- Career Paths

- Diversity, Equity, and Inclusion

- DMSE Job Opportunities

- Our Faculty

- Computing and Data Science

- Energy and the Environment

- Health and Medicine

- Manufacturing

- Transportation and Infrastructure

- Archaeological Materials

- Semiconductors

- Soft Matter

- Characterization

- Computation and Design

Device Fabrication

- Synthesis and Processing

- Impact Stories

- Research Facilities

- Majors, Minors, and Concentration

- Opportunities For First-Year Students

- Opportunities for DMSE Undergraduates

- DMSE Breakerspace

- Wulff Lecture

- Application Assistance and Resources

- Doctoral Degree and Requirements

- Master’s Degree and Requirements

- Interdisciplinary Graduate Programs

- Funding Opportunities

- Postdoctoral Program

- MITx Online

- Newsletter Archive

- FORGE Initiative

Putting it All Together

In materials science and engineering, device fabrication is the process of assembling discrete materials into a functional form. Materials scientists and engineers build devices, such as electronic or optical devices, with tailored properties that can be used for a range of applications, including information technology, renewable energy, and medical treatment.

The steps involved in device fabrication can vary depending on the type of device being developed and the materials used. For example, the fabrication process for a solar cell may involve the layering of thin films of photovoltaic materials onto a surface; producing a semiconductor device may involve the use of lithography to etch a silicon wafer.

Device Fabrication at DMSE

DMSE researchers make all kinds of devices. They’re developing new materials and processes for fabricating more efficient solar cells and devices for storing energy such as solar cells and batteries. Research teams are assembling electronics components such as diodes and transistors, including a rechargeable battery in the form of a fiber that can be woven into fabrics. And for health and medicine, they’re fashioning fibers from polymers and composite materials that can deliver drugs to the brain.

Related Materials

Related faculty and researchers.

Key Publications

Significantly enhanced sub-ambient passive cooling enabled by evaporation, radiation, and insulation, what we did.

Achieved substantial cooling capacity by controlling the effects of evaporative cooling, radiation, and thermal transport. Even in high-humidity areas, the process works without electricity and needs very little water.

Why we did it

Why it matters, reconfigurable all-dielectric metalens with diffraction-limited performance.

Proved that you don’t need mechanical movement to change the focus of a lens. Instead, a transparent “metalens” changes the way it interacts with infrared light when it undergoes heat-based phase transformation. To see objects far and near, one would simply heat the material using microheaters.

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Perspective

- Published: 19 June 2023

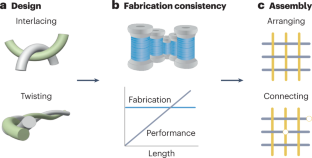

Design, fabrication and assembly considerations for electronic systems made of fibre devices

- Kaiwen Zeng 1 na1 ,

- Xiang Shi 1 na1 ,

- Chengqiang Tang 1 na1 ,

- Ting Liu 2 &

- Huisheng Peng ORCID: orcid.org/0000-0002-2142-2945 1

Nature Reviews Materials volume 8 , pages 552–561 ( 2023 ) Cite this article

4989 Accesses

12 Citations

4 Altmetric

Metrics details

- Electronic devices

- Electronic materials

Fibre electronic devices with one-dimensional configurations have attracted increasing interest because they are highly flexible and can be deformed. In particular, they can be woven into breathable and comfortable textiles for wearable applications. Fibre devices with various functionalities, such as energy harvesting and storage, sensing, and display, have thus been extensively explored. However, most fibre devices work individually rather than as systems. This Perspective aims to highlight promising design concepts, assembly strategies and performance improvements for fibre electronic systems. Their real-life applications are then analysed from a multidisciplinary point of view involving materials science, electrical engineering, textile engineering and health monitoring. The remaining challenges are finally summarized to guide future research for both academia and industry.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

24,99 € / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

111,21 € per year

only 9,27 € per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

High-quality semiconductor fibres via mechanical design

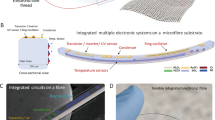

Integration of multiple electronic components on a microfibre towards an emerging electronic textile platform

Design and fabrication of wearable electronic textiles using twisted fiber-based threads

Xu, X., Xie, S., Zhang, Y. & Peng, H. The rise of fiber electronics. Angew. Chem. Int. Ed. 58 , 13643–13653 (2019).

CAS Google Scholar

Heo, J. S., Eom, J., Kim, Y. H. & Park, S. K. Recent progress of textile-based wearable electronics: a comprehensive review of materials, devices, and applications. Small 14 , 1703034 (2018).

Google Scholar

Zeng, W. et al. Fiber-based wearable electronics: a review of materials, fabrication, devices, and applications. Adv. Mater. 26 , 5310–5336 (2014).

Fakharuddin, A. et al. Fiber-shaped electronic devices. Adv. Energy Mater. 11 , 2101443 (2021).

Liu, R., Wang, Z. L., Fukuda, K. & Someya, T. Flexible self-charging power sources. Nat. Rev. Mater. 7 , 870–886 (2022).

Chen, C. et al. Functional fiber materials to smart fiber devices. Chem. Rev. 123 , 613–662 (2023).

Chen, G. et al. Electronic textiles for wearable point-of-care systems. Chem. Rev. 122 , 3259–3291 (2022).

Libanori, A., Chen, G., Zhao, X., Zhou, Y. & Chen, J. Smart textiles for personalized healthcare. Nat. Electron. 5 , 142–156 (2022).

Wang, L. et al. Application challenges in fiber and textile electronics. Adv. Mater. 32 , 1901971 (2020).

Ates, H. C. et al. End-to-end design of wearable sensors. Nat. Rev. Mater. 7 , 887–907 (2022).

Zheng, Y. Q. et al. Monolithic optical microlithography of high-density elastic circuits. Science 373 , 88–94 (2021).

Dong, K. et al. Advances in high-performance autonomous energy and self-powered sensing textiles with novel 3D fabric structures. Adv. Mater. 34 , 2109355 (2022).

Wang, Y., Yokota, T. & Someya, T. Electrospun nanofiber-based soft electronics. npg Asia Mater. 13 , 22 (2021).

Peng, H. Fiber electronics. Adv. Mater. 32 , 1904697 (2020).

Xu, Y. et al. A one-dimensional fluidic nanogenerator with a high power conversion efficiency. Angew. Chem. Int. Ed. 56 , 12940–12945 (2017).

Liu, P. et al. Polymer solar cell textiles with interlaced cathode and anode fibers. J. Mater. Chem. A 6 , 19947–19953 (2018).

Chen, C. et al. Direct current fabric triboelectric nanogenerator for biomotion energy harvesting. ACS Nano 14 , 4585–4594 (2020).

Liao, M., Ye, L., Zhang, Y., Chen, T. & Peng, H. The recent advance in fiber-shaped energy storage devices. Adv. Electron. Mater. 5 , 1800456 (2019).

Wang, L. et al. Functionalized helical fibre bundles of carbon nanotubes as electrochemical sensors for long-term in vivo monitoring of multiple disease biomarkers. Nat. Biomed. Eng. 4 , 159–171 (2020).

Shi, X. et al. Large-area display textiles integrated with functional systems. Nature 591 , 240–245 (2021).

Choi, H. W. et al. Smart textile lighting/display system with multifunctional fibre devices for large scale smart home and IoT applications. Nat. Commun. 13 , 814 (2022).

He, J. et al. Scalable production of high-performing woven lithium-ion fibre batteries. Nature 597 , 57–63 (2021).

Seyedin, S. et al. Fibre electronics: towards scaled-up manufacturing of integrated e-textile systems. Nanoscale 13 , 12818–12847 (2021).

Zhao, X. et al. Soft fibers with magnetoelasticity for wearable electronics. Nat. Commun. 12 , 6755 (2021).

AMERI Research. Smart textiles market to 2024: key product categories (active, passive, ultra smart), application (sensing, thermo-electricity, energy harvesting, luminescence & aesthetics), end-use, regional segmentation, competitive dynamics, M&A insights, pricing analysis (OPP, IPP, RAP) and segment forecast. AMERI Research https://www.ameriresearch.com/product/smart-textiles-market/ (2017).

Sun, H., Zhang, Y., Zhang, J., Sun, X. & Peng, H. Energy harvesting and storage in 1D devices. Nat. Rev. Mater. 2 , 17023 (2017).

Khudiyev, T. et al. Thermally drawn rechargeable battery fiber enables pervasive power. Mater. Today 52 , 80–89 (2022).

Liao, M. et al. Industrial scale production of fibre batteries by a solution-extrusion method. Nat. Nanotechnol. 17 , 372–377 (2022).

Zhang, Y., Wang, H., Lu, H., Li, S. & Zhang, Y. Electronic fibers and textiles: recent progress and perspective. iScience 24 , 102716 (2021).

Agcayazi, T., Chatterjee, K., Bozkurt, A. & Ghosh, T. K. Flexible interconnects for electronic textiles. Adv. Mater. Technol. 3 , 1700277 (2018).

Castano, L. M. & Flatau, A. B. Smart fabric sensors and e-textile technologies: a review. Smart Mater. Struct. 23 , 053001 (2014).

Loke, G. et al. Digital electronics in fibres enable fabric-based machine-learning inference. Nat. Commun. 12 , 3317 (2021).

Rein, M. et al. Diode fibres for fabric-based optical communications. Nature 560 , 214–218 (2018).

Zhang, Z. et al. A one-dimensional soft and color-programmable light-emitting device. J. Mater. Chem. C 6 , 1328–1333 (2018).

Zhang, Z. et al. Textile display for electronic and brain-interfaced communications. Adv. Mater. 30 , 1800323 (2018).

Zhang, Z. et al. A colour-tunable, weavable fibre-shaped polymer light-emitting electrochemical cell. Nat. Photon. 9 , 233–238 (2015).

Ye, L. et al. Stabilizing lithium into cross-stacked nanotube sheets with an ultra-high specific capacity for lithium oxygen batteries. Angew. Chem. Int. Ed. 58 , 2437–2442 (2019).

Chen, J. Y. et al. Electrospun poly(3-hexylthiophene) nanofibers with highly extended and oriented chains through secondary electric field for high-performance field-effect transistors. Adv. Electron. Mater. 1 , 1400028 (2015).

Yang, Q. et al. In situ formation of Co 9 S 8 quantum dots in MOF-derived ternary metal layered double hydroxide nanoarrays for high-performance hybrid supercapacitors. Adv. Energy Mater. 10 , 1903193 (2020).

Fu, X., Xu, L., Li, J., Sun, X. & Peng, H. Flexible solar cells based on carbon nanomaterials. Carbon 139 , 1063–1073 (2018).

Hu, Y. et al. Photo-to-electricity generation of aligned carbon nanotubes in water. J. Mater. Chem. A 7 , 1996–2001 (2019).

Gao, Z. et al. Flexible self-powered textile formed by bridging photoactive and electrochemically active fiber electrodes. J. Mater. Chem. A 7 , 14447–14454 (2019).

