Black Soldier Fly Farm Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business Plans » Agriculture Sector » Livestock Farming

Do you want to start a black soldier fly farm and need to write a plan? If YES, here is a sample black soldier fly farming business plan template & feasibility report.

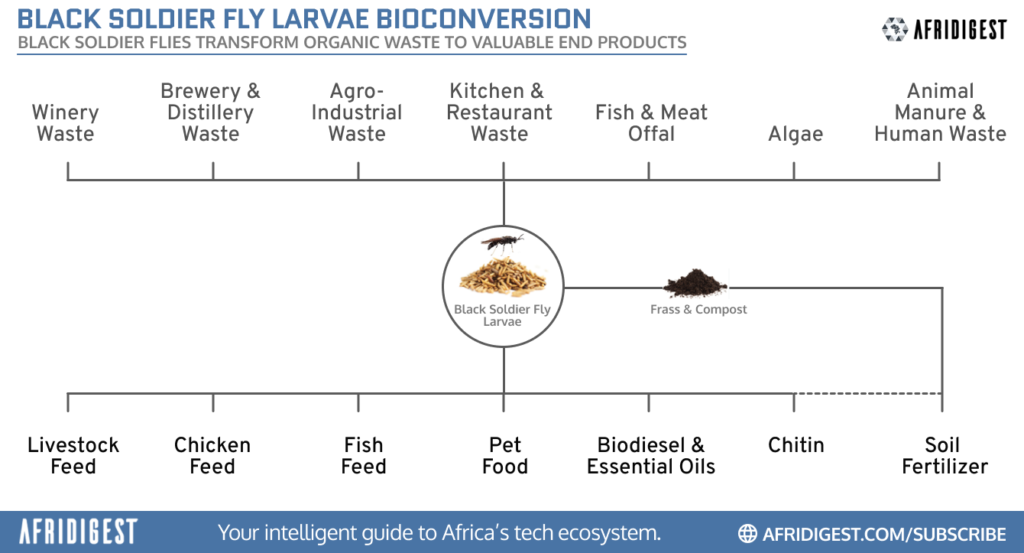

Black Soldier Flies (BSF) is the type of flies that are slightly bigger than the normal flies and known for its extraordinary ability to consume and reduce organic waste. It is also sold to poultries and dairy farms as a new protein source.

Black fly larvae alone can contain up to 43 percent of protein, and they are a great source of calcium and amino acids as well.

Why Breed Black Soldier Fly?

In modern America, any animal raised for its meat must be a clean source of food, both before and after being processed. For poultries or cattle, black soldier flies mean the process is a whole lot faster and easier, since no matter what they eat, a black soldier fly’s digestive process kills any bacteria they encounter in their food.

A black soldier fly can easily lay up to 500 eggs in one go, and since they only live for 6 weeks, be ready to get more eggs from the next generation of BSFL. Compared to that, a chicken usually lays only about 200 eggs in a year.

To further show how advantageous their reproduction rate is when compared to other animals, black soldier fly larvae excel at converting fodder into food. While you would need 10 kg of fodder to make 1 kg of beef, BSFL only need around 1.5 kg of feed to produce 1 kg of meat.

If you are seeking for a fresh, organic source of protein that you can easily farm, this is it. It is unique and stress free. Once you put a little ramp in their feeding area with a bucket at the end, the BSFL will harvest it selves: just before they enter the final stage of their growth, they will look for a dark and dry place, and climb into the bucket by themselves.

They also prefer to stay very close together. This means that what counts as cruel towards other livestock, is actually a humane, and practical solution here. In addition, they produce zero waste since their remains are fertilizer, and take a lot less space than other animals, so farming black soldier flies in environmentally sustainable.

A Sample Black Soldier Fly Farming Business Plan Template

1. industry overview.

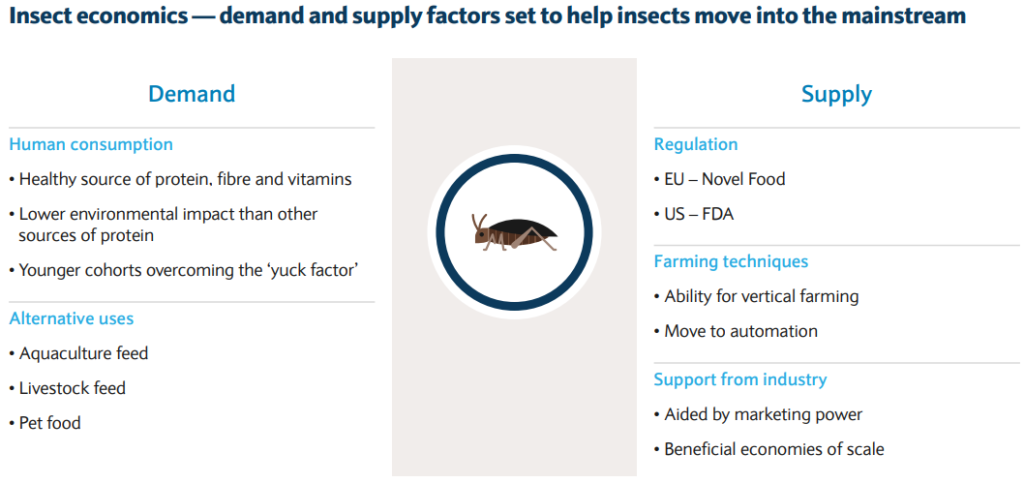

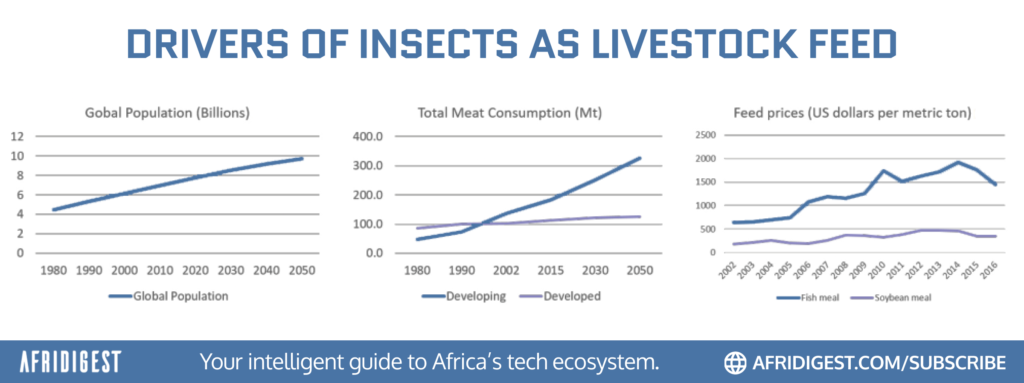

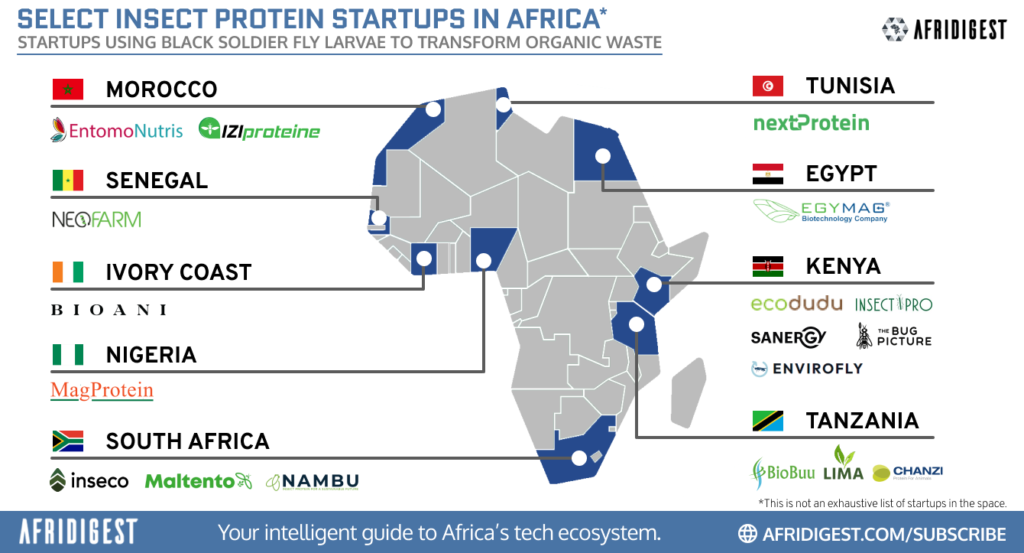

According to industry reports, the global black soldier fly market will reach $2.57 billion by 2030 with a CAGR of 33.3 percent during the forecast period of 2019 to 2030. The high growth of the black soldier fly market is due to the growing global meat demand, growing aquaculture industry, and the demand from animal feed industry for alternative proteins due to rising prices of soy meal.

In addition, growing government support for the use of insect meal in livestock feed, and growing investments by the key players operating in the BSF industry is fuelling overall growth. Although, factors such as non-standardized regulatory framework across Europe and limited acceptance and approval for BSFL application in human diet are negatively affecting the growth of this market.

In terms of industry product, in terms of value, protein meal maintained the largest share of the overall black soldier fly market in 2019.

