- Guide: A3 Problem Solving

Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

- Last Updated: June 13, 2023

- Learn Lean Sigma

Problem-solving is one of the key tools a successful business needs to structure improvements and one I have been using to solve problems in a structured way in my career at a range of businesses over the years. When there is a problem in business that is leading to increased costs, waste , quality issues, etc., it is necessary to address these problems. A3 structured problem solving is a Lean Six Sigma methodology that has been designed and developed to support continuous improvement and solve complex business problems in a logical and structured process.

The guide will give you a full understanding of what A3 Problem solving is and a breakdown of all the steps of how to apply it within your business with an example of where I have made improvements with it previously.

Table of Contents

Importance of a3 in lean management.

The A3 problem-solving method is a key tool in Lean Six Sigma and continuous improvement in business, and in my experience, it is often the standard approach all improvement activities must follow and is particularly popular in the automotive industry. This is because of the following:

Focus on Root Causes : Rather than applying a quick fix to a problem or jumping to conclusions and solutionizing, A3 requires gaining a deep understanding of the root causes of the problem. By addressing these root causes, the chances of recurrence is reduced.

Standardization : With a consistent format, the A3 process ensures that problems are approached in a standardized way, regardless of the team or department. This standardization creates a common language and understanding across the organization and ensures all problems are addressed to the same standard and approach.

Team Involvement : An A3 isn’t an individual process. It requires a cross-functional team to work together on problem-solving, ensuring that a range of perspectives and expertise is considered. This collective approach builds a stronger understanding of the problem and ensures that solutions are well-rounded and robust.

Visual Storytelling : The A3 report serves as a visual storyboard, making it easier for stakeholders at all levels to understand the problem, the analysis, and the countermeasures. This visualization enhances communication and drives alignment.

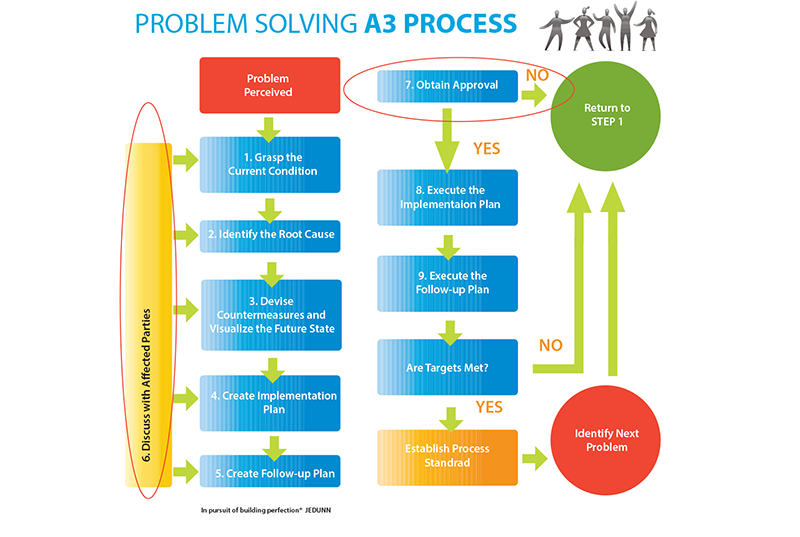

The 6 Steps of A3 Problem Solving (With Real Example)

The A3 problem-solving process can initially seem difficult if you have never done one before and particularly if you have never been a team member in one. To help you with this we will break down the 6 steps into manageable activities, followed by a real-life example to help you apply this method within your business.

As a side note, the A3 problem-solving process was actually one of the first Lean Six Sigma tools I learned to use three weeks into my continuous improvement career after being thrown into the deep end due to resource availability, so I can understand how difficult it can be to understand.

Step 1: Describe the problem

Problem description.

The problem description is an important first step in the process as it ensures a common understanding with the team of what the issue is that needs to be addressed. This can be done by using a technique called the 5W1H Is/Is Not method to help gain a clear understanding of the problem.

To understand the 5W1H Is/Is Not the Process, check out our guide for details of that technique. However, in short, it’s about asking key questions about the problem, for example, “What IS the problem?” and “What IS NOT the problem?”

Let’s say you have been asked to look into a problem where “Machine downtime on the automotive assembly line has increased by 30% over the past three months, leading to production delays and increased costs.”

An example of a 5W1H Is/Is Not on this may result in the following output:

Based on this we can create a clear problem description as the focus of the project that give the team a clear and common understanding of the issue looking to be resolved in the next steps of the process. The problem description could then be written as:

“Over the past three months, machine downtime on Automotive Assembly Line No.3 has increased by 30%. This has predominantly affected the assembly line workers and leads, leading to production delays and higher labour costs. “

Current Condition

Next is demonstrating the current condition and demonstrating the impact on the business. This can often be done with data and charts to back up the problem that might show trends or changes in outputs.

This might look something like the below and demonstrate a good baseline for confirming the improvement at the end of the A3

Containment Actions

Next is containment actions. Since you have identified a problem, there is likely an impact on the business or the customer. As a team, you should consider what can be done to limit or eliminate this problem in the short term. Remember this is just a containment action and should not be seen as a long-term fix.

In our situation we decided to “Implement temporary overtime shifts to meet production goals, leading to an increase in labor costs.”

At this stage, the A3 should look similar to the one below; you can use charts and graphics to represent the current state as well if they fit within the limit area. Remember, we must include the content of the A3 within the 1-page A3 Document.

Step 2: Set the A3 Goals

The next step of the A3 is to, as a team, set the goal for the project. As we have a clear understanding of the current condition of the problem, we can use that as our baseline for improvement and set a realistic target for improvement.

A suggested method for setting the Target condition would be to use the SMART Target method.

If you are not familiar with SMART Targets , read our guide; it will cover the topic in much more detail. In short, a SMART target creates a goal statement that is specific, measurable, achievable, relevant and time-bound.

By doing this you make it very clear what the goal of the project is, how it will be measured, it is something that can be achieved, relevant to the needs of the business and has a deadline for when results need to be seen.

For our A3 we decided that the goal would be “Our goal is to achieve at least a 20% reduction in machine downtime on Automotive Assembly Line No.3, lowering it from 90 minutes to no more than 72 minutes per day per machine, within the next 60 days. This reduction is crucial for increasing productivity and reducing labour costs, aligning with our overall business objectives.”

I also recommend using charts in this section to visualize the benefit or improvement to ensure you have stakeholder and sponsor support. Visuals are much easier and faster for people to understand.

At this point, your A3 might look something like the one below, with the first 1/4 or section complete. The next step is to move on to the root cause analysis to get to the root of the problem and ensure the improvement does not focus on addressing the symptoms of the problem.

Step 3: Root Cause Analysis

Root cause analysis is the next step in the process, often referred to as gap analysis, as this step focuses on how to get to the goal condition from the current condition.

Tip: If at this point you find the team going off-topic and focusing on other issues, Ask the question, “Is this preventing us from hitting our goal statement?” I have found this very useful for keeping on track in my time as an A3 facilitator.

For root cause analysis, a couple of key tools are usually used: a fishbone diagram and a five-why Analysis . Again, we won’t go into the full details of these tools within this guide, as they have been covered in extensive detail in their own guides.