Nakanishi, Y. et al. Concentrated-polymer-brush-modified silica nanoparticles self-assembled in ionic liquid containing iodide/tTriiodide (I – /I 3 – )-redox system as quasi-solid electrolytes for dye-sensitized solar cells. ACS Appl. Nano Mater. 4 , 6620–6628 (2021).

Liu, Y. et al. Electron-affinity-triggered variations on the optical and electrical properties of dye molecules enabling highly efficient dye-sensitized solar cells. Angew. Chem. Int. Ed. 57 , 14125–14128 (2018).

Xie, X., Criddle, C. & Cui, Y. Design and fabrication of bioelectrodes for microbial bioelectrochemical systems. Energy Environ. Sci. 8 , 3418–3441 (2015).

Pereira, A. R., de Souza, J. C. P., Iost, R. M., Sales, F. C. P. F. & Crespilho, F. N. Application of carbon fibers to flexible enzyme electrodes. J. Electroanal. Chem. 780 , 396–406 (2016).

Khudiyev, T. et al. 100 m long thermally drawn supercapacitor fibers with applications to 3D printing and textiles. Adv. Mater. 32 , 2004971 (2020).

Hong, S. et al. Carbon nanotube fibers with high specific electrical conductivity: synergistic effect of heteroatom doping and densification. Carbon 184 , 207–213 (2021).

Zhang, X., Lu, W., Zhou, G. & Li, Q. Understanding the mechanical and conductive properties of carbon nanotube fibers for smart electronics. Adv. Mater. 32 , 1902028 (2020).

Shen, B., Zhai, W. & Zheng, W. Ultrathin flexible graphene film: an excellent thermal conducting material with efficient EMI shielding. Adv. Funct. Mater. 24 , 4542–4548 (2014).

Fang, B., Chang, D., Xu, Z. & Gao, C. A review on graphene fibers: expectations, advances, and prospects. Adv. Mater. 32 , 1902664 (2020).

Zhang, R. et al. Growth of half-meter long carbon nanotubes based on Schulz–Flory distribution. ACS Nano 7 , 6156–6161 (2013).

Zhang, R., Zhang, Y. & Wei, F. Controlled synthesis of ultralong carbon nanotubes with perfect structures and extraordinary properties. Acc. Chem. Res. 50 , 179–189 (2017).

Ren, J., Sun, X., Chen, P., Wang, Y. & Peng, H. Research progress of fiber-shaped electrochemical energy storage devices. Chin. Sci. Bull. 65 , 3150–3159 (2020).

Lim, H.-R. et al. Advanced soft materials, sensor integrations, and applications of wearable flexible hybrid electronics in healthcare, energy, and environment. Adv. Mater. 32 , 1901924 (2020).

Jain, R. et al. Nanostructuring versus microstructuring in battery electrodes. Nat. Rev. Mater. 7 , 736–746 (2022).

Liu, X. H. et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano 6 , 1522–1531 (2012).

Yan, W. et al. Single fibre enables acoustic fabrics via nanometre-scale vibrations. Nature 603 , 616–623 (2022).

Zeng, S. et al. Hierarchical-morphology metafabric for scalable passive daytime radiative cooling. Science 373 , 692–696 (2021).

Wang, Y. et al. 3D-printed all-fiber Li-ion battery toward wearable energy storage. Adv. Funct. Mater. 27 , 1703140 (2017).

Fu, K. et al. Graphene oxide-based electrode inks for 3D-printed lithium-ion batteries. Adv. Mater. 28 , 2587–2594 (2016).

Li, Y. et al. 3D-printed, all-in-one evaporator for high-efficiency solar steam generation under 1 sun illumination. Adv. Mater. 29 , 1700981 (2017).

Kaufman, J. J. et al. Structured spheres generated by an in-fibre fluid instability. Nature 487 , 463–467 (2012).

Kanik, M. et al. Strain-programmable fiber-based artificial muscle. Science 365 , 145–150 (2019).

Shen, Y. et al. Thermally drawn multifunctional fibers: toward the next generation of information technology. InfoMat 4 , e12318 (2022).

Fuller, B. J. Cryoprotectants: the essential antifreezes to protect life in the frozen state. Cryoletters 25 , 375–388 (2004).

de Ryck, A. & Quéré, D. Fluid coating from a polymer solution. Langmuir 14 , 1911–1914 (1998).

Mirri, F. et al. Lightweight, flexible, high-performance carbon nanotube cables made by scalable flow coating. ACS Appl. Mater. Interf. 8 , 4903–4910 (2016).

Haefner, S. et al. Influence of slip on the Plateau–Rayleigh instability on a fibre. Nat. Commun. 6 , 7409 (2015).

Wang, P. et al. Bioinspired anti-Plateau–Rayleigh-instability on dual parallel fibers. Adv. Mater. 32 , 2003453 (2020).

Richardson, J. J., Björnmalm, M. & Caruso, F. Technology-driven layer-by-layer assembly of nanofilms. Science 348 , aaa2491 (2015).

Xu, S. et al. Preparation and controlled coating of hydroxyl-modified silver nanoparticles on silk fibers through intermolecular interaction-induced self-assembly. Mater. Des. 95 , 107–118 (2016).

Tan, Y. J. et al. A transparent, self-healing and high- κ dielectric for low-field-emission stretchable optoelectronics. Nat. Mater. 19 , 182–188 (2020).

Luo, Y. S. & Liu, S. I. A voltage multiplier with adaptive threshold voltage compensation. IEEE J. Solid-State Circuits 52 , 2208–2214 (2017).

Li, D. et al. Scalable and hierarchically designed polymer film as a selective thermal emitter for high-performance all-day radiative cooling. Nat. Nanotechnol. 16 , 153–158 (2021).

Liu, M. et al. A review: electrospun nanofiber materials for lithium–sulfur batteries. Adv. Funct. Mater. 29 , 1905467 (2019).

de Mulatier, S., Nasreldin, M., Delattre, R., Ramuz, M. & Djenizian, T. Electronic circuits integration in textiles for data processing in wearable technologies. Adv. Mater. Technol. 3 , 1700320 (2018).

Shi, J. et al. Smart textile-integrated microelectronic systems for wearable applications. Adv. Mater. 32 , 1901958 (2020).

Canales, A. et al. Multifunctional fibers for simultaneous optical, electrical and chemical interrogation of neural circuits in vivo. Nat. Biotechnol. 33 , 277–284 (2015).

Ibanez Labiano, I. et al. Screen printing carbon nanotubes textiles antennas for smart wearables. Sensors 21 , 4934 (2021).

Ding, C. et al. Durability study of thermal transfer printed textile electrodes for wearable electronic applications. ACS Appl. Mater. Interf. 14 , 29144–29155 (2022).

Hong, H., Hu, J. & Yan, X. UV curable conductive ink for the fabrication of textile-based conductive circuits and wearable UHF RFID tags. ACS Appl. Mater. Interf. 11 , 27318–27326 (2019).

Xiao, Y. et al. Fabrication of silver electrical circuits on textile substrates by reactive inkjet printing. IEEE Sens. J. 22 , 11056–11064 (2022).

Sungyong, S., Kim, B., Son, Y. K., Ji Eun, K. & Il-Yeon, C. A flexible textile wristwatch using transfer printed textile circuit technique. In 2012 IEEE Int. Conf. on Consumer Electronics (ICCE) 21–22 (IEEE, 2012).

Yoon, J. et al. Robust and stretchable indium gallium zinc oxide-based electronic textiles formed by cilia-assisted transfer printing. Nat. Commun. 7 , 11477 (2016).

Komolafe, A. et al. Integrating flexible filament circuits for e-textile applications. Adv. Mater. Technol. 4 , 1900176 (2019).

Li, Q. & Tao, X. M. Three-dimensionally deformable, highly stretchable, permeable, durable and washable fabric circuit boards. Proc. R. Soc. A 470 , 20140472 (2014).

Lin, R. et al. Digitally-embroidered liquid metal electronic textiles for wearable wireless systems. Nat. Commun. 13 , 2190 (2022).

Linz, T. et al. Embroidered interconnections and encapsulation for electronics in textiles for wearable electronics applications. Adv. Sci. Technol. 60 , 85–94 (2009).

Dhawan, A., Seyam, A. M., Ghosh, T. K. & Muth, J. F. Woven fabric-based electrical circuits: Part I. Evaluating interconnect methods. Text. Res. J. 74 , 913–919 (2004).

Molla, M. T. I. et al. Surface-mount manufacturing for e-textile circuits. In Proc. 2017 ACM Int. Symp. on Wearable Computers , 18–25 (ACM, 2017).

Post, E. R., Orth, M., Russo, P. R. & Gershenfeld, N. E-broidery: design and fabrication of textile-based computing. IBM Syst. J. 39 , 840–860 (2000).

Zysset, C., Kinkeldei, T. W., Munzenrieder, N., Cherenack, K. & Troster, G. Integration method for electronics in woven textiles. IEEE Trans. Compon. Packaging Manuf. Technol. 2 , 1107–1117 (2012).

Wu, H. Y. et al. Seamlessly-integrated textile electric circuit enabled by self-connecting interwoven points. Chin. J. Polym. Sci. 40 , 1323–1330 (2022).

Dils, C. et al. Interconnecting embroidered hybrid conductive yarns by ultrasonic plastic welding for e-textiles. Text. Res. J. 92 , 4501–4520 (2022).

Park, S. et al. Adaptive and multifunctional hydrogel hybrid probes for long-term sensing and modulation of neural activity. Nat. Commun. 12 , 3435 (2021).

Luo, Y. et al. Learning human–environment interactions using conformal tactile textiles. Nat. Electron. 4 , 193–201 (2021).

Park, Y. G., Lee, S. & Park, J. U. Recent progress in wireless sensors for wearable electronics. Sensors 19 , 4353 (2019).

Tian, X. et al. Wireless body sensor networks based on metamaterial textiles. Nat. Electron. 2 , 243–251 (2019).

Stanley, J., Hunt, J. A., Kunovski, P. & Wei, Y. A review of connectors and joining technologies for electronic textiles. Eng. Rep. 4 , e12491 (2022).

Chen, M. et al. Imperceptible, designable, and scalable braided electronic cord. Nat. Commun. 13 , 7097 (2022).

Hwang, S. et al. Integration of multiple electronic components on a microfibre towards an emerging electronic textile platform. Nat. Commun. 13 , 3173 (2022).

Pattinson, S. W. et al. Additive manufacturing of biomechanically tailored meshes for compliant wearable and implantable devices. Adv. Funct. Mater. 29 , 1901815 (2019).

Loke, G. et al. Structured multimaterial filaments for 3D printing of optoelectronics. Nat. Commun. 10 , 4010 (2019).

Vu, C. H. T. & Won, K. Leaching-resistant carrageenan-based colorimetric oxygen indicator films for intelligent food packaging. J. Agric. Food Chem. 62 , 7263–7267 (2014).