Geographically, Europe will enjoy rapid growth during the forecast period. This rapid growth can be due to the government approvals for the use of BSF in animal feed and pet food; growing funding and investments in BSF industry; and the presence of a large number of start-ups.

Howbeit, factors such as growing demand for protein-rich animal feed; large supply of organic waste, including pre-consumer food waste from agriculture and food and beverage sectors; and supportive government policies for BSF farming conditions are also encouraging the BSF insect farming, and their consumption in food, feed, and other industrial applications.

2. Executive Summary

Feed Special® Black Soldier Fly Farm, Inc. is a new Black Soldier Fly Farm and Animal feed Production facility in Chicago, Illinois dedicated to sustainable, profitable and unique products. Black soldier flies are slightly bigger than the normal flies and known for its extraordinary ability to consume and reduce organic waste. We plan to sell them as new protein source used as animal feed.

Our mission at Feed Special® Black Soldier Fly Farm, Inc. is to breed these amazing flies, and use them to produce animal proteins to supply local poultries and consumers in Chicago. Our goals include high quality products and processes, and all our methods include new technology utilizing sustainable agriculture and best management practices.

Feed Special® Black Soldier Fly Farm, Inc. would earn revenue through the production and selling of the feeds for cattle, swine and poultry using the black soldier flies. Livestock animals are increasing in their numbers and there is increase in demand of feeds for livestock especially in winter.

Our breeding and production would go on around the year since there is availability of key resources all time of the year. At Feed Special® Black Soldier Fly Farm, Inc., we hope to increase production by 20 percent and sales by 30 percent in the next five years. Thomas and Patricia Kent own Feed Special® Black Soldier Fly Farm, Inc.

The farm and facility will be located on 3 acres of land belonging to the family and has two round style greenhouses for production and the reduction of production risk. The Kent family have been farming for 4 years and is relatively new to the industry although Thomas grew up on a ranch.

From our market research, it is evident that consumers are interested in high-end speciality products. There is a move toward health and local that will benefit our operation. Few limitations to our business include time and labour to devote to the operation and feed production.

Feed Special® Black Soldier Fly Farm, Inc. is well prepared to grow into one of the leading commercial BSF farms in the united states of America. We have organised the processes and strategies that will enable us employ best practices within the proximity of the law.

3. Our Products and Services

Cattles are one of the major contributors in the livestock market across the United States and they are a significant component of the American dietary system that includes the dairy products like butter and cheese. Poultry also remains one of the important livestock components in this modern age.

Animal feed plays a vital role in the food chain, as feed is one of the most crucial contributors in ensuring safe, abundant and affordable animal protein. Incessant population growth and rising affordability has surged demand for animal protein in the United States.

Feed Special® Black Soldier Fly Farm, Inc. will leverage extensive farming practices to bred black solider flies for both the United States’ market and the world as a whole.

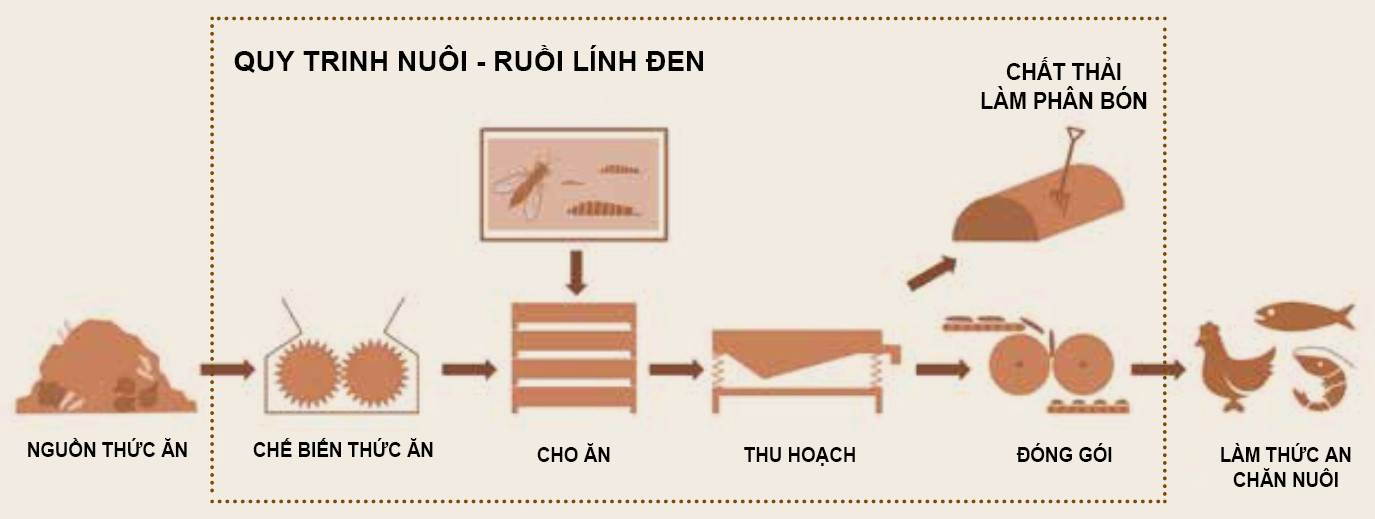

We also plan to produce both animal feed and fertilisers in very large quantities to meet the demand for clean protein source for livestock farmers and organic efficient fertilisers for crop farmers. We will also produce dried larvae, larvae oil, and chitin and chitosan. We plan to market them to the feed, agriculture, pet food, and other segments.

4. Our Mission and Vision Statement

- The Vision of Feed Special® Black Soldier Fly Farm, Inc. is to grow to become one of the leading commercial insect farms in the whole world, starting from the United States.

- Our mission at Feed Special® Black Soldier Fly Farm, Inc. is to provide unique and wholesome animal feeds that are affordable and sustainable.

- We work harmoniously with nature to grow quality black soldier flies to supply local poultries, cattle and swine in Chicago, Illinois

Our Business Structure

Feed Special® Black Soldier Fly Farm, Inc. is a black soldier fly farm that will be offering a wide range of animal feed and fertilizer produce. We plan to hire a number of employees to help us build a farm that will be able to meet the demand in the Chicago livestock industry.

We would also be hiring workers at intervals to help us deliver on our promise to provide sustainable options to our customers. Outlined below is the business structure of Feed Special® Black Soldier Fly Farm, Inc.:

Chief Operating Officer

Farm General Manager

Business Accountant

- Black Soldier Fly Farming Manager/Supervisor

- Field Employees

Receptionist

5. Job Roles and Responsibilities

- Will be in charge of providing direction for the business

- Well be In charge of Creating, communicating, and implementing the farm’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall farm’s strategy.

- Will be in charge of the day to day running of the farm

- Will be in charge of handling high profile clients and deals

- Will be in charge of fixing prices and signing business deals

- Will be in charge of signing checks and documents on behalf of the company

- In charge of calculating the success of the farm at regular interval

- Will be in charge of the planning, management and coordinating all farm activities across the various sections on behalf of the farm

- Ensures compliance during project executions

- Obligated to provide advice on the management of farming activities across all section

- Should be able to use IT systems and software to keep track of people and progress of the growth of the insects

- In charge of overseeing the accounting, costing and sale of farm produce after harvest

- Is charged with representing the farm’s interest at various stakeholders meetings

- Makes sure that farming goals desired result are achieved, the most efficient resources are used and different interests involved are satisfied.

- In charge of overseeing the smooth running of HR and administrative tasks for the farm

- It’s obligated to define the job positions for recruitment and managing interviewing process

- Carries out induction for new team members

- In charge of training, evaluation and assessment of employees

- In charge of overseeing the smooth running of the daily farming activities across the various farming sections

- Tasked with defining job positions for recruitment and managing interviewing process

- In charge of preparing financial reports, budgets, and financial statements for the farm

- In charge of financial forecasting and risks analysis

- In charge of developing and managing financial systems and policies

- In charge of administering payrolls

- Ensures compliance with taxation legislation

- Handles all financial transactions for the company

- Serves as internal auditor for the company

Black Soldier fly Manager/Supervisor

- In charge of managing the black soldier farming section of the farm

- Tasked with supervising other workers within the department

- Works closely with the General Manager to achieve the farms’ goals and objectives

Field Workers/Contract Staff

- In charge of feeding flies

- Helps in carrying out task in line with the stated job description

- Help in transport working tools and equipment from the farm and back to the designated store room

- Handles any other duties as assigned my the line manager

- Tasked with Receiving Visitors / customers on behalf of the farm

- Tasked with receiving parcels / documents for the company

- Tasked with handling enquiries via e-mail and phone calls for the farm

- Tasked with handling any other duties as assigned by the manager

- In charge of protecting the farm and its environs

- Controls traffic and organize parking

- Tasked with giving security tips when necessary

- Patrols around the farm on a 24 hours basis

- Presents security reports weekly

6. SWOT Analysis

Feed Special® Black Soldier Fly Farm, Inc. will compete favourably with leading feed production businesses in the United States of America. We will be offering a good number of agricultural resources, have properly analysed our market and our possibility for success.

