Fabrication and synthesis of SnO X thin films: a review

- ORIGINAL ARTICLE

- Published: 03 November 2020

- Volume 111 , pages 2809–2831, ( 2020 )

Cite this article

- Emeka Charles Nwanna 1 ,

- Patrick Ehi Imoisili 1 &

- Tien-Chien Jen ORCID: orcid.org/0000-0003-1743-4668 1

1160 Accesses

12 Citations

Explore all metrics

Due to its exceptional electrical, optical, chemical and magnetic properties, tin oxide (SnO and SnO 2 ), which is a functional material, has gained enormous attention for use in a variety of applications. Films of SnO X have a direct band gap between the ranges of 2.2 and 3.6 eV, with these films finding usefulness in various functions such as solar cells, transparent conducting oxides for gas sensors, lithium-ion batteries and microelectronics, and use in the optoelectronics industries. In order to satisfy the needs of a broad range of these applications, thin films with an extensive properties span defined by film composition, thickness, structural properties and morphology are required. This article explains the theory and research status of the various manufacturing processes of tin oxide. The purpose is to analyze the effects of the thin films through distinct forms of deposition. The general finding summarized in this research on SnO X showed that various researchers studied specific characteristics of tin oxide properties restricted by experimental conditions.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Synthesis and characterization of tin (IV) oxide thin films

M. Rahayi, M. H. Ehsani, … Fabian I. Ezema

Structural, Optical, Electrical, and Nanomechanical Properties of F-Doped Sno2 Fabricated by Ultrasonic Spray Pyrolysis

Jaewon Kim, Gahui Kim & Young-Bae Park

Influence of deposition techniques on quality and photodetection properties of tin disulfide (SnS2) thin films

Ankurkumar J. Khimani, Sunil H. Chaki, … M. P. Deshpande

Epifani M, Francioso L, Siciliano P, Helwig A, Mueller G, Díaz R, Arbiol J, Morante JR (2007) SnO2 thin films from metalorganic precursors: Synthesis, characterization, microelectronic processing and gas-sensing properties. Sensors Actuators B Chem 124(1):217–226. https://doi.org/10.1016/j.snb.2006.12.029

Article Google Scholar

Göpel W, Schierbaum KD (1995) SnO2 sensors: current status and future prospects. Sensors Actuators B Chem 26(1-3):1–12. https://doi.org/10.1016/0925-4005(94)01546-t

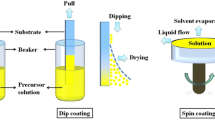

Aswathy BR, Vinay K, Arjun M, Manoj PK. (2019) Deposition of tin oxide thin film by sol-gel dip coating technique and its characterization. Proceedings of the international conference on advanced materials: ICAM 2019 [Internet]. AIP Publishing; 2019; Available from: https://doi.org/10.1063/1.5130344

McAleer JF, Moseley PT, Norris JOW, Williams DE, Taylor P, Tofield BC (1997) Tin oxide based gas sensors. Mater Chem Phys 17(6):577–583. https://doi.org/10.1016/0254-0584(87)90017-4

Zhitomirsky VN, David T, Boxman RL, Goldsmith S, Verdyan A, Soifer YM, Rapoport L (2005) Properties of SnO2 coatings fabricated on polymer substrates using filtered vacuum arc deposition. Thin Solid Films 492(1-2):187–194. https://doi.org/10.1016/j.tsf.2005.06.061

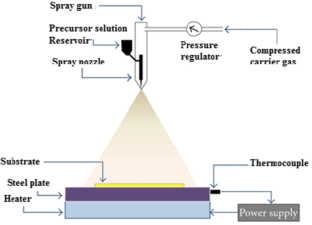

Albin D, Risbud S (1997) Spray pyrolysis processing of optoelectronic materials. Adv Ceram Mater(USA) 2(3A). https://doi.org/10.1111/j.1551-2916.1987.tb00089.x

Manifacier J, Fillard J, Bind J (1991) Deposition of In2O3 SnO2 layers on glass substrates using a spraying method. Thin Solid Films 77(1-3):67–80. https://doi.org/10.1016/0040-6090(81)90361-8

Chopra K, Major S, Pandya D (1993) Transparent conductors—a status review. Thin Solid Films 102(1):1–46. https://doi.org/10.1016/0040-6090(83)90256-0

Bel Hadj Tahar R, Ban T, Ohya Y, Takahashi Y (1998) Tin doped indium oxide thin films: Electrical properties. J Appl Phys 83(5):2631–2645. https://doi.org/10.1063/1.367025

Studenikin S, Golego N, Cocivera M (1998) Optical and electrical properties of undoped ZnO films grown by spray pyrolysis of zinc nitrate solution. J Appl Phys 83(4):2104–2111. https://doi.org/10.1063/1.366944

Coutts TJ, Wu X, Mulligan WP, Webb JM (1996) High-performance, transparent conducting oxides based on cadmium stannate. J Electron Mater 25(6):935–943. https://doi.org/10.1007/bf02666727

Omura K, Veluchamy P, Tsuji M, Nishio T, Murozono M (1999) A pyrosol technique to deposit highly transparent, low-resistance SnO2: F Thin films from dimethyltin dichloride. J Electrochem Soc 146(6):2113. https://doi.org/10.1002/chin.199939215

Kar A, Kundu S, Patra A (2011) Surface defect-related luminescence properties of SnO2 nanorods and nanoparticles. J Phys Chem C 115(1):118–124. https://doi.org/10.1021/jp110313b

Vijayarangamuthu K, Rath S (2014) Nanoparticle size, oxidation state, and sensing response of tin oxide nanopowders using Raman spectroscopy. J Alloys Compd 610:706–712. https://doi.org/10.1016/j.jallcom.2014.04.187

Calestani D, Zha M, Zappettini A, Lazzarini L, Salviati G, Zanotti L, Sberveglieri G (2005) Structural and optical study of SnO2 nanobelts and nanowires. Mater Sci Eng C 25(5-8):625–630. https://doi.org/10.1016/j.msec.2005.07.014

Nemade KR, Waghuley SA (2014) Comparative study of carbon dioxide sensing by Sn-doped TiO2 nanoparticles synthesized by microwave-assisted and solid-state diffusion route. Appl Nanosci 5(4):419–424. https://doi.org/10.1007/s13204-014-0333-2

Kinumoto T, Nagano K, Yamamoto Y, Tsumura T, Toyoda M (2014) Anticorrosion properties of tin oxide coatings for carbonaceous bipolar plates of proton exchange membrane fuel cells. J Power Sources 249:503–508. https://doi.org/10.1016/j.jpowsour.2013.10.065

Tosun BS, Feist RK, Gunawan A, Mkhoyan KA, Campbell SA, Aydil ES (2012) Sputter deposition of semicrystalline tin dioxide films. Thin Solid Films 520(7):2554–2561. https://doi.org/10.1016/j.tsf.2011.10.169

Behrendt A, Friedenberger C, Gahlmann T, Trost S, Becker T, Zilberberg K, Polywka A, Görrn P, Riedl T (2015) Highly robust transparent and conductive gas diffusion barriers based on tin oxide. Adv Mater 27(39):5961–5967. https://doi.org/10.1002/adma.201502973

Beneking C, Rech B, Wieder S, Kluth O, Wagner H, Frammelsberger W, Geyer R, Lechner P, Rübel H, Schade H (1999) Recent developments of silicon thin film solar cells on glass substrates. Thin Solid Films 351(1-2):241–246. https://doi.org/10.1016/s0040-6090(98)01793-3

Rosental A, Tarre A, Gerst A, Uustare T, Sammelselg V (2001) Atomic-layer chemical vapor deposition of SnO2 for gas-sensing applications. Sensors Actuators B Chem 77(1-2):297–300. https://doi.org/10.1016/s0925-4005(01)00746-8

Jin C, Yamazaki T, Ito K, Kikuta T, Nakatani N (2006) H 2 S sensing property of porous SnO2 sputtered films coated with various doping films. Vacuum 80(7):723–725. https://doi.org/10.1016/j.vacuum.2005.11.002

Yang H, Zhang X, Tang A (2006) Mechanosynthesis and gas-sensing properties of In 2 O 3 /SnO 2 nanocomposites. Nanotechnology 17(12):2860. https://doi.org/10.1088/0957-4484/17/12/006

Hagemeyer A, Hogan Z, Schlichter M, Smaka B, Streukens G, Turner H, Volpe Jr A, Weinberg H, Yaccato K (2007) High surface area tin oxide. Appl Catal A Gen 317(2):139–148. https://doi.org/10.1016/j.apcata.2006.09.040

Hosono H, Ohta H, Orita M, Ueda K, Hirano M (2002) Frontier of transparent conductive oxide thin films. Vacuum 66(3-4):419–425. https://doi.org/10.1016/s0042-207x(02)00165-3

Wang GF, Tao XM, Huang HM (2005) Light-emitting devices for wearable flexible displays. Color Technol 121(3):132–138. https://doi.org/10.1111/j.1478-4408.2005.tb00263.x

Vergöhl M, Malkomes N, Matthee T, Bräuer G, Richter U, Nickol FW, Bruch J (2001) In situ monitoring of optical coatings on architectural glass and comparison of the accuracy of the layer thickness attainable with ellipsometry and photometry. Thin Solid Films 392(2):258–264. https://doi.org/10.1016/s0040-6090(01)01040-9

Chen JS, Lou XW (2013) SnO 2 -based nanomaterials: synthesis and application in lithium-ion batteries. Small 9(11):1877–1893. https://doi.org/10.1002/smll.201202601

Nazarov DV, Maximov MY, Novikov PA, Popovich AA, Silin AO, Smirnov VM et al (2017) Atomic layer deposition of tin oxide using tetraethyltin to produce high-capacity Li-ion batteries. J Vac Sci Technol A 35(1):01B137. https://doi.org/10.1116/1.4972554

Roy P, S.K. (2015) Srivastava, Nanostructured anode materials for lithium ion batteries. J Mater Chem A 3(6):2454–2484. https://doi.org/10.1039/c4ta04980b

Reddy M, Subba Rao G, B. (2013) Chowdari, Metal oxides and oxysalts as anode materials for Li ion batteries. Chem Rev 113(7):5364–5457. https://doi.org/10.1021/cr3001884