Idros, N. & Chu, D. Triple-indicator-based multidimensional colorimetric sensing platform for heavy metal ion detections. ACS Sens. 3 , 1756–1764 (2018).

Xiong, J., Chen, J. & Lee, P. S. Functional fibers and fabrics for soft robotics, wearables, and human–robot interface. Adv. Mater. 33 , 2002640 (2021).

Jinno, H. et al. Stretchable and waterproof elastomer-coated organic photovoltaics for washable electronic textile applications. Nat. Energy 2 , 780–785 (2017).

Kwon, C. et al. Self-bondable and stretchable conductive composite fibers with spatially controlled percolated Ag nanoparticle networks: novel integration strategy for wearable electronics. Adv. Funct. Mater. 30 , 2005447 (2020).

Ma, R., Lee, J., Choi, D., Moon, H. & Baik, S. Knitted fabrics made from highly conductive stretchable fibers. Nano Lett. 14 , 1944–1951 (2014).

Ryu, S. et al. Extremely elastic wearable carbon nanotube fiber strain sensor for monitoring of human motion. ACS Nano 9 , 5929–5936 (2015).

Huang, J. et al. Stretchable and heat-resistant protein-based electronic skin for human thermoregulation. Adv. Funct. Mater. 30 , 1910547 (2020).

Torres Alonso, E. et al. Graphene electronic fibres with touch-sensing and light-emitting functionalities for smart textiles. npj Flex. Electron. 2 , 25 (2018).

Yang, Z. et al. Conductive and elastic 3D helical fibers for use in washable and wearable electronics. Adv. Mater. 32 , 1907495 (2020).

Chen, S. et al. Transparent and waterproof ionic liquid-based fibers for highly durable multifunctional sensors and strain-insensitive stretchable conductors. ACS Appl. Mater. Interf. 10 , 4305–4314 (2018).

Meng, W., Nie, M., Liu, Z. & Zhou, J. Buckled fiber conductors with resistance stability under strain. Adv. Fiber Mater. 3 , 149–159 (2021).

Lee, J. et al. Intrinsically strain-insensitive, hyperelastic temperature-sensing fiber with compressed micro-wrinkles for integrated textronics. Adv. Mater. Technol. 5 , 2000073 (2020).

Lee, W. et al. Universal assembly of liquid metal particles in polymers enables elastic printed circuit board. Science 378 , 637–641 (2022).

Cao, J. et al. Ultra-robust stretchable electrode for e-skin: in situ assembly using a nanofiber scaffold and liquid metal to mimic water-to-net interaction. InfoMat 4 , e12302 (2022).

Lv, Z. et al. Autonomous chemistry enabling environment-adaptive electrochemical energy storage devices. CCS Chem. 5 , 11–29 (2023).

Deng, J. et al. A shape-memory supercapacitor fiber. Angew. Chem. Int. Ed. 54 , 15419–15423 (2015).

Rao, J. et al. All-fiber-based quasi-solid-state lithium-ion battery towards wearable electronic devices with outstanding flexibility and self-healing ability. Nano Energy 51 , 425–433 (2018).

Yang, P. et al. Thermal self-protection of zinc-ion batteries enabled by smart hygroscopic hydrogel electrolytes. Adv. Energy Mater. 10 , 2002898 (2020).

Degenstein, L. M., McQueen, R. H. & Krogman, N. T. ‘What goes where?’ Characterizing Edmonton’s municipal clothing waste stream and consumer clothing disposal. J. Clean. Prod. 296 , 126516 (2021).

Zamani, B., Sandin, G. & Peters, G. M. Life cycle assessment of clothing libraries: can collaborative consumption reduce the environmental impact of fast fashion? J. Clean. Prod. 162 , 1368–1375 (2017).

Dulal, M. et al. Toward sustainable wearable electronic textiles. ACS Nano 16 , 19755–19788 (2022).

Yousef, S. et al. Sustainable green technology for recovery of cotton fibers and polyester from textile waste. J. Clean. Prod. 254 , 120078 (2020).

Satyanarayana, K. G., Arizaga, G. G. C. & Wypych, F. Biodegradable composites based on lignocellulosic fibers — an overview. Prog. Polym. Sci. 34 , 982–1021 (2009).

Daria, M., Krzysztof, L. & Jakub, M. Characteristics of biodegradable textiles used in environmental engineering: a comprehensive review. J. Clean. Prod. 268 , 122129 (2020).

Tempro Tec. Stainless steel sewing thread. Tempro Tec https://www.temprotec.com/textiles-for-insulation-covers/stainless-steel-accessories-and-threads/ (2015).

SWICOFIL. Metal-plated chemical yarns. SWICOFIL https://www.swicofil.com/commerce/products/2swicosilver/619/introduction (2019).

DexMat. Galvorn CNT yarn. DexMat https://store.dexmat.com/ (2023).

Google. Jacquard by Google weaves new digital experiences into the things you love, wear, and use every day. Google https://atap.google.com/jacquard/ (2021).

Clim8. Garments that can monitor the body and environment temperature and regulate the skin temperature based on the sensing modules and electrical heating of conductive fibres. Clim8 https://myclim8.com/products/ (2021).

Embro. Technical embroidery according to your specifications. Embro https://embro-tech.com/en/ (2021).

Gong, W. et al. Continuous and scalable manufacture of amphibious energy yarns and textiles. Nat. Commun. 10 , 868 (2019).

Luo, Y. et al. Technology roadmap for flexible sensors. ACS Nano 17 , 5211–5295 (2023).

Lee, H. & Roh, J. S. Wearable electromagnetic energy-harvesting textiles based on human walking. Text. Res. J. 89 , 2532–2541 (2019).

Xiang, S., Zhang, N. & Fan, X. From fiber to fabric: progress towards photovoltaic energy textile. Adv. Fiber Mater. 3 , 76–106 (2021).

Wang, M. et al. Fusing stretchable sensing technology with machine learning for human–machine interfaces. Adv. Funct. Mater. 31 , 2008807 (2021).

Wang, M. et al. Gesture recognition using a bioinspired learning architecture that integrates visual data with somatosensory data from stretchable sensors. Nat. Electron. 3 , 563–570 (2020).

Download references

Acknowledgements

H.P. acknowledges funding support from the Ministry of Science and Technology of China (2022YFA1200023) and the Science and Technology Commission of Shanghai Municipality (21511104900, 20JC1414902). K.Z. acknowledges funding support from the National Natural Science Foundation of China (22105045).

Author information

These authors contributed equally: Kaiwen Zeng, Xiang Shi, Chengqiang Tang.

Authors and Affiliations

State Key Laboratory of Molecular Engineering of Polymers, Department of Macromolecular Science and Laboratory of Advanced Materials, Fudan University, Shanghai, China

Kaiwen Zeng, Xiang Shi, Chengqiang Tang & Huisheng Peng

Department of Gastroenterology, Xiangya Hospital, Central South University, Changsha, Hunan, China

You can also search for this author in PubMed Google Scholar

Contributions

K.Z., X.S. and C.T. contributed equally to this work. All authors contributed to the writing and editing of the manuscript.

Corresponding authors

Correspondence to Ting Liu or Huisheng Peng .

Ethics declarations

Competing interests.

The authors declare no competing interests.

Peer review

Peer review information.

Nature Reviews Materials thanks Xiaodong Chen, Wei Gao and Xiaoming Tao for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Cite this article.

Zeng, K., Shi, X., Tang, C. et al. Design, fabrication and assembly considerations for electronic systems made of fibre devices. Nat Rev Mater 8 , 552–561 (2023). https://doi.org/10.1038/s41578-023-00573-x

Download citation

Accepted : 22 May 2023

Published : 19 June 2023

Issue Date : August 2023

DOI : https://doi.org/10.1038/s41578-023-00573-x

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

This article is cited by

Vertical-aligned and ordered-active architecture of heterostructured fibers for high electrochemical capacitance.

- Xiaolin Zhu

Advanced Fiber Materials (2024)

Calcium–Oxygen Fiber Batteries for Next-Generation Wearables

Quick links.

- Explore articles by subject

- Guide to authors

- Editorial policies

Sign up for the Nature Briefing newsletter — what matters in science, free to your inbox daily.

Organic Devices: Fabrication, Applications, and Challenges

- Review Article

- Published: 27 November 2021

- Volume 51 , pages 447–485, ( 2022 )

Cite this article

- A. K. Chauhan ORCID: orcid.org/0000-0003-4896-9278 1 , 2 ,

- Purushottam Jha 1 , 2 ,

- D. K. Aswal 1 , 2 &

- J. V. Yakhmi 1

1978 Accesses

19 Citations

Explore all metrics

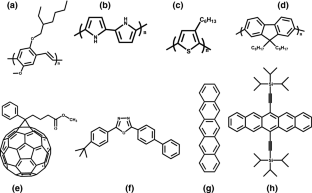

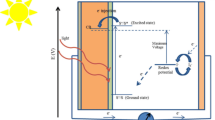

The low cost of organic starting materials and ease of their fabrication processes have propelled the development of various organic devices and have also generated a considerable research interest in the scientific community. These devices make use of organic materials in the form of dielectrics, conductive polymers, or small organic molecules deposited mainly on flexible substrates to bring about the advantages of stretchability and moldability. Focussed and dedicated R&D activities conducted in this field during the last few decades have led to the development of novel and efficient organic devices that hold tremendous promise of a highly optimistic future. This review provides an insight into the area of organic devices with a particular emphasis on organic light emitting diodes, organic field effect transistors, organic solar cells, and organic thermoelectric devices. It presents a comprehensive survey that includes important milestones, fabrication processes, and applications of these devices. New materials and processes that enabled the recent technological advancements have been highlighted and discussed for each device category. The current challenges of the field are also discussed with a glance at the future prospects and directions for this emerging field.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Dye-Sensitized Solar Cells: Fundamentals and Current Status

The Roadmap of 2D Materials and Devices Toward Chips

An overview of conductive composite hydrogels for flexible electronic devices

H.E. Katz, and J. Huang, Thin-film organic electronic devices. Annu. Rev. Mater. Res. 39, 71 (2009).

Article CAS Google Scholar

R. Das, and P. Harrop, Printed, organic & flexible electronics: forecasts, players & opportunities 2013–2023 (Cambridge: IDTechEx, 2013).

Google Scholar

C. Adachi, S. Lee, T. Nakagawa, K. Shizu, K. Goushi, T. Yasuda, and W.J. Potscavage, Organic Electronics Materials and Devices . ed. S. Ogawa (Tokyo: Springer, 2015), p. 43.

Chapter Google Scholar

P. Cossari, M. Pugliese, S. Gambino, A. Cannavale, V. Maiorano, G. Gigli, and M. Mazzeo, Fully integrated electrochromic-OLED devices for highly transparent smart glasses. J. Mater. Chem. C 6, 7274 (2018).