But the aim at this point is as a team, to brainstorm what is preventing us from achieving our target condition. This is done by allowing all members of the team to input the reasons they think it is not being achieved. These inputs are often written on sticky notes and placed on the fishbone diagram. Following this, you may have results similar to the ones below. Note: it is important that the inputs are specific so they can be understood. e.g. “Calibration” alone is not specific to how it’s causing the problem; specify it with “Calibration: Inaccurate measurements affecting machine settings.”

After the fishbone diagram has been populated and the team has exhausted all ideas, the team should then vote on the most likely cause to explore with a 5 Whys analysis. This is done because, due to resource limitations, it is unlikely all of the suggestions can be explored and actioned.

In this situation the team decided the “lack of preventative machines: machines not being serviced regularly” was the cause of increased downtime. This was explored with the 5 Whys to get to the root cause of why Assembly Line 3 did not have preventative maintenance implemented.

The result of this root cause analysis can be seen below, and you may end up with more ideas on the fishbone, as generally there are a lot of ideas generated by a diverse team during brainstorming.

Step 4: Solutions and Corrective Actions

Now that we understand what the root cause of the problem is, we need to address it with solutions and corrective actions. Again, as a team, consider the root cause of the problem and discuss what actions need to be taken by the team, who will do them, and when they will be done. The result should be an action plan, for example, like the one below:

This action plan needs to be carried out and implemented.

The result of this section will likely just be an action list and look like the below section.

Step 5: Validate Solution and Standardize

Within step 5 it is time to collect data to validate and confirm the actions that have been implemented resulting in solving the problem and meeting the target state of the problem. This is done by continuing to collect data that demonstrates the problem in the baseline to see if the problem is being reduced.

For example, below, the project team continued to collect Assembly Line 3 downtime data on a weekly basis. Initially, there was a steady reduction, likely due to the focus of the project on the problem, which had some impact. However, once the majority of the action was implemented, a huge drop in product downtime was seen, exceeding the target. This showed the actions have been successful

If, in the validation stage, you find that the improvement required is not being made, you should go back to step 3 and reconsider the root cause analysis with the team, pick another area to focus on, and create an action plan for that following the same steps.

Step 6: Preventive Actions and Lessons Learned

In step 6 after the confirmation of project success you should look at preventive actions and lessons learned to be shared from this project:

- Preventive Action: The new preventive maintenance schedule will be standardized across all assembly lines. This will prevent other lines having similar issues and make further improvements

- Lessons Learned: A formal review will be conducted to document the process, including challenges faced and how they were overcome, which will then be archived for future reference.

In our project, this looked like the one below and will be used as a reference point in the future for similar issues.

And that is the successful completion of a structured A3 problem-solving technique.

The complete A3 looks like the below image. Yours may slightly differ as the problem and information vary between projects.

Downloadable A3 Reporting Template

To support you with your A3 problem solving, you can download our free A3 problem solving report from the template section of the website.

Problem-solving is important in businesses, specifically when faced with increased costs or quality issues. A3 Structured Problem Solving, rooted in Lean Six Sigma, addresses complex business challenges systematically.

Originally from Toyota’s lean methodology, A3, named after the 11″x17″ paper size, visually maps problem-solving processes. This method ensures concise communication and focuses on crucial details, as illustrated by the provided example.

Emphasized in Lean Management, A3 stresses understanding root causes, standardization across teams, team collaboration, and visual representation for clarity. This tool is not only a guide to understanding the issue but is a standardized format ensuring robust solutions. Particularly for novices, breaking down its six steps, from problem description to setting A3 goals and root cause analysis, provides clarity. Visual aids further enhance comprehension and alignment across stakeholders.

- Sobek II, D.K. and Jimmerson, C., 2004. A3 reports: tool for process improvement. In IIE Annual Conference. Proceedings (p. 1). Institute of Industrial and Systems Engineers (IISE).

- Matthews, D.D., 2018. The A3 workbook: unlock your problem-solving mind . CRC Press.

Q: What is A3 problem solving?

A: A3 problem solving is a structured approach used to tackle complex problems and find effective solutions. It gets its name from the A3-sized paper that is typically used to document the problem-solving process.

Q: What are the key benefits of using A3 problem solving?

A: A3 problem solving provides several benefits, including improved communication, enhanced teamwork, better problem understanding, increased problem-solving effectiveness, and the development of a culture of continuous improvement.

Q: How does A3 problem solving differ from other problem-solving methods?

A: A3 problem solving emphasizes a systematic and structured approach, focusing on problem understanding, root cause analysis, and the development and implementation of countermeasures. It promotes a holistic view of the problem and encourages collaboration and learning throughout the process.

Q: What are the main steps in the A3 problem-solving process?

A: The A3 problem-solving process typically involves the following steps: problem identification and description, current condition analysis, goal setting, root cause analysis, countermeasure development, implementation planning, action plan execution, and follow-up and evaluation.

Q: What is the purpose of the problem identification and description step?

A: The problem identification and description step is crucial for clarifying the problem, its impact, and the desired outcome. It helps establish a common understanding among the team members and ensures everyone is working towards the same goal.

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Other Guides

This page uses JavaScript. Please make sure that JavaScript is enabled in your browser.

- kanban library

- pricing & sign up

Thank you! We have sent you an email with details about your accounts.

- Kanban Guide

- Introduction

- History of Kanban

- Agile Framework

- Kanban Fundamentals

- ⬞ Visualize the Workflow

- ⬞ Limit Work in Progress

- ⬞ Manage Flow

- ⬞ Make Policies Explicit

- ⬞ Improve Continuously

- Kanban Elements

- ⬞ Kanban Method

- ⬞ Kanban Card

- ⬞ Kanban Board

- ⬞ Kanban Software

- ⬞ Personal Kanban

- ⬞ Manufacturing

- ⬞ Business Management

- ⬞ Bottlenecks

- Lean Thinking

- ⬞ Lean & Kanban

- ⬞ Just-In-Time (JIT)

- ⬞ Lean Manufacturing

- ⬞ Theory of Constraints (TOC)

- ⬞ Water Spider

- ⬞ Hoshin Kanri

- ⬞ Toyota Kata

- ⬞ Lean Project Management

- ⬞ Lean Accounting

- Lean Methodology

- ⬞ 5S in Lean

- ⬞ Six Sigma

- ⬞ Gemba Walk

- ⬞ Poka-Yoke

- ⬞ The 5 Whys

- ⬞ Flowcharts

- ⬞ Fishbone Diagram

- ⬞ A3 Problem Solving

- ⬞ SIPOC (COPIS)

- ⬞ Design of Experiments

- Lean Metrics

- ⬞ Cumulative Flow

- ⬞ Cycle Time

- ⬞ Lead Time

- ⬞ Process Throughput

- ⬞ Root Cause Analysis

- ⬞ Takt Time

- Kanban Use Cases

What is A3 Problem Solving?

A3 problem solving is a Lean approach to reporting issues and presenting ways of addressing them. The simple method, developed by Toyota, bases on documenting a problem, together with its current outcome and a suggested change, on a single sheet of A3 paper (420x297mm), giving it the name. You can use it to make a process change proposal, report on project status, or solve a problem.

A3 takes from the Plan-Do-Check-Act cycle . Though it appears to be a step-by-step process, the method tends to be used iteratively, with the problem and solution sections being cyclically updated.