Shrotriya V, Li G, Yao Y, Chu CW, Yang Y (2006) Transition metal oxides as the buffer layer for polymer photovoltaic cells. Appl Phys Lett 88(7):073508. https://doi.org/10.1063/1.2174093

Betz U, Olsson MK, Marthy J, Escolá MF, Atamny F (2006) Thin films engineering of indium tin oxide: large area flat panel displays application. Surf Coat Technol 200(20-21):5751–5759. https://doi.org/10.1016/j.surfcoat.2005.08.144

Adnane M, Cachet H, Folcher G, Hamzaoui S (2005) Beneficial effects of hydrogen peroxide on growth, structural and electrical properties of sprayed fluorine-doped SnO2 films. Thin Solid Films 492(1-2):240–247. https://doi.org/10.1016/j.tsf.2005.06.085

Viirola H, Niinistö L (1994) Controlled growth of antimony-doped tin dioxide thin films by atomic layer epitaxy. Thin Solid Films 251(2):127–135. https://doi.org/10.1016/0040-6090(94)90677-7

Aguir K, Bernardini S, Lawson B, Fiorido T (2020) Trends in metal oxide thin films: Synthesis and applications of tin oxide. Tin Oxide Mater:219–246. https://doi.org/10.1016/b978-0-12-815924-8.00008

Benhaoua A, Rahal A, Benhaoua B, Jlassi M (2014) Effect of fluorine doping on the structural, optical and electrical properties of SnO 2 thin films prepared by spray ultrasonic. Superlattice Microst 70:61–69. https://doi.org/10.1016/j.spmi.2014.02.005

Mishra S, Ghanshyam C, Ram N, Singh S, Bajpai RP, Bedi RK (2002) Alcohol sensing of tin oxide thin film prepared by sol-gel process. Bull Mater Sci 25(3):231–234. https://doi.org/10.1007/bf02711159

Batzill M, Diebold U (2005) The surface and materials science of tin oxide. Prog Surf Sci 79(2-4):47–154. https://doi.org/10.1016/j.progsurf.2005.09.002

Das S, Jayaraman V (2014) SnO 2 : A comprehensive review on structures and gas sensors. Prog Mater Sci 66:112–255. https://doi.org/10.1016/j.pmatsci.2014.06.003

Krivetskiy VV, Rumyantseva MN, Gaskov AM (2013) Chemical modification of nanocrystalline tin dioxide for selective gas sensors. Russ Chem Rev 82(10):917. https://doi.org/10.1070/rc2013v082n10abeh004366

Arafat MM, Dinan B, Akbar SA, Haseeb ASMA (2012) Gas sensors based on one dimensional nanostructured metal-oxides: a review. Sensors 12(6):7207–7258. https://doi.org/10.3390/s120607207

Choi G, Satyanarayana L, Park J (2006) Effect of process parameters on surface morphology and characterization of PE-ALD SnO 2 thin films for gas sensing. Appl Surf Sci 252(22):7878–7883. https://doi.org/10.1016/j.apsusc.2005.09.069

Dutaive M, Lalauze R, Pijolat C (1995) Sintering, catalytic effects and defect chemistry in polycrystalline tin oxide. Sensors Actuators B 26:26–27. https://doi.org/10.1016/0925-4005(94)01552-s

Ray SC, Karanjai MK, DasGupta D (1998) Tin dioxide based transparent semiconducting films deposited by the dip-coating technique. Surf Coat Technol 102(1-2):73–80. https://doi.org/10.1016/s0257-8972(97)00561-6

Rahal A, Benhaoua A, Jlassi M, Benhaoua B (2015) Structural, optical and electrical properties studies of ultrasonically deposited tin oxide (SnO 2 ) thin films with different substrate temperatures. Superlattice Microst 86:403–411. https://doi.org/10.1016/j.spmi.2015.08.003

Ichimura M, Shibayama K, Masui K (2004) Fabrication of SnO 2 thin films by a photochemical deposition method. Thin Solid Films 466(1-2):34–36. https://doi.org/10.1016/j.tsf.2004.01.117

Abdul-Hamead AA (2018) Properties of SnO 2 thin films deposited by chemical spray pyrolysis using different precursor solutions. https://doi.org/10.1063/1.5039204

Park JJ, Kim KK, Roy M, Song JK, Park SM (2015) Characterization of SnO2thin films grown by pulsed laser deposition under transverse magnetic field. Rapid Commun Photosci 4(3):50–53. https://doi.org/10.5857/rcp.2015.4.3.50

Shamala K, Murthy L, Rao KN (2004) Studies on tin oxide films prepared by electron beam evaporation and spray pyrolysis methods. Bull Mater Sci 27(3):295–301. https://doi.org/10.1007/bf02708520

Monteiro OC, Mendonca MHM, Pereira MIS, Nogueira JMF (2006) Preparation of lead and tin oxide thin films by spin coating and their application on the electrodegradation of organic pollutants. J Solid-State Electrochem 10(1):41–47. https://doi.org/10.1007/s10008-005-0652-z

Van Mol AMB, Chae Y, McDaniel AH, Allendorf MD (2006) Chemical vapor deposition of tin oxide: fundamentals and applications. Thin Solid Films 502(1-2):72–78. https://doi.org/10.1016/j.tsf.2005.07.247

Ponraj JS, Attolini G, Bosi M (2013) Review on atomic layer deposition and applications of oxide thin films. Critic Rev Solid State Mater Sci 38(3):203–233. https://doi.org/10.1080/10408436.2012.736886

Akl AA (2004) Microstructure and electrical properties of iron oxide thin films deposited by spray pyrolysis. Appl Surf Sci 221(1-4):319–329. https://doi.org/10.1016/s0169-4332(03)00951-6

Murthy L, Rao KK (1999) Thickness dependent electrical properties of CdO thin films prepared by spray pyrolysis method. Bull Mater Sci 22(6):953–957. https://doi.org/10.1007/bf02745685

Blunden SJ, Cusack PA, Hill R (1995) The industrial uses of tin chemicals. Vol. 337. Royal Society of Chemistry, London. https://doi.org/10.1002/ange.19860981142

Book Google Scholar

Pengyi L, Junfang C, Wangdian S (2004) Sheet resistance and gas-sensing properties of tin oxide thin films by Plasma enhanced chemical vapor deposition. Plasma Sci Technol 6(2):2259. https://doi.org/10.1088/1009-0630/6/2/015

Brinzari V, Korotcenkov G, Golovanov V, Schwank J, Lantto V, Saukko S (2002) Morphological rank of nano-scale tin dioxide films deposited by spray pyrolysis from SnCl 4 ·5H 2 O water solution. Thin Solid Films 408(1-2):51–58. https://doi.org/10.1016/s0040-6090(02)00086-x

Saadie J (2014) Influence of thickness on electrical and optical properties of tellurium thin films deposited by chemical spray pyrolysis. Int J Appl Math Electron Comput 3, 96(2):–101. https://doi.org/10.18100/ijamec.27133

Akl AA (2004) Optical properties of crystalline and non-crystalline iron oxide thin films deposited by spray pyrolysis. Appl Surf Sci 233(1-4):307–319. https://doi.org/10.1016/j.apsusc.2004.03.263

Yadav AA (2015) SnO 2 thin film electrodes deposited by spray pyrolysis for electrochemical supercapacitor applications. J Mater Sci Mater Electron 27(2):1866–1872. https://doi.org/10.1007/s10854-015-3965-4

Patil GE, Kajale DD, Gaikwad VB, Jain GH (2012) Spray pyrolysis deposition of nanostructured tin oxide thin films. ISRN Nanotechnol 2012:2012–2015. https://doi.org/10.5402/2012/275872

Sears W, Gee MA (1998) Mechanics of film formation during the spray pyrolysis of tin oxide. Thin Solid Films 165(1):265–277. https://doi.org/10.1016/0040-6090(88)90698-0

Thiagarajan S, Sanmugam A, Vikraman D (2017) Facile methodology of sol-gel synthesis for metal oxide nanostructures. Recent Applications in Sol-Gel Synthesis, p. 1-17. https://doi.org/10.5772/intechopen.68708

Levy D, Zayat M (Eds.). (2015). The Sol-Gel Handbook. https://doi.org/10.1002/9783527670819

López TM, Avnir D, Aegerter MA (2013) Emerging fields in sol-gel science and technology: Springer Science & Business Media. doi https://doi.org/10.1007/978-1-4615-0449-8

Lee SC, Lee JH, Oh TS, Kim YH (2003) Fabrication of tin oxide film by sol–gel method for photovoltaic solar cell system. Sol Energy Mater Sol Cells 75(3-4):481–487. https://doi.org/10.1016/s0927-0248(02)00201-5

Korotcenkov G, Brinzari V, Ivanov M, Cerneavschi A, Rodriguez J, Cirera A, Morante J (2005) Structural stability of indium oxide films deposited by spray pyrolysis during thermal annealing. Thin Solid Films 479(1-2):38–51. https://doi.org/10.1016/j.tsf.2004.11.107

Dislich H, Hussmann E (1991) Amorphous and crystalline dip coatings obtained from organometallic solutions: procedures, chemical processes and products. Thin Solid Films 77(1-3):129–140. https://doi.org/10.1016/0040-6090(81)90369-2

Chatelon JP, Terrier C, Bernstein E, Berjoan R, Roger JA (1994) Morphology of SnO 2 thin films obtaibed by the sol-gel technique. Thin Solid Films 247(2):162–168. https://doi.org/10.1016/0040-6090(94)90794-3

Kumar A, Nanda D (2019) Methods and fabrication techniques of superhydrophobic surfaces, in Superhydrophobic Polymer Coatings. Elsevier. p. 43-75. doi https://doi.org/10.1016/b978-0-12-816671-0.00004-7

Neacşu IA, Nicoară AI, Vasile OR, Vasile BŞ (2016) Inorganic micro- and nanostructured implants for tissue engineering. Nanobiomater Hard Tissue Eng 4:271–295. https://doi.org/10.1016/b978-0-323-42862-0.00009-2

Karanjai MK, Dasgupta D (1997) Preparation and study of sulphide thin films deposited by the dip technique. Thin Solid Films 155(2):309–315. https://doi.org/10.1016/0040-6090(87)90075-7

Zhao J, Huo LH, Gao S, Zhao H, Zhao JG (2006) Alcohols and acetone sensing properties of SnO 2 thin films deposited by dip-coating. Sensors Actuators B Chem 115(1):460–464. https://doi.org/10.1016/j.snb.2005.10.024