Our SWOT analysis is to be analysed with a keen eye to capitalize on our strengths and make adjustments based on findings. Properly explained below is a summary of the result of the SWOT analysis of Feed Special® Black Soldier Fly Farm, Inc.,

- Devotion to the farm business

- Off farm income is helpful for start of the farm enterprise

- Well known in the community and reputation for quality

- Commitment to quality and success

- Constant trainings and workshops for management and production

- Do not have some of the machinery for feed production

- Lack of farm experience and new to black soldier fly farming

- Off farm jobs take precedence over farm

- Time and labour are an issue at peak time

Opportunities

- Local livestock movement is growing

- Promotion of Farmers Markets and coupon programs by state

- Lack of quality and affordable animal feed

- Local Farms and feed production businesses are Competitors

- Consumer preferences vary

- Product liability insurance are required by some potential clients

7. MARKET ANALYSIS

- Market Trends

In North America and Europe, black soldier fly prices are enormous compared to Asian countries, especially South Korea, Japan, Malaysia, and Vietnam, given the production cost differential between North America and Europe and Asia.

In addition, in the US, the prices for BSF products are higher than in European countries, especially due to standardized regulatory framework and low BSF production units compared to Europe.

At Feed Special® Black Soldier Fly Farm, Inc., we also understand that the availability of fishmeal has become increasingly limited with the expansion of the aquaculture industry, causing volatility in the price of the ingredient. There are growing concerns about the deforestation link with soybean meal, and it is fuelling industry’s search for sustainable alternatives, leading to growing interest in insect derived protein.

Insect species that are mass-reared such as black soldier fly (BSF) have received significant attention mainly due to their ability to feed on different substrates including organic waste streams. Coupled with increasing demand from the feed industry for alternative proteins, we also understand at Feed Special® Black Soldier Fly Farm, Inc. that the growth of the BSF market stems from a hike in global demand.

8. Our Target Market

Poultry, cattle and swine are the fastest growing livestock sectors in the United States. These livestock need adequate feed to obtain high quality, improved growth rate and lower mortality rate. Although the feedstock is of different types depending on the product such as for eggs or meat, Black soldier fly feedstock are important feeding component in almost every livestock farm owing to its cost effective and desired results.

Our market at Feed Special® Black Soldier Fly Farm, Inc. is a part of the vast animal feed market that makes an important part of it as meat and livestock products consumed in most parts of the country.

Our Competitive Advantage

At Feed Special® Black Soldier Fly Farm, Inc., we aspire to deliver quality products that would be beneficial for the health of the livestock and improve their longevity and productivity. It is expected that there would be a demand-pull at the customer end.

This can be further strengthened through innovative promotional strategies. The demand-pull is estimated to be significant thereby ensuring lowering of costs through economies of scale. It is expected that some of the competition would eventually be eliminated.

9. SALES AND MARKETING STRATEGY

At Feed Special® Black Soldier Fly Farm, Inc., we perfectly understand the importance of a well-detailed marketing plan and we have perfected ours by networking with livestock merchants and companies that rely on animal feeds for their farms.

Properly aligned below are the basic sales and marketing strategies we will be adopted ongoing at Feed Special® Black Soldier Fly Farm, Inc.:

- We will be introducing our farm and products by sending introductory letters alongside our brochure to poultries, cattle ranches, crop farmers and industry businesses.

- We will also advertise our farm and products in livestock and agricultural related magazines and websites

- We will strive to attend related agriculture expos, seminars, and business fairs et al

- We also plan to make use of the internet to promote our business

- We also plan to engage in direct marketing

- We will also Encourage the use of Word of mouth marketing (referrals)

10. Sales Forecast

We at Feed Special® Black Soldier Fly Farm, Inc. after our extensive research and feasibility studies have been able to discover what our sales might look like over the next three years. We believe in our strength and the products we offer from our farm, and we believe we will achieve these goals and figures.

We have also perfected our sales and marketing strategies to help us achieve our aim and goals, we have employed experienced hands and individuals we believe can help us be what we want, when we want.

Our sales forecast was actually based on what we believe is attainable for a new entrant in this industry and we have made everything possible in order to achieve it within the specified time or year. Outlined perfectly below is the three years forecast for Feed Special® Black Soldier Fly Farm, Inc.:

- First Year: $125,000

- Second Year: $449,000

- Third Year: $1,082,000

11. Publicity and Advertising Strategy

At Feed Special® Black Soldier Fly Farm, Inc., we boast of the zeal to grow our farm into a market leader in the industry. We have perfected plans to grow our brand awareness and create a corporate identity.

After our due market research, we know the critical points to leverage when deciding on the best strategies that will help us boost our brand awareness and to create a corporate identity for our farm. Summarized below are the strategies we have decided to use to boost our farm image:

- We plan to encourage our loyal customers to help with Word of Mouth mode of advertisement (referrals)

- We also plan to advertise our black soldier fly farm business in relevant magazines (agriculture and livestock related magazines), local newspaper, local TV and radio stations

- We will also promote our farm online via our official website and other farmers market publication

- We will list our farm business on local directories (yellow pages ads)

- We will make use of the internet and social media platforms like; Instagram, Google+, LinkedIn, Badoo, Facebook , twitter, et al to promote our farm business

- We plan to distribute our fliers and handbills in target areas (farm markets) at regular intervals.

Sources of Income

Feed Special® Black Soldier Fly Farm, Inc. is a privately owned farm that was established with the aim maximizing profits. Therefore, we have decided to leverage all available opportunities within our range to make Feed Special® Black Soldier Fly Farm, Inc. break even in the nearest possible time.

Feed Special® Black Soldier Fly Farm, Inc. would earn revenue through the production and selling of black soldier larvae and flies as feeds for cattle, swine and poultry.

We also plan to produce fertilisers in very large quantities to meet the demand for clean organic efficient fertilisers for crop farmers. We will earn revenue by selling dried larvae, larvae oil, and chitin and chitosan. All these products will be marketed to the feed, agriculture, pet food, and other segments.

12. Our Pricing Strategy

To get the right pricing for our farm resources, we need to make sure that we reduce the cost of running our farm to the smallest minimum and make sure we attract buyers, as against taking our products to the market to source for buyers. With this, we would have successfully removed the cost of transporting the goods to the market and other logistics from the equation.

We believe the nature of the industry has made it possible for farmers to place prices on their products based on their discretion without any outlined procedure in the industry. We plan to price our products efficiently to buttress its quality and nutrients.

- Payment Options

We all at Feed Special® Black Soldier Fly Farm, Inc. after our extensive research and thorough discussion are aware that different customers prefer different payment options as it suits them. We plan to make sure that we provide them with payment options that will make their transactions less stressful and very open. Listed below are the payment options we are making available to our customers:

- Payment via bank transfer

- Payment with cash

- Payment via online bank transfer

- Payment via check

- Payment via bank draft

13. Startup Expenditure (Budget)

As a farm that will be offering a good number of agricultural resources, we have properly analysed our market and our possibility for success. Our goals include high quality products and processes, and all our methods include new technology utilizing sustainable agriculture and best management practices.

We plan to offer a wide variety of services at Feed Special® Black Soldier Fly Farm, Inc. and we know what we need to make this farm profitable in no time.

The business would have only one production line with the production of feeds for cattle, swine and poultry. The production requires four types of machineries, which includes crusher machine, mixer machine, pelleting machine and conveyor machine, which works simultaneously one after the other accordingly.

Outlined below are some of the basic areas we plan to spend our start up fund for Feed Special® Black Soldier Fly Farm, Inc.

- The price for registering our farm in United States of America – $750

- Our budget for key insurance policies, permits and business license – $4,000

- The cost of preparing our production facility – $55,000

- The budget for preparing the farm– $25,000

- The price for acquiring the required working tools and equipment / machines / et al– $600,000

- The price of Launching an official Website – $600

- The budget for paying our workers for 1 year – $500,000

- Other business requirements (Business cards, Signage, Adverts and Promotions et al) – $2,000

- Miscellaneous – $5,000

As you can see from our above cost analysis, we will need $1,192,350 to start Feed Special® Black Soldier Fly Farm, Inc. and make the farm ready to serve the needs of our customers.

Generating Funding/Start-up Capital for Feed Special® Black Soldier Fly Farm, Inc.

Feed Special® Black Soldier Fly Farm, Inc. is owned and operated by Thomas and Patricia Kent. The farm and facility will be located on 3 acres of land belonging to the family that has two round style greenhouses for production.

Feed Special® Black Soldier Fly Farm, Inc. is a privately owned farm that will be solely finance by the owners and their immediate family. Outlined below are the possible means we plan to raising funds for Feed Special® Black Soldier Fly Farm, Inc.,

- Raising part of the startup capital from personal savings and sale of his stocks

- Raising part of the startup capital from family members and friends (soft loans and gifts et al)

- Raising a larger chunk of the start-up capital from the banks (loan facility)

14. Sustainability and Expansion Strategy

Although Feed Special® Black Soldier Fly Farm, Inc. should try to focus much in winters to serve the farmers as there will be scarcity of natural feed during this period. Nevertheless, for institutional side, we have to focus on meeting up the demand all throughout the year.

Our sales team, headed by the Chief Operating Officer, should have clearly spelt out responsibilities for team members to address the above segment with a properly devised sales plan. As our work forces are mostly unskilled, there is a need to develop their skills according to the need of the industry.