Taiichi Ōno of Toyota was known for not appreciating reports longer than one page, which helped the proliferation of the A3 approach within the automotive giant’s offices. A3 is similar to the 8D report also widespread in the automotive industry, though typically for complaints management. Furthermore, the ability to quickly discern a problem and understand its solution is innate to Lean values.

Lean emphasizes visualization, with examples in value stream mapping and Kanban’s visual workflows. That made a single-page report presenting what is going on was a welcome addition to a Lean operation.

Through shared use of A3s to solve all problems and plan initiatives, companies can start to operate an A3 system thinking methodology: address difficulties, suggest change, innovate, and curate logical reasoning rooted in the current needs.

Why use the A3 approach to solving problems?

Lean provides a competitive advantage, strategic and operational benefits through its objective to increase the value delivered to the customer and to reduce waste. Engaging in a process that allows the team to find the correct, best solution in the shortest possible time is highly beneficial.

Understandably, some reports and proposals must contain extensive amounts of data, and they have their place in a business environment. But imagine the value and advantage that distilling this information to 1 page has. Consider how much faster decisions can be made based on that. Besides the time savings, the opportunity to use the systematic approach of PDCA supplements the problem-solving skills required to propose accurate solutions.

In preparing for battle I have always found that plans are useless, but planning is indispensable. Dwight Eisenhower

It’s the act of planning that is important, as it spells out all known obstacles, visualizes the action plan, and helps to foresee potential outcomes and issues along the way. While documenting your problem on an A3 piece of paper may or may not yield benefits, the act of implementing A3 thinking is what makes the difference.

The benefits of using A3 thinking are:

- Quicker problem solving through logical reasoning and application of a step-by-step, visual process. Demanding a root cause identification ensures that difficulties are dealt with, not just temporarily masked.

- Easier planning thanks to the application of objective, critical thinking promoted by the A3’s structure.

- Team development through repeated use of a structural tool to find root causes of problems and their best solutions. The use of one tool across all company levels also promotes cross-department collaboration and knowledge sharing.

- Company growth A3 reports help maintain and keep company knowledge on record, helping to sustain good operating policies and build a strong growth culture rooted in solving a company’s actual problems, not abstract ideas.

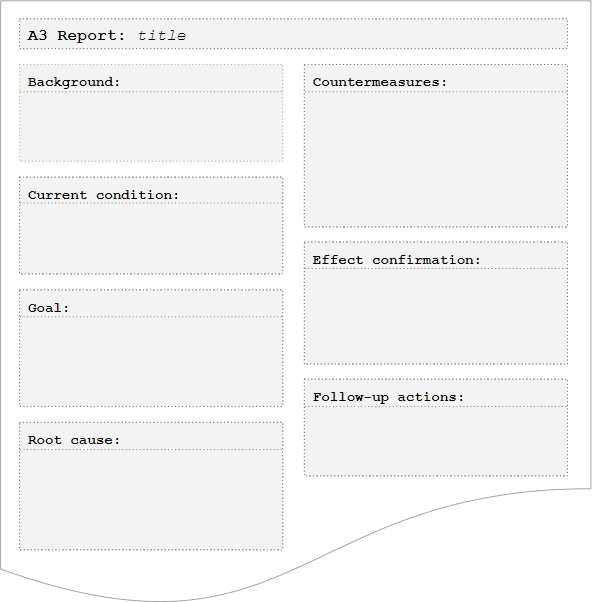

How to create an A3 report?

Step 1: The title

It should focus on the problem you are trying to solve and not the solution you want to convey. Examples of titles are: “Decrease Team Misunderstanding of Task Instructions” or “Reduce Customer Complaints with Product XYZ” .

Step 2: Background

According to the authors of “Understanding A3 Thinking: A Critical Component of Toyota’s PDCA Management System” , one of the main strengths of Toyota is that they place importance on understanding a problem. Rather than rush onto a solution, Toyota takes the time to precisely understand what is going on. The principle of going on a Gemba walk attests to this need to perceive problems first-hand.

The report’s background section conveys important related facts and how the problem aligns with the company’s strategic objectives. Presenting this right there on the page helps minimize the cost that a board of highly paid executives would need to spend looking at a problem, without a guarantee of them understanding it, nor coming up with the right solution. Consider this checklist for your background section:

- Do I know the needs of my report’s audience?

- Have I provided enough context?

- Does what it presents align with the audience’s strategic goals?

- Can the background be explained in 30 seconds?

Step 3: Current condition

A correct definition and a good understanding of the problem is your path to finding the right solution. That makes working on defining the current condition 90 % of the A3 effort.

The objective here is to make sure everyone is aware of the problem, whether the report documents it appropriately, and whether anyone questions the report’s findings. The use of graphs, charts, or other visual aids is beneficial.

Step 4: Goal

Your target - if you hit it, you know that your problem-solving effort has been a success. But you need to know what metrics will measure success and what the definition of success is. An example could be “reducing customer complaints by 15%, as measured by call center statistics” .

Step 5: The root cause

The focus of the root cause section should be to differentiate between facts and opinions regarding a problem’s cause and effect. You can include your findings from 5 Whys exercises , an Ishikawa diagram , or any other result of your RCA efforts . If the root cause is not defined correctly, the problem will likely resurface, causing waste and negating the Lean principles.

Step 6: Countermeasures

The countermeasures should be the corrective actions to take for the root cause of the problem to be resolved. If not possible - without a process overhaul - you can use containment actions instead to stop the issue from directly impacting the customer. It is OK to address complex problems iteratively, along with the values of continuous improvement .

The section may include a table of the problem causes, actions taken, action owners, and the achieved results.

Step 7: Effect confirmation

Since the A3 exercise bases on the PDCA cycle, this section of your report should show the effort you expended to confirm your findings. The proof that you have indeed solved the problem. For example, software engineers include samples that replicate the bugs and verify they are no longer present after a fix.

If the exercise has not taken place yet, i.e., when you’re presenting a plan to gain approval, you should outline what exercises you will conduct to check if the aim is successful.

Step 8: Follow up actions

The final section should include any other actions that you might want to consider. A principle worth adhering to here is the “Shitsuke - sustain” step of the 5S plan . Consider what you should do to ensure the benefits of this exercise are maintained. And could they possibly be translated to other areas of the company?

An A3 problem-solving report will help you deliver information in a way that provides instant value and can quickly reduce waste.

The most important thing to remember is that the act of Lean problem solving is more important than creating an A3 document that may contain no valid data and be simply a tick on some corporate checklist.

The same is true of all Lean methods and tools - their application alone will not make your company Lean. To truly implement Lean principles, your company culture, thinking, and planning all have to transform.

Did you know?

A low-risk, tiny step in attempting a culture change in a company could be getting the teams to collaborate on digital Kanban Tool ® boards. Their WIP limits monitoring and process visualization stand a chance to slowly change people’s way of thinking towards more Lean patterns. Please enter valid URL This name is not available Please enter valid email address

Did you like this article?

Anything to change or improve - let us know.

Further reading

- Understanding A3 Thinking: A Critical Component of Toyota’s PDCA Management System (BOOK)

- Kanban Tool

- Pricing & sign up

- Kanban Tool On-Site

- Kanban Library

- Kanban Tool Support

- Integrations

- Developer API

- Terms of service

- Privacy policy

© 2009-2024 Kanban Tool ® by Shore Labs . All rights reserved. | All other trademarks, logos and images mentioned on this site belong to their respective owners. | We use cookies on our website.