Dominguez M, Luna-Lopez JA, Flores FJ (2017) Semiconductor materials by ultrasonic spray pyrolysis and their application in electronic devices. Pyrolysis, p. 251. doi https://doi.org/10.5772/67548

Alarcon-Flores G, Aguilar-Frutis MIGUEL, García-Hipolito MANUEL, Guzman-Mendoza J, Canseco MA, Falcony C (2008) Optical and structural characteristics of Y 2 O 3 thin films synthesized from yttrium acetylacetonate. J Mater Sci 43(10):3582–3588. https://doi.org/10.1007/s10853-008-2566-5

Sánchez-García MA, Maldonado A, Castañeda L, Silva-González R, de la Luz Olvera M (2012) Characteristics of SnO 2 : F thin films deposited by ultrasonic spray pyrolysis: effect of water content in solution and substrate temperature. Mater Sci Appl 3(10):690–696. https://doi.org/10.4236/msa.2012.310101

Jadsadapattarakul D, Euvananont C, Thanachayanont C, Nukeaw J, Sooknoi T (2008) Tin oxide thin films deposited by ultrasonic spray pyrolysis. Ceram Int 34(4):1051–1054. https://doi.org/10.1016/j.ceramint.2007.09.096

Park H-H, Park H-H, Hill RH (2004) Stacking effect on the ferroelectric properties of PZT/PLZT multilayer thin films formed by photochemical metal-organic deposition. Appl Surf Sci 237(1-4):427–432. https://doi.org/10.1016/j.apsusc.2004.06.103

Gao M, Hill RH (1998) High efficiency photoresist-free lithography of UO 3 patterns from amorphous films of uranyl complexes. J Mater Res 13(5):1379–1389. https://doi.org/10.1557/jmr.1998.0196

Park H-H, Kim WS, Yang J-K, Park H-H, Hill RH (2004) Characterization of PLZT thin film prepared by photochemical deposition using photosensitive metal-organic precursors. Microelectron Eng 71(2):215–220. https://doi.org/10.1016/j.mee.2003.11.004

Park H-H, Park H-H, Hill RH (2006) Direct-patterning of SnO 2 thin film by photochemical metal-organic deposition. Sensors Actuators A Phys 132(2):429–433. https://doi.org/10.1016/j.sna.2006.02.030

Ichimura M, Goto F, Arai E (1999) Photochemical deposition of CdS from aqueous solutions. J Electrochem Soc 146(3):1028. https://doi.org/10.1149/1.1391716

Ichimura M, Takeuchi K, Nakamura A, Arai E (2001) Photochemical deposition of Se and CdSe films from aqueous solutions. Thin Solid Films 384(2):157–159. https://doi.org/10.1016/s0040-6090(00)01826-5

Sasaki H, Shibayama K, Ichimura M, Masui K (2002) Preparation of (Bi, Sb) 2S3 semiconductor films by photochemical deposition method. J Cryst Growth 237:2125–2129. https://doi.org/10.1016/s0022-0248(01)02280-1

Bravo-Vasquez JP, Hill RH (2000) Photolithographic deposition of conducting gold films from thin amorphous films of AuPR 3 X (X = NO 3 , RCO 2 ) on silicon surfaces. Polyhedron. 19(3):343–349. https://doi.org/10.1016/s0277-5387(99)00364-2

Avey AA, Hill RH (1996) Solid state photochemistry of Cu 2 (OH 2 ) 2 (O 2 C (CH 2 ) 4CH 3 ) 4 in thin films: The photochemical formation of high-quality films of copper and copper (I) oxide. Demonstration of a novel lithographic technique for the patterning of copper. J Am Chem Soc 118(1):237–238. https://doi.org/10.1021/ja952937j

Park HH, Yoon S, Park HH, Hill RH (2004) Electrical properties of PZT thin films by photochemical deposition. Thin Solid Films 447:669–673. https://doi.org/10.1016/j.tsf.2003.09.005

Law W, Hill RH (2000) Photolithographic deposition of insulating Al 2 O 3 films from thin amorphous films of aluminum complexes on silicon surfaces. Thin Solid Films 375(1-2):42–45. https://doi.org/10.1016/s0040-6090(00)01177-9

Ando M, Suto S, Suzuki T, Tsuchida T, Nakayama C, Miura N, Yamazoe N (1994) H2S-sensitive thin film fabricated from hydrothermally synthesized SnO 2 sol. J Mater Chem 4(4):631. https://doi.org/10.1039/jm9940400631

Baik NS, Sakai G, Miura N, Yamazoe N (2000) Hydrothermally treated sol solution of tin oxide for thin-film gas sensor. Sensors Actuators B Chem 63(1-2):74–79. https://doi.org/10.1016/s0925-4005(99)00513-4

Ren X, Pang L, Zhang Y, Ren X, Fan H, Liu SF (2015) One-step hydrothermal synthesis of monolayer MoS 2 quantum dots for highly efficient electrocatalytic hydrogen evolution. J Mater Chem A 3(20):10693–10697. https://doi.org/10.1039/c5ta02198g

Chen Q, Qian Y, Chen Z, Zhou G, Zhang Y (1995) Fabrication of ultrafine SnO 2 thin films by the hydrothermal method. Thin Solid Films 264(1):25–27. https://doi.org/10.1016/0040-6090(95)06586-5

Baik, Seok N, Sakai G, Miura N, Yamazoe N (2000) Preparation of stabilized nanosized tin oxide particles by hydrothermal treatment. J Am Ceram Soc 83(12):2983–2987. https://doi.org/10.1111/j.1151-2916.2000.tb01670.x

Jackson T, Palmer S (1994) Oxide superconductor and magnetic metal thin film deposition by pulsed laser ablation: a review. J Phys D Appl Phys 27(8):1581. https://doi.org/10.1088/0022-3727/27/8/001

Torrisi L, Margarone D (2006) Investigations on pulsed laser ablation of Sn at 1064 nm wavelength. Plasma Sources Sci Technol 15(4):635. https://doi.org/10.1088/0963-0252/15/4/007

Handbook of Physical Vapor Deposition (PVD) Processing. (2010) https://doi.org/10.1016/c2009-0-18800-1

Koinkar V, Ogale S (1991) Pulsed excimer laser processing of optical thin films. Thin Solid Films 206(1-2):259–263. https://doi.org/10.1016/0040-6090(91)90432-w

Dawar AL, Kumar A, Sharma S, Tripathi KN, Mathur PC (1993) Effect of laser irradiation on structural, electrical and optical properties of SnO 2 films. J Mater Sci 28(3):639–644. https://doi.org/10.1007/bf01151238

Galindo H, Vincent AB, Sánchez-R JC, Laude LD (1993) Excimer laser processing for surface improvement of tin oxide thin films. J Appl Phys 74(1):645–648. https://doi.org/10.1063/1.355226

Kunz R, Rothschild M, Ehrlich D (1998) Selective—area laser photodeposition of transparent conductive SnO 2 films. MRS Online Proceedings Library Archive. 129. doi https://doi.org/10.1557/proc-129-447

Treece RE, Horwitz JS, Claassen JH, Chrisey DB (1994) Pulsed laser deposition of high-quality NbN thin films. Appl Phys Lett 65(22):2860–2862. https://doi.org/10.1063/1.112516

Kim H, Gilmore AC, Pique A, Horwitz JS, Mattoussi H, Murata H, ..., Chrisey DB (1999) Electrical, optical, and structural properties of indium–tin–oxide thin films for organic light-emitting devices. J Appl Phys 86(11):6451-6461. doi https://doi.org/10.1063/1.371708

Kim H, Horwitz JS, Kushto GP, Kafafi ZH, Chrisey DB (2001) Indium tin oxide thin films grown on flexible plastic substrates by pulsed-laser deposition for organic light-emitting diodes. Appl Phys Lett 79(3):284–286. https://doi.org/10.1063/1.1383568

Phillips HM, Li Y, Bi Z, Zhang B (1996) Reactive pulsed laser deposition and laser induced crystallization of SnO 2 transparent conducting thin films. Appl Phys A 63(4):347–351. https://doi.org/10.1007/s003390050397

Dolbec R, El Khakani MA, Serventi AM, Trudeau M, Saint-Jacques RG (2002) Microstructure and physical properties of nanostructured tin oxide thin films grown by means of pulsed laser deposition. Thin Solid Films 419(1-2):230–236. https://doi.org/10.1016/s0040-6090(02)00769-1

Xu NS, Huq SE (2005) Novel cold cathode materials and applications. Mater Sci Eng R Rep 48(2-5):47–189. https://doi.org/10.1016/j.mser.2004.12.001

Electron Beam Physical Vapor Deposition (EBPVD). (2019) Encyclopedia of Nanotechnology, 1057–1057. doi https://doi.org/10.1007/978-94-017-9780-1_100290

George J, Menon C (2000) Electrical and optical properties of electron beam evaporated ITO thin films. Surf Coat Technol 132(1):45–48. https://doi.org/10.1016/s0257-8972(00)00726-x

Kachouane A, Addou M, Bougrine A, Messoussi R, Regragui M, Bérnede JC (2001) Preparation and characterisation of tin-doped indium oxide films. Mater Chem Phys 70(3):285–289. https://doi.org/10.1016/s0254-0584(00)00492-2

Park YC, Kim YS, Seo HK, Ansari SG, Shin HS (2002) ITO thin films deposited at different oxygen flow rates on Si (100) using the PEMOCVD method. Surf Coat Technol 161(1):62–69. https://doi.org/10.1016/s0257-8972(02)00476-0

Wang CP, Do KB, Beasley MR, Geballe TH, Hammond RH (1997) Deposition of in-plane textured MgO on amorphous Si 3 N 4 substrates by ion-beam-assisted deposition and comparisons with ion-beam-assisted deposited yttria-stabilized-zirconia. Appl Phys Lett 71(20):2955–2957. https://doi.org/10.1063/1.120227

Ektessabi A, Sato S, Kitamura H, Masaki Y (1993) Simulation of ion beam assisted deposition—a comparison with experimental results. Vacuum 44(3-4):213–217. https://doi.org/10.1016/0042-207x(93)90156-5

Ektessabi AM, Kimura H (1995) Characterization of the surface of bio-ceramic thin films. Thin Solid Films 270(1-2):335–340. https://doi.org/10.1016/0040-6090(95)06714-0