Workshops or on-site short-term trainings will be organized by the farming alignment with suppliers of machineries on how to control the temperature, operate machineries etc. The training would be a combination of theory sessions, on-the-job coaching sessions and on-the-job supervision.

For people joining with no relevant experience, training in their respective functional area would be mandatory. There would be a periodic skill assessment done by the farm management based on observation of on-the-job performance. Based on the findings, a training calendar needs to be drawn up;

One of the most common complaints associated with insect farms and feed production are the odours produced. The odours that feed production emits are a complex mixture of ammonia, hydrogen sulphide, and carbon dioxide, as well as volatile and semi-volatile organic compounds.

These odours are worse than smells formerly associated with smaller livestock farms. The anaerobic reaction that occurs when manure is stored in pits or lagoons for long amounts of time is the main cause of the smells. Odours from waste will be carried away from farm areas to be disposed according to water management laws in the region.

- Insect Vectors

Feed production and their waste can be breeding grounds for insect vectors. Houseflies, stable flies, and mosquitoes are the most common insects associated with feed production. Houseflies breed in manure, while stable and other flies breed in decaying organic material, such as livestock bedding.

Mosquitoes breed in standing water, and water on the edges of manure lagoons can cause mosquito infestations to rise. Flies can change from eggs to adults in only 10 days, which means that substances in which flies breed on need to be cleaned up regularly at our facility.

- Antibiotics

Antibiotics are commonly administered in animal feed in the United States. Antibiotics are included at low levels in animal feed to reduce the chance of infection and to eradicate the need for animals to expend energy fighting off bacteria, with the assumption that saved energy will be translated into growth.

The main purposes of using non-therapeutic doses of antimicrobials in animal feed are so that animals will grow faster, produce more meat, and avoid illnesses.

Supporters of antibiotic use say that it allows animals to digest their food more efficiently, get the most benefit from it, and grow into strong and healthy animals. The trend of using antibiotics in feed has increased with the greater number of animals held in confinement.

The more animals that are in close quarters, the more likely it is that infection or bacteria can spread among the animals.

Exit Strategy

Thomas and Patricia Kent will like to retire in 15 years and turn the farm over to their Son Austin. They have decided not to put more than $260,000 of their cash reserves at risk at anytime in the farm business. They want to work as a family unit in decision making regarding insects, enterprises, marketing and finances.

They also plan to invest in the farm business and hope to have a positive cash flow in 5 years. If not they will re-evaluate the farm business practice, market and product. At that time, they will decide to keep the farm in production or not.

Check List/Milestone

- Business Name Availability Check : Completed

- Business Incorporation: Completed

- Opening of Corporate Bank Accounts : Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of Insurance for the Business: Completed

- Conducting Feasibility Studies: Completed

- Leasing, renovating and equipping our facility: Completed

- Generating part of the startup capital from the founder: Completed

- Applications for Loan from our Bankers: In Progress

- writing of business plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents: In Progress

- Design of The Company’s Logo: Completed

- Printing of Promotional Materials: Completed

- Recruitment of employees: In Progress

- Purchase of software applications, furniture, office equipment, electronic appliances and facility facelift: In progress

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business (Business PR): In Progress

- Health and Safety and Fire Safety Arrangement: In Progress

- Establishing business relationship with banks, financial lending institutions, vendors and key players in the industry: In Progress

Related Posts:

- Rabbit Farming Business Plan [Sample Template]

- Ostrich Farming Business Plan [Sample Template]

- Broiler Farming Business Plan [Sample Template]

- Layer Farming Business Plan [Sample Template]

- Chicken Egg Hatchery Business Plan [Sample Template]

- Also available in:

- हिन्दी भाषा (hi)

- Bahasa Indonesia (id)

- ភាសាខ្មែរ (km)

- မြန်မာ (my)

- Tiếng Việt (vi)

Establishing a Scaled-Up Black Soldier Fly System

By: sombat chalermliamthong and patrick trail, echo asia impact center, published: 2021-09-01, from: echo asia note articles.

[Editor’s Note: This step-by-step guide follows the BSF production system of the ECHO Asia Small Farm Resource Center in Chiang Mai, Thailand. This is only one example of a functional system and should be adapted according to local context and availability of inputs. This article aims to elaborate on a ‘scaled-up’ system, adding to the wide variety of materials written about backyard and household BSF production.]

Figure 1. Author displays healthy Black Soldier Fly larvae to workshop participants at the ECHO Asia Small Farm Resource Center.

Introduction to Black Soldier Fly Production

Critical to the success of a small-scale farm is its ability to turn on-farm waste into alternative value-added products. By integrating the Black Soldier Fly ( Hermetia illucens ) on the farm, small-scale enterprises can do just that. Taking common waste products such as food scraps and manure, the Black Soldier Fly can be used to efficiently convert raw waste materials into high-protein feed sources for livestock, while simultaneously producing a by-product suited for amending soils.

The production of BSF larvae also has particular potential for areas in which feed protein sources are difficult to come by. In remote mountainous regions for example, the production of pigs, poultry, and fish are often limited by the availability of affordable protein inputs such as fishmeal and/or soy meal. Black Soldier Fly larvae production may be suited as an affordable alternative. While, humans can safely consume BSF larvae as well, the focus of this article will target production of feed sources for livestock.

There are many potential advantages to producing BSF and few drawbacks. Of particular note, BSF are extremely efficient converters of waste, can be produced quickly, and require a comparatively small footprint to other livestock or agricultural enterprises. It is also important to note that the Black Soldier Fly is not considered a pest, a common misconception. The BSF is not a known vector of disease, nor does it bite or sting.

Nutritional Value of BSF Larvae

Figure 2. Nutritional break down of [dehydrated] Black Soldier Fly ( Hermetia illucens ) larvae. Source: Feedipedia, 2021.

The larvae of the BSF are packed full of nutrients, both in quantity and quality. In addition to their high percentage levels of protein and fat content, larvae offer a complete nutritional make-up, including micronutrients, chitins, amino acids, and vitamins. Figure 2 below offers a snapshot of the nutritional make-up of the BSF larvae. For further details and break down of individual nutritional components of BSF larvae, see summary article by Barragan-Fonseca et al., 2017 .

A Step-By Step Guide to Scaled-Up BSF Production

This photo guide tracks the current Black Soldier Fly production system of the ECHO Asia Small Farm Resource Center, located outside of Chiang Mai, Thailand. This particular system aims to produce a steady flow of BSF larvae for feed of chickens and fish on the farm, but should not be considered large-scale or industrial by any means. Many resources currently exist online for the set-up and maintenance of small backyard BSF systems, such as those produced in buckets, bins, and barrels, but this system aims to produce larger quantities of larvae at various stages of production and life cycle. At the time of writing, this system consistently produces larvae in the range of 10 kilograms per week.

Step 1. Getting Started

Figure 3. Close up of an adult Black Soldier Fly (Hermetia illucens) .

As noted earlier in the article, the Hermetia illucens (Figure 3) can be found in most parts of the world, having adapted itself from its native region of the Americas into a now commonly seen insect species. To start a BSF production system, flies can either be captured from the wild or purchased from a local source. This article assumes the latter, that the reader is starting with eggs, larvae, or adult flies already in hand.

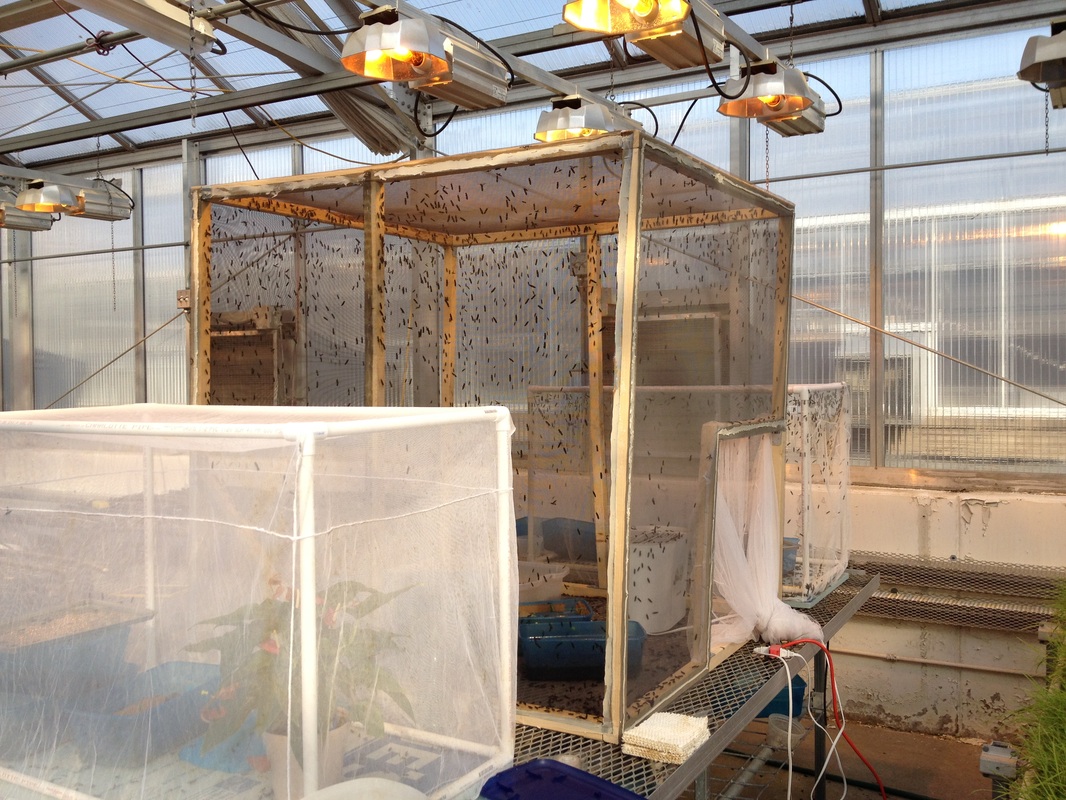

Figure 4. The screened-in BSF mating enclosure, including a dark room and overhead sprinklers for moisture control. Here adult flies mate and females will lay their eggs.