Kanban Tool is a visual management solution that helps companies visualize workflow, track project progress, and analyze and significantly improve business processes. Kanban Tool provides powerful online Kanban boards with seamless time tracking and insightful analytics. Our Kanban software works perfectly in any business process and is designed for teams that want to visualize work on a Kanban board .

- Consultancy

- Online Courses

SIGN UP TODAY

- Lean , Lean Culture , Lean Training , Lean Wiki , Tools

A Deep Dive into the A3 Problem-Solving Approach

- 11 mins to read

- June 20, 2023

- By Reagan Pannell

In today’s fast-paced and fiercely competitive business world, organisations must find ways to continuously adapt, evolve, and excel. Amidst the myriad methods and techniques for achieving improvements and driving continuous improvement, few have proven as profound and transformative as Toyota’s A3 problem-solving approach.

A significant driving force behind the company’s rise to global prominence, the A3 process fosters a culture where problems are embraced as opportunities for growth and learning. In this article, we’ll explore the origins and underlying principles of the A3 approach and uncover the secrets to its success in unlocking the power of improvements.

Understanding the A3 Approach

The A3 methodology is an integral part of the Toyota Production System (TPS), a set of principles and practices that have shaped the company’s approach to manufacturing, management, and continuous improvement over the years. Named after the A3 sheet of paper that was historically used to capture the plan, analysis, and follow-up on a single page, the A3 process represents a simple, yet powerful, tool for addressing complex challenges and discovering lasting solutions.

At its core, the A3 approach is rooted in three key elements:

1. Thorough problem analysis: The foundation of the A3 process lies in digging deep to diagnose the true nature and root cause of an issue, rather than jumping to hastily devised fixes that merely address symptoms.

2. Structured documentation: The A3 report serves as both a communication tool and an iterative planning device, with each section building on the previous ones to guide problem solvers through a comprehensive analysis, solution development, and execution process. It’s the foundation of good continuous improvement.

3. Cyclical learning and improvement: Leadership and employees alike are encouraged to commit to hypothesis-driven inquiry, observation, experimentation, and reflection, leading to a culture that actively seeks and leverages opportunities for growth by solving problems.

How to Implement the A3 Process in Your Organisation

The Lean Thinking A3 approach can be distilled into seven essential steps:

1. Identify the problem:

Clearly articulate and define the issue at hand, avoiding the temptation to jump to solutions or assume important facts to be self-evident..

When identifying the problem, it is important to ensure that all relevant stakeholders in the organisation are consulted. This helps to ensure that the issue is accurately described and understood from multiple perspectives. A thorough problem analysis should also include conducting research into possible causes or root issues, and clearly documenting any observed symptoms of the problem. Additionally, it is essential to identify any major risks associated with not finding a solution and recognise any constraints (both external and internal) that may exist which could limit potential solutions. Lastly, it is important to consider any potential opportunities which may arise from addressing the issue that may have been overlooked at first glance. This is the problem statement part which is a critical component that identifies the difference between the current condition and the target condition.

At this stage, we are not looking at how to solve problems being faced or at the potential solution to solving problems. It’s about developing a good understanding of how the actual results differ from the expected results and providing an in-depth systematic approach to process improvement and developing problem-solving skills.

2. Establish the context and background:

Provide a high-level overview of the problem, describing the stakeholders involved, relevant data, and the broader organisational context in which the challenge has arisen..

It is important to ensure that all stakeholders are properly considered when identifying any potential solutions as their perspectives can play a vital role in determining an effective solution. All related data should be thoroughly analysed to understand the full scope of potential solutions. This includes resources, costs, timelines, and any legal or regulatory issues that may need to be considered. Additionally, it is important to consider how well-proposed solutions fit within existing organisational policies and procedures as this could impact implementation success. Finally, understanding how proposed solutions would interact with other initiatives or processes currently taking place in the organisation can help inform decisions about whether or not they are viable options. It may include conducting some value stream mapping to dig deeper into the current state.

It is important to fully explore any underlying factors that may be contributing to the issue at hand and ensure in-depth problem analysis. This includes looking deeper into existing systems, structures, and processes related to the problem in order to identify potential areas of improvement or optimisation. Additionally, it is essential to consider any relevant industry trends or external influences that could impact how the problem manifests within the organisation.

When analysing a problem, collecting data from various sources is important to get a more comprehensive understanding of how a particular issue can be addressed. This includes mapping the current process using the VSM, SIPOC, Process Mapping or Flowcharting techniques. Additionally, interviews and surveys can be conducted with stakeholders to gain insights into how they perceive the issue and their perspectives on potential solutions. Lastly, it is important to observe any real-world activities related to the problem to uncover key areas where time, effort, resources, money etc is being wasted. This is the time improvement that may not have been identified otherwise.

GB MASTERCLASS COURSE

Get access to our free gb mastercourse classes, free course previews, fundamentals of lean.

Ready to start your journey into the world of Lean with this free course?

FREE COURSE

Lean Thinking

A Lean focused continious improvement certification course

LSS Yellow Belt

Propel your career forward, tackle complex problems and drive change

LEAN SIX SIGMA GREEN BELT

Get 3-days free access to our green belt course, accelerate your career, 3. set a goal:, now that you have identified the problem and outlined the relevant context, it is time to set a project goal or outcome..

This involves clearly articulating the desired state of affairs and any key deliverables of the proposed solution. Whether it is reducing operational costs, increasing efficiency, improving customer experience, or something else entirely – defining specific objectives with measurable metrics can help ensure that project teams stay focused and remain aligned on their ultimate destination.

At this stage, it is also important to consider how long it will take to reach the desired outcome. Establishing an implementation timeline will help safeguard progress and provide a framework for tracking results along the way. Setting milestones for achieving particular goals at certain points in time can be especially helpful in keeping teams accountable throughout the process. Additionally, having a plan for evaluating success after reaching the end target will allow stakeholders to gain further insights into how effective their approach has been in addressing underlying problems, as well as how well-proposed solutions have fared once implemented.

4. Investigate root causes:

Use a variety of techniques (e.g., the 5 whys, fishbone diagrams, pareto charts) to probe the problem’s underlying causes and avoid settling on proximate reasons..

The process of identifying root causes is essential when using data-driven tools. We always want to find the simplest root cause approach.

One of the most widely used methods for root cause analysis is the ‘5 Whys’ technique. This method involves asking a series of ‘why’ questions to determine the underlying cause of a particular symptom or issue. The goal is to keep asking “Why?” until you reach an answer that can provide insight into how to address the problem and prevent it from occurring in the future.

Another commonly used tool for root cause analysis is the fishbone diagram (also known as Ishikawa diagrams). This approach involves visualising all potential causes which could be causing a symptom or issue in a logical format, allowing users to identify patterns and uncover links between root causes and their respective effects. This technique can be helpful in identifying and focusing on key areas for improvement, as well as helping to identify interdependencies between components within an organisation’s systems.

Finally, Pareto Charts are useful for analysing data collected from surveys, interviews, observations, etc., concerning the severity or frequency of occurrence. This type of chart helps users quickly identify which factors are contributing most significantly towards an issue, allowing them to focus resources towards addressing those areas first and foremost. Additionally, Pareto charts can also be used to prioritise different solutions based on their estimated effectiveness in addressing an issue.