Fursey G (1996) Early field emission studies of semiconductors. Appl Surf Sci 94-95:44–59. https://doi.org/10.1016/0169-4332(95)00518-8

Hossain MF, Naka S, Okada H (2018) Annealing effect of E-beam evaporated TiO 2 films and their performance in perovskite solar cells. J Photochem Photobiol A Chem 360:109–116. https://doi.org/10.1016/j.jphotochem.2018.04.025

Pan XQ, Fu L, Dominguez JE (2001) Structure–property relationship of nanocrystalline tin dioxide thin films grown on (1̄012) sapphire. J Appl Phys 89(11):6056–6061. https://doi.org/10.1063/1.1368866

Nam SC, Kim YH, Cho WI, Cho BW, Chun HS, Yun KS (1998) Charge-discharge performance of electron-beam-deposited tin oxide thin-film electrodes. Electrochem Solid-State Lett 2(1):9. https://doi.org/10.1149/1.1390717

Vuong DD, Sakai G, Shimanoe K, Yamazoe N (2004) Preparation of grain size-controlled tin oxide sols by hydrothermal treatment for thin film sensor application. Sensors Actuators B Chem 103(1-2):386–391. https://doi.org/10.1016/j.snb.2004.04.122

Adedokun O, Odebunmi BM, Sanusi YK (2018) Effect of fluorine doping on the structural, optical and electrical properties of spin coated tin oxide thin films for solar cells application. (2019). Sci Focus J. https://doi.org/10.36293/sfj.2019.0002

Yilbas BS, Al-Sharafi A, Ali H (2019) Surfaces for self-cleaning. Self-Cleaning Surf Water Droplet Mobil 45–98. doi https://doi.org/10.1016/b978-0-12-814776-4.00003-3

Boudrioua A, Chakaroun M, Fischer A (2017) Introduction. Org Lasers, Elsiver. https://doi.org/10.1016/b978-1-78548-158-1.50009-2

Senez V, Thomy V, Dufour R (2014) Nanotechnologies for synthetic super non-wetting surfaces. Nanotechnol Synth Super Non-Wetting Surf:1–12. https://doi.org/10.1002/9781119015093.ch1

Cavicchi RE, Walton RM, Aquino-Class M, Allen JD, Panchapakesan B (2001) Spin-on nanoparticle tin oxide for microhotplate gas sensors. Sensors Actuators B Chem 77(1-2):145–154. https://doi.org/10.1016/s0925-4005(01)00686-4

Gu F, Wang SF, Lü MK, Cheng XF, Liu SW, Zhou GJ, Xu D, Yuan DR (2004) Luminescence of SnO2 thin films prepared by spin-coating method. J Cryst Growth 262(1-4):182–185. https://doi.org/10.1016/j.jcrysgro.2003.10.028

Kääriäinen T, Cameron D, Kääriäinen M-L, Sherman A (2013) Atomic layer deposition: principles, characteristics, and nanotechnology applications. doi https://doi.org/10.1002/9781118747407

Babu Krishna Moorthy S (Ed.) (2015) Thin Film Structures in Energy Applications. doi https://doi.org/10.1007/978-3-319-14774-1

Morosanu CE (1990) Thin film structure. Thin Films by Chemical Vapour Deposition 177–200. doi https://doi.org/10.1016/b978-0-444-98801-0.50013-6

Seshan K, Schepis D (2018) Handbook of thin film deposition, 103. William Andrew. doi https://doi.org/10.1016/b978-0-12-812311-9.00030-x

Manawi Y, Ihsanullah, Samara A, Al-Ansari T, Atieh M (2018) A Review of carbon nanomaterials’ synthesis via the chemical vapor deposition (CVD) method. Materials 11(5):822. https://doi.org/10.3390/ma11050822

Pierson HO (1999) Fundamentals of chemical vapor deposition. Handbook of Chemical Vapor Deposition (CVD), 36–67. doi https://doi.org/10.1016/b978-081551432-9.50005-x

Ho P (1998) Chemical Vapor Deposition for microelectronics: principles, technology and applications. Arthur Sherman (Noyes Publications, 1987). MRS Bull 13(11):78–78. https://doi.org/10.1557/s0883769400064046

George SM, Park BK, Kim CG, Chung T-M (2014) Heteroleptic group 2 metal precursors for metal oxide thin films. Eur J Inorg Chem 2014(11):2002–2010. https://doi.org/10.1002/ejic.201301296

Giunta CJ, Strickler DA, Gordon RG (1993) Kinetic modeling of the chemical vapor deposition of tin oxide from dimethyltin dichloride and oxygen. J Phys Chem 97(10):2275–2283. https://doi.org/10.1021/j100112a032

Yadava Y, Denicoló G, Arias A, Roman L, Hümmelgen I (1997) Preparation and characterization of transparent conducting tin oxide thin film electrodes by chemical vapour deposition from reactive thermal evaporation of SnCl2. Mater Chem Phys 48(3):263–267. https://doi.org/10.1016/s0254-0584(96)01899-8

Buchanan JL, McKown C (1997) Off-line sheet glass coating system. J Non-Cryst Solids 218:179–184. https://doi.org/10.1016/s0022-3093(97)00292-5

Gordon R (1997) Chemical vapor deposition of coatings on glass. J Non-Cryst Solids 218:81–91. https://doi.org/10.1016/s0022-3093(97)00198-1

McCurdy RJ (1999) Successful implementation methods of atmospheric CVD on a glass manufacturing line. Thin Solid Films 351(1-2):66–72. https://doi.org/10.1016/s0040-6090(99)00199-6

Choy K (2003) Chemical vapour deposition of coatings. Prog Mater Sci 48(2):57–170. https://doi.org/10.1016/s0079-6425(01)00009-3

Yusta FJ, Hitchman ML, Shamlian SH (1997) CVD preparation and characterization of tin dioxide films for electrochemical applications. J Mater Chem 7(8):1421–1427. https://doi.org/10.1039/a608525c

Melsheimer J, Ziegler D (1993) Thin tin oxide films of low conductivity prepared by chemical vapour deposition. Thin Solid Films 109(1):71–83. https://doi.org/10.1016/0040-6090(83)90032-9

Houssa M (Ed.) (2004) High k Gate Dielectrics. https://doi.org/10.1201/9781420034141

Heil SBS, van Hemmen JL, Hodson CJ, Singh N, Klootwijk JH, Roozeboom F, … Kessels WMM (2007) Deposition of TiN and HfO[sub 2] in a commercial 200 mm remote plasma atomic layer deposition reactor. J Vacuum Sci Technol A: Vacuum Surf Films 25(5):1357. https://doi.org/10.1116/1.2753846

Ritala M, Leskelä M (2002) Atomic layer deposition. Handbook of Thin Films, 103–159. doi https://doi.org/10.1016/b978-012512908-4/50005-9

Gerritsen E, Emonet N, Caillat C, Jourdan N, Piazza M, Fraboulet D, Boeck B, Berthelot A, Smith S, Mazoyer P (2005) Evolution of materials technology for stacked-capacitors in 65 nm embedded-DRAM. Solid State Electron 49(11):1767–1775. https://doi.org/10.1016/j.sse.2005.10.024

Jakschik S, Schroeder U, Hecht T, Dollinger G, Bergmaier A, Bartha J (2004) Physical properties of ALD-Al2O3 in a DRAM-capacitor equivalent structure comparing interfaces and oxygen precursors. Mater Sci Eng B 107(3):251–254. https://doi.org/10.1016/j.mseb.2003.09.044

Suk Yang W, Kwan Kim Y, Yang S-Y, Hwak Choi J, Soo Park H, In Lee S, Yoo J-B (2000) Effect of SiO2 intermediate layer on Al2O3/SiO2/n + -poly Si interface deposited using atomic layer deposition (ALD) for deep submicron device applications. Surf Coat Technol 131(1-3):79–83. https://doi.org/10.1016/s0257-8972(00)00763-5

Suntola T (1999) Atomic layer epitaxy. Mater Sci Rep 4(5):261–312. https://doi.org/10.1016/s0920-2307(89)80006-4

Kim H (2003) Atomic layer deposition of metal and nitride thin films: Current research efforts and applications for semiconductor device processing. J Vacuum Sci Technol B: Microelectron Nanometer Struct 21(6):2231. https://doi.org/10.1116/1.1622676

Leskelä M, Ritala M (2003) Atomic layer deposition chemistry: recent developments and future challenges. Angew Chem Int Ed 42(45):5548–5554. https://doi.org/10.1002/anie.200301652

Ghosh AP, Gerenser LJ, Jarman CM, Fornalik JE (2005) Thin-film encapsulation of organic light-emitting devices. Appl Phys Lett 86(22):223503. https://doi.org/10.1063/1.1929867

Groner MD, George SM, McLean RS, Carcia PF (2006) Gas diffusion barriers on polymers using Al2O3 atomic layer deposition. Appl Phys Lett 88(5):051907. https://doi.org/10.1063/1.2168489

Agostinelli G, Delabie A, Vitanov P, Alexieva Z, Dekkers HFW, De Wolf S, Beaucarne G (2006) Very low surface recombination velocities on p-type silicon wafers passivated with a dielectric with fixed negative charge. Sol Energy Mater Sol Cells 90(18-19):3438–3443. https://doi.org/10.1016/j.solmat.2006.04.014

Reijnen L, Meester B, Goossens A, Schoonman J (2003) Atomic Layer Deposition of CuxS for Solar Energy Conversion. Chem Vap Depos 9(1):15–20. https://doi.org/10.1002/cvde.200290001

Van TT, Chang JP (2005) Controlled erbium incorporation and photoluminescence of Er-doped Y2O3. Appl Phys Lett 87(1):011907. https://doi.org/10.1063/1.1984082

King JS, Neff CW, Summers CJ, Park W, Blomquist S, Forsythe E, Morton D (2003) High-filling-fraction inverted ZnS opals fabricated by atomic layer deposition. Appl Phys Lett 83(13):2566–2568.10.1063/1 1609240

Mayer TM, Elam JW, George SM, Kotula PG, Goeke RS (2003) Atomic-layer deposition of wear-resistant coatings for microelectromechanical devices. Appl Phys Lett 82(17):2883–2885. https://doi.org/10.1063/1.1570926