Step 2. Establishing a Mating Enclosure

The establishment of a mating enclosure is critical to the production of eggs, the primary step in producing BSF larvae. Such enclosures depend on the targeted scale of the enterprise, with many options and adaptations available. Mating enclosures can range from large screened-in rooms such as the above example from the ECHO Asia Farm, or smaller systems that utilize mosquito nets or even mesh laundry baskets. No matter the scale or design, it is necessary that the mating enclosure maintain adequate moisture and temperature. It is also critical that these enclosures remain sealed environments, both to keep the BSF in, and pests such as bird and rats out.

Within this enclosure a few provisions should be made for the adult flies, including a water source, some vegetation and surface on which to hide and mate, and a ‘dark room’ inside of which females will lay their eggs. At his stage in their life cycle, neither the pupae nor the mature adults will eat any food, therefore only a small food source is provided for the purposes of enticing the females to lay their eggs.

Step 3. Collecting Eggs

In order to collect the eggs of the adult female BSF, provisions must be made within the mating enclosure. At the ECHO Asia Farm we have discovered that small blocks of wood work well, providing both an inviting egg-laying environment for the female flies and a convenient mode of egg collection for staff. It is common practice to use small pieces of cardboard as egg laying material (Wong, 2020), however we prefer the aforementioned method as it is more convenient for the collection of eggs and tends to result in higher quantities of eggs. At this stage it is important to note that BSF do not lay their eggs directly on (or in) a food source, but rather nearby to one. Therefore, laying blocks should be situated nearby a food source, as depicted in Figure 5.

Figure 5. Inside the breeding enclosure, wooden blocks with small crevices are provided for the female BSF to lay their eggs. Blocks are placed above a food source, but not directly in contact with the food source.

In order to collect eggs, blocks should be removed, separated, and carefully scraped off. It is important to note at this stage that eggs can be of different ages if the blocks are not removed each day. By having eggs of different ages, the larvae will hatch and grow at different stages, requiring additional sorting and separating at maturity. Ideally, when producing larger batches of BSF, it is better to have larvae at uniform age and maturity. Typically, a mature female will produce anywhere from three to four hundred eggs in her lifetime.

Figure 6. Once the eggs have been laid, the wooden blocks can be removed and taken apart for easier access to the eggs. Toothpicks are used to separate blocks to provide small gaps in which females may deposit their eggs.

Step 4. Transitioning from Eggs to Larvae

Once eggs have been collected, they can be transferred to a food source where they will hatch and crawl their way to the nearby feedstock provided. Eggs will typically hatch within 4 days of being laid. At this stage, when larvae remain small, plastic trays can be used to hold small quantities of feed/waste and larvae. Mesh screen is used to keep the eggs from directly contacting the food source.

Figure 7. Collected eggs can be gently placed on top of the food source. Eggs are laid on screen mesh to avoid direct contact with the moist food. Once eggs hatch, they will quickly find their way to the food source.

Step 5. Selecting Appropriate Feedstock

One of the great benefits of the Black Soldier Fly is its ability to consume a wide array of different products, consuming market waste (fruit & vegetable), manure, table scraps, bone meal, and most other products. This article will not provide a prescriptive list of feed sources, but rather encourages the producer to identify the so-called ‘waste’ resources available to him/her. Ideally, low-cost, or even free, waste by-products should be targeted, including market waste, cafeteria food scraps, rice bran, brewer’s spent grains, soy cake, etc…

Figure 8. Many food source options exist for the production of BSF larvae, such as pineapple waste byproducts collected from the market, as seen here.

In order to ensure a balanced, or ‘complete’ feed source, it is recommended to mix a number of various waste resources together. This helps ‘bulk up’ the feedstock to ensure higher yields of larvae produced, but is not necessary.

Figure 9. To ensure that BSF larvae grow strong and healthy, it is possible to mix higher quality waste byproducts such as rice bran and soy meal, with lower quality waste byproducts.

Step 6. Stepping Up Production

As larvae hatch and feed, they will need to be ‘stepped up’ into larger containers or bays for adequate production. During this step, additional feedstock is provided and larvae are left to eat.

***NOTE: It is critical to control moisture to avoid foul smells and rotting feed material. Piles of feed or waste should never be allowed to go anaerobic. Trays or bays should have a way to drain off moisture to avoid any standing liquid. On the ECHO Asia Farm, we use a dry material such as rice bran or rice powder to rapidly absorb moisture when needed.

Figure 10. A scaled-up Black Soldier Fly system at a local farm in northern Thailand. This farm uses individual bays with different waste sources to grow BSF larvae at various stages of their life cycles.

Step 7. Knowing When to Harvest Larvae

Within the next 13 to 18 days larvae will feed voraciously, eating as much as twice their own body weight each day. It is critical during this time to identify the desired stage at which to harvest the larvae. At the end of the larval stage, before reaching the pre-pupae stage (Figure 11), larvae will reach their maximum nutrional capacity as a feed resource (Barragan-Fonseca et al., 2017). If harvested too late the producer runs the risk of lower feed quality, whicle harvesing too early might mean missing out on additional weight and size, and therefore potentially higher yields.

It is important to note that the decision to harvest larvae at this stage, before reaching maturity, will likely require some form of sorting or sizing, or separation of larvae from their feed material. This can be a laborious task and it is recommended that screens of various sizes be used in this process. Mechanized shakers do exist and can be repurposed for this purpose, or it can be done manually.

Figure 11. The life cycle of the Black Soldier Fly ( Hermetia illucens ), lasting approximately 45 days in its entirety. Before reaching the pre-pupal stage, BSF larvae are at their maximum nutritional quality as a feed resource. Source: Nutrinews 2020.

Step 8. Sorting and Sizing

In order to produce larvae at their peak nutritional stage they must be ‘harvested’ from their feed material. This involves some level of sorting and screening to isolate the larvae. This can be done with various sizes of screens and is made easier by transferring larvae to a finer feed source at the end of their production, allowing for easier separation. This can be done by hand or through investment in mechanized shakers, similar to technologies used in vermicast systems. For larvae that are fed directly, it may not be necessary to clean them completely.

Figure 12. Sorting and sizing BSF larvae.

Step 9. The Final Product

These larvae are at their final and most nutritionally rich stage, before turning into pupae, at which time their nutritional value will begin to decline.

Figure 13. The final product!

Step 10. Raising Pupae for Reproduction Purposes

Many BSF systems take advantage of the ‘self-harvesting’ nature of the BSF pupae. At this stage in its life, a BSF pupae will migrate from its food source in search of a dark quiet place to transform into a mature fly. As seen in the example above (Figure 14), many set-ups have been designed to funnel the crawling pupae out of the food source and into a bucket or other catchment arrangement. This is an extremely convenient phenomenon, but as noted earlier, only happens at the pupal stage when the BSF has already passed its prime as a feed source.

At the ECHO Asia Farm we have found that the ‘self-harvesting’ system works very well for [re]supplying the mating enclosure. If checked regularly it can be convenient and is capable of providing a steady supply of pupae for reproduction purposes.

Figure 14. A BSF larvae ‘self-harvesting’ bay. When pupae have reached the end of their pupal cycle, they will crawl away from their food source and will fall into the troughs where they can be collected.

Production Challenges to Consider

Pests such as birds, rats, and other critters should be considered before establishing a BSF system of any scale. Closed systems are necessary to keep flies in and unwanted pests out. Unfortunately, this necessary process of installing screens and nets can become expensive, and adds significantly to a producer’s bottom line.

Foul Smells

As previously mentioned, it is critical to the success of any BSF system to control moisture properly. Many food wastes, such as fruit scraps, contain high moisture contents and can lead to systems that become anaerobic. Preventing this from happening is not only crucial to the success of the overall system, but also to overall smell and subsequent perception of neighbors and clients. As previously mentioned, it is recommended to install drainage options and to keep on hand substances such as rice bran and rice flour that can be added to rapidly absorb moisture.

Uses of Black Soldier Fly Products

Livestock feeds.

Figure 15. Comparison of commercial chicken feed supplemented with various rates of BSF larvae at the ECHO Asia Farm. In this case, larvae are being integrated whole.