In conclusion, understanding the root cause of an issue through rigorous techniques such as 5 Whys, fishbone diagrams, and Pareto charts provides invaluable insight into how best to address it effectively while preventing it from reoccurring in the future. By leveraging these tools along with other data-led approaches such as process mapping and flowcharting, organisations can ensure that any proposed solutions are well-informed by both qualitative and quantitative data sources as well as ensure they are building consensus across the entire organisation.

5. Countermeasures:

Identify the right countermeasures (corrective actions) to implement that will directly impact the root causes identified..

Brainstorming is a useful tool for identifying potential improvements. It involves coming up with ideas and solutions in an open and collaborative manner, without judgement or criticism. By allowing team members to share their thoughts freely, brainstorming can help uncover innovative solutions that may have otherwise gone unnoticed. Additionally, looking at how waste reduction, flow and pull can be used to improve processes can also provide valuable insights into where improvement opportunities lie.

Brainstorm potential solutions that directly target the root causes and create detailed action plans for implementation, complete with assigned roles, responsibilities, and timelines.

Once the countermeasures are identified, it is important to design an implementation plan and assign roles & responsibilities. This will help ensure that all stakeholders understand their part in the implementation and can work together to achieve the desired outcome. Additionally, it is important to track progress along the way – setting measurable milestones that can be tracked against goals established during the initial problem-solving phase will help keep teams accountable and allow for course corrections if needed.

By utilising A3 Problem Solving Tools such as a template, organisations can easily document and share their analyses with relevant stakeholders throughout each stage of the project. Having detailed record-keeping like this also helps teams stay on target over time while providing insights into how proposed solutions may need to be re-evaluated down the line. This implementation plan provides the entire organisation with a clear project status on a one-page report.

6. Evaluate the results:

Measure the impact of your countermeasures against the problem, using well-defined success criteria, key performance indicators, or other relevant metrics..

Once the countermeasures have been implemented, it is essential to measure and evaluate their success. This can be done by tracking performance against the initial objectives established during the goal phase, as well as establishing key performance indicators to gauge how well the proposed solutions have fared.

Additionally, stakeholders should also consider conducting a post-implementation evaluation in order to assess how successful their approach has been in addressing underlying issues and determining what lessons can be learned from the experience. This will enable teams to identify strengths and weaknesses within their existing processes and make any necessary adjustments going forward. By understanding the outcomes of their improvements, organisations are able to gain valuable insights into how well they’ve succeeded in achieving their goals and ensure continued success moving forward.

Once the countermeasures have been implemented and their success measured, it is important to compare the results against the initial objective. This can be done in a variety of ways, including graphical analysis such as charts, process maps or flow diagrams. Graphical analysis helps to visualise the differences between results achieved before and after the implementation of new measures in a meaningful way. It also provides an increased level of clarity when assessing whether the desired outcomes have been achieved or not.

Process maps can be useful in understanding how changes made during the improvement phase have impacted processes within an organisation. By mapping out existing processes and then comparing them against those following implementation of countermeasures, teams can easily pinpoint where improvements were made and analyse how they led to improved performance overall.

Charts, on the other hand, enable users to quickly identify trends that may have emerged from data collected during the project. For example, if performance metrics are tracked before and after countermeasures are implemented, users can use charts and graphs to more clearly observe any patterns that may indicate an improvement or regression in performance over time – providing further insights into which areas need further attention or adjustment moving forward.

Finally, dashboard views provide an effective means of displaying results at a glance while highlighting any anomalies that might warrant further investigation. Dashboards allow stakeholders to gain access to important information quickly and easily while also helping them keep track of progress towards goals set out during initial problem-solving phases. Additionally, because dashboards support data visualisation capabilities they offer a highly interactive user experience which can help teams understand underlying trends with greater clarity and precision.

7. Standardise and share:

If a countermeasure proves successful, integrate it into the organisation’s standard operating procedures and share it with other teams as a best practice..

Once the countermeasures have been successfully implemented and measured against the initial objectives, these changes need to be integrated into the organisation’s standard operating procedures (SOPs) and shared with other teams as best practices. This will ensure that any improvements made during the problem-solving phase are consistently applied across all teams within the organisation.

In order to ensure that these improvements become part of the organisation’s long-term strategy, process maps should be updated to reflect the new improved way of working. Process maps provide a visual representation of how workflows are structured within an organisation, and by updating them in line with newly-implemented countermeasures, organisations can ensure that their processes continue to remain up-to-date and efficient moving forward. It may also be necessary to build a follow-up plan if not all tasks are fully completed as well as develop a Lean-focused PDCA cycle to ensure long-term effective collaboration on the solutions that were implemented.

Process documentation should also be updated in order to keep track of changes made during problem-solving. By documenting not just the solutions that were proposed but also why they were proposed, teams can gain valuable insights into their decision-making process which they can leverage for similar future problems.

Furthermore, it is important to update key performance indicators (KPIs) to accurately reflect any progress made during problem-solving. By tracking performance against objectives established before and after countermeasures were implemented, organisations will be able to identify any areas that may still need improvement or require further adjustment going forward. Additionally, tracking KPIs over time will help teams understand whether or not their current strategies are leading them towards meeting their goals in a timely manner or if additional measures may need to be taken in order to achieve desired results more quickly.

Finally, organisations should share successful solutions with other teams in order to promote collaboration and knowledge sharing amongst stakeholders throughout different parts of the business. This will allow for ideas generated through one team’s problem-solving efforts to benefit multiple departments – helping foster creativity and innovation while ensuring that everyone is on board with necessary changes being made throughout the organisation. The last step is key to Toyota’s PDCA management system designed for the entire organisation.

By breaking down the problem-solving process into these seven discrete stages, the A3 method offers practitioners a comprehensive, end-to-end framework for tackling complex challenges and driving improvements in any organisation.

- Corporate Training

- Courses for Individuals

Training the team on A3

To get A3 started, everyone in the entire organisation needs to learn how to use this single-sheet or single-page document. This means training people across all parts of the company so that everyone knows how to use the A3 Problem Solving Tool and A3 template. Training will help make sure that everyone follows a structured approach when using A3.

Getting the organisation fully onboard with A3 Problem Solving is not an easy task and will require a dedicated effort to ensure its successful implementation. To this end, it is important to start with specific areas of the business – whether it be operations, finance or marketing – by setting up targeted training sessions for both operational teams and senior managers. This will help everyone understand how and why A3 is used, as well as the potential benefits it can bring to their business.

Once everyone has mastered the basics of working with an A3 template, companies should look to regularly review and evaluate its effectiveness. This could include setting up quarterly reviews or running workshops where teams discuss successes and areas for improvement when using the A3 tool. Doing this will ensure that any issues are identified early on, allowing the team to quickly adjust accordingly.

At Leanscape, we understand that transitioning to A3 Problem Solving can be a daunting task. With our team of specialists, we can provide your teams with the necessary training and coaching to ensure that they are able to adapt quickly and efficiently. Our comprehensive approach to A3 will equip your team with the knowledge and skills needed to successfully use this powerful tool for improving performance in all areas of your business.

We are committed to helping you develop a culture of continuous improvement within your organisation by teaching best practices and providing guidance through every step of the problem-solving process. Through our specialised training programs, we will help your teams learn how to use the A3 template more effectively, as well as how to interpret data visualisations quickly and accurately – enabling them to take action swiftly when required. Our experienced coaches will also share insights from industry experts on how best to integrate countermeasures into standard operating procedures (SOPs) and process maps, keeping up-to-date with industry trends in order to stay ahead of the competition.