D. Yin, Z.-Y. Chen, N.-R. Jiang, Y.-F. Liu, Y.-G. Bi, X.-L. Zhang, W. Han, J. Feng, and H.-B. Sun, Highly transparent and flexible fabric-based organic light emitting devices for unnoticeable wearable displays. Org. Electron. 76, 105494 (2020).

M.J. Griffith, S. Cottam, J. Stamenkovic, J.A. Posar, and M. Petasecca, Printable organic semiconductors for radiation detection: from fundamentals to fabrication and functionality. Front. Phys. 8, 22 (2020).

Article Google Scholar

Q. Jiang, J. Yang, P. Hing, and H. Ye, Recent advances, design guidelines, and prospects of flexible organic/inorganic thermoelectric composites. Mater. Adv. 1, 1038 (2020).

Y. Chen, Y. Zhao, and Z. Liang, Solution processed organic thermoelectrics: towards flexible thermoelectric modules. Energy Environ. Sci. 8, 401 (2015).

M. Bendikov, F. Wudl, and D.F. Perepichka, Tetrathiafulvalenes, oligoacenenes, and their Buckminsterfullerene derivatives: the brick and mortar of organic electronics. Chem. Rev. 104, 4891 (2004).

C. Zhan, G. Yu, Y. Lu, L. Wang, E. Wujcik, and S. Wei, Conductive polymer nanocomposites: a critical review of modern advanced devices. J. Mater. Chem. C 5, 1569 (2017).

M. Bharti, A. Singh, S. Samanta, and D.K. Aswal, Conductive polymers for thermoelectric power generation. Prog. Mater Sci. 93, 270 (2018).

Y. Lu, and D.J. Young, Coordination polymers for n -type thermoelectric applications. Dalton Trans. 49, 7644 (2020).

N. Koch, Organic electronic devices and their functional interfaces. ChemPhysChem 8, 1438 (2007).

M. Riede, D. Spoltore, and K. Leo, Organic solar cells—the path to commercial success. Adv. Energy Mater. 11, 2002653 (2021).

S.-J. Zou, Y. Shen, F.-M. Xie, J.-D. Chen, Y.-Q. Li, and J.-X. Tang, Recent advances in organic light-emitting diodes: toward smart lighting and displays. Mater. Chem. Front. 4, 788 (2020).

N. Li, X. Niu, Q. Chen, and H. Zhou, Towards commercialization: the operational stability of perovskite solar cells. Chem. Soc. Rev. 49, 8235 (2020).

J.-H. Bahk, H. Fang, K. Yazawa, and A. Shakouri, Flexible thermoelectric materials and device optimization for wearable energy harvesting. J. Mater. Chem. C 3, 10362 (2015).

S. Biswas, and H. Kim, Solar cells for indoor applications: progress and development. Polymers 12, 1338 (2020).

J. Borges-González, C.J. Kousseff, and C.B. Nielsen, Organic semiconductors for biological sensing. J. Mater. Chem. C 7, 1111 (2019).

L.M. Cowen, J. Atoyo, M.J. Carnie, D. Baran, and B.C. Schroeder, Review—organic materials for thermoelectric energy generation. ECS J. Solid State Sci. Technol. 6, N3080 (2017).

L. Duan, and A. Uddin, Progress in stability of organic solar cells. Adv. Sci. 7, 1903259 (2020).

H. Kleemann, K. Krechan, A. Fischer, and K. Leo, A review of vertical organic transistors. Adv. Func. Mater. 30, 1907113 (2020).

H. Kleemann, G. Schwartz, S. Zott, M. Baumann, and M. Furno, Megahertz operation of vertical organic transistors for ultra-high resolution active-matrix display. Flexible Printed Electron. 5, 014009 (2020).

J.-H. Lee, C.-H. Chen, P.-H. Lee, H.-Y. Lin, M.-K. Leung, T.-L. Chiu, and C.-F. Lin, Blue organic light-emitting diodes: current status, challenges, and future outlook. J. Mater. Chem. C 7, 5874 (2019).

M. Lindorf, K.A. Mazzio, J. Pflaum, K. Nielsch, W. Brütting, and M. Albrecht, Organic-based thermoelectrics. J. Mater. Chem. A 8, 7495 (2020).

S. Yuvaraja, A. Nawaz, Q. Liu, D. Dubal, S.G. Surya, K.N. Salama, and P. Sonar, Organic field-effect transistor-based flexible sensors. Chem. Soc. Rev. 49, 3423 (2020).

Z. Zhu, Y. Guo, and Y. Liu, Application of organic field-effect transistors in memory. Mater. Chem. Front. 4, 2845 (2020).

S. Koiry, D. Aswal, V. Saxena, N. Padma, A. Chauhan, N. Joshi, S. Gupta, J. Yakhmi, D. Guerin, and D. Vuillaume, Electrochemical grafting of octyltrichlorosilane monolayer on Si. Appl. Phys. Lett. 90, 113118 (2007).

N. Padma, S. Koiry, V. Saxena, A. Chauhan, D. Aswal, S. Gupta, and J. Yakhmi, Electrical characterization of self-assembled monolayers of alkyltrichlorosilanes on native oxide of silicon. J. Nanosci. Nanotechnol. 9, 5273 (2009).

A. Chauhan, D. Aswal, S. Koiry, S. Gupta, J. Yakhmi, C. Sürgers, D. Guerin, S. Lenfant, and D. Vuillaume, Self-assembly of the 3-aminopropyltrimethoxysilane multilayers on Si and hysteretic current–voltage characteristics. Appl. Phys. A 90, 581 (2008).

A. Chauhan, D. Aswal, S. Koiry, N. Padma, V. Saxena, S. Gupta, and J. Yakhmi, Resistive memory effect in self-assembled 3-aminopropyltrimethoxysilane molecular multilayers. Phys. Status Solidi (a) 205, 373 (2008).

S. Koiry, D. Aswal, A. Chauhan, V. Saxena, S. Nayak, S. Gupta, and J. Yakhmi, Electrical bistability in electrografted 5-(4-undecenyloxyphenyl)-10, 15, 20-triphenylporphyrin monolayer on Si. Chem. Phys. Lett. 453, 68 (2008).

R. Parashkov, E. Becker, S. Hartmann, G. Ginev, D. Schneider, H. Krautwald, T. Dobbertin, D. Metzdorf, F. Brunetti, C. Schildknecht, A. Kammoun, M. Brandes, T. Riedl, H.-H. Johannes, and W. Kowalsky, Vertical channel all-organic thin-film transistors. Appl. Phys. Lett. 82, 4579 (2003).

A.F. Paterson, S. Singh, K.J. Fallon, T. Hodsden, Y. Han, B.C. Schroeder, H. Bronstein, M. Heeney, I. McCulloch, and T.D. Anthopoulos, Recent progress in high-mobility organic transistors: a reality check. Adv. Mater. 30, 1801079 (2018).

O. Bubnova, and X. Crispin, Towards polymer-based organic thermoelectric generators. Energy Environ. Sci. 5, 9345 (2012).

L. Torsi, A. Dodabalapur, L. Sabbatini, and P.G. Zambonin, Multi-parameter gas sensors based on organic thin-film-transistors Sens. Actuators B 67, 312 (2000).

A.J.C. Kuehne, and M.C. Gather, Organic lasers: recent developments on materials, device geometries, and fabrication techniques. Chem. Rev. 116, 12823 (2016).

I.D.W. Samuel, and G.A. Turnbull, Organic semiconductor lasers. Chem. Rev. 107, 1272 (2007).

F. Zhang, Y. Zang, D. Huang, C.-A. Di, and D. Zhu, Flexible and self-powered temperature–pressure dual-parameter sensors using microstructure-frame-supported organic thermoelectric materials. Nat. Commun. 6, 8356 (2015).

F.-C. Chen, Encyclopedia of Modern Optics (2nd Edition) . ed. B.D. Guenther, and D.G. Steel (Oxford: Elsevier, 2018), p. 220.

T. Okamoto, C.P. Yu, C. Mitsui, M. Yamagishi, H. Ishii, and J. Takeya, Bent-shaped p-type small-molecule organic semiconductors: a molecular design strategy for next-generation practical applications. J. Am. Chem. Soc. 142, 9083 (2020).

A. Mishra, and P. Bäuerle, Small molecule organic semiconductors on the move: promises for future solar energy technology. Angew. Chem. Int. Ed. 51, 2020 (2012).

M.A. Baldo, D.F. O’Brien, Y. You, A. Shoustikov, S. Sibley, M.E. Thompson, and S.R. Forrest, Highly efficient phosphorescent emission from organic electroluminescent devices. Nature 395, 151 (1998).

A. Maliakal, K. Raghavachari, H. Katz, E. Chandross, and T. Siegrist, Photochemical stability of pentacene and a substituted pentacene in solution and in thin films. Chem. Mater. 16, 4980 (2004).

C.M. Drain, A. Varotto, and I. Radivojevic, Self-organized porphyrinic materials. Chem. Rev. 109, 1630 (2009).

P.Y. Yu, and M. Cardona, Fundamentals of Semiconductors: Physics and Materials Properties . ed. P.Y. Yu, and M. Cardona (Berlin: Springer, 2010), p. 17.

S.Y. Lee, J. Lyu, S. Kang, S.J. Lu, and C.W. Bielawski, Ascertaining the carbon hybridization states of synthetic polymers with x-ray induced auger electron spectroscopy. J. Phys. Chem. C 122, 11855 (2018).

E.J. Baerends, From the Kohn-Sham band gap to the fundamental gap in solids. An integer electron approach. Phys. Chem. Chem. Phys. 19, 15639 (2017).

H. Shirakawa, E.J. Louis, A.G. MacDiarmid, C.K. Chiang, and A.J. Heeger, Synthesis of electrically conducting organic polymers: halogen derivatives of polyacetylene, (CH). J. Chem. Soc. Chem. Commun. 16, 578 (1977).

L. Chen, R. Batra, R. Ranganathan, G. Sotzing, Y. Cao, and R. Ramprasad, Electronic structure of polymer dielectrics: the role of chemical and morphological complexity. Chem. Mater. 30, 7699 (2018).

D.C. Reynolds, and T.C. Collins, Encyclopedia of Physical Science and Technology (3rd Edition) . ed. R.A. Meyers (New York: Academic, 2003), p. 687.

W. Barford, Excitons in conjugated polymers: a tale of two particles. J. Phys. Chem. A 117, 2665 (2013).

K.W. Böer, and U.W. Pohl, Semiconductor Physics . ed. K.W. Böer, and U. Pohl (Cham: Springer, 2014), p. 1.

A. Chauhan, S. Gupta, D. Taguchi, T. Manaka, P. Jha, P. Veerender, C. Sridevi, S. Koiry, S. Gadkari, and M. Iwamoto, Enhancement of the carrier mobility of conducting polymers by formation of their graphene composites. RSC Adv. 7, 11913 (2017).

B. Lüssem, M. Riede, and K. Leo, Doping of organic semiconductors. Phys. Status Solidi (a) 210, 9 (2013).

C. Yumusak, N.S. Sariciftci, and M. Irimia-Vladu, Purity of organic semiconductors as a key factor for the performance of organic electronic devices. Mater. Chem. Front. 4, 3678 (2020).