While it is possible to produce BSF larvae for human consumption, the primary impetus for producers remains as a source for livestock feed, particularly fish and poultry. Larvae can be fed directly, or they can be integrated into an existing feed ration. Staff on the ECHO Asia Farm are currently experimenting with commercial fish and chicken feeds supplemented with various rates of BSF larvae (Figure 15). To use larvae practically and regularly, they can be fed fresh, whole, dried, ground, or frozen depending on the context and equipment available to the producer.

Soil Amendment

In addition to the larvae produced, BSF also leaves behind a valuable manure similar to vermicasts. These ‘casts’ or ‘frass’ can be applied to soil as a rich amendment, providing additional value to an overall production system. In commercial enterprises this by-product is often bagged and sold as a separate product, another income generating component the small and medium producer might consider. At a minimum, this product can be reintegrated onto the farm in vegetable beds, nursery potting mixes, etc…

Lastly, there also comes with the production of BSF a liquid product that can be collected and used to amend soils. This liquid can be collected during the feeding process when larvae are voraciously consuming waste products such as food scraps, manure, and other feedstock materials.

Figure 16. BSF ‘casts’ or ‘frass’. A potentially valuable by-product of BSF production systems.

BSF production may or may not be beneficial on every farm or every context. Critical to any success will be the identification of an affordable, preferably free waste resource to serve as feedstock for the production of BSF. In many cases, BSF have been identified as an economical solution to the management of existing farm waste, such as manure and other un-used by-products.

Acknowledgments

The authors would like to thank Mr. Phai from Phai BSF Ecofarm CNX, for his willingness to share is his knowledge and experience. We learned so much from you, thank you.

Barragan-Fonseca, K.B., M. Dicke, and J.J.A. van Loon. 2017. Nutritional value of the black soldier fly (Hermetia illucens L.) and its suitability as animal feed – a review. Journal of Insects as Food and Feed. 3(2): 105-120. Available : https://avingstan.com/wordpress/wp-content/uploads/2019/08/Barragan-Fonseca-et-al-2017-Nutritional-value.pdf

Feedipedia, 2021. Tables of chemical composition and nutritional value of Black soldier fly larvae (Hermetia illucens), dehydrated. Available: https://www.feedipedia.org/node/16388

Nutrinews. 2020. Using black soldier fly larvae as a source of protein. The Animal Nutrition. Available : https://theanimalnutrition.com/using-black-soldier-fly-larvae-as-a-source-of-protein/

Wong, A. 2020. Black Soldier Fly of the Frangipani Langkawi Organic Farm. ECHO Asia Notes. 41. Available: https://www.echocommunity.org/en/resources/e3d5b1f1-0ec8-4a86-97e0-d80f26e7a951

Permanent Links

Permanent links, collections.

- 2021 ECHO Asia Black Soldier Fly (BSF) Production Workshop

- 2022 ECHO Asia On-Farm Feeds WS Resources

- Black Soldier Fly

ECHOcommunity.org is the online collaborative membership community of ECHO, an international nonprofit organization. ECHO exists to reduce hunger and improve lives through agricultural training and resources. Working through regional impact centers around the world ECHO connects small-scale farmers, and those working to eliminate world hunger, with essential resources, and each other. These resources include a vast knowledgebase of practical information, experienced technical support and an extensive seed bank focused on highly beneficial underutilized plants.

- Search Menu

- Themed Issues

- High-Impact Collection

- Infographics

- Author Guidelines

- Open Access Options

- Self-Archiving Policy

- Why Publish with Us?

- About Animal Frontiers

- About the American Society of Animal Science

- Editorial Board

- Advertising & Corporate Services

- Journals Career Network

- Journals on Oxford Academic

- Books on Oxford Academic

Article Contents

Introduction, agroecological insect-fish farming, income generation and financial projections, bsf and fish costs structure, market scenarios, income generation when adopting aiff, income differences in the short, medium, and long-term, enabling aspects to promote aiff, aspects to promote aiff in countries of the global south, authors’ contributions, conflict of interest, acknowledgments.

- < Previous

Small-scale Black Soldier Fly-fish farming: a model with socioeconomic benefits

- Article contents

- Figures & tables

- Supplementary Data

Karol B Barragán-Fonseca, Julián Cortés-Urquijo, Julián Pineda-Mejía, Diego Lagos-Sierra, Marcel Dicke, Small-scale Black Soldier Fly-fish farming: a model with socioeconomic benefits, Animal Frontiers , Volume 13, Issue 4, August 2023, Pages 91–101, https://doi.org/10.1093/af/vfad030

- Permissions Icon Permissions

While previous research has focused on Black Soldier Fly production on a large industrial scale, our research focuses on economic and social advantages for local economies and small-holder farmers.

Our findings indicate that Black Soldier Fly provides an important alternative protein source that can be locally produced by small- or medium-scale farmers, and can be combined on farms with fish production.

Our data show that Black Soldier Fly can provide an economically viable feed component for small-holder farmers

These results build on existing evidence that a circular approach to insect-fish farming is a viable option that empowers farmers and can contribute to developing the local community through a local value-chain approach in the Global South.

Over the past 20 years, aquaculture has become more integrated into the global food system, with a rapid growth in production and major transformations in feed ingredients, production technologies, farm management, and value chains ( Naylor et al., 2021 ). This growth in production as well as consumption relates almost entirely to countries in the Global South, where almost all (98%) of the world’s smallholder fish farmers are located, mostly in rural areas ( FAO, 2020 ). Smallholder fish producers operate across production intensities to cultivate a variety of species, relying primarily on their own labor and relatively small areas of land ( Marschke and Wilkings, 2014 ). In many communities, fish farming has been practiced as a tradition ( Bhujel, 2013 ), and in general, small-scale aquaculture is a peasant activity managed by families, with few employees or operated by a small community ( FAO, 2015 ). Such medium- and smallholder fish farmers are found in countries on different continents, most of them belonging to the Global South where poverty rates are high and high-quality nutrition is needed. Environmental impact of production, scarcity and increasing prices of raw ingredients for fish feed are among the most important challenges for this sector ( Tran et al., 2022a ), because feed is the largest single cost item for fish production, accounting for 60–70% of the total costs, including smallholder fish farmers ( van Huis, 2013 ).

Therefore, to reduce costs, the exploration of new opportunities is needed. Circular economy ( CE ) may provide these opportunities and may bring innovation into the aquaculture sector ( Thorarinsdottir et al., 2011 ). CE is not a new concept among smallholder farmers because it has been practiced in circular agriculture and agroecology for a long time ( Barragan-Fonseca et al., 2022a ). However, since aquaculture in the Global South faces similar challenges and opportunities, CE should be implemented by aiming for social equality, promoting a radical change in the creation of wealth and the production, distribution, and consumption of goods and services, and recovering culture ( Betancourt Morales and Zartha Sossa, 2020 ).

Several studies ( van Huis, 2013 ; Dicke, 2018 ; Chia et al., 2019 ; Madau et al., 2020 ; Tran et al., 2022a ), have shown how insects may be used to close the loop when referring to serious environmental and social problems that global agriculture is facing. Agriculture is responsible for more than 70% of the water footprint ( Pfister and Bayer, 2014 ) and food production is responsible for more than 30% of overall greenhouse gas emissions from all sources globally ( Smetana et al., 2019 ), aquaculture having a lower impact than livestock ( Jiang et al., 2022 ). Insects provide innovative solutions as an alternative protein source for animal nutrition ( van Huis, 2013 ; Smetana et al., 2019 ; Tran et al., 2022b ), a source to add value and improving health, natural behavior and quality of animals ( Foysal et al., 2019 ; Rawski et al., 2021 ), and a valuable tool for the transition to a bio-based CE in the agri-food sector, which aims to close the loop of agroproduction through recycling and reuse ( Madau et al., 2020 ). The use of insects as component of fish feed has been recently covered by various reviews focussing on production performance of aquaculture species ( Nogales-Merida et al., 2019 ; Tran et al., 2022b ). These reviews indicate that insects such as the Black Soldier Fly ( BSF , Hermetia illucens ) are promising components of feed for various fish species including salmonids ( Weththasinghe et al., 2022 ) and tilapia ( Oreochromis niloticus ) ( Tippayadara et al., 2021 ). The BSF can be used in innovations that provide environmental, social, and economical improvements of the performance of agri-food systems ( Onsongo et al., 2018 ; Chia et al., 2019 ), not only by large-scale, but also by medium- and smallholder farmers ( Barragan-Fonseca et al., 2022a ). Some initiatives using insects by medium- and smallholder farmers have shown that insects can support several of the Sustainable Development Goals ( SDGs ), focusing on food security, sustainable agriculture, combating climate change, and promoting stability and peace ( Dicke, 2018 ; Chia et al., 2019 ; Barragán-Fonseca et al., 2020b ; Madau et al., 2020 ).

Currently, it is not clear to what extent circular agriculture, based on producing insects for feed, can foster sustainable livelihoods for peasant families within the fish-producing economy. We recently proposed a theoretical model: Agroecological Insect-Fish Farming ( AIFF ), as a new opportunity to develop a CE by implementing practices such as those related to the agroecological field for crop production and the use of insects, especially the BSF ( Barragan-Fonseca et al., 2022a ). Here, we present the economic impact of the transition from an industrialized linear economy to a smallholder farmer circular aquaculture, and analyze the feasibility and the conditions under which AIFF might be developed by small- and medium-scale peasant farmers in the Global South based on a case study in Colombia.