Scharf T, Prasad S, Dugger M, Kotula P, Goeke R, Grubbs R (2006) Growth, structure, and tribological behavior of atomic layer-deposited tungsten disulphide solid lubricant coatings with applications to MEMS. Acta Mater 54(18):4731–4743. https://doi.org/10.1016/j.actamat.2006.06.009

Johnson RW, Hultqvist A, Bent SF (2014) A brief review of atomic layer deposition: from fundamentals to applications. Mater Today 17(5):236–246. https://doi.org/10.1016/j.mattod.2014.04.026

George SM (2010) Atomic layer deposition: an overview. Chem Rev 110(1):111–131. https://doi.org/10.1021/cr900056b

Knez M, Nielsch K, Niinistö L (2007) Synthesis and surface engineering of complex nanostructures by atomic layer deposition. Adv Mater 19(21):3425–3438. https://doi.org/10.1002/adma.200700079

Sundqvist J, Lu J, Ottosson M, Hårsta A (2006) Growth of SnO2 thin films by atomic layer deposition and chemical vapour deposition: A comparative study. Thin Solid Films 514(1-2):63–68. https://doi.org/10.1016/j.tsf.2006.02.031

Choi W-S (2009) The fabrication of tin oxide films by atomic layer deposition using tetrakis(ethylmethylamino) tin precursor. Trans Electr Electron Mater 10(6):200–202. https://doi.org/10.4313/teem.2009.10.6.200

Tiznado H, Zaera F (2006) Surface chemistry in the atomic layer deposition of tin films from TiCl4and ammonia. J Phys Chem B 110(27):13491–13498. https://doi.org/10.1021/jp062019f

Aaltonen T, Ritala M, Sajavaara T, Keinonen J, Leskelä M (2003) Atomic layer deposition of platinum thin films. Chem Mater 15(9):1924–1928. https://doi.org/10.1021/cm021333t

Pan D, Guan D, Jen T-C, Yuan C (2016) Atomic layer deposition process modeling and experimental investigation for sustainable manufacturing of nano thin films. J Manuf Sci Eng 138(10). https://doi.org/10.1115/1.4034475

Bachmann J (Ed.) (2017) Atomic layer deposition in energy conversion applications. doi https://doi.org/10.1002/9783527694822

Shaeri MR, Jen T-C, Yuan CY (2015) Reactor scale simulation of an atomic layer deposition process. Chem Eng Res Des 94:584–593. https://doi.org/10.1016/j.cherd.2014.09.019

Marquardt AE, Breitung EM, Drayman-Weisser T, Gates G, Phaneuf RJ (2015) Protecting silver cultural heritage objects with atomic layer deposited corrosion barriers. Herit Sci 3(1):37. https://doi.org/10.1186/s40494-015-0066-x

Farmer DB, Gordon RG (2005) ALD of high-κ dielectrics on suspended functionalized SWNTs. Electrochem Solid-State Lett 8(4):G89. https://doi.org/10.1149/1.1862474

Nwanna EC, Coetzee RAM, Jen T-C (2019) Investigating the purge flow rate in a reactor scale simulation of an atomic layer deposition process. Volume 2B: Advanced Manufacturing. doi https://doi.org/10.1115/imece2019-10692

Lim BS, Rahtu A, Gordon RG (2003) Atomic layer deposition of transition metals. Nat Mater 2(11):749–754. https://doi.org/10.1038/nmat1000

Aaltonen T, Ritala M, Sammelselg V, Leskelä M (2004) Atomic layer deposition of iridium thin films. J Electrochem Soc 151(8):G489. https://doi.org/10.1149/1.1761011

Wang X, Tabakman SM, Dai H (2008) Atomic layer deposition of metal oxides on pristine and functionalized graphene. J Am Chem Soc 130(26):8152–8153. https://doi.org/10.1021/ja8023059

Frank MM, Wilk GD, Starodub D, Gustafsson T, Garfunkel E, Chabal YJ, Muller DA (2005) HfO 2 and Al 2 O 3 gate dielectrics on GaAs grown by atomic layer deposition. Appl Phys Lett 86(15):152904. https://doi.org/10.1063/1.1899745

Ritala M, Kaupo K, Antti R, Räisänen PI, Markku L, Timo S, Juhani K (2000) Atomic layer deposition of oxide thin films with metal alkoxides as oxygen sources. Science 288(5464):319–321. https://doi.org/10.1126/science.288.5464.319

Kim JY, George SM (2010) Tin monosulfide thin films grown by atomic layer deposition using tin 2,4-pentanedionate and hydrogen sulfide. J Phys Chem C 114(41):17597–17603. https://doi.org/10.1021/jp9120244

Yousfi E, Weinberger B, Donsanti F, Cowache P, Lincot D (2001) Atomic layer deposition of zinc oxide and indium sulfide layers for Cu(In,Ga)Se2 thin-film solar cells. Thin Solid Films 387(1-2):29–32. https://doi.org/10.1016/s0040-6090(00)01838-1

Zaera F (2008) The surface chemistry of thin film atomic layer deposition (ALD) processes for electronic device manufacturing. J Mater Chem 18(30):3521. https://doi.org/10.1039/b803832e

Pellin MJ, Stair PC, Xiong G, Elam JW, Birrell J, Curtiss L, Wang H-H (2005) Mesoporous catalytic membranes: synthetic control of pore size and wall composition. Catal Lett 102(3-4):127–130. https://doi.org/10.1007/s10562-005-5843-9

Elam JW, Routkevitch D, Mardilovich PP, George SM (2003) Conformal coating on ultrahigh-aspect-ratio nanopores of anodic alumina by atomic layer deposition. Chem Mater 15(18):3507–3517. https://doi.org/10.1021/cm0303080

Wei Z, Hai Z, Akbari MK, Qi D, Xing K, Zhao Q, Verpoort F, Hu J, Hyde L, Zhuiykov S (2018) Atomic layer deposition-developed two-dimensional α-MoO3 windows excellent hydrogen peroxide electrochemical sensing capabilities. Sensors Actuators B Chem 262:334–344. https://doi.org/10.1016/j.snb.2018.01.243

Bakke JR, Pickrahn KL, Brennan TP, Bent SF (2011) Nanoengineering and interfacial engineering of photovoltaics by atomic layer deposition. Nanoscale 3(9):3482. https://doi.org/10.1039/c1nr10349k

Van Delft JA, Garcia-Alonso D, Kessels WMM (2012) Atomic layer deposition for photovoltaics: applications and prospects for solar cell manufacturing. Semicond Sci Technol 27(7):074002. https://doi.org/10.1088/0268-1242/27/7/074002

Hatanpää T, Ritala M, Leskelä M (2013) Precursors as enablers of ALD technology: contributions from University of Helsinki. Coord Chem Rev 257(23-24):3297–3322. https://doi.org/10.1016/j.ccr.2013.07.002

Miikkulainen V, Leskelä M, Ritala M, Puurunen RL (2013) Crystallinity of inorganic films grown by atomic layer deposition: overview and general trends. J Appl Phys 113(2):021301. https://doi.org/10.1063/1.4757907

Warner EJ, Johnson F, Campbell SA, Gladfelter WL (2015) Atomic layer deposition of tin oxide and zinc tin oxide using tetraethyltin and ozone. J Vac Sci Technol A 33(2):021517. https://doi.org/10.1116/1.4907562

Heo J, Hock AS, Gordon RG (2010) Low temperature atomic layer deposition of tin oxide. Chem Mater 22(17):4964–4973. https://doi.org/10.1021/cm1011108

Mullings MN, Hägglund C, Bent SF (2013) Tin oxide atomic layer deposition from tetrakis(dimethylamino)tin and water. J Vac Sci Technol A 31(6):061503. https://doi.org/10.1116/1.4812717

Li AD, Liu WC (2010) Optical properties of ferroelectric nanocrystal/polymer composites. In Physical Properties and Applications of Polymer Nanocomposites (pp. 108-158). Woodhead Publishing. doi https://doi.org/10.1533/9780857090249.1.108

Sōmiya S, Roy R (2000) Hydrothermal synthesis of fine oxide powders. Bull Mater Sci 23(6):453–460. https://doi.org/10.1007/bf02903883

Du X, George SM (2008) Thickness dependence of sensor response for CO gas sensing by tin oxide films grown using atomic layer deposition. Sensors Actuators B Chem 135(1):152–160. https://doi.org/10.1016/j.snb.2008.08.015

Download references

Acknowledgements

The authors hereby devote acknowledgement to the University Research Commission (URC), the Global Excellence Stature (GES) as well as the National Research Foundation (NRF) South Africa for being supportive financially.

Author information

Authors and affiliations.

Department of Mechanical Engineering Science, Faculty of Engineering and the Built Environment, University of Johannesburg, Auckland, Johannesburg, 2006, South Africa

Emeka Charles Nwanna, Patrick Ehi Imoisili & Tien-Chien Jen

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Tien-Chien Jen .

Additional information

Publisher’s note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Reprints and permissions

About this article

Nwanna, E.C., Imoisili, P.E. & Jen, TC. Fabrication and synthesis of SnO X thin films: a review. Int J Adv Manuf Technol 111 , 2809–2831 (2020). https://doi.org/10.1007/s00170-020-06223-8

Download citation

Received : 24 August 2020

Accepted : 05 October 2020

Published : 03 November 2020

Issue Date : December 2020

DOI : https://doi.org/10.1007/s00170-020-06223-8

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Transparent conducting oxide

- Solar cells

- Find a journal

- Publish with us

- Track your research

Open Access is an initiative that aims to make scientific research freely available to all. To date our community has made over 100 million downloads. It’s based on principles of collaboration, unobstructed discovery, and, most importantly, scientific progression. As PhD students, we found it difficult to access the research we needed, so we decided to create a new Open Access publisher that levels the playing field for scientists across the world. How? By making research easy to access, and puts the academic needs of the researchers before the business interests of publishers.

We are a community of more than 103,000 authors and editors from 3,291 institutions spanning 160 countries, including Nobel Prize winners and some of the world’s most-cited researchers. Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too.

Brief introduction to this section that descibes Open Access especially from an IntechOpen perspective

Want to get in touch? Contact our London head office or media team here

Our team is growing all the time, so we’re always on the lookout for smart people who want to help us reshape the world of scientific publishing.

Home > Books > Thin Films - Deposition Methods and Applications

Thin Films Processed by SILAR Method

Submitted: 11 June 2022 Reviewed: 11 July 2022 Published: 22 December 2022

DOI: 10.5772/intechopen.106476

Cite this chapter

There are two ways to cite this chapter:

From the Edited Volume

Thin Films - Deposition Methods and Applications

Edited by Dongfang Yang

To purchase hard copies of this book, please contact the representative in India: CBS Publishers & Distributors Pvt. Ltd. www.cbspd.com | [email protected]

Chapter metrics overview

361 Chapter Downloads

Impact of this chapter

Total Chapter Downloads on intechopen.com

Total Chapter Views on intechopen.com

Overall attention for this chapters

SILAR is one of the simplest techniques in terms of the better flexibility of the substrate choice, capability of large-area fabrication, deposition of stable and adherent film, low processing temperature for the film fabrication as well as reproducibility. This technique is very budget friendly since it does not require any sophisticated equipment. Moreover, various fabrication parameters such as solution concentration, precursors, the number of cycles during immersion, pH, annealing, doping, and growth temperature affect the rate of fabrication as well as the structural, optical, and electrical properties of the fabricated thin films led the technique unique to study in an extensive manner. A chapter regarding different aspects of semiconductors-based optoelectronics by SILAR has yet to be published. This chapter will concern the recent progress that has recently been made in different aspects of materials processed by the SILAR. It will describe the theory, mechanism, and factors affecting SILAR deposition as well as recent advancements in the field. Finally, conclusions and perspectives concerning the use of materials in optoelectronic devices will be represented.

- supercapacitors

- photovoltaics

- water splitting

Author Information

Md abdul majed patwary *.

- Department of Chemistry, Comilla University, Cumilla, Bangladesh

*Address all correspondence to: [email protected]

1. Introduction

The thin film is generally fabricated on a simply cleaned and rigid planar substrate having no dimensional limits. There is no restriction on the surface of the coating materials, so films can be fabricated on temperature-sensitive substrates like plastics. Even oxidation or corrosion of metal backing substrates can be used to deposit films by choosing suitable precursors.

The deposition rates and film thickness can be well controlled by monitoring reactant precursors, which are generally the desired cationic and anionic salts dissolved in solvents, while the anticipated stoichiometry can be attained through changing their type, concentration, or other involved dipping parameters.

By controlling the number of deposition cycles and concentration of species, the thicknesses of the thin films can be simply tuned over a wide range such as from nm scale to μm.

SILAR fabrications are very convenient and energy efficient as the technique is mostly controlled at room or low temperature. If required, the as-deposited coating materials can be annealed post-deposition to activate grain growth, crystallization, etc.

Besides, the fabricated thin films can be reformed to show preferential crystallographic orientation as well as grain assembly due to the controllability of ionic reactions performed at the substrate solution interface.

The SILAR method supports film development only on the surface of the substrate that is immersed into the solution, hence diminishing unnecessary consumption of the used reactants. If required, precursor solutions could also be reloaded and reprocessed.

Therefore, SILAR is a vastly multipurpose and influential process for the fabrication of numerous thin film materials having huge technological attention and, hence, unlocked a wide window in optoelectronic device applications.

2. Theory and process mechanism

SILAR is widely used, simple technique to fabricate high-quality thin films [ 3 , 15 ]. During deposition, successive ionic layer adsorption and reaction of the ions take place at the solid-solution interface of the substrate. Thus, the thin film of the compound, A p B y is deposited on to the substrate surface by dint of the adsorbed cations, xA y+ and anions, qB p− due to the following heterogeneous chemical reactions:

where x, y, p, q and y + , q + , x − , p − are the number and charges of the corresponding ions A (metal ions), P (cationic precursor), Q (anionic precursor), and B (anions) respectively [ 2 , 16 ]. Sometimes, the ligands L n are a necessity to complete the reaction [ 17 , 18 , 19 , 20 ]. The solution having the first element containing the final target material can be thought as the compound A x Q y fully dissociated in the chosen solvent such as in water (Reaction 3). Usually, A x Q y is a metal salt where A y + represents cations such as Zn 2+ , Cu 2+ , Mn 2+ , Cd 2+ , Bi 3+ , and B p − represents anions such as NO 3− , Cl − , SO 4 2− .

Hence, a basic SILAR cycle comprises four different steps, correlating alternate immersion of the substrate into cationic and anionic precursor solution followed by rinsing in every immersion cycle to eliminate loosely adhered particles as shown in Figure 1 and described below:

Representation of different steps during a SILAR cycle.

2.1 Adsorption

First step of the SILAR process is the formation of the Helmholtz double layer, which is due to the initial adsorption of cationic precursor, x A y + , on the surface of the substrate. This layer is generally composed of two charged layers, the positively charged inner layer and negatively charged outer layers. The positive (+ve) layer consists of the cations, x A y + , while the negative (−ve) layer, y Q x − , is the counter ions of the cations.

2.2 Rinsing I

In the second step, excessive adsorbed ions, x A y + and y Q x − , are rinsed away from the diffusion layer toward the bulk solution and a hypothetical monolayer is formed. This results in a saturated electrical double layer showing an ideal scenario of the process.

2.3 Reaction

In the reaction stage, the anions, qB p − , from anionic precursor solution are introduced into the system. A solid substance, A p B y , is formed on the interface due to the low stability of the material. This process employs the reaction of x A y + surface species with the anionic precursor, qB p − .

2.4 Rinsing II

In the final step of a SILAR cycle, the excess and unreacted species ( y Q x − , pP q+ ) and the reaction by product from the diffusion layer are removed leaving expected films.

A schematic presentation of a single cycle for the fabrication of Cu 2 SnS 3 film is shown in Figure 2 [ 21 ]. In the case of Cu 2 SnS 3 film fabrication, ion-by-ion type of deposition takes place through nucleation spots of the adsorbed surfaces [ 22 ]. Nucleation occurs due to the surface condensation of the ions and outcomes of, that is, an dense adherent thin film [ 23 ]. The substrate was firstly dipped into the cationic precursor containing mixed CuCl 2 and SnCl 2 solutions, where Cu 2+ and Sn 2+ species were available. Sn 2+ ion in solution is good reducing agents, and thus, Cu 2+ reduces to Cu + and Sn 2+ is oxidized to Sn 4+ in cationic solution as shown by the following reaction:

Schematic representation of Cu 2 SnS 3 thin film fabrication by SILAR technique [ 21 ].

The substrate was then rinsed off with DI H 2 O to eliminate the loosely bounded reactants. Then, it was dipped into an anionic precursor containing Na 2 S.xH 2 O solution, which gave sulfide ions (S 2− ) to react with the cations Cu + and Sn 4+ . Finally, the reaction occurred between the pre-adsorbed Cu + , Sn 4+ cations, and the S 2− anion to form a solid Cu 2 SnS 3 thin film as,

In the last step of the process, the substrate was again dipped into the DI H 2 O to remove the unwanted excessive particles to provide a uniform surface containing Cu 2 SnS 3 thin film.

3. SILAR-facilitated material deposition: A summary

The deposition of the series of chalcogenide mainly metal oxides, sulfides, selenides, and tellurides films has been always on numerous attentions in the advancement of the SILAR since its launch. Currently, SILAR has become a broadly functional technique in the deposition of a huge variety of semiconductor thin films. For the simplicity of discussion, we have summarized most of the metals still synthesized as metal compounds by SILAR in Table 1 .

List of the metals still grown by SILAR technique.

A list of materials deposited using SILAR technique with their growth conditions with the required raw materials for the growth is summarized in Table 2 . For the simplicity, the discussion is divided into four parts as of Table 1 , as specified below:

A list of materials deposited using SILAR technique with their growth conditions. (C, a: Cationic, anionic).

3.1 Metal oxides

An increasing number of oxide materials deposited by SILAR have demonstrated high chemical, thermal, and expected stability that is one of the reasons to increase the popularity of oxide synthesis by SILAR. However, the technique of oxide synthesis is somehow difficult compared to sulfides, selenides, and tellurides due to the unavailability of the anionic precursors, which is the direct source of O 2− to form oxides. For example, in case of the synthesis of most of the binary metal oxides, H 2 O, NaOH, and NH 4 OH are used as anionic precursors with a mild thermal treatment of around (70 ∼ 90) 0 C to activate the precipitation of hydroxides. On the other hand, the most common cationic precursors are mainly of metal thiosulfates, sulfates, chlorides, nitrates, etc., to provide metal ion adsorption on the substrate surface. Until today, Cu x O, ZnO, TiO 2 , and CdO are the most examined materials by SILAR. The investigation of Mn 3 O 4 , NiO, and Bi 2 O 3 is also increasing [ 31 , 32 , 33 , 34 ]. Recently, both nanostructured Fe 2 O 3 and Fe 3 O 4 have been fabricated applying sulfate and chloride salts using NaOH as the anionic precursor via SILAR [ 30 , 66 ]. But research on WO 3 [ 32 ], MgO [ 34 ], and SnO [ 67 ] fabrication is still rare. In case of ternary metal oxides, the SILAR deposition has been widely increased due to their ability to the additional modulate characteristics by controlling the composition of the materials. The synthesis of CST is discussed in the theory and mechanism section, which can be again done by two ways—a combined solution of both the deposited metal cations or, an alternating (one by one) fabrication of the two cations. A good technique to produce ternary metal oxides with excessive control on stoichiometry is to react one of the two metal ions by its own oxyanion. For example, Bi(NO 3 ) 3 and NH 4 VO 3 react to fabricate BiVO 4 [ 37 ], as ammonium vanadates are extremely soluble in water, while the anticipated metal vanadates are not. Consequently, they precipitate out of solution as the expected phase on the substrate surface. The other oxides such as Ag 3 VO 4 [ 36 ], BiVO 4 [ 37 , 68 ], Cu 2 V 2 O 7 [ 35 ], and Fe 2 V 4 O 13 [ 38 ] follow similar trends. Though bismuth oxyhalides, for instance, BiOI [ 69 , 70 ] is not a pure oxide but have been synthesized by the SILAR using cationic precursor of bismuth nitrate and anionic precursor of KI [ 71 ].

3.2 Metal sulfides

The characteristic easiness of the procedure and wide-ranging obtainability of the anionic precursors afford metal sulfides the most fabricated materials by employing SILAR technique. The easiest way of sulfide thin film deposition is to use metal salts as cationic precursors and H 2 O-soluble sodium sulfides or thiosulfates as anionic precursors. For example, NiS thin films could be fabricated using NiSO 4 (pH: 8) as cationic precursors and Na 2 S (pH: 10) as anionic precursors even at room temperature [ 47 ]. Generally, the solubility product constants of used sulfide materials in water are higher than 10 −20 , for instance, CuS: ≈10 −36 and CdS: ≈10 −27 , which is the key force of the deposition of the expected metal sulfides. Among the sulfides, CuS [ 72 ], ZnS [ 43 , 73 ], CdS [ 46 ], Ag 2 S [ 44 , 45 ], SnS [ 48 ], and PbS [ 49 ] have been broadly investigated mostly depending on the usage of chlorides and nitrates as the metal precursors and Na 2 S as anionic precursors for the S 2− source. Moreover, the investigation on NiS [ 47 ], Bi 2 S 3 [ 52 ] and MoS 2 [ 13 , 50 ], As 2 S 3 [ 13 , 51 ], MnS [ 53 ] are growing fast, while in the case of CoS [ 57 ], La 2 S 3 [ 58 ] studies are still infrequent. Moreover, core@shell-like SnS 2 @Co 3 S 4, ternary (NiCo 2 S 4 ) , and quaternary (Cu 2 BaSnS 4 ) films as well as nanocomposites of CdS and Bi 2 S 3 have been reported with their potential applications.

3.3 Metal selenides

In most of the cases, SILAR fabrication of the metal selenides has been directed through a solution of chloride, nitrate, or sulfate functioned as cationic precursor consisting of the anticipated metal, and a solution of Na 2 SeSO 3 worked as the anionic precursor consisting of the source of Se 2− to form selenides. For example, 0.2 M CdCl 2 . H 2 O (pH: 8) reacts with 0.1 M Na 2 SeSO 3 (pH: 11.3) to fabricate CdSe thin film [ 61 ]. Based on requirements, sometimes NaHSe, ethanolic NaBH 4 , or Na 2 Se can also be used as an anionic precursor to fabricate metal selenides. The SILAR deposition of Cu 3 Se 2 , Sb 2 Se 3 , Bi 2 Se 3 , and CdSe were studied and investigated mainly at room temperature avoiding thermal treatment during the sample growth, which was always maintained at (70–90) 0 C in the traditional cases.

3.4 Metal tellurides

The minimum studied materials among the chalcogen members via SILAR technique are metal tellurides because of the unavailability of the appropriate anionic precursors. Na 2 TeO 3 or ethanolic Te or TeO 2 with NaBH 4 is the mostly used anionic precursor performed as the source of Te 2− to form tellurides. For example, 0.1 M CuSO 4 . 5H 2 O (pH: 5) and 0.05 M Na 2 TeO 3 (pH: 9) react at an ambient temperature to synthesize Cu 2 Te film. Till now, CdTe, Cu 2 Te, La 2 Te 3 , Cu 7 Te 4 , and Bi 2 Te 3 thin films were fabricated and investigated via SILAR technique having potential uses in case of radiation detectors, photovoltaics, and thermo-electric devices [ 63 , 64 , 65 ]. More scientific research is expected to understand and control the characteristics of such fabricated films to build outstanding optoelectronic devices.

4. Recent advances by SILAR

The optoelectronic properties of SILAR grown thin films have been demonstrated in many more applications, for example, supercapacitors, photovoltaics, photoelectrochemical water splitting, gas sensors, and many more. The technique seems to be simpler and represents an efficient way to fabricate devices. Three potential applications such as supercapacitors, photovoltaics, and photoelectrochemical water splitting will be discussed in the following section.

4.1 Supercapacitors

The rapid progress in state-of-the-art tools has guided to a profound reliance on energy storage devices. Satellites, electric vehicles, laptops, cellphones, and sensors need some species of energy storage to function properly. The lead-acid battery was the first device, discovered around the 1800s, and most common storage energy till today. Supercapacitors, another promising energy storage device, well known as electrochemical capacitor or ultracapacitor creates a gap bridging role between conventional capacitors and batteries [ 74 ]. They can offer 1 ∼ 2 orders of higher magnitude of power density than rechargeable batteries as well as supply much more energy than traditional dielectric capacitors.

A supercapacitor works following two-charge storage mechanisms: (i) surface ion adsorption such as electric double-layer capacitance (EDLC) and (ii) redox reactions such as pseudo capacitance. Supercapacitors reveal an extraordinary set of features in comparison with batteries, for instance, high-power density, low maintenance cost, reliable cycling life, fast rates of charge or discharge, and safe operation as well as offer versatile powering solutions to many appeals ranging from portable consumer electronic appliance and electric automobiles to large-scale smart utility grids. Nevertheless, carbon-based EDLC supercapacitors show very low energy densities, which are limited through the finite electrical charge separation at the interface of electrolyte and electrode materials, as well as the approachability of surface area. Consequently, efforts to surge the energy densities of supercapacitors have involved the application of better pseudo-capacitance electrode supplies, equipped by conducting polymers and nanostructured metal oxides, bearing the low cost of high-power density as well as chemical stability, which have the significance of phase changes and faradaic reactions in it [ 74 ].

Several types of metal oxides, sulfides, and tellurides have been used in supercapacitor device fabrication so far, by utilizing the ever-fast-growing technique SILAR as summarized in Tables 3 and 4 . Initially the single metal oxides or sulfides such as CuO, NiO, NiMoO 4 , WO 3 , Bi 2 O 3 , Mn 3 O 4 , or MnS have been prepared by following SILAR technique and then tested for the supercapacitor behaviors to acquire the results of specific capacitance with their retention stability using cyclic voltammetry (CV) with the assistance of 3-electrode measurement system. Higher capacitance was attained at the lower scan rate and/or lower current density during such measurements and usually a relatively small quantity of electrochemical active material was developed atop of the working electrode. Moreover, the performance found using the 3-electrode system is higher than 2-electrode test cells, and the latter can be either a symmetric (S) or asymmetric (A) cell. Generally, in a symmetric cell both positive and negative electrodes are alike, whereas they are different active materials in an asymmetric cell.

Properties of various electrode materials deposited by SILAR for electrochemical capacitors by 3-electrode system.

Supercapacitors performance of SILAR grown films measured by 2-electrode system.

Not only binary, but also ternary or even doped metal oxides, sulfides or tellurides were synthesized via SILAR for supercapacitor device application. For example, ZnCo 2 O 4 and ZnFe 2 O 4 were synthesized via SILAR technique from binary cationic solutions in the presence of Zn and Co (or Fe) precursors and demonstrate high energy density of 9.67 and 28 Wh kg −1 as well as power density of 1451 and 7970 W kg −1 , respectively. La 2 S 3 and La 2 Te 3 with mesoporous pine-leaf structure prepared with SILAR showed 35 and 60 WhKg −1 energy density and power density of 1260 and 7220 WKg −1 , respectively. A flexible La 2 Te 3 │LiClO 4 -PVA│La 2 Te 3 supercapacitor cell was further fabricated and is represented as in Figure 3 .

Schematic diagrams of La 2 Te 3 │LiClO 4 -PVA│La 2 Te 3 supercapacitor device [ 65 ].

Hybrid supercapacitors, EDLC and pseudo-capacitance, build of charge storage mechanisms reduce the superior features of the device. On the other hand, among the other EDLC electrode materials multiwalled carbon nanotubes (MWCNTs) fascinated major interest due to their favorable features such as high surface area and mesoporous network, good mechanical strength and flexibility, excellent electrical conductivity, and chemical stability. The facile synthesis of composites of metal oxides with carbon materials was facilitated by SILAR as well. For instance, the fabrication of NiO/MWCNTs nanohybrid thin films via SILAR and the specific capacitance was as high as 1727 Fg −1 and current density 5 mAcm −2 with 91% retention ability after 2000 cycles as demonstrated in the Figure 4 [ 84 ]. Moreover, an analogous synthesis style was employed to NiCoO x /Carbon-black hybrid thin films accomplishing coatings with a high specific capacitance of 1811 Fg −1 at 0.5 mAcm −2 [ 85 ].

Assembly of highly flexible symmetric NiO/MWCNTs-NiO/MWCNTs nanohybrid device: (a) image of flexible NiO/MWCNTs thin film deposited on the stainless steel, (b) NiO/MWCNTs nanohybrid thin film electrodes with closed ends (2 × 3 cm 2 area), (c) coating of the electrode by PVA/LiClO 4 gel electrolyte, (d) flexible supercapacitor built under the ∼1 ton pressure through sandwiching the two-gel electrolyte coated electrodes, (e) two flexible supercapacitors in series can successfully light a LED [ 84 ].

Therefore, SILAR is a unique as well as multipurpose technique to fabricate thin films for supercapacitor device application with superior power and energy densities in comparison with other available and more conventional deposition techniques, justifying the quality of the SILAR growth thin films.

4.2. Solar cells

Photovoltaic (PV) is a simple device, which promotes the direct conversion of light radiation into electrical energy by following the photovoltaic effect [ 91 ]. The discovery of such a device for the conversion of sunlight radiation directly into electricity was first carried out during the late 1800s. C. Fritts first demonstrated the solid-state PV by fabricating a thin layer of Au on Se semiconductor material [ 92 ]. At American Telephone and Telegraph Bell Laboratory the modern PV was discovered by Ohl in 1946 [ 93 ] but demonstrated by Chapin, Fuller and Pearson in 1954 [ 94 ]. The cell was fabricated by single-crystal Si wafer having an efficiency of ∼5%.

At present for feasible use, extensive research is going for efficiency enhancement of solar cells, as the efficiency of solar cells is one of the very vibrant parameters to promote this technology. Over the years, the efficiency of single crystal-Si solar cells has shown a sound development. In 1950s, it was only 15% and nowadays it is improved to around 26.7% [ 95 ]. The commercial efficiency of Si solar cell is approaching in between 12% and 15%, while the theoretical Shockley-Queisser (SQ) limit energy conversion efficiency is of around 28% [ 96 ]. The PV cell and module market was mostly occupied on first-generation Si-based cells until 2004, for example, sc- and poly-Si cells, which covered about 85% of the overall international PV modules market. In the meantime, thin film cells or second-generation PV have exhibited great advantages, for instance, the ease of large area fabrication and usage of minimum materials, though their market share was much smaller in comparison with the Si-cells [ 97 ]. After 2005, the developments were spurred by the sharp increase in the country’s implementation of solar energy due to the rapid advancement of the PV production industry in China. The price of PVs is generally supplemented by the strict requirement for fabricating high-purity materials such as GaAs and Si, or the rare-earth elements such as CIGS. The element, In, is rare and can be certainly exhausted, which might affect the prospect of such PVs. Later, CdTe thin-film PVs have increased longing in the market of South-Eastern countries. But Cd has a serious environmental distress, which is due to its high toxicity [ 98 , 99 ]. For example, chronic Cd exposure breeds an extensive acute and chronic effects in humans [ 100 , 101 ]. Moreover, Cd is a rare earth element and it will also generate a higher cost within the demand in future. Further, a third generation of devices has newly developed in addition to the thin-film solar cells, based on fresh organic materials such as dye-sensitized solar cells (DSSC) [ 102 ], quantum dot solar cells (QDSC), perovskites, bulk heterojunctions, having innovative device architectures with the usage of multiple exciton generation, upconverting layers, and others. Though, organic materials-built PVs have small life spans as the nature of the materials, for example, thermal stability [ 103 ] or concerns of electrolyte-based variability [ 104 ]. Inherently, a mostly striking new field of PV devices using metal oxide (MO) semiconductors has performed [ 105 ]. Atop of the MO thin films, favorable next-generation PV cells such as exciting thin absorber cells [ 106 ], DSSC [ 107 ], and QDSC [ 46 , 108 ] are built as they are promising applicants for being stable, eco-friendly, and ultra-low-cost PV materials.

SILAR accounts itself directly into the third generation, by affording ultra-thin, compositionally fabricated by layers of several semiconductors that could be subjugated in a diversity of device architectures. Besides Si, most of the absorbers in PVs are conventionally II–VI, III–V semiconductors, or organic polymers, or small molecules, or perovskites. Still, the number of metal oxides is not adequate, which can be effectively used as absorber layers. Consequently, research into SILAR-grown light absorber layers for PV device applications has been aimed mainly on selective transition metal oxides, sulfides, and selenides. These materials have drawn incredible interest in technological and scientific research due to their unique optical, electrical, and mechanical properties in the past few decades [ 109 , 110 , 111 ]. Nevertheless, there are some examples of SILAR grown metal oxides, sulfides, and selenides applied in different types of solar cells such as thin film, DSSC, perovskite, and QDSC as summarized in Table 5 . The layers were used not only to achieve high efficiency, but also served diverse roles inside the PVs such as light absorber, selective charge transport (electrons or holes), and passivation.

SILAR growth PV cells demonstrating with the cell properties.

N.B. N3: ethanolic 0.3 mM cis-Bis (isothiocyanato) bis (2,2′-bipyridyl-4,4′-dicarboxylato ruthenium (II).

In many cases, the core light-absorbing layers, within the solar cells, fabricated via SILAR have been investigated. For example, in ITO/CdS/PbS/C heterojunction solar cell, n-type layer, CdS thin films were deposited by CBD on transparent conductive oxide (ITO) substrates, whereas PbS film by SILAR using different deposition cycles, 15, 20, 30, 40 and 60 to obtain different thicknesses, showed that 40 cycles PbS film has a greater photovoltaic conversion efficiency [ 115 ]. In another study, p -type CuO was utilized as photo-absorber in the p-CuO/n-Si heterojunction cell [ 123 ], where a vibrant role of the SILAR deposition was observed in the overall device performance, depending mainly on the concentration of the copper precursor solution. In an all-oxide solar cell, NiO/Cu 2 O or CuO/ZnO/SnO 2 , both Cu 2 O and CuO fabricated were examined as light absorber fabricated by SILAR and the hole transporting layer ( p -type NiO), buffer layer (ZnO) as well as n -type SnO 2 were deposited by sol-gel method [ 124 ]. The cell having Cu 2 O showed better performance than CuO, which is due to the reduced conductivity, mobility, and carrier concentration of CuO. However, the study showed an overall efficiency over 1%. In a different study, heterojunction solar cells have been fabricated between layers of p-type CuS and n-type Ag 2 S deposited via SILAR method and Sn 2+ and Al 3+ heterovalent dopants are introduced in Ag 2 S so that Fermi energy of the semiconductor can be modified to alter the band diagram of pn junctions. The Sn 2+ -doped Ag 2 S resulted in better solar cell parameters with an efficiency of 2.85% as compared to that based on Al 3+ -doped Ag 2 S, which consists of many defect states due to mismatch in ionic radii of the cation and the dopant ions [ 44 ].

Further, metal oxides were worked in charge transportation in between different layers in solar cells, and both electron transport layer (ETL) and hole transport layer (HTL) can enhance the performance of PVs. Since the early 1990s, TiO 2 is one of the key materials used as ETL owing to its wide popularity in DSSC [ 120 ]. In a recent study, TiO 2 nanocrystalline film was directly deposited using SILAR at 90°C for perovskite solar cell applications and used as an ETL [ 114 ]. Due to the fast charge transport, kinetics and slow charge recombination process of the TiO 2 ETL synthesized from the solutions of TiCl 4 and hot K 2 S 2 O 8 , with subsequent annealing at 450°C, advances the efficiency of the cell to around 10%. Further, a couple of studies showed the deposition of TiO 2 layers from solutions of TiCl 3 and NaOH [ 27 , 125 ] followed by annealing at 400°C, as ETLs in DSSC with the modest efficiency of just over 1%. Other SILAR-fabricated layers used as ETLs in PVs consist of ZnO and ZrO 2 as interfacial layer attached to porous TiO 2 , both demonstrated performance in DSSC [ 102 , 126 ].

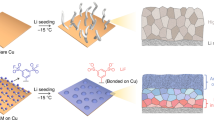

In this study, Cu 2 O thin films were introduced as a HTL in a planar perovskite solar cell and successfully enhanced the efficiency of the cell to around 8.23%, as shown in Figure 5(a-c) . The Cu 2 O films were deposited via SILAR by followed the complexation reaction of copper and ammonia with H 2 O 2 [ 112 ]. The methylammonium lead triiodide (MAPbI 3 ) perovskite layer is sandwiched between a p -type Cu 2 O HTL layer and another n -type PCBM (phenyl-C61-butyric acid methyl ester) ETL layer, respectively. The Cu 2 O films demonstrated suitable band structure after annealing at 170°C and boosted device performances better than conventional sol-gel-deposited NiO and Cu-doped NiO hole transport layers, confirming the quality of the SILAR-Cu 2 O.

(a) Cell structure, (b) schematic energy level diagram; the dashed line represents the Fermi energy after contact (c) current-voltage characteristics of under dark and a white light illumination condition of Cu 2 O/MAPbI 3 /PCBM heterojunction [ 112 ].

In a report of 2009, Lee et al. showed a novel technique for preparing selenide (Se 2− ) by the SILAR process in pursuit of efficient QD-sensitized solar cells atop of mesoporous TiO 2 photoanodes. After several optimization of the QD-sensitized TiO 2 films via regenerative photoelectrochemical cells in presence of a cobalt redox couple [Co(o-phen) 3 2+/3+ ], with a final layer of CdTe, the overall efficiencies of the was recorded around 4.2% at 100 Wm −2 [ 127 ]. To find the answer to a question, “How does a SILAR CdSe film grow?” Becker et al. tuned the deposition steps to suppress interfacial charge recombination in FTO/TiO 2 /CdSe/Na 2 S: S/CoS 2 cell by showing an efficiency of 3.53% [ 117 ]. Recently, in another report, SILAR- and CBD-grown CdSe-sensitized TiO 2 solar cells were examined concentrating on the influences of two commonly used QD deposition techniques [ 119 ], and atop of pre-accumulated CdS seed layers, a successful CdSe deposition was performed. The PEC of both the cells has been recorded as 4.85%, for CBD grown CdS/CdSe cell, whereas for SILAR grown cell the value was 3.89%. One research group enhanced the PCE of CdS/CdSe/S 2− -S/RGO/Cu 2 S cell to 5.4% by employing Mn 2+ doping of CdS via SILAR method [ 118 ], whereas another group reported on a PbS: Hg QD-sensitized solar cell by Hg 2+ doping into PbS employing similar deposition technique and showed an unprecedentedly high J SC of 30 mA/cm 2 with the PEC of 5.6% [ 120 ]. More studies are ongoing with great efforts to find new alternative, clean, and environment-friendly energy resources due to the increasing demands.

4.3. Photoelectrochemical water splitting

Hydrogen energy is a key issue to cope with the present global energy crisis and environmental complication exploiting clean and inexhaustible energy [ 128 ]. Photoelectrochemical (PEC) water splitting is a promising technique to create hydrogen fuel by utilizing solar energy. Within the nonstop efforts in developing efficient photoelectrodes, the major challenge researchers presently face is to explore cost effective, nontoxic, and earth-abundant photoelectrodes with high efficiency [ 129 ]. In a recent study, Ag/Ag 2 WO 4 was fabricated on ZnO nanorods using 0.05 M AgNO 3 and 0.05 M Na 2 WO 4 as the cationic and anionic precursors, respectively, by following SILAR technique and the composite material demonstrated outstanding performances in PEC water splitting with 3 mAcm −2 at 1.23 V versus RHE in the presence of 0.1 M Na 2 SO 4 electrolyte. Based on these results, a brief possible updated mechanism of the PEC activity was demonstrated by Adam et al. for the better understanding of the technique with Figure 6 [ 130 ]. The development of PEC activity of the semiconductors was principally attributed to electrons and hole transfer at the interfaces of the photoelectrodes. The band edge potentials of the Ag/Ag 2 WO 4 and the ZnO materials showed a significant role in the efficiency of growth and separation technique of the electron (e − ) and hole (h + ) pairs. The energy of valence band (E VB ) of ZnO and Ag 2 WO 4 is calculated as +2.86 and + 3.03 eV, whereas energy of conduction band (E CB ) of them is projected as −0.34 and − 0.07 eV, respectively [ 131 ].

(a) and (b) FM-SEM images of the ZnO NRs and the ZnO/Ag/Ag 2 WO 4 heterostructure. (c) Curves of the ZnO NRs, and the ZnO/Ag/Ag 2 WO 4 photo-electrodes under light and dark conditions using linear sweep voltammetry. Schematic diagram presenting the energy band structure and probable electron-hole separation as well as transportation in ZnO/Ag/Ag 2 WO 4 heterostructure with the SPR effect [ 130 ].