P. Jha, S.P. Koiry, V. Saxena, P. Veerender, A.K. Chauhan, D.K. Aswal, and S.K. Gupta, Growth of free-standing polypyrrole nanosheets at air/liquid interface using J-aggregate of porphyrin derivative as in-situ template. Macromolecules 44, 4583 (2011).

P. Veerender, V. Saxena, P. Jha, S. Koiry, A. Gusain, S. Samanta, A. Chauhan, D. Aswal, and S. Gupta, Free-standing polypyrrole films as substrate-free and Pt-free counter electrodes for quasi-solid dye-sensitized solar cells. Org. Electron. 13, 3032 (2012).

C. Bizzarri, E. Spuling, D.M. Knoll, D. Volz, and S. Bräse, Sustainable metal complexes for organic light-emitting diodes (OLEDs). Coord. Chem. Rev. 373, 49 (2018).

H.-W. Chen, J.-H. Lee, B.-Y. Lin, S. Chen, and S.-T. Wu, Liquid crystal display and organic light-emitting diode display: present status and future perspectives. Light Sci. Appl. 7, 17168 (2018).

J. Haruyama, K. Sodeyama, L. Han, and Y. Tateyama, First-principles study of ion diffusion in perovskite solar cell sensitizers. J. Am. Chem. Soc. 137, 10048 (2015).

R. Ieuji, K. Goushi, and C. Adachi, Triplet–triplet upconversion enhanced by spin–orbit coupling in organic light-emitting diodes. Nat. Commun. 10, 5283 (2019).

J.-H. Jou, S. Kumar, A. Agrawal, T.-H. Li, and S. Sahoo, Approaches for fabricating high efficiency organic light emitting diodes. J. Mater. Chem. C 3, 2974 (2015).

S. Reineke, M. Thomschke, B. Lüssem, and K. Leo, White organic light-emitting diodes: Status and perspective. Rev. Mod. Phys. 85, 1245 (2013).

A. Salehi, X. Fu, D.-H. Shin, and F. So, Recent advances in OLED optical design. Adv. Func. Mater. 29, 1808803 (2019).

C.W. Tang, and S.A. VanSlyke, Organic electroluminescent diodes. Appl. Phys. Lett. 51, 913 (1987).

C.W. Tang, S.A. VanSlyke, and C.H. Chen, Electroluminescence of doped organic thin films. J. Appl. Phys. 65, 3610 (1989).

C. Adachi, T. Tsutsui, and S. Saito, Organic electroluminescent device having a hole conductor as an emitting layer. Appl. Phys. Lett. 55, 1489 (1989).

C. Adachi, M.A. Baldo, M.E. Thompson, and S.R. Forrest, Nearly 100% internal phosphorescence efficiency in an organic light-emitting device. J. Appl. Phys. 90, 5048 (2001).

K.-H. Kim, C.-K. Moon, J.-H. Lee, S.-Y. Kim, and J.-J. Kim, Highly efficient organic light-emitting diodes with phosphorescent emitters having high quantum yield and horizontal orientation of transition dipole moments. Adv. Mater. 26, 3844 (2014).

H. Shin, Y.H. Ha, H.-G. Kim, R. Kim, S.-K. Kwon, Y.-H. Kim, and J.-J. Kim, Controlling horizontal dipole orientation and emission spectrum of Ir complexes by chemical design of ancillary ligands for efficient deep-blue organic light-emitting diodes. Adv. Mater. 31, 1808102 (2019).

J.-L. Liao, P. Rajakannu, P. Gnanasekaran, S.-R. Tsai, C.-H. Lin, S.-H. Liu, C.-H. Chang, G.-H. Lee, P.-T. Chou, Z.-N. Chen, and Y. Chi, Luminescent diiridium complexes with bridging pyrazolates: characterization and fabrication of OLEDs using vacuum thermal deposition. Adv. Opt. Mater. 6, 1800083 (2018).

X. Yang, H. Guo, B. Liu, J. Zhao, G. Zhou, Z. Wu, and W.-Y. Wong, Diarylboron-based asymmetric red-emitting Ir(III) complex for solution-processed phosphorescent organic light-emitting diode with external quantum efficiency above 28%. Adv. Sci. 5, 1701067 (2018).

W.-P. To, D. Zhou, G.S.M. Tong, G. Cheng, C. Yang, and C.-M. Che, Highly luminescent pincer Gold(III) aryl emitters: thermally activated delayed fluorescence and solution-processed OLEDs. Angew. Chem. Int. Ed. 56, 14036 (2017).

J. Wang, J. Liang, Y. Xu, B. Liang, J. Wei, C. Li, X. Mu, K. Ye, and Y. Wang, Purely organic phosphorescence emitter-based efficient electroluminescence devices. J. Phys. Chem. Lett. 10, 5983 (2019).

T.-L. Wu, M.-J. Huang, C.-C. Lin, P.-Y. Huang, T.-Y. Chou, R.-W. Chen-Cheng, H.-W. Lin, R.-S. Liu, and C.-H. Cheng, Diboron compound-based organic light-emitting diodes with high efficiency and reduced efficiency roll-off. Nat. Photonics 12, 235 (2018).

C.-M. Hsieh, T.-L. Wu, J. Jayakumar, Y.-C. Wang, C.-L. Ko, W.-Y. Hung, T.-C. Lin, H.-H. Wu, K.-H. Lin, C.-H. Lin, S. Hsieh, and C.-H. Cheng, Diboron-based delayed fluorescent emitters with orange-to-red emission and superior organic light-emitting diode efficiency. ACS Appl. Mater. Interfaces 12, 23199 (2020).

J.H. Kim, K.H. Lee, and J.Y. Lee, Design of thermally activated delayed fluorescent sensitizers for high efficiency over 20% and long lifetime in yellow fluorescent organic light-emitting diodes. J. Mater. Chem. C 8, 5265 (2020).

T.-A. Lin, T. Chatterjee, W.-L. Tsai, W.-K. Lee, M.-J. Wu, M. Jiao, K.-C. Pan, C.-L. Yi, C.-L. Chung, K.-T. Wong, and C.-C. Wu, Sky-blue organic light emitting diode with 37% external quantum efficiency using thermally activated delayed fluorescence from spiroacridine-triazine hybrid. Adv. Mater. 28, 6976 (2016).

J.H. Burroughes, D.D.C. Bradley, A.R. Brown, R.N. Marks, K. Mackay, R.H. Friend, P.L. Burns, and A.B. Holmes, Light-emitting diodes based on conjugated polymers. Nature 347, 539 (1990).

G. Gustafsson, Y. Cao, G.M. Treacy, F. Klavetter, N. Colaneri, and A.J. Heeger, Flexible light-emitting diodes made from soluble conducting polymers. Nature 357, 477 (1992).

M.T. Bernius, M. Inbasekaran, J. O’Brien, and W. Wu, Progress with light-emitting polymers. Adv. Mater. 12, 1737 (2000).

M.S. AlSalhi, J. Alam, L.A. Dass, and M. Raja, Recent advances in conjugated polymers for light emitting devices. Int. J. Mol. Sci. 12, 2036 (2011).

S. Scholz, D. Kondakov, B. Lüssem, and K. Leo, Degradation mechanisms and reactions in organic light-emitting devices. Chem. Rev. 115, 8449 (2015).

B. Minaev, G. Baryshnikov, and H. Agren, Principles of phosphorescent organic light emitting devices. Phys. Chem. Chem. Phys. 16, 1719 (2014).

H. Nakanotani, T. Higuchi, T. Furukawa, K. Masui, K. Morimoto, M. Numata, H. Tanaka, Y. Sagara, T. Yasuda, and C. Adachi, High-efficiency organic light-emitting diodes with fluorescent emitters. Nat. Commun. 5, 4016 (2014).

N. Thejo Kalyani, and S.J. Dhoble, Novel materials for fabrication and encapsulation of OLEDs. Renew. Sustain. Energy Rev. 44, 319 (2015).

D. Volz, Review of organic light-emitting diodes with thermally activated delayed fluorescence emitters for energy-efficient sustainable light sources and displays. J. Photonics Energy 6, 020901 (2016).

Z. Yang, Z. Mao, Z. Xie, Y. Zhang, S. Liu, J. Zhao, J. Xu, Z. Chi, and M.P. Aldred, Recent advances in organic thermally activated delayed fluorescence materials. Chem. Soc. Rev. 46, 915 (2017).

C.-Y. Chan, M. Tanaka, Y.-T. Lee, Y.-W. Wong, H. Nakanotani, T. Hatakeyama, and C. Adachi, Stable pure-blue hyperfluorescence organic light-emitting diodes with high-efficiency and narrow emission. Nat. Photonics 15, 203 (2021).

P. Bharmoria, H. Bildirir, and K. Moth-Poulsen, Triplet–triplet annihilation based near infrared to visible molecular photon upconversion. Chem. Soc. Rev. 49, 6529 (2020).

J.-H. Chang, W.-H. Lin, P.-C. Wang, J.-I. Taur, T.-A. Ku, W.-T. Chen, S.-J. Yan, and C.-I. Wu, Solution-processed transparent blue organic light-emitting diodes with graphene as the top cathode. Sci. Rep. 5, 9693 (2015).

J. Chung, H. Cho, T.-W. Koh, J. Lee, E. Kim, J. Lee, J.-I. Lee, and S. Yoo, Towards highly efficient and highly transparent OLEDs: advanced considerations for emission zone coupled with capping layer design. Opt. Express 23, 27306 (2015).

S. Choi, C.-M. Kang, C.-W. Byun, H. Cho, B.-H. Kwon, J.-H. Han, J.-H. Yang, J.-W. Shin, C.-S. Hwang, N.S. Cho, K.M. Lee, H.-O. Kim, E. Kim, S. Yoo, and H. Lee, Thin-film transistor-driven vertically stacked full-color organic light-emitting diodes for high-resolution active-matrix displays. Nat. Commun. 11, 2732 (2020).

S.-Y. Chen, T.-Y. Chu, J.-F. Chen, C.-Y. Su, and C.H. Chen, Stable inverted bottom-emitting organic electroluminescent devices with molecular doping and morphology improvement . Appl. Phys. Lett. 89, 053518 (2006).

T.-Y. Chu, J.-F. Chen, S.-Y. Chen, C.-J. Chen, and C.H. Chen, Highly efficient and stable inverted bottom-emission organic light emitting devices. Appl. Phys. Lett. 89, 053503 (2006).

J.-B. Kim, J.-H. Lee, C.-K. Moon, and J.-J. Kim, Highly efficient inverted top emitting organic light emitting diodes using a transparent top electrode with color stability on viewing angle. Appl. Phys. Lett. 104, 073301 (2014).

B.W. Lim, H.S. Jeon, and M.C. Suh, Top-emission organic light emitting diodes with lower viewing angle dependence. Synth. Met. 189, 57 (2014).

S.-R. Park, and M.C. Suh, Enhanced device performances of a new inverted top-emitting OLEDs with relatively thick Ag electrode. Opt. Express 26, 4979 (2018).

A.B. Chwang, R.C. Kwong, and J.J. Brown, Graded mixed-layer organic light-emitting devices. Appl. Phys. Lett. 80, 725 (2002).

D. Ma, C.S. Lee, S.T. Lee, and L.S. Hung, Improved efficiency by a graded emissive region in organic light-emitting diodes. Appl. Phys. Lett. 80, 3641 (2002).

F.A. Boroumand, P.W. Fry, and D.G. Lidzey, Nanoscale conjugated-polymer light-emitting diodes. Nano Lett. 5, 67 (2005).

H. Chen, W. Zhang, M. Li, G. He, and X. Guo, Interface engineering in organic field-effect transistors: principles. Appl. Perspect. Chem. Rev. 120, 2879 (2020).

CAS Google Scholar

C.D. Dimitrakopoulos, and D.J. Mascaro, Organic thin-film transistors: A review of recent advances. IBM J. Res. Dev. 45, 11 (2001).

H. Klauk, Organic thin-film transistors. Chem. Soc. Rev. 39, 2643 (2010).

Y.H. Lee, M. Jang, M.Y. Lee, O.Y. Kweon, and J.H. Oh, Flexible field-effect transistor-type sensors based on conjugated molecules. Chemistry 3, 724 (2017).

R.P. Ortiz, A. Facchetti, and T.J. Marks, High-k organic, inorganic, and hybrid dielectrics for low-voltage organic field-effect transistors. Chem. Rev. 110, 205 (2010).

X. Ren, F. Yang, X. Gao, S. Cheng, X. Zhang, H. Dong, and W. Hu, Organic field-effect transistor for energy-related applications: low-power-consumption devices, near-infrared phototransistors, and organic thermoelectric devices. Adv. Energy Mater. 8, 1801003 (2018).

C. Wang, H. Dong, W. Hu, Y. Liu, and D. Zhu, Semiconducting π-conjugated systems in field-effect transistors: a material odyssey of organic electronics. Chem. Rev. 112, 2208 (2012).

J. Yang, Z. Zhao, S. Wang, Y. Guo, and Y. Liu, Insight into high-performance conjugated polymers for organic field-effect transistors. Chemistry 4, 2748 (2018).

P. Jha, S. Koiry, V. Saxena, P. Veerender, A. Gusain, A. Chauhan, A. Debnath, D. Aswal, and S. Gupta, Air-stability and bending properties of flexible organic field-effect transistors based on poly [N-9′-heptadecanyl-2, 7-carbazole-alt-5, 5-(4′, 7′-di-2-thienyl-2′, 1′, 3′-benzothiadiazole)]. Org. Electron. 14, 2635 (2013).

P. Jha, N.S. Ramgir, P.K. Sharma, N. Datta, S. Kailasaganapathi, M. Kaur, S. Koiry, V. Saxena, A. Chauhan, and A. Debnath, Charge transport and ammonia sensing properties of flexible polypyrrole nanosheets grown at air–liquid interface. Mater. Chem. Phys. 140, 300 (2013).

N. Padma, S. Sen, A. Chauhan, D. Aswal, S. Gupta, J. Yakhmi, R.R. Navan, and H. Raval, Effect of gate insulator on the performance of copper phthalocyanine-based organic thin film transistors. Int. J. Nanosci. 10, 745 (2011).

F. Ebisawa, T. Kurokawa, and S. Nara, Electrical properties of polyacetylene/polysiloxane interface. J. Appl. Phys. 54, 3255 (1983).

A. Tsumura, H. Koezuka, and T. Ando, Macromolecular electronic device: Field-effect transistor with a polythiophene thin film. Appl. Phys. Lett. 49, 1210 (1986).

A. Assadi, C. Svensson, M. Willander, and O. Inganäs, Field-effect mobility of poly(3-hexylthiophene). Appl. Phys. Lett. 53, 195 (1988).

H. Sirringhaus, N. Tessler, and R.H. Friend, Integrated optoelectronic devices based on conjugated polymers. Science 280, 1741 (1998).

S. Cho, K. Lee, J. Yuen, G. Wang, D. Moses, A.J. Heeger, M. Surin, and R. Lazzaroni, Thermal annealing-induced enhancement of the field-effect mobility of regioregular poly(3-hexylthiophene) films. J. Appl. Phys. 100, 114503 (2006).

B.H. Hamadani, D.J. Gundlach, I. McCulloch, and M. Heeney, Undoped polythiophene field-effect transistors with mobility of 1cm2V−1s−1. Appl. Phys. Lett. 91, 2435 (2007).

H.N. Tsao, D.M. Cho, I. Park, M.R. Hansen, A. Mavrinskiy, D.Y. Yoon, R. Graf, W. Pisula, H.W. Spiess, and K. Müllen, Ultrahigh mobility in polymer field-effect transistors by design. J. Am. Chem. Soc. 133, 2605 (2011).

H.-R. Tseng, L. Ying, B.B.Y. Hsu, L.A. Perez, C.J. Takacs, G.C. Bazan, and A.J. Heeger, High mobility field effect transistors based on macroscopically oriented regioregular copolymers. Nano Lett. 12, 6353 (2012).

H. Chen, Y. Guo, G. Yu, Y. Zhao, J. Zhang, D. Gao, H. Liu, and Y. Liu, Highly π-extended copolymers with diketopyrrolopyrrole moieties for high-performance field-effect transistors. Adv. Mater. 24, 4618 (2012).

J. Li, Y. Zhao, H.S. Tan, Y. Guo, C.-A. Di, G. Yu, Y. Liu, M. Lin, S.H. Lim, Y. Zhou, H. Su, and B.S. Ong, A stable solution-processed polymer semiconductor with record high-mobility for printed transistors. Sci. Rep. 2, 754 (2012).

J. Lee, A.R. Han, J. Kim, Y. Kim, J.H. Oh, and C. Yang, Solution-Processable ambipolar diketopyrrolopyrrole-selenophene polymer with unprecedentedly high hole and electron mobilities. J. Am. Chem. Soc. 134, 20713 (2012).

P. Sonar, T.R.B. Foong, S.P. Singh, Y. Li, and A. Dodabalapur, A furan-containing conjugated polymer for high mobility ambipolar organic thin film transistors. Chem. Commun. 48, 8383 (2012).

X. Zhang, L.J. Richter, D.M. DeLongchamp, R.J. Kline, M.R. Hammond, I. McCulloch, M. Heeney, R.S. Ashraf, J.N. Smith, T.D. Anthopoulos, B. Schroeder, Y.H. Geerts, D.A. Fischer, and M.F. Toney, Molecular packing of high-mobility diketo pyrrolo-pyrrole polymer semiconductors with branched alkyl side chains. J. Am. Chem. Soc. 133, 15073 (2011).

G. Horowitz, D. Fichou, X. Peng, Z. Xu, and F. Garnier, A field-effect transistor based on conjugated alpha-sexithienyl. Solid State Commun. 72, 381 (1989).

G. Horowitz, X.-Z. Peng, D. Fichou, and F. Garnier, Role of the semiconductor/insulator interface in the characteristics of π-conjugated-oligomer-based thin-film transistors. Synth. Met. 51, 419 (1992).

F. Garnier, A. Yassar, R. Hajlaoui, G. Horowitz, F. Deloffre, B. Servet, S. Ries, and P. Alnot, Molecular engineering of organic semiconductors: design of self-assembly properties in conjugated thiophene oligomers. J. Am. Chem. Soc. 115, 8716 (1993).

C.D. Dimitrakopoulos, B.K. Furman, T. Graham, S. Hegde, and S. Purushothaman, Field-effect transistors comprising molecular beam deposited α, ω-di-hexyl-hexathienylene and polymeric insulator. Synth. Met. 92, 47 (1998).

C.D. Dimitrakopoulos, A.R. Brown, and A. Pomp, Molecular beam deposited thin films of pentacene for organic field effect transistor applications. J. Appl. Phys. 80, 2501 (1996).

H.E. Katz, A.J. Lovinger, J. Johnson, C. Kloc, T. Siegrist, W. Li, Y.Y. Lin, and A. Dodabalapur, A soluble and air-stable organic semiconductor with high electron mobility. Nature 404, 478 (2000).

G.J. Chae, S.-H. Jeong, J.H. Baek, B. Walker, C.K. Song, and J.H. Seo, Improved performance in TIPS-pentacene field effect transistors using solvent additives. J. Mater. Chem. C 1, 4216 (2013).

V. Raghuwanshi, D. Bharti, and S.P. Tiwari, Flexible organic field-effect transistors with TIPS-Pentacene crystals exhibiting high electrical stability upon bending. Org. Electron. 31, 177 (2016).

L. Yen-Yi, D.I. Gundlach, S.F. Nelson, and T.N. Jackson, Pentacene-based organic thin-film transistors. IEEE Trans. Electron Devices 44, 1325 (1997).

Y. Yang, and A.J. Heeger, A new architecture for polymer transistors. Nature 372, 344 (1994).

H. Kleemann, A.A. Günther, K. Leo, and B. Lüssem, High-performance vertical organic transistors. Small 9, 3670 (2013).

R. Parashkov, E. Becker, G. Ginev, T. Riedl, M. Brandes, H.-H. Johannes, and W. Kowalsky, .Organic vertical-channel transistors structured using excimer laser Appl. Phys. Lett. 85, 5751 (2004).

L. Ma, and Y. Yang, Unique architecture and concept for high-performance organic transistors. Appl. Phys. Lett. 85, 5084 (2004).

Y. Chen, and I. Shih, Fabrication of vertical channel top contact organic thin film transistors. Org. Electron. 8, 655 (2007).

S.-Y. Fujimoto, K.-I. Nakayama, and M. Yokoyama, Fabrication of a vertical-type organic transistor with a planar metal base. Appl. Phys. Lett. 87, 133503 (2005).

M.P. Klinger, A. Fischer, F. Kaschura, J. Widmer, B. Kheradmand-Boroujeni, F. Ellinger, and K. Leo, Organic power electronics: transistor operation in the kA/cm2 regime. Sci. Rep. 7, 44713 (2017).

B. Kheradmand-Boroujeni, M.P. Klinger, A. Fischer, H. Kleemann, K. Leo, and F. Ellinger, A pulse-biasing small-signal measurement technique enabling 40 mhz operation of vertical organic transistors. Sci. Rep. 8, 7643 (2018).

J. Zaumseil, and H. Sirringhaus, Electron and ambipolar transport in organic field-effect transistors. Chem. Rev. 107, 1296 (2007).

Z. Suo, E.Y. Ma, H. Gleskova, and S. Wagner, Mechanics of rollable and foldable film-on-foil electronics. Appl. Phys. Lett. 74, 1177 (1999).

A. Nigam, G. Schwabegger, M. Ullah, R. Ahmed, I.I. Fishchuk, A. Kadashchuk, C. Simbrunner, H. Sitter, M. Premaratne, and V.R. Rao, Strain induced anisotropic effect on electron mobility in C60 based organic field effect transistors. Appl. Phys. Lett. 101, 083305 (2012).

A. Kumar, P. Jha, A. Singh, A.K. Chauhan, S.K. Gupta, D.K. Aswal, K.P. Muthe, and S.C. Gadkari, Modeling of gate bias controlled NO2 response of the PCDTBT based organic field effect transistor. Chem. Phys. Lett. 698, 7 (2018).

Y. Wen, Y. Liu, Y. Guo, G. Yu, and W. Hu, Experimental techniques for the fabrication and characterization of organic thin films for field-effect transistors. Chem. Rev. 111, 3358 (2011).

H. Rost, J. Ficker, J.S. Alonso, L. Leenders, and I. McCulloch, Air-stable all-polymer field-effect transistors with organic electrodes. Synth. Met. 145, 83 (2004).

L. Li, L. Jiang, W. Wang, C. Du, H. Fuchs, W. Hu, and L. Chi, High-performance and stable organic transistors and circuits with patterned polypyrrole electrodes. Adv. Mater. 24, 2159 (2012).

D.K. Aswal, S. Lenfant, D. Guerin, J.V. Yakhmi, and D. Vuillaume, Self assembled monolayers on silicon for molecular electronics. Anal. Chim. Acta 568, 84 (2006).

Y. Shi, Y. Zheng, J. Wang, R. Zhao, T. Wang, C. Zhao, K.-C. Chang, H. Meng, and X. Wang, Hysteresis-free, high-performance polymer-dielectric organic field-effect transistors enabled by supercritical fluid. Research 2020, 6587102 (2020).

P. Jha, S.P. Koiry, V. Saxena, P. Veerender, A. Gusain, A.K. Chauhan, A.K. Debnath, D.K. Aswal, and S.K. Gupta, Air-stability and bending properties of flexible organic field-effect transistors based on poly[N-9′-heptadecanyl-2,7-carbazole-alt-5,5-(4′,7′-di-2-thienyl-2′,1′,3′-benzothiadiazole)]. Org. Electron. 14, 2635 (2013).

Y.-H. Chou, S. Takasugi, R. Goseki, T. Ishizone, and W.-C. Chen, Nonvolatile organic field-effect transistor memory devices using polymer electrets with different thiophene chain lengths. Polym. Chem. 5, 1063 (2014).

Q. Li, T. Li, Y. Zhang, Z. Chen, Y. Li, L. Jin, H. Zhao, J. Li, and J. Yao, Photoerasable organic field-effect transistor memory based on a one-step solution-processed hybrid floating gate layer. J. Phys. Chem. C 124, 23343 (2020).

T. Xu, L. Xiang, M. Xu, W. Xie, and W. Wang, Excellent low-voltage operating flexible ferroelectric organic transistor nonvolatile memory with a sandwiching ultrathin ferroelectric film. Sci. Rep. 7, 8890 (2017).

J. Li, R. Bao, J. Tao, Y. Peng, and C. Pan, Recent progress in flexible pressure sensor arrays: from design to applications. J. Mater. Chem. C 6, 11878 (2018).

A. Dey, A. Singh, D. Dutta, S.S. Ghosh, and P.K. Iyer, Rapid and label-free bacteria detection using a hybrid tri-layer dielectric integrated n-type organic field effect transistor. J. Mater. Chem. A 7, 18330 (2019).

M.Y. Mulla, P. Seshadri, L. Torsi, K. Manoli, A. Mallardi, N. Ditaranto, M.V. Santacroce, C. Di Franco, G. Scamarcio, and M. Magliulo, UV crosslinked poly(acrylic acid): a simple method to bio-functionalize electrolyte-gated OFET biosensors. J. Mater. Chem. B 3, 5049 (2015).

B. O’Regan, and M. Grätzel, A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353, 737 (1991).

A. Hagfeldt, G. Boschloo, L. Sun, L. Kloo, and H. Pettersson, Dye-sensitized solar cells. Chem. Rev. 110, 6595 (2010).

K. Sharma, V. Sharma, and S.S. Sharma, Dye-sensitized solar cells: fundamentals and current status. Nanoscale Res. Lett. 13, 381 (2018).

V. Saxena, P. Veerender, A. Chauhan, P. Jha, D. Aswal, and S. Gupta, Efficiency enhancement in dye sensitized solar cells through co-sensitization of TiO2 nanocrystalline electrodes. Appl. Phys. Lett. 100, 81 (2012).

L. Zhang, X. Yang, W. Wang, G.G. Gurzadyan, J. Li, X. Li, J. An, Z. Yu, H. Wang, B. Cai, A. Hagfeldt, and L. Sun, 13.6% Efficient organic dye-sensitized solar cells by minimizing energy losses of the excited state. ACS Energy Lett. 4, 943 (2019).

L. Han, A. Islam, H. Chen, C. Malapaka, B. Chiranjeevi, S. Zhang, X. Yang, and M. Yanagida, High-efficiency dye-sensitized solar cell with a novel co-adsorbent. Energy Environ. Sci. 5, 6057 (2012).

K. Kakiage, Y. Aoyama, T. Yano, K. Oya, J.-I. Fujisawa, and M. Hanaya, Highly-efficient dye-sensitized solar cells with collaborative sensitization by silyl-anchor and carboxy-anchor dyes. Chem. Commun. 51, 15894 (2015).

J.-M. Ji, H. Zhou, Y.K. Eom, C.H. Kim, and H.K. Kim, 14.2% efficiency dye-sensitized solar cells by co-sensitizing novel thieno[3,2-b]indole-based organic dyes with a promising porphyrin sensitizer. Adv. Energy Mater. 10, 2000124 (2020).

I. Benesperi, H. Michaels, and M. Freitag, The researcher’s guide to solid-state dye-sensitized solar cells. J. Mater. Chem. C 6, 11903 (2018).

Y. Cao, Y. Saygili, A. Ummadisingu, J. Teuscher, J. Luo, N. Pellet, F. Giordano, S.M. Zakeeruddin, J.E. Moser, M. Freitag, A. Hagfeldt, and M. Grätzel, 11% efficiency solid-state dye-sensitized solar cells with copper(II/I) hole transport materials. Nat. Commun. 8, 15390 (2017).

P. Selvaraj, H. Baig, T.K. Mallick, J. Siviter, A. Montecucco, W. Li, M. Paul, T. Sweet, M. Gao, A.R. Knox, and S. Sundaram, Enhancing the efficiency of transparent dye-sensitized solar cells using concentrated light. Sol. Energy Mater. Sol. Cells 175, 29 (2018).

G. Yu, J. Gao, J.C. Hummelen, F. Wudl, and A.J. Heeger, Polymer photovoltaic cells: enhanced efficiencies via a network of internal donor–acceptor heterojunctions. Science 270, 1789 (1995).

J.W. Jung, J.W. Jo, E.H. Jung, and W.H. Jo, Recent progress in high efficiency polymer solar cells by rational design and energy level tuning of low bandgap copolymers with various electron-withdrawing units. Org. Electron. 31, 149 (2016).

H. Sun, F. Chen, and Z.-K. Chen, Recent progress on non-fullerene acceptors for organic photovoltaics. Mater. Today 24, 94 (2019).

G. Zhang, J. Zhao, P.C.Y. Chow, K. Jiang, J. Zhang, Z. Zhu, J. Zhang, F. Huang, and H. Yan, Nonfullerene acceptor molecules for bulk heterojunction organic solar cells. Chem. Rev. 118, 3447 (2018).

A. Chauhan, A. Gusain, P. Jha, S. Koiry, V. Saxena, P. Veerender, D. Aswal, and S. Gupta, Graphene composite for improvement in the conversion efficiency of flexible poly 3-hexyl-thiophene:[6,6]-phenyl C71 butyric acid methyl ester polymer solar cells. Appl. Phys. Lett. 104, 133901 (2014).

X. Li, G. Huang, N. Zheng, Y. Li, X. Kang, S. Qiao, H. Jiang, W. Chen, and R. Yang, High-efficiency polymer solar cells over 13.9% with a high VOC beyond 1.0 V by synergistic effect of fluorine and sulfur. Solar RRL 3, 1900005 (2019).

X. Xu, K. Feng, Z. Bi, W. Ma, G. Zhang, and Q. Peng, Single-junction polymer solar cells with 16.35% efficiency enabled by a platinum(II) complexation strategy. Adv. Mater. 31, 1901872 (2019).

S. Liu, J. Yuan, W. Deng, M. Luo, Y. Xie, Q. Liang, Y. Zou, Z. He, H. Wu, and Y. Cao, High-efficiency organic solar cells with low non-radiative recombination loss and low energetic disorder. Nat. Photonics 14, 300 (2020).

S. Wen, Y. Li, N. Zheng, I.O. Raji, C. Yang, and X. Bao, High-efficiency organic solar cells enabled by halogenation of polymers based on 2D conjugated benzobis(thiazole). J. Mater. Chem. A 8, 13671 (2020).

Q. Liu, Y. Jiang, K. Jin, J. Qin, J. Xu, W. Li, J. Xiong, J. Liu, Z. Xiao, K. Sun, S. Yang, X. Zhang, and L. Ding, 18% Efficiency organic solar cells. Sci. Bull. 65, 272 (2020).

M. Helgesen, R. Søndergaard, and F.C. Krebs, Advanced materials and processes for polymer solar cell devices. J. Mater. Chem. 20, 36 (2010).

F.C. Krebs, Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 93, 394 (2009).

F.C. Krebs, T. Tromholt, and M. Jørgensen, Upscaling of polymer solar cell fabrication using full roll-to-roll processing. Nanoscale 2, 873 (2010).

J.Y. Kim, J.-W. Lee, H.S. Jung, H. Shin, and N.-G. Park, High-efficiency perovskite solar cells. Chem. Rev. 120, 7867 (2020).

A. Kojima, K. Teshima, Y. Shirai, and T. Miyasaka, Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc. 131, 6050 (2009).

H.-S. Kim, C.-R. Lee, J.-H. Im, K.-B. Lee, T. Moehl, A. Marchioro, S.-J. Moon, R. Humphry-Baker, J.-H. Yum, J.E. Moser, M. Grätzel, and N.-G. Park, Lead iodide perovskite sensitized all-solid-state submicron thin film mesoscopic solar cell with efficiency exceeding 9%. Sci. Rep. 2, 591 (2012).

W.A. Dunlap-Shohl, Y. Zhou, N.P. Padture, and D.B. Mitzi, Synthetic approaches for halide perovskite thin films. Chem. Rev. 119, 3193 (2019).

A.K. Jena, A. Kulkarni, and T. Miyasaka, Halide perovskite photovoltaics: background, status, and future prospects. Chem. Rev. 119, 3036 (2019).

S. Yun, A. Hagfeldt, and T. Ma, Pt-free counter electrode for dye-sensitized solar cells with high efficiency. Adv. Mater. 26, 6210 (2014).

Y. Cui, L. Hong, and J. Hou, Organic photovoltaic cells for indoor applications: opportunities and challenges. ACS Appl. Mater. Interfaces 12, 38815 (2020).

M. Mainville, and M. Leclerc, Recent progress on indoor organic photovoltaics: from molecular design to production scale. ACS Energy Lett. 5, 1186 (2020).

D. Landerer, D. Bahro, H. Röhm, M. Koppitz, A. Mertens, F. Manger, F. Denk, M. Heidinger, T. Windmann, and A. Colsmann, Solar glasses: a case study on semitransparent organic solar cells for self-powered, smart, wearable devices. Energy Technol. 5, 1936 (2017).

B. Lee, L. Lahann, Y. Li, and S.R. Forrest, Cost estimates of production scale semitransparent organic photovoltaic modules for building integrated photovoltaics. Sustain. Energy Fuels 4, 5765 (2020).

A. Chauhan, A. Gusain, P. Jha, P. Veerender, S. Koiry, C. Sridevi, D. Aswal, S. Gupta, D. Taguchi, and T. Manaka, Interfacial charge trapping in the polymer solar cells and its elimination by solvent annealing. AIP Adv. 6, 095012 (2016).

A. Gusain, S. Singh, A. Chauhan, V. Saxena, P. Jha, P. Veerender, A. Singh, P. Varde, S. Basu, and D. Aswal, Electron density profile at the interfaces of bulk heterojunction solar cells and its implication on the S-kink characteristics. Chem. Phys. Lett. 646, 6 (2016).

H. Wang, and C. Yu, Organic Thermoelectrics: materials preparation, performance optimization, and device integration. Joule 3, 53 (2019).

D. Kim, Y. Kim, K. Choi, J.C. Grunlan, and C. Yu, Improved thermoelectric behavior of nanotube-filled polymer composites with poly(3,4-ethylenedioxythiophene) poly(styrenesulfonate). ACS Nano 4, 513 (2010).

O. Bubnova, Z.U. Khan, A. Malti, S. Braun, M. Fahlman, M. Berggren, and X. Crispin, Optimization of the thermoelectric figure of merit in the conducting polymer poly(3,4-ethylenedioxythiophene). Nat. Mater. 10, 429 (2011).

Z. Fan, and J. Ouyang, Thermoelectric properties of PEDOT:PSS. Adv. Electron. Mater. 5, 1800769 (2019).

Z. Liang, Y. Zhang, M. Souri, X. Luo, A.M. Boehm, R. Li, Y. Zhang, T. Wang, D.-Y. Kim, J. Mei, S.R. Marder, and K.R. Graham, Influence of dopant size and electron affinity on the electrical conductivity and thermoelectric properties of a series of conjugated polymers. J. Mater. Chem. A 6, 164 (2018).

Z. Fan, D. Du, X. Guan, and J. Ouyang, Polymer films with ultrahigh thermoelectric properties arising from significant seebeck coefficient enhancement by ion accumulation on surface. Nano Energy 51, 481 (2018).

J. Ding, Z. Liu, W. Zhao, W. Jin, L. Xiang, Z. Wang, Y. Zeng, Y. Zou, F. Zhang, Y. Yi, Y. Diao, C.R. McNeill, C.-A. Di, D. Zhang, and D. Zhu, Selenium-substituted diketopyrrolopyrrole polymer for high-performance p -type organic thermoelectric materials. Angew. Chem. Int. Ed. 58, 18994 (2019).

C.-K. Mai, R.A. Schlitz, G.M. Su, D. Spitzer, X. Wang, S.L. Fronk, D.G. Cahill, M.L. Chabinyc, and G.C. Bazan, Side-chain effects on the conductivity, morphology, and thermoelectric properties of self-doped narrow-band-gap conjugated polyelectrolytes. J. Am. Chem. Soc. 136, 13478 (2014).

M. Bharti, A. Singh, A.K. Debnath, A.K. Chauhan, K.P. Muthe, S.K. Gupta, K. Marumoto, T. Mori, and D.K. Aswal, Anionic conduction mediated giant n -type Seebeck coefficient in doped poly(3-hexylthiophene) free-standing films. Mater. Today Phys. 16, 100307 (2021).

H. Kojima, R. Abe, F. Fujiwara, M. Nakagawa, K. Takahashi, D. Kuzuhara, H. Yamada, Y. Yakiyama, H. Sakurai, T. Yamamoto, H. Yakushiji, M. Ikeda, and M. Nakamura, Universality of the giant Seebeck effect in organic small molecules. Mater. Chem. Front. 2, 1276 (2018).

H. Kojima, R. Abe, M. Ito, Y. Tomatsu, F. Fujiwara, R. Matsubara, N. Yoshimoto, and M. Nakamura, Giant Seebeck effect in pure fullerene thin films. Appl. Phys. Express 8, 121301 (2015).

F. Huewe, A. Steeger, K. Kostova, L. Burroughs, I. Bauer, P. Strohriegl, V. Dimitrov, S. Woodward, and J. Pflaum, Low-cost and sustainable organic thermoelectrics based on low-dimensional molecular metals. Adv. Mater. 29, 1605682 (2017).

J. Liu, B. van der Zee, R. Alessandri, S. Sami, J. Dong, M.I. Nugraha, A.J. Barker, S. Rousseva, L. Qiu, X. Qiu, N. Klasen, R.C. Chiechi, D. Baran, M. Caironi, T.D. Anthopoulos, G. Portale, R.W.A. Havenith, S.J. Marrink, J.C. Hummelen, and L.J.A. Koster, N-type organic thermoelectrics: demonstration of ZT > 0.3. Nat. Commun. 11, 5694 (2020).

Z. Liu, T. Liu, C.N. Savory, J.P. Jurado, J.S. Reparaz, J. Li, L. Pan, C.F.J. Faul, I.P. Parkin, G. Sankar, S. Matsuishi, M. Campoy-Quiles, D.O. Scanlon, M.A. Zwijnenburg, O. Fenwick, and B.C. Schroeder, Controlling the thermoelectric properties of organometallic coordination polymers via ligand design. Adv. Func. Mater. 30, 2003106 (2020).

G. Xing, Y. Li, Z. Feng, D.J. Singh, and F. Pauly, Copper(I)-based flexible organic-inorganic coordination polymer and analogues: high-power factor thermoelectrics. ACS Appl. Mater. Interfaces 12, 53841 (2020).

Y. Sun, L. Qiu, L. Tang, H. Geng, H. Wang, F. Zhang, D. Huang, W. Xu, P. Yue, Y.-S. Guan, F. Jiao, Y. Sun, D. Tang, C.-A. Di, Y. Yi, and D. Zhu, Flexible n -type high-performance thermoelectric thin films of poly(nickel-ethylenetetrathiolate) prepared by an electrochemical method. Adv. Mater. 28, 3351 (2016).

H. Wang, J.-H. Hsu, S.-I. Yi, S.L. Kim, K. Choi, G. Yang, and C. Yu, Thermally driven large n -type voltage responses from hybrids of carbon nanotubes and poly(3,4-ethylenedioxythiophene) with Tetrakis(dimethylamino)ethylene. Adv. Mater. 27, 6855 (2015).

L. Wang, Z. Zhang, Y. Liu, B. Wang, L. Fang, J. Qiu, K. Zhang, and S. Wang, Exceptional thermoelectric properties of flexible organic−inorganic hybrids with monodispersed and periodic nanophase. Nat. Commun. 9, 3817 (2018).

S.K. Gupta, P. Jha, A. Singh, M.M. Chehimi, and D.K. Aswal, Flexible organic semiconductor thin films. J. Mater. Chem. C 3, 8468 (2015).

M. Bharti, P. Jha, A. Singh, A.K. Chauhan, S. Misra, M. Yamazoe, A.K. Debnath, K. Marumoto, K.P. Muthe, and D.K. Aswal, Scalable free-standing polypyrrole films for wrist-band type flexible thermoelectric power generator. Energy 176, 853 (2019).

Z. Zhang, J. Qiu, and S. Wang, Roll-to-roll printing of flexible thin-film organic thermoelectric devices. Manuf. Lett. 8, 6 (2016).

D. Kim, D. Ju, and K. Cho, Heat-sink-free flexible organic thermoelectric generator vertically operating with chevron structure. Adv. Mater. Technol. 3, 1700335 (2018).

S. Mardi, M. Risi Ambrogioni, and A. Reale, Developing printable thermoelectric materials based on graphene nanoplatelet/ethyl cellulose nanocomposites. Mater. Res. Express 7, 085101 (2020).

Y. Zhang, J. Fang, C. He, H. Yan, Z. Wei, and Y. Li, Integrated energy-harvesting system by combining the advantages of polymer solar cells and thermoelectric devices. J. Phys. Chem. C 117, 24685 (2013).

Download references

Author information

Authors and affiliations.

Technical Physics Division, Bhabha Atomic Research Centre, Trombay, Mumbai, 400085, India

A. K. Chauhan, Purushottam Jha, D. K. Aswal & J. V. Yakhmi

Homi Bhabha National Institute, Anushaktinagar, Mumbai, 400094, India

A. K. Chauhan, Purushottam Jha & D. K. Aswal

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to A. K. Chauhan .

Ethics declarations

Conflict of interest.

The authors declare that they have no conflict of interest.

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Reprints and permissions

About this article

Chauhan, A.K., Jha, P., Aswal, D.K. et al. Organic Devices: Fabrication, Applications, and Challenges. J. Electron. Mater. 51 , 447–485 (2022). https://doi.org/10.1007/s11664-021-09338-0

Download citation

Received : 20 July 2021

Accepted : 08 November 2021

Published : 27 November 2021

Issue Date : February 2022

DOI : https://doi.org/10.1007/s11664-021-09338-0

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Organic devices

- organic electronics

- photovoltaics

- thermoelectric

- Find a journal

- Publish with us

- Track your research

Do-It-Yourself Devices: Personal Fabrication of Custom Electronic Products

Sept. 1, 2015

- David A. Mellis Former Research Assistant

- Mitchel Resnick LEGO Papert Professor of Learning Research

Share this publication

Mellis, D. "Do-It-Yourself Devices: Personal Fabrication of Custom Electronic Products"

Many domains of DIY (do-it-yourself) activity, like knitting and woodworking, offer two kinds of value: the making process itself and using the resulting products in one's life. With electronics, the sophistication of modern devices makes it difficult to combine these values. Instead, when people make electronics today, they generally use toolkits and other prototyping processes that aren't well suited to extended use.

This dissertation investigates digital fabrication (ofboth electronic circuit boards and enclosures) as an alternative approach to DIY electronics, one that can support individuals in both making devices and using them in their daily lives. The dissertation explores three questions: (1) What are the scope and limits of the personal fabrication of electronic products? (2) How can we engage people in the personal fabrication of electronic products? (3) Why make electronic products using personal fabrication?