By leveraging Leanscape’s expertise in A3 Problem Solving, you can rest assured knowing that your team is in good hands. Our team is dedicated to providing you with the support needed for successful implementation so that you can achieve sustained performance improvements over time.

100% Free Fundamentals of Lean COURSE

Take our free course.

JOIN FOR FREE

Join our Lean Six Sigma Yellow Belt Certification Course

The implementation of A3 Problem Solving provides a comprehensive framework for organisations looking to successfully address complex problems in an efficient and cost-effective manner. By breaking down the problem-solving process into seven distinct stages, users can structure their approach and track the progress of their countermeasures over time.

In order to ensure successful implementation, organisations should dedicate time towards training their teams on how to use the A3 Problem Solving Tool and A3 template. This will give everyone a solid foundation for carrying out future problem-solving activities more effectively, as well as provide insights into the effectiveness of certain countermeasures over time.

Through Leanscape’s specialised training programs, you can ensure that your team is fully equipped with the necessary skills to successfully adopt and incorporate A3 Problem Solving into all areas of your business. Our experienced coaches are committed to helping you develop a culture of continuous improvement within your organisation – providing guidance through every step of the process

Final Thoughts

The A3 approach is an invaluable tool for unlocking the power of improvements within any organisation. By leveraging its structured framework and cyclical learning approach, businesses can remain agile and responsive to ever-changing conditions, allowing them to navigate change more successfully and emerge stronger than ever before. Ultimately, this makes Toyota’s A3 problem-solving process one of the most effective ways to ensure long-term success in today’s fast-paced and competitive market.

Our Newsletter

Reagan pannell.

Reagan Pannell is a highly accomplished professional with 15 years of experience in building lean management programs for corporate companies. With his expertise in strategy execution, he has established himself as a trusted advisor for numerous organisations seeking to improve their operational efficiency.

Our Training Courses

- Lean Six Sigma White Belt Course

- Lean Thinking Business Course

- Lean Six Sigma Yellow Belt Course

- Lean Six Sigma Green Belt Course

- Lean Six Sigma Black Belt Course

Yellow Belt Course

View all courses, recent articles, 5 essential problem-solving strategies every business leader should know, unveiling the secrets of blue ocean strategy for business growth, the difference between strategy and strategic execution, small steps, big gains: the case for incremental improvement, maximising efficiency and profitability: exploring the benefits of lean consultancy, empowering leaders: the imperative for problem-solving training, view all articles, green belt course, other articles, poka yoke: the lean concept of mistake proofing, what are some of the benefits of using benchmarking in lean six sigma, data distributions explained | what are the different types of distribution, 90-day facility management turnaround with 27% lift in performance, unlocking the power of the balanced scorecard: maximizing efficiency and driving growth, how “timwoods” and the 8 wastes of lean drive efficiencies in business process, what makes the best lean six sigma certification program, what are the benefits of cpd for lean certifications, facilitation skills for project managers: learning to lead change management, the assessment criteria for solutions, what is the difference between lean & six sigma, principle 4: create balance | heijunka | principles of lean.

- | lean , lean thinking , problem solving , toolkit , tools

Related Articles

Dpmo: defects per million opportunities explained, using the probability plot | probability distribution tool, the analysis of variance (anova) explained, what is a priortisation matrix, a comprehensive guide to integrating hoshin kanri into strategic planning, lean six sigma online courses.

FREE COURSE | YELLOW BELT | GREEN BELT | BLACK BELT | MASTERCLASS | WORKSHOPS

Lean Accelerator Progam

A Lean Six Sigma Green Belt Masterclass

LSS Green Belt

The ultimate fast-track for future leadership

LSS Black Belt

Become an expert in change management and complex problem-solving.

Subscribe to Newsletter

Keep up to date to the latest insights, courses, training, webinars and more. Join our newsletter today.

Lean Accelerator Program

Discover the power of problem-solving, 15 min per day | 3-months | only €999 | learn from experts.

Continuous Improvement Toolkit

Effective Tools for Business and Life!

A3 Thinking: A Structured Approach to Problem Solving

- 5 MINUTES READ

Also known as A3 Problem Solving.

Variants include 8D and CAPA.

A significant part of a leader’s role involves addressing problems as they arise. Various approaches and tools are available to facilitate problem-solving which is the driving force behind continuous improvement. These methods range from the advanced and more complex methodologies like Six Sigma to the simpler and more straightforward A3 thinking approach.

The power of the A3 approach lies in its systematic and structured approach to problem-solving. Although it appears to be a step-by-step process, A3 is built around the PDCA philosophy. It relies on the principle that it is much better to address the real root-cause rather than trying to find a solution. Hence, it’s important not to jump to the solution when solving a problem as it is likely to be less effective.

A3 thinking provides an effective way to bring together many of the problem-solving tools into one place. For example, techniques such as the 5 Whys and fishbone analysis can be used during the ‘Analysis’ stage to help identifying the root causes. Additionally, visual aids and graphs are highly recommended in the A3 report, as they are more effective than text in communicating ideas and providing concise project updates.

A3 thinking involves the practice of consolidating the problem, analysis, countermeasures, and action plan onto a single sheet of paper, commonly an A3-sized sheet. This brief document serves as a summary of the project at hand and is regarded as a valuable storytelling tool for project communication. Utilizing the A3 approach doesn’t require any specialized software or advanced computer skills. You may however use readily available A3 templates , or rely on basic tools such as paper, pencil and an eraser as you will need to erase and rewrite several times.

One of the characteristics of the A3 approach is that it does not get into specific details. Detailed documents are usually attached to the A3 report to prevent overwhelming the reader with an excess of information.

The A3 process is typically structured in multiple stages based on the PDCA model. The primary focus is on developing understanding of the current situation and defining the desired outcome before thinking about the solution. While the exact number of stages may vary depending on the preference of the company, what truly matters is adhering to a structured approach to problem-solving.

A3 Seven Stages Model

An A3 process is often managed by an individual who should own and maintain the A3 report. This individual takes the lead in steering the process, facilitating team involvement, and preparing the A3 report with team input. One of the most common models for A3 thinking is the seven stages model which is described in the following.

1. Background – The first step is to identify the business reason for choosing this problem or opportunity. In this stage, you need to identify the gap in performance and the extent of the problem.

2. Current situation – The purpose of this stage is to document the current state of the problem. You may need to refer to the process map or go to the Gemba to truly understand the current situation.

3. Target – The purpose of this stage is to define the desired future state. Clearly identify the expected benefits from solving the problem, the scope, and the key metrics that will help measure the success of the project.

4. Analysis – The objective of this stage is to conduct an in-depth analysis of the problem and understand why it’s happening. It might involve tools like the 5 Whys and cause-and-effect analysis, as well as advanced statistical methods.

5. Countermeasures – Countermeasures are the actions to be taken to eliminate root causes or reduce their effects. The team should brainstorm and evaluate possible countermeasures based on the analysis conducted earlier.

6. Implementation Plan – To achieve the target, develop a workable plan to implement the countermeasures. Gantt charts are great ways to manage implementation plans very simply and easily. Once the action plan is finalized, the team should begin working on the activities needed to implement the countermeasures.

7. Follow-up – The final stage involves evaluating the implementation of the plan and the results achieved. Follow-up actions are important to ensure the benefits extend beyond the project’s completion.

A3 thinking is considered to be the practical form of the PDCA model.

There are many online templates that can be used to manage your problem-solving efforts. One of the simplest and most straightforward ways is to use this A3 problem solving template .

Wrapping Up

A3 thinking represents a logical and structured approach for problem solving and continuous improvement. This approach can be used for most kinds of problems and in any part of the business. Originating from the Toyota Production System (TPS), it has been adopted by many Lean organizations around the world.

A3 thinking not only provides a systematic approach for problem-solving. The development of a continuous improvement culture is at the core of A3 thinking. It has become one of the most popular Lean tools today where people and teams work together to solve problems, share results and learn from each other.

Other Formats

Do you want to use the slides in your training courses?

A3 Thinking Training Material – $18.85

Related Articles

Project Charter

Gantt Chart

Related Templates

A3 Problem Solving

Written by:

CIToolkit Content Team

- MY LCI Login

- LCI Design & LCI Engineering Design Award

- Our Mission & Vision

- Our Strengths

- History of LCI

- How We Serve

- Board of Directors

- LCI Congress 2024

- Lean in Design Forum 2024

- Respect For People

- Communities

- New to Lean

- Learn by Pathway

- For Designers

- For Constructors

- Field Crew Huddle

- Assessments

- Classroom Learning

- Instructor Program

- LCI Publications

- Learning Videos

- Partner Programs

- Simulations

- Certification FAQs

- Certification Practice Quiz

- Designation Directory

- Lean Construction

- Lean Design

- Lean Project Delivery

- What is Lean?

- Founder’s White Papers

- Lean Construction Journal

- LCI Research

- Newsletter Archives

- Past Event Presentations

- Blog & Buzz

- Lean Consultant Members

- Member Directory

A3: Thinking, Reports, Examples & Templates

A3 thinking.

An Introduction to A3

In the design and construction industry – as in all industries – complex problems arise daily. Each project contains hundreds of decisions containing thousands of variables, and sorting them out to arrive at the best outcome is critical.

A3 problem solving provides teams with a strategy to effectively and efficiently deal with problems that they encounter and decisions that need to be reached. In true Lean fashion, A3 process improvement brings the entire team into the collaborative problem-solving process and allows teams to embrace out-of-the-box solutions.

What is A3?

An A3 is a one-page report prepared on a single 11 x 17 sheet of paper that adheres to the discipline of PDCA thinking as applied to collaborative problem solving, strategy development or reporting. The A3 includes the background, problem statement, analysis, proposed actions, and the expected results.

The History

A3 thinking was developed by Toyota in the 1940s. Toyota believed that any problem should be capable of being explained and solved using one sheet of paper (an 11 x 17 sheet being the largest sized paper that is capable of being faxed and closest in size to the traditional A3).

The company also believed that if a problem is too complex to fit onto an A3 report, it should be broken down into smaller bits that would be solved individually. If your problem cannot fit onto an A3, you should reconsider the scope of what you are hoping to accomplish.

Who Uses A3 Strategies?

Today, A3 strategies are deployed across various industries that employ Lean thinking such as:

- Design & Construction

- Manufacturing

- Project Management

- Engineering & Architecture

- Service Industries

LCI’s Meaning of A3

A3 thinking is an extremely useful tool when utilized correctly. By distilling the entirety of a problem on a single sheet of paper, A3 Lean thinking forces team members to collaborate and rationalize through the problem solving process. A3 thinking makes for more effective problem solving and produces written explanations that can then be passed on to senior management. An effectively completed A3 report will also build management’s confidence in the team and its ability to solve problems.

A3 Reporting

A well-written A3 report should show and explain the consideration that went into the counter-measure to the problem listed. Properly executed plans include the input of team members from all across the stakeholder spectrum and should allow members to emerge as leaders in its problem solving. A3 papers can also be referenced later, allowing the lessons learned during the process to be shared with future project teams.

Understanding A3 Thinking

A3 thinking does not provide a solution to the problem your team is facing. Rather, it guides your team’s process to help it reach the best possible countermeasure with the tools it has at its disposal.

An A3 report is to be filled out by one person on the team – the “champion” – who will gather assessments and intel from other members in a collaborative fashion. Bringing all of the knowledge and expertise of the team to bear when solving a problem is the best way to come to a satisfying outcome.

Problem Solving: An A3 Process

A3 thinking allows for many different types of decision-making. But ultimately, all decisions are fundamentally a form of problem solving. For example, A3 thinking can be deployed to guide the team in optimizing decisions during the design phase, or for solving a constructability challenge.

The First Step to A3 Thinking

The first step of the A3 process for problem solving is to correctly identify the problem. From unexpected lead times on materials to communication breakdowns among design teams, “problems” are in no short supply in the design and construction industry. Before engaging in A3, ask yourself the following questions about the problem you are working to solve.

Questions to Facilitate the Process

- What are you trying to address or solve?

- What is the current situation?

- What are clear Conditions of Satisfaction (CoS) I can develop?

- Where can I brainstorm and analyze the 5 whys/root cause ideas?

- What’s a recommendation I can put forth?

- What is my plan to implement the recommendation above (if applicable)?

State plan to check and adjust using the PDCA cycle.

More on the PDCA Cycle

PDCA stands for Plan, Do, Check, Adjust. Explore each element of this acronym for more information about how it supports both the problem solving questions above as well as A3 problem solving as a whole.

Identify an issue in your process and exercise continuous improvement by planning your course of change.

Perform your case study by applying the corrective actions outlined in the “plan” stage in an experimental manner.

Follow the performance of your experiment and measure it to determine whether it is having the desired effect.

If your plan worked, implement the change to the necessary areas of your process. If it did not, determine what you will do differently next time and repeat the cycle.

A3 Reports for Solutions

While A3 reports broadly follow the PDCA cycle, the actual journey of an A3 process is a bit more granular. Let’s analyze the various steps and sections of an A3 report.

Describe the problem, theme, or issue. List out all of the details including the champion’s name, date, and the names of all of the collaborators who will be helping with the report.

Establish the business context & importance. Provide additional information on the problem being addressed.

Current State

Describe what is currently known about the problem. Note potential variables and roadblocks that may stop your team from solving this problem and additional information you hope you acquire.

Future State or Goal

Identify the desired outcome for your experiment. Identify the Conditions of Satisfaction (CoS) for the project.

Analyze the situation and underlying cause.

Recommendation

Provide a recommendation for process improvement that your team can implement for the future.

Create a follow-up/review process.

A3 Examples

A3 thinking is frequently applied in Lean design and Lean construction during all phases of the process for the purposes of making sound decisions. In the example below, A3 thinking is applied to the process of learning Lean design and construction techniques.

A3 Template

The Lean Construction Institute seeks to educate companies all throughout the design and construction industry on Lean practices and methods. Here is our A3 template which you can use to guide your decision-making processes.

A3 Training

The Lean Construction Institute offers A3 training as well as tools , events , education , and networking opportunities for Lean practitioners in design and construction all around the world. Whether you’re a Lean expert or are just learning about Lean for the first time, LCI can provide the tools you need for problem solving and continuous improvement in your business.

Lean Assessments

How strong is your Lean knowledge? Take a Lean assessment to determine your current state so you have a baseline for improvement. Lean assessments are available for individuals, teams, and organizations alike. Whether you’re new to Lean or are an experienced Lean practitioner, Lean assessments are a great way to get started at LCI!

William R. (Bill) Seed, Executive Editor

Executive Editors: Kristin Hill, Katherine Copeland and Christian Pikel

More lean topics.

From 5s to IPD, explore more popular Lean design and construction topics below.

The Lean Post / Articles / How to A3: Resources for Developing Structured Problem-Solving and Leadership Skills

Problem Solving

How to A3: Resources for Developing Structured Problem-Solving and Leadership Skills

June 18, 2020

As LEI prepares its next course on Managing to Learn, here's a popular article rounding up a wealth of resources about practicing A3 Thinking by Tom Ehrenfeld

A3 reports have become one of the most popular lean tools today, a way for people and teams to work together to solve problems; and their widespread adoption could easily be viewed in lean terms as…a problem.

Tools often provide traction for getting started with lean practice, and A3s often deliver immediate results. The A3 ‘problem’ (a gap, in this case, between the intended purpose and actual usage) echoes the broader challenge facing widespread adoption of any proven TPS methodology: moving from lean tools to lean management , according to Jim Womack. As he notes, “Tools—for process analysis and for management—are wonderful things. And they are absolutely necessary. And managers love them because they seem to provide shortcuts to doing a better job. But they can’t achieve their potential results, and often can’t achieve any results, without managers with a lean state of mind to wield them.”

Let’s keep in mind the purpose of A3s, from the Introduction to John Shook’s key book on the topic, Managing to Learn ( MtL ).

“Writing an A3 is the first step toward learning to use the A3 process, toward learning to learn. Some benefits in improved problem-solving, decision-making, and communications ability can be expected when individual A3 authors adopt this approach.”

All well and good. Unfortunately most organizations stop there, and don’t proceed to the next step. As Shook cautions, “unless the broader organization embraces the broader process, the much greater benefit will be unrealized. The entire effort may degenerate into a ‘check-the-box’ exercise, as A3s will join unused SPC charts, ignored standardized work forms, and disregarded value -stream maps as corporate wallpaper.”

So what exactly are A3 reports? A3 reports are a way of structuring and sharing knowledge that enables teams and their members to practice scientific thinking as a way of discovering and learning together. The tool promises immediate benefits by helping people structure and design more effective approaches to problems (framing them in solvable ways, taking a data-based approach, using root-cause-analysis to find the point of origin for problems (gaps), encouraging careful problem analysis over quick abstract “solutions,” and so forth).

Definitions include:

- A storyboard

- 5S for information

- Standardized story-telling

- A “visual manifestation of a problem-solving thought process involving continual dialogue between the owner of an issue and others in an organization.”

They are all that, and more. Essentially, A3 reports, named for the international-sized A3 paper (a larger page of roughly 11 by 17 inches), enable people in organizations to capture issues through a commonly understood template, permitting people to see problems through the same lens. The sequence is designed along the logic of scientific thinking—the PDCA cycle at the heart of lean thinking. You can download A3 templates from LEI here .

The basic thinking process captured by this format is relatively simple, and has been around in many other forms and formats for a long time. There are different types of A3s , according to the situation. But don’t work too hard to find the precisely right format; in fact, veterans such as David Verble stress the importance of starting your A3 not by writing but by thinking .

“The most fundamental use of the A3 is as a simple problem-solving tool. But the underlying principles and practices can be applied in any organizational setting. Given that the first use of the A3 as a tool is to standardize a methodology to understand and respond to problems, A3s encourage root cause analysis, reveal processes, and represent goals and actions in a format that triggers conversation and learning,” says John Shook in this piece sharing his purpose for writing MtL .

There’s no doubt that those with deep experience have found great power in A3 practice. For example, lean veteran Gary Convis says that he, “used the A3 format as a way of seeing inside the minds of the 113 plant managers,” citing his experience at Dana Holdings Corp , as well as elaborating on using A3 problem solving to make the thinking process visible .

Toyota veteran Tracey Richardson shares a hugely practical step-by-step tour of the A3 thinking process in her great article Create a Real A3, Do More than Fill In Boxes . In so doing she explains how an A3 is “a way of thinking with deeper benefits, a process based on the PDCA (plan, do, check, adjust) cycle designed to “share wisdom” with the rest of the organization.” Another terrific A3 “stroll” is provided in this recent piece by Jon Miller .

Tracey complements her brief user’s guide with a piece that suggests you Test Your PDCA Thinking By Reading Your A3 Backwards as a way of avoiding a common A3 hazard—jumping to conclusions.

When given a problem to solve, most individuals rush to provide the bestest solution the fastest. Yet the nature of A3 thinking requires careful framing of the problem, rigorous analysis of a clearly defined (and improvable “gap”), patient observation at the source, and real dialogue with the people touching the problem.

The A3 form exists to capture and document this material; it is not a formal document in and of itself. “If you’re ‘doing’ or ‘filling out’ an A3 behind your desk, I can say most of the time you will not be able to answer the questions above [listing the cause and effect logic of an A3],” says Tracey.

It’s worth noting that while there are different types of A3 reports, it’s useful to recognize that “not every situation requires an A3,” according to Norbert Majerus of Goodyear. In To A3 or Not to A3 , he proposes a situational application that avoids a one-size-fits-all tool mindset. Specifically, he explains how the cynefin framework developed by Dave Snowden and Mary Boone can help navigate the different situations in one might apply A3 thinking.

Some argue that good problem-solving is not about having the right answers; it’s about practicing a useful, and commonly understood approach to thinking about thinking (learning). “Never lose sight of the thinking process that enables you to complete an A3—which then serves as a way of capturing, communicating, and building on what was learned,” says Tracey in A3: Tool or Process? Both…

In deepening this thinking-process through “A3 Mind,” you and your teammates can learn to activate what Daniel Kahneman calls both “fast” and “slow” thinking, says Michael Balle. “The key is to look at A3s as a physical support for managerial relationships based on expertise and teaching,” as a way to sustain A3 thinking in your organization , he notes. Such a shared approach can bring about a core lean goal: helping a problem-solving culture take root .

Managing to Learn

An Introduction to A3 Leadership and Problem-Solving.

Leave a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Revolutionizing Logistics: DHL eCommerce’s Journey Applying Lean Thinking to Automation

Podcast by Matthew Savas

Transforming Corporate Culture: Bestbath’s Approach to Scaling Problem-Solving Capability

Teaching Lean Thinking to Kids: A Conversation with Alan Goodman

Podcast by Alan Goodman and Matthew Savas

Related books

A3 Getting Started Guide

by Lean Enterprise Institute

The Power of Process – A Story of Innovative Lean Process Development

by Eric Ethington and Matt Zayko

Related events

June 10, 2024 | Coach-Led Online Course

June 12, 2024 | Morgantown, PA

Building a Lean Operating and Management System

Explore topics.

Subscribe to get the very best of lean thinking delivered right to your inbox

Privacy overview.

A3 Problem Solving

– The A3 Report –

⇓ Introduction to A3

⇓ What is A3

⇓ Why Implement A3

⇓ How to Implement A3

⇓ A3 Services

Introduction to A3 Problem Solving

In order for any business to be successful, they must strive to improve quality and efficiency as well as build a problem solving continuous improvement culture. The A3 Report is a very useful problem solving and continuous improvