Prototyping

- Vacuum Casting

- Rapid Tooling

- 3D Printing

- Parts Finishing

- About WayKen

- Get A Quote

- Quality Assurance

- Privacy Policy

- Service Agreement

An Inquiry-Based Introduction to Engineering pp 71–78 Cite as

Engineering Problem-Solving

- Michelle Blum 2

- First Online: 21 September 2022

549 Accesses

You are becoming an engineer to become a problem solver. That is why employers will hire you. Since problem-solving is an essential portion of the engineering profession, it is necessary to learn approaches that will lead to an acceptable resolution. In real-life, the problems engineers solve can vary from simple single solution problems to complex opened ended ones. Whether simple or complex, problem-solving involves knowledge, experience, and creativity. In college, you will learn prescribed processes you can follow to improve your problem-solving abilities. Also, you will be required to solve an immense amount of practice and homework problems to give you experience in problem-solving. This chapter introduces problem analysis, organization, and presentation in the context of the problems you will solve throughout your undergraduate education.

This is a preview of subscription content, log in via an institution .

Buying options

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Available as EPUB and PDF

- Compact, lightweight edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

- Durable hardcover edition

Tax calculation will be finalised at checkout

Purchases are for personal use only

https://www.merriam-webster.com/dictionary , viewed June 3, 2021.

Mark Thomas Holtzapple, W. Dan Reece (2000), Foundations of Engineering, McGraw-Hill, New York, New York, ISBN:978-0-07-029706-7.

Google Scholar

Aide, A.R., Jenison R.D., Mickelson, S.K., Northup, L.L., Engineering Fundamentals and Problem Solving, McGraw-Hill, New York, NY, ISBN: 978-0-07-338591-4.

Download references

Author information

Authors and affiliations.

Syracuse University, Syracuse, NY, USA

Michelle Blum

You can also search for this author in PubMed Google Scholar

End of Chapter Problems

1.1 ibl questions.

IBL1: Using standard problem-solving technique, answer the following questions

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, draw the vector representation of your path (hint: use a compass legend to help create your coordinate system)

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, explain how to calculate the velocity you ran in the north direction.

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, explain how to calculate the velocity you ran in the east direction.

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, explain how to calculate how far you ran in the north direction.

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, explain how to calculate how far you ran in the east direction.

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, how far north have you traveled in 5 min?

If you run in a straight line at a velocity of 10 mph in a direction of 35 degree North of East, how far east have you traveled in 5 min?

What type of problem did you solve?

IBL2: For the following scenarios, explain what type of problem it is that needs to be solved.

Scientists hypothesize that PFAS chemicals in lawn care products are leading to an increase in toxic algae blooms in lakes during summer weather.

An engineer notices that a manufacturing machine motor hums every time the fluorescent floor lights are turned on.

The U.N. warns that food production must be increased by 60% by 2050 to keep up with population growth demand.

Engineers are working to identify and create viable alternative energy sources to combat climate change.

1.2 Practice Problems

Make sure all problems are written up using appropriate problem-solving technique and presentation.

The principle of conservation of energy states that the sum of the kinetic energy and potential energy of the initial and final states of an object is the same. If an engineering student was riding in a 200 kg roller coaster car that started from rest at 10 m above the ground, what is the velocity of the car when it drops to 2.5 m above the ground?

Archimedes’ principle states that the total mass of a floating object equals the mass of the fluid displaced by the object. A 45 cm cylindrical buoy is floating vertically in the water. If the water density is 1.00 g/cm 3 and the buoy plastic has a density of 0.92 g/cm 3 determine the length of the buoy that is not submerged underwater.

A student throws their textbook off a bridge that is 30 ft high. How long would it take before the book hits the ground?

Rights and permissions

Reprints and permissions

Copyright information

© 2022 Springer Nature Switzerland AG

About this chapter

Cite this chapter.

Blum, M. (2022). Engineering Problem-Solving. In: An Inquiry-Based Introduction to Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-91471-4_6

Download citation

DOI : https://doi.org/10.1007/978-3-030-91471-4_6

Published : 21 September 2022

Publisher Name : Springer, Cham

Print ISBN : 978-3-030-91470-7

Online ISBN : 978-3-030-91471-4

eBook Packages : Engineering Engineering (R0)

Share this chapter

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Publish with us

Policies and ethics

- Find a journal

- Track your research

FREE K-12 standards-aligned STEM

curriculum for educators everywhere!

Find more at TeachEngineering.org .

- TeachEngineering

- Solving Everyday Problems Using the Engineering Design Cycle

Hands-on Activity Solving Everyday Problems Using the Engineering Design Cycle

Grade Level: 7 (6-8)

(two 60-minutes class periods)

Additional materials are required if the optional design/build activity extension is conducted.

Group Size: 4

Activity Dependency: None

Subject Areas: Science and Technology

NGSS Performance Expectations:

TE Newsletter

Engineering connection, learning objectives, materials list, worksheets and attachments, introduction/motivation, vocabulary/definitions, investigating questions, activity extensions, user comments & tips.

This activity introduces students to the steps of the engineering design process. Engineers use the engineering design process when brainstorming solutions to real-life problems; they develop these solutions by testing and redesigning prototypes that work within given constraints. For example, biomedical engineers who design new pacemakers are challenged to create devices that help to control the heart while being small enough to enable patients to move around in their daily lives.

After this activity, students should be able to:

- Explain the stages/steps of the engineering design process .

- Identify the engineering design process steps in a case study of a design/build example solution.

- Determine whether a design solution meets the project criteria and constraints.

- Think of daily life situations/problems that could be improved.

- Apply the engineering design process steps to develop their own innovations to real-life problems.

- Apply the engineering design cycle steps to future engineering assignments.

Educational Standards Each TeachEngineering lesson or activity is correlated to one or more K-12 science, technology, engineering or math (STEM) educational standards. All 100,000+ K-12 STEM standards covered in TeachEngineering are collected, maintained and packaged by the Achievement Standards Network (ASN) , a project of D2L (www.achievementstandards.org). In the ASN, standards are hierarchically structured: first by source; e.g. , by state; within source by type; e.g. , science or mathematics; within type by subtype, then by grade, etc .

Ngss: next generation science standards - science, international technology and engineering educators association - technology.

View aligned curriculum

Do you agree with this alignment? Thanks for your feedback!

State Standards

Massachusetts - science.

Each group needs:

- Marisol Case Study , one per student

- Group Leader Discussion Sheet , one per group

To share with the entire class:

- computer/projector setup to show the class the Introduction to the Engineering Design Cycle Presentation , a Microsoft® PowerPoint® file

- paper and pencils

- (optional) an assortment of scrap materials such as fabric, super glue, wood, paper, plastic, etc., provided by the teacher and/or contributed by students, to conduct the hands-on design/build extension activity

(Have the 19-slide Introduction to the Engineering Design Cycle Presentation , a PowerPoint® file, ready to show the class.)

Have you ever experienced a problem and wanted a solution to it? Maybe it was a broken backpack strap, a bookshelf that just kept falling over, or stuff spilling out of your closet? (Let students share some simple problems with the class). With a little bit of creativity and a good understanding of the engineering design process, you can find the solutions to many of these problems yourself!

But what is the engineering design process? (Listen to some student ideas shared with the class.) The engineering design process, or cycle, is a series of steps used by engineers to guide them as they solve problems.

(Show students the slide presentation. Refer to the notes under each slide for a suggested script and comments. The slides introduce the main steps of the engineering design process, and walk through a classroom problem—a teacher’s disorganized desk that is preventing timely return of graded papers—and how students devise a solution. It also describes the work of famous people—Katherine Johnson, Lee Anne Walters, Marc Edwards, James E. West and Jorge Odón—to illustrate successful examples of using the steps of the engineering design process.)

Now that we’ve explore the engineering design process, let’s see if we can solve a real-world problem. Marisol is a high-school student who is very excited to have their own locker. They have lots of books, assignments, papers and other items that they keep in their locker. However, Marisol is not very organized. Sometimes they are late to class because they need extra time to find things that were stuffed into their locker. What is Marisol’s problem? (Answer: Their locker is disorganized.) In your groups, you’ll read through Marisol’s situation and see how they use the engineering design process to solve it. Let’s get started!

This activity is intended as an introduction to the engineering design cycle. It is meant to be relatable to students and serve as a jumping off point for future engineering design work.

Engineers follow the steps of the engineering design process to guide them as they solve problems. The steps shown in Figure 1 are:

Ask: identify the need & constraints

- Identify and define the problem. Who does the problem affect? What needs to be accomplished? What is the overall goal of the project?

- Identify the criteria and constraints. The criteria are the requirements the solution must meet, such as designing a bag to hold at least 10 lbs. Constraints are the limitations and restrictions on a solution, such as a maximum budget or specific dimensions.

Research the problem

- Learn everything you can about the problem. Talk to experts and/or research what products or solutions already exist.

- If working for a client, such as designing new filters for a drinking water treatment plant, talk with the client to determine the needs and wants.

Imagine: develop possible solutions

- Brainstorm ideas and come up with as many solutions as possible. Wild and crazy ideas are welcome! Encourage teamwork and building on ideas.

Plan: select a promising solution

- Consider the pros and cons of all possible solutions, keeping in mind the criteria and constraints.

- Choose one solution and make a plan to move forward with it.

Create: build a prototype

- Create your chosen solution! Push for creativity, imagination and excellence in the design.

Test and evaluate prototype

- Test out the solution to see how well it works. Does it meet all the criteria and solve the need? Does it stay within the constraints? Talk about what worked during testing and what didn’t work. Communicate the results and get feedback. What could be improved?

Improve: redesign as needed

- Optimize the solution. Redesign parts that didn’t work, and test again.

- Iterate! Engineers improve their ideas and designs many times as they work towards a solution.

Some depictions of the engineering design process delineate a separate step—communication. In the Figure 1 graphic, communication is considered to be incorporated throughout the process. For this activity, we call out a final step— communicate the solution —as a concluding stage to explain to others how the solution was designed, why it is useful, and how they might benefit from it. See the diagram on slide 3.

For another introductory overview of engineering and design, see the What Is Engineering? What Is Design? lesson and/or show students the What Is Engineering? video.

Before the Activity

- Make copies of the five-page Marisol Case Study , one per student, and the Group Leader Discussion Sheet , one per group.

- Be ready to show the class the Introduction to the Engineering Design Cycle Presentation , a PowerPoint® file.

With the Students

- As a pre-activity assessment, spend a few minutes asking students the questions provided in the Assessment section.

- Present the Introduction/Motivation content to the class, which includes using the slide presentation to introduce students to the engineering design cycle. Throughout, ask for their feedback, for example, any criteria or constraints that they would add, other design ideas or modifications, and so forth.

- Divide the class into groups of four. Ask each team to elect a group leader. Hand out the case study packets to each student. Provide each group leader with a discussion sheet.

- In their groups, have students work through the case study together.

- Alert students to the case study layout with its clearly labeled “stop” points, and direct them to just read section by section, not reading beyond those points.

- Suggest that students either taking turns reading each section aloud or read each section silently.

- Once all students in a group have read a section, the group leader refers to the discussion sheet and asks its questions of the group, facilitating a discussion that involves every student.

- Encourage students to annotate the case study as they like; for example, they might note in the margins Marisol’s stage in the design process at various points.

- As students work in their groups, walk around the classroom and encourage group discussion. Ensure that each group member contributes to the discussion and that group members are focused on the same section (no reading ahead).

- After all teams have finished the case study and its discussion questions, facilitate a class discussion about how Marisol used the engineering design cycle. This might include referring back to questions 4 and 5 in “Stop 5” to discuss remaining questions about the case study and relate the case study example back to the community problems students suggested in the pre-activity assessment.

- Administer the post-activity assessment.

brainstorming: A team creativity activity with the purpose to generate a large number of potential solutions to a design challenge.

constraint: A limitation or restriction. For engineers, design constraints are the requirements and limitations that the final design solutions must meet. Constraints are part of identifying and defining a problem, the first stage of the engineering design cycle.

criteria: For engineers, the specifications and requirements design solutions must meet. Criteria are part of identifying and defining a problem, the first stage of the engineering design cycle.

develop : In the engineering design cycle, to create different solutions to an engineering problem.

engineering: Creating new things for the benefit of humanity and our world. Designing and building products, structures, machines and systems that solve problems. The “E” in STEM.

engineering design process: A series of steps used by engineering teams to guide them as they develop new solutions, products or systems. The process is cyclical and iterative. Also called the engineering design cycle.

evaluate: To assess something (such as a design solution) and form an idea about its merit or value (such as whether it meets project criteria and constraints).

optimize: To make the solution better after testing. Part of the engineering design cycle.

Pre-Activity Assessment

Intro Discussion: To gauge how much students already know about the activity topic and start students thinking about potential design problems in their everyday lives, facilitate a brief class discussion by asking students the following questions:

- What do engineers do? (Example possible answers: Engineers design things that help people, they design/build/create new things, they work on computers, they solve problems, they create things that have never existed before, etc.)

- What are some problems in your home, school or community that could be solved through engineering? (Example possible answers: It is too dark in a community field/park at night, it is hard to carry shopping bags in grocery store carts, the dishwasher does not clean the dishes well, we spend too much time trying to find shoes—or other items—in the house/garage/classroom, etc.)

- How do engineers solve problems? (Example possible answers: They build new things, design new things, etc. If not mentioned, introduce students to the idea of the engineering design cycle. Liken this to how research scientists are guided by the steps of the scientific method.)

Activity Embedded Assessment

Small Group Discussions: As students work, observe their group discussions. Make sure the group leaders go through all the questions for each section, and that each group member contributes to the discussions.

Post-Activity Assessment

Marisol’s Design Process: Provide students with writing paper and have them write “Marisol’s Design Process” at the top. Direct them to clearly write out the steps that Marisol went through as they designed and completed their locker organizer design and label them according to where they fit in the engineering design cycle. For example, “Marisol had to jump back to avoid objects falling out of their locker” and they stated a desire to “wanted to find a way to organize their locker” both illustrate the “identifying the problem” step.

- Which part of the engineering design cycle is Marisol working on as they design an organizer?

- Why is it important to identify the criteria and constraints of a project before building and testing a prototype? (Example possible answers: So that the prototype will be the right size, so that you do not go over budget, so that it will solve the problem, etc.)

- Why do engineers improve and optimize their designs? (Example possible answers: To make it work better, to fix unexpected problems that come up during testing, etc.)

To make this a more hands-on activity, have students design and build their own locker organizers (or other solutions to real-life problems they identified) in tandem with the above-described activity, incorporating the following changes/additions to the process:

- Before the activity: Inform students that they will be undertaking an engineering design challenge. Without handing out the case study packet, introduce students to Marisol’s problem: a disorganized locker. Ask students to bring materials from home that they think could help solve this problem. Then, gather assorted materials (wood and fabric scraps, craft materials, tape, glue, etc.) to provide for this challenge, giving each material a cost (for example, wood pieces cost 50¢, fabric costs 25¢, etc.) and write these on the board or on paper to hand out to the class.

- Present the Introduction/Motivation content and slides to introduce students to the engineering design process (as described above). Then have students go through the steps of the engineering design process to create a locker organizer for Marisol. Inform them Marisol has only $3 to spend on an organizer, so they must work within this budget constraint. As a size constraint, tell students the locker is 32 inches tall, 12 inches wide and 9.5 inches deep. (Alternatively, have students measure their own lockers and determine the size themselves.)

- As students work, ask them some reflection questions such as, “Which step of the engineering design process are you working on?” and “Why have you chosen that solution?”

- Let groups present their organizers to the class and explain the logic behind their designs.

- Next, distribute the case study packet and discussion sheets to the student groups. As the teams read through the packet, encourage them to discuss the differences between their design solutions and Marisol’s. Mention that in engineering design there is no one right answer; rather, many possible solutions may exist. Multiple designs may be successful in imagining and fabricating a solution that meets the project criteria and constraints.

Engineering Design Process . 2014. TeachEngineering, Web. Accessed June 20, 2017. https://www.teachengineering.org/k12engineering/designprocess

Contributors

Supporting program, acknowledgements.

This material is based upon work supported by the National Science Foundation CAREER award grant no. DRL 1552567 (Amy Wilson-Lopez) titled, Examining Factors that Foster Low-Income Latino Middle School Students' Engineering Design Thinking in Literacy-Infused Technology and Engineering Classrooms. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Last modified: October 26, 2023

Understanding the engineering design process

Last updated

5 March 2024

Reviewed by

Mary Mikhail

To avoid the likelihood of failure, experienced engineers and designers use a structured decision-making process during the product innovation and development phase. This engineering design process facilitates problem-solving through:

Innovative thinking

Learning from failure

Using the engineering design process, you can identify how your products can solve problems and enable you to troubleshoot issues that could prevent the end product from delivering ideal results.

In this article, we'll explain exactly what the engineering design process is and provide a step-by-step guide for using it for the development of your next product.

- What is the engineering design process?

The engineering design process is an iterative process of brainstorming, troubleshooting, and developing a product to solve a specific problem. The steps in the process encourage open-ended problem-solving and learning from failure.

When product designers use the engineering design process, they apply engineering experience, industry knowledge, and technology to design and build solutions for specific problems.

While the process follows a defined pattern, it is iterative to yield the best results. Some steps may be completed out of order or repeated to eliminate issues or examine areas of concern. The engineering design process is commonly used on any project that requires designing, building, and testing a product.

The principles of good engineering design

There are multiple variations of the engineering design process. However, good engineering design incorporates specific underlying principles.

These principles create a foundation to guide the engineering design process:

Engineering is a process with defined steps to provide the best solution to a specific problem.

The design process is iterative, requiring some steps to be repeated or carried out in a nonsequential format.

Analyzing and evaluating different solutions is an essential part of the process, to identify different strengths and weaknesses and follow the design specifications.

Failure is expected and used as a learning tool during the process.

Why is engineering design important for innovation?

The engineering design process was developed to create products that meet the needs of a target audience. By taking a structured approach to design that follows a defined path from problem to solution, engineers can research multiple ideas to determine which solution is most viable.

The process is iterative and flexible to encourage creativity. These features combine to create a method that produces innovative thinking and multiple solutions to complex problems.

- Benefits of the engineering design process

The engineering design process turns ideas into practical solutions. This structured approach that cultivates creativity and breeds innovation brings several benefits.

Improved product quality

The engineering product design process follows specific steps to ensure every possibility is explored. Since the process promotes problem-solving, working in iterations, and extensive testing, the most innovative ideas bubble to the top for further development.

Collaboration

By using tactics like brainstorming, group thinking, prototyping, and testing, you encourage collaboration between various stakeholders, including:

Manufacturers

Multiple experts working toward a common goal can help you eliminate possible issues or shortfalls before a product is in the hands of customers.

Cost savings

By working with multiple ideas and identifying potential design flaws early in the process, you can greatly reduce the risk of a product going all the way to completion with flaws. Testing throughout the process addresses errors in real time and keeps rework to a minimum.

Faster time to market

Since the process requires teams to often repeat steps multiple times, you may be concerned about the development phase being prolonged. However, the ability to identify potential issues early reduces overall project duration, as less time is spent on revisions later on.

Increased innovation

The engineering design process is centered around creative thinking to promote the best solutions for a specific problem. It is typically carried out by multiple team members and encourages the use of failed projects as stepping stones to a better solution.

- A step-by-step guide to the engineering design process

The engineering design process is designed to be versatile to meet the requirements of different types of projects. As such, the process can be adapted to include fewer or more steps.

It's also important to remember that the process is iterative, and steps may be repeated as needed to achieve a specific objective.

These steps cover the basics of the engineering design process.

1. Define the problem you want to solve with your product

To develop an effective solution, you must clearly define the problem, any known constraints to solving it, and the end user's needs.

Once you've identified the problem, clarify why it's a problem and the size of the audience who will be interested in a solution. Examine the problem from different viewpoints to ensure you understand its impact.

2. Ask questions and conduct relevant research

Dig deeper into the reason for the problem and whether potential solutions already exist. Ask these questions to guide your research:

Why is this a problem?

Why is it important to develop a solution to this problem?

Who can the right solution help?

Do solutions already exist? If so, why aren't they being used, or how is our solution going to be better?

Are there financial, legal, technical, or other restraints that could introduce new requirements for the solution?

3. Imagine possible solutions

Once you have all the information to hand, brainstorm a list of possible solutions.

Generate as many ideas as possible, including unconventional ones. Involve industry experts, employees, experienced professionals, and other stakeholders in the brainstorming process to get multiple perspectives.

Combine all prospective solutions into a list for consideration.

Examine your list and research each proposed solution. List the pros and cons of each solution to rank your list in order of viability.

Eliminate solutions that are less viable or have too many flaws. Continue to narrow down the list until you arrive at the ideal solution.

Draw up a product design to solve the problem while addressing constraints and potential issues that may arise during the build.

5. Develop a prototype

Use your plan to create an early prototype of your product. The prototype should be designed with cost-effectiveness in mind and can be made from different materials than the final product. It's also common to leave finishing touches off early prototypes so that you can concentrate on the overall concept.

Once you've created a usable prototype, it's time to conduct testing. Run a series of tests to determine how well the product works, not only in normal operating conditions but also in different conditions that introduce extra stress.

Use the tests to simulate potential real-life scenarios. Even if the prototype is functional, it may not meet all your expectations. Note where the product falls short, so improvements can be made during subsequent iterations.

7. Make improvements

If the prototype is a complete failure, you have choices to make. You can either revisit some of your earlier solutions or brainstorm ideas that will eliminate the problems.

If your prototype didn't meet all your expectations, it can still be called a success. Use your notes to investigate the areas where the prototype under-performed and consider ways to improve these specific issues.

Improve upon your existing prototype or design a new iteration of the prototype and test your product again. Repeat the testing and improvement process as many times as necessary to yield the best possible product.

8. Communicate the results

The final stage of the engineering design process is to share your results. You can create reports, presentations, and displays as needed to share the functionality of your product and why it's the best solution to the problem at hand.

Your documentation will be used to share the product's value with stakeholders and enable the finished product to be manufactured to the required standards. You may need to participate in meetings and presentations to share the results of the engineering design process with managers, engineers, board directors, shareholders, and even potential customers.

Once you have the go-ahead from all decision-makers, you’re ready to build.

- Engineering design process examples

The engineering design process can be applied to a broad range of products. Let’s look at a couple of examples.

Developing a new gaming app

Let’s imagine you’d like to develop a new app in the form of a game.

Define the problem: What is the problem that your app will solve? Boredom? Lack of mental stimulation? Kids needing to be kept occupied? Parents needing to unwind? Relieving anxiety?

Research: How widespread is this problem? Find out what games are already available that solve this problem. Do they do it well, or is there a gap in the market for a game that will do it better? Are there any good reasons not to develop such a game?

Imagine solutions: With your team and relevant stakeholders, brainstorm as many games as possible. Let your imagination run riot!

Plan: List the pros and cons of each of your game ideas. Narrow down the list and plan a design for the one you decide to go ahead with.

Develop a prototype: The prototype doesn’t need to be complex, just with enough elements to give testers an idea of the game and how it can solve the problem you originally pinpointed.

Test: Find testers to try out your prototype game. Gather feedback from them.

Make improvements: Adjust your prototype based on the feedback from testers. Return to the testing step and keep repeating these two stages (testing and improving) until you have the best possible version of the game.

Share results: Create a report or presentation to communicate your decisions to stakeholders. Convince them of why this is the best solution. Once your game idea is signed off, it’s time to start developing the actual product!

Creating a kitchen appliance

There are so many gadgets available to make our lives easier in the kitchen, and people always seem to want more! Imagine you’d like to be the next big thing in the world of kitchen appliances.

Define the problem: What is the problem that your appliance will solve? Will it save time, effort, or money (or all three?) Will it reduce mess? Maybe it will increase safety in the kitchen or make it easier to create delicious meals.

Research: How widespread is the problem you’re trying to solve? Find out what appliances are already available that solve this problem. Do they do it well, or is there a gap in the market for a better appliance? Are there any good reasons not to create this appliance?

Imagine solutions: Brainstorm as many appliance solutions as possible. Be creative. Nothing is impossible at this stage!

Plan: What advantages and disadvantages are there for each of your appliance ideas? Narrow down the list of possible appliances, and plan a design for your favorite one.

Develop a prototype: This doesn’t need to be made from the same materials as the final appliance, nor does it need to have the same functionality. It needs to be enough for the testers to get an idea of the appliance and how it will solve a particular problem in the kitchen.

Test: Gather feedback from people who are willing to test your prototype appliance.

Make improvements: Adjust your prototype appliance based on the feedback from testers. Return to the testing step and keep repeating these two stages (testing and improving) until your prototype appliance receives no more negative feedback.

Share results: Tell your stakeholders about your appliance through a report or presentation. Convince them of why this is the best solution. Once it is signed off, you can start the production phase.

Get started today

Go from raw data to valuable insights with a flexible research platform

Editor’s picks

Last updated: 8 April 2024

Last updated: 17 April 2024

Last updated: 12 April 2024

Last updated: 18 April 2024

Last updated: 27 March 2023

Last updated: 26 May 2023

Last updated: 12 April 2023

Latest articles

Related topics, log in or sign up.

Get started for free

- Business Essentials

- Leadership & Management

- Credential of Leadership, Impact, and Management in Business (CLIMB)

- Entrepreneurship & Innovation

- Digital Transformation

- Finance & Accounting

- Business in Society

- For Organizations

- Support Portal

- Media Coverage

- Founding Donors

- Leadership Team

- Harvard Business School →

- HBS Online →

- Business Insights →

Business Insights

Harvard Business School Online's Business Insights Blog provides the career insights you need to achieve your goals and gain confidence in your business skills.

- Career Development

- Communication

- Decision-Making

- Earning Your MBA

- Negotiation

- News & Events

- Productivity

- Staff Spotlight

- Student Profiles

- Work-Life Balance

- AI Essentials for Business

- Alternative Investments

- Business Analytics

- Business Strategy

- Business and Climate Change

- Design Thinking and Innovation

- Digital Marketing Strategy

- Disruptive Strategy

- Economics for Managers

- Entrepreneurship Essentials

- Financial Accounting

- Global Business

- Launching Tech Ventures

- Leadership Principles

- Leadership, Ethics, and Corporate Accountability

- Leading with Finance

- Management Essentials

- Negotiation Mastery

- Organizational Leadership

- Power and Influence for Positive Impact

- Strategy Execution

- Sustainable Business Strategy

- Sustainable Investing

- Winning with Digital Platforms

7 Engineering Challenges Design Thinking Can Help Solve

- 19 Jan 2023

Several challenges face the engineering industry. Addressing them requires innovative solutions and structured processes, such as design thinking.

If you’re an engineer who wants to develop business skills , here's an overview of design thinking and seven engineering challenges it can help solve.

What Is Design Thinking?

Design thinking is one of the most effective approaches to problem-solving. It’s a solutions-based methodology focused on human-centered design and observing problems with empathy.

In the online course Design Thinking and Innovation , Harvard Business School Dean Srikant Datar structures the process using a four-stage framework. The stages are:

In the clarification stage, you observe a situation or challenge without bias and frame your findings in the form of a problem statement.

“Before you begin to generate innovative solutions for your own design problem, you must always think hard about how you’re going to frame that problem,” Datar says in the course.

Reframing the problem as a question is an excellent way to do this. For example, using "how might we" instead of "the problem is" can encourage empathy in the design process and shift your mindset toward potential solutions.

These questions are particularly important when considering empathetic design. According to the Harvard Business Review , engineers who put themselves in their audience's shoes while designing often develop innovative products . By understanding your audience’s unexpressed needs, you can effectively leverage your technical knowledge to create innovative solutions to previously unknown problems.

Once you've made your observations, you can explore potential solutions. The ideate stage is for divergent thinking—the process of exploring as many ideas as possible. It involves:

- Finding and categorizing similarities in users' pain points

- Considering the resources available to you and how you can use them to solve a problem

- Brainstorming potential solutions

Creativity and an open mind are vital at this stage. As you explore ideas, they can highlight other problems you were unaware of.

The development stage focuses on turning your ideas into workable prototypes. For ideas to be innovative, they must be both new and useful ; many, though creative, aren't feasible.

"As you prototype concepts in phase three, you may discover results that force you to return to phases one and two to reframe your question," Datar says in Design Thinking and Innovation .

This iteration can occur in any of the four stages because each involves a different level of exploration that highlights new problems, questions, or solutions. This isn't cause for discouragement.

"Do not think of this as a setback,” Datar says in the course. “Iterating on solutions is a normal and expected result of design thinking.”

Design thinking’s ultimate objective is finding effective, workable solutions. The implementation phase involves finalizing developments and communicating their value to stakeholders.

This final stage can be challenging for many engineers. Since their work is so technical, it’s sometimes difficult for stakeholders to understand their impact on the organization. As a result, engineers should develop effective communication skills to ensure their ideas are implemented.

The Importance of Design Thinking in Engineering

Design thinking is a valuable skill for engineers to learn for several reasons. For one, engineering positions are among the most common occupations requiring design thinking skills .