To assess the direct impact of the inclusion of BSF larvae ( BSFL ) as a protein source to decrease the costs related to fish feed, smallholder farmers in Icononzo (Tolima, Colombia) engaged in setting up such novel circular approach of producing tilapia fish ( O. niloticus ) fed with BSFL as an alternative component of commercial feed. These farmers were ex-guerrilla members who had put down their arms in the peace process and started fish production within the frame of the project “Insects for Peace” ( I4P ) ( Barragán-Fonseca et al., 2020b ). These farmers replaced between 25% and 38% of the traditional tilapia feed with sundried BSFL, fish were fed five times a day during the fingerling phase, three times a day during the juvenile phase and twice a day during the growing and final phase. Fish exposed to traditional production and those exposed to the AIFF model were fed with the same regime and frequency. Italcol´s brand fish feed was used as the commercial feed. Based on this case and information collected from fish and insect producers in Colombia, a CE model called “Agroecological Insect-Fish Farming” (AIFF) was developed ( Barragan-Fonseca et al., 2022a ). This model conceptualizes the synergies between CE and agroecology approaches as a new opportunity to develop a CE by implementing practices such as the use of insects, especially BSF, producing high value proteins and organic fertilizer (insect waste streams— IWS ) while empowering small- and medium-holder fish farmers’ economies by raising profitability ( Figure 1 ).

General description of the Agroecological Insect-Fish Farming model—AIFF (adapted from Barragan-Fonseca et al., 2022a ). This model conceptualizes the synergies between CE and agroecology approaches as a new opportunity to develop a circular economy by implementing practices such as the use of insects, especially BSF, producing high value proteins and organic fertilizer (insect waste streams—IWS) while empowering small- and medium-holder fish farmers’ economies by raising profitability. More than an economy, this is a concept based on the next three principles: Principle 1—Inputs: Preserve and enhance natural capital by controlling finite stocks and balancing renewable resource flows. Principle 2—Processes: Optimize resource yields by circulating production components and materials in both technical and biological cycles. Principle 3—Outputs: Foster system effectiveness by revealing and phasing out negative externalities.

The economic impact and financial projections of partially replacing commercial feed ingredients with BSFL based on a circular approach, used data obtained from insect farmers and fish farmers in Colombia and the case study of Icononzo ( Barragan-Fonseca et al., 2022a ). This relates to an analysis of the economic impact of the transition to a peasant circular aquaculture to support peasant economy and small- and medium-scale farmers in Latin America according to the AIFF model. To gain insight into the economic effects of using BSF as protein source in fish feed, the income of farmers when including AIFF (circular production) should be compared to a traditional linear fish production (non-AIFF). When producing fish fed with BSF as protein source, two production systems may be used: 1) producing BSF and fish in two different places, as was done in Icononzo or 2) by executing both production systems at the same physical location or production center. Fish costs: We used a two-cost structure for fish production. One is based on Icononzo′s case study (AIFF model) and the other is a cost structure without including BSF as fish feed (non-AIFF model). In this way, with BSF and fish cost structures we have a starting point to analyze other market scenarios.

In the case of BSF production, the costs incurred by having the BSF production unit and the fish production unit in different production centers (being BSF and fish production of the same owner) or in the same production center are presented. The fish cost structure is subdivided into two, the first structure refers to a fish production system that applies a circular economy production through the AIFF model, which uses BSFL as feed component for fish, thus reducing the use of conventional fish feed and, in turn, their respective total costs. Table 1 presents BSF and fish production costs of Icononzo′s case study. All costs and revenues are expressed for an AIFF with 7,000 fish (2.1 tons of total biomass were produced with an average weight of 300 g/tilapia) and 1,400 kg of BSF production capacity during a period of 4 months, which represents the duration of the tilapia production cycle. AIFF and non-AIFF production methods had similar responses of the tilapia performance, both had an average Feed Conversion Ratio of 1.3 and mortality of 30% where the tilapia reached the weight target (±300g). BSFL production : is done through vertically stacking trays in a facility. Larvae were fed on organic waste streams from community waste and from Icononzo´s local market. Average production of BSF: 15 kg of organic waste (wet weight) to produce ~2 kg (wet weight) of harvested BSFL, or ~0.6 kg of sundried BSFL, and 4.5 kg of frass (wet weight). Tilapia production : The facilities for tilapia production consisted of three tanks where the tilapia fingerlings were distributed according to the water volume availability. Tanks 1, 2, and 3 had a capacity of 2,500, 2,500, and 2,000 animals respectively. Each tank had constant water replacement and air flow with a net that covers and protects the fish from natural predators.

Structure of BSF production for a 4-month fish production cycle in a different production center or in the same location as fish production, and fish production costs per fish-production cycle (4 months) with AIFF and non-AIFF model

Underlined figures represent costs that differ between scenarios. All costs in euro’s based on Colombian conditions. N/A, not applicable.

a Cost structure includes: Fixed costs that do not depend on production volume; they are constant in time; Variable costs which depend on the production volume. The sum of the fixed and variable costs equals Total costs .

b Icononzo market scenario.

c The type of peasant family economy applied in this context recognizes working conditions where the producer families exchange working hours with neighboring farms and family members, which is why it is optional to pay wages in cash or in working hours. For cost accounting purposes, it is calculated that an average worker dedicates 3 to 4 h of work per day in each of the two activities, with an average payment of 1.2 Euros for each hour of work (higher than the payment of 1 h of work stipulated by the legal minimum wage in force in Colombia in 2023).

d Costs that are reduced in BSF’s cost structure by incorporating both production systems (BSF and fish) within the same production center.

e This cost relates to both cost structures, because variation in the costs of BSF production affects the cost structure of fish production, because for circular fish production (AIFF), the production of BSF is previously incurred.

Table 1 presents the costs related to both BSF and fish production systems. There are variables such as organic waste transport that only relate to the production of BSF. Land rent, marketing, telephone/internet, and organic waste transport represent those costs of BSF production that, when BSF and fish are produced on the same farm, should not be included for BSF production because they are included in the costs of fish production.

We use two variables to propose four different market scenarios, Icononzo´s case being one of them. Variable A: BSF production and fish production are in the same or in different production centers or farms. Variable B: The sales price of fish produced in a linear economy (non-AIFF) is the same or different from that produced in a circular economy (AIFF). We selected these variables based on the actual situation in Icononzo for small and medium-scale fish farmers. A difference in fish prices for the circular and linear production systems was selected because there is a tendency toward the consumption of food with better nutritional quality and benefit for human health due to the management and type of complementary feeding used ( Feldmann and Hamm, 2015 ). Both variables combined generate four different market scenarios. The market scenario of Icononzo’s BSF production is based on the following principles: different sales prices (€1.00/ fish produced in a circular system [AIFF] vs. €0.71/fish produced in a linear system [non-AIFF]) and production systems in different production centers. After analyzing Icononzo's market scenario (hereafter Scenario 3) we assessed the consequences of changing variables A and B. The prices were obtained by the local sales market experience. In the local market, traditional tilapia price was € 0.71/fish, compared with a different market price of € 1.00/fish, based on the Porter’s five tendency force: threat of substitution, where the customers prefer a more sustainable product on their dish (from farm to fork).

Table 2 presents four market scenarios based on the two variables: Variable A—BSF and fish produced in the same or in different production centers, and Variable B—fish produced in a circular and linear production system are sold at the same or different prices. Variable A only affects the cost structure of the AIFF model, reducing or maintaining costs; while variable B only affects the income of the non-AIFF model (linear economy). Therefore, there are four market scenarios each with two cost structures: under the AIFF model and the non-AIFF model, and we can calculate the profit differences between fish production with AIFF and non-AIFF models.

Fish production with (AIFF) and without (non-AIFF) the use of Black Soldier Fly as feed component

All costs in euro’s.

Costs, revenues, and break-even point for four different market scenarios per fish-production cycle (4 months) including and excluding the AIFF model based on two variables (A and B).

Fish production revenues are derived directly from the total sales of fish (at the farm gate), and by-products’ revenues are the income obtained from the sales of the by-products generated by the fish production. In the case of AIFF production, by-product revenues refer to the fertilizers obtained after harvesting the BSF (frass, i.e., non-consumed substrate, insect manure, and moulting skins), which are sold to neighboring crop farmers ( Barragán-Fonseca et al., 2022a ); in the case of non-AIFF fish production by-products’ revenues (leftover fish parts) refer to the surplus fish marketable in the area. Break-even point refers to the level of sales (in quantities sold) where the revenues obtained cover both fixed and variable costs, and that from these values profits start to be generated. Operating profit is the difference between Total Revenues and Total Costs, being the profits obtained from the total sale of fish, after discounting the costs. Difference in Operating Profit for a 4-month production cycle represents the difference between the fish production systems (AIFF and Non-AIFF) of each of the cases, for a period of 4 months, a value that will allow be projected to some future periods, as we will see later.

Bold values indicate the main values, that are calculated on the basis of several lines above the value.

a Icononzo´s market scenario.

b Break-even point represents the point at which total revenues equal total costs. At this point there is no profit or loss. In the table they are presented as the number of units sold.

In scenarios 1 and 3, higher fixed costs are generated by the obligation to pay rent for the land, marketing, telephone, and transport of organic waste to the BSF farm, which are unavoidable when the BSF production plant is located in a different location than the fish production plant. Hence, in this first case, the difference between operating profits when producing AIFF compared to non-AIFF is 200 euros. In Scenario 2, the costs are lower than in Scenario 1, because here the advantage is that both BSF and fish production systems are in the same place, which reduces AIFF fixed costs by €300 for each production cycle: total fixed costs are €2,291 for AIFF in the same production center and €2,591 for AIFF in different production centers. Therefore, fixed costs like marketing, internet and telephone, land rent, and organic waste transport are not present. As a result, the difference between Operating Profit between producing with AIFF and without AIFF increases from €200 to €500. Scenarios 3 and 4 differ considerably in income from scenarios 1 and 2, mainly generated by the differentiation of sales prices of fish (€0.71 and €1 for non-AIFF and AIFF, respectively). The differences in break-even point between AIFF and non-AIFF models, regardless of scenario, show that the AIFF model presents better income to the farmer, with the best market scenarios being 3 and 4.

In the Icononzo case (Scenario 3), where BSF production is not located at the fish farm, the final price of fish produced with BSF as feed ingredient (€1.00/fish) at the farm gate is higher than without including BSF (€0.71/fish). This result is achieved because local consumers are willing to pay more for fish locally produced through an AIFF model by ex-combatants, based on the experience with local consumers in Icononzo. However, this principle may or may not be fulfilled in other communities because it depends on the preferences of consumers that may change over time, depending on their situation and economic stability. If their economic situation deteriorates, consumers may prefer a lower price over quality. This is why it is important to recognize other possible sources of economic sustainability, which do not fundamentally depend on the sales price of fish produced through AIFF compared to the non-AIFF model. For instance, when there is a cost structure where both production systems (fish and BSF) are on the same land or within the same production center, the BSF production cost is lower than when both production systems are in different places. The AIFF model provides opportunities to yield up to 44% higher revenues, and to reduce the costs up to 23%.

The AIFF and non-AIFF approaches in scenarios 3 and 4 differ considerably in income compared with the two approaches in scenarios 1 and 2, mainly caused by the differentiation of sales prices of fish (€0.71 and €1.00). It is a strong assumption considering economic crises that farmers (local consumers) have in relation to the commercialization of their products or basic services access. Reduced income of these local fish consumers may make them decide to choose cheaper fish. However, the wish for healthy and environmentally friendly food encourages consumers to make decisions where quality prevails over price, which is why they decide to opt for fish produced through a circular-economy approach. The differences in break-even point between AIFF and non-AIFF models, regardless of scenario, show that the AIFF model presents better income (Operating profit) to the farmer, with the best market scenarios being 3 and 4.

In relation to the break-even point, in Scenario 1 and Scenario 2, the main difference between the production systems with AIFF and Non-AIFF is that feeding fish from BSF production requires higher fixed costs and lower variable costs due to the constant production of BSF which is required, unlike the case of opting for the traditional production system where costs depend to a large extent on the purchase of concentrate that varies according to the level of production. In scenarios 3 and 4, the main difference in break-even point of both production systems is due to the price difference, which is ahead of the production system with BSF where comparatively a point of zero losses can be reached sooner than in the case of producing by the non-AIFF model. In all cases, the constant sales level of 7,000 fish would allow reaching and exceeding the break-even point in the first period of application.

Additional to that, as mentioned before, the AIFF model has the possibility of generating a by-product in the transformation process: organic fertilizer from BSF frass, which can be used for crops ( Poveda, 2021 ; Barragan-Fonseca et al., 2022b ) and can improve profits for farmers as was reported, for example, Kenya ( Beesigamukama et al., 2022 ; Tanga et al., 2022 ). This fertilizer is generated without increasing the costs of fish production and also increases the family income by supplying the inputs that a peasant family needs to increase the quality of other products that they grow on their farm. With the sale of these, an increase in the family income is estimated at 500 euros. Therefore, the AIFF model may produce a return rate up to 45% considering that total sales are €7,500 and the costs associated to its production are around 50% of it.

However, there are some risks to consider for the proposed market scenarios. For instance, there may be a previous unproductive stage typical of the application of the BSF production system, which may vary among production centers which could affect each of the models contemplated because in this time there would not be income. On the other hand, the aforementioned market models do not consider monetary inflation fluctuations or eventual cases of increases in the prices of inputs in the local area, which is why it is important when evaluating scenarios that require more detail to consider the need to add to the final sale price the inflationary percentage that allows projections more faithful to reality. Thus, the evaluation of more precise AIFF scenarios is needed according to different geographic and socio-economic factors in the AIFF implementation.

The income projections are based on the calculation of the operating profits of both production systems (AIFF and non-AIFF models) presented in each of the four scenarios analyzed. The projections are made for the short (2 years), medium (5 years), and long-term (10 years), where each year of production contains three production cycles of fish, each lasting 4 months. The difference in accumulated earnings is bigger in the AIFF model than in the non-AIFF model in all four scenarios and in the long-term projection. The income differences (Difference Operating Profit for 4 months) in the short, medium, and long-term between AIFF and non-AIFF models of the four scenarios ( Figure 2 ) shows that even in the least profitable scenario (Scenario 1) the income based on AIFF is higher than for the non-AIFF situation. Even with this small income difference and starting from a moderately profitable scenario (Scenario 1), when projecting the income over several years into the future after 10 years the income difference between both systems is €5,970.

Income of farmers using the AIFF and non-AIFF models in four market scenarios (see Table 2 for details on the four scenarios). The income differences (Difference Operating Profit for 4 months) are based on the calculation of the operating profits of both production systems (AIFF and non-AIFF models) presented in each of the four scenarios analysed. The projections are made in the short (2 years), medium (5 years), and long term (10 years), where each year of production contains three production cycles of fish. The income differences between AIFF and non-AIFF model of the four scenarios shows that the income based on AIFF is higher than for the non-AIFF situation.

The transition to a sustainable organic waste management with insects should establish the best ways to put AIFF into practice in a local scenario. Experience shows that this transition cannot be merely technological. By nature, it is multidimensional and requires active participation by different actors through an inter- and transdisciplinary approach ( Chia et al., 2019 ; Barragán-Fonseca et al., 2020a , b ). Here, we analyze success and risk factors and we present a strengths, weaknesses, opportunities, and threats ( SWOT ) analysis of an AIFF model to identify enabling aspects to implement AIFF schemes in developing countries. For this SWOT analysis all observations and inferences suggested are based on the previously documented literature, Icononzo´s experience, insect production with small-holder farmers in Kenya ( Chia et al., 2019 ), workshops with ex-combatant communities in Colombia ( Barragán-Fonseca et al., 2020a ), and private and public institutions in Colombia regarding the use of insects as feed ( Dicke et al., 2020 ), and the authors’ experience.

SWOT analysis for AIFF

Pros and cons of the use of insect farming in aquaculture in countries of the Global South are assessed through a SWOT analysis to identify key factors that could support or impair the development of AIFF in those countries as protein source for the aquaculture sector. In Table 3 we present the SWOT of implementing the AIFF model in the Global South.

Strengths, weaknesses, opportunities, and threats (SWOT) analysis of implementing AIFF model in the Global South

The transition from linear to circular aquaculture by smallholder farmers in low-income countries requires a local analysis of the value chain and the actors (stakeholders) involved, that can potentially intervene so that the system is successful and that it adjusts to specific conditions at each place. A value chain of the AIFF model consists of four main segments: 1) The substrate segment, aimed at providing organic waste for insects, 2) the insect segment, aimed at production of insects, 3) the feed production segment, aimed at products resulting in resources for fish feed, and 4) the fish production, valorization, and consumption segment ( Dicke et al., 2020 ). Each segment has specific stakeholders. We propose four main aspects to promote the AIFF model in developing countries: 1) socio-economic, 2) technical, 3) communication and marketing, 4) education, research, and innovation, and 5) policy-making and legislation.

Socio-economic aspects

Peasant family farming has traditionally been more focused on self-consumption of food and other goods to satisfy their own needs and on the selling of surpluses rather than on cash crops ( van der Ploeg, 2008 ). Entrepreneurial farming in the Global South usually engages small- and middle-scale farmers in business models addressed to big, national, international, or highly profitable markets, that normally require high inputs of innovation, capital, knowledge, and skills and a fruitful economic environment which, in some developing countries, are currently difficult to achieve. Value chains and business models promoted through public policies and cooperation programs in the Global South usually fail due to the lack of understanding of the local economic environment. Most of the time, the local economic environment lacks public support and infrastructure, is embedded in criminal activities, involves high levels of land concentration and is managed by violent power structures, among others. In this context, promoting peasant and family farming within the AIFF model, would be a more realistic approach to provide sustainable livelihoods to peasants, increasing local knowledge, safeguarding culture, conserving nature, feeding themselves, and being autonomous, among other benefits ( van der Ploeg, 2014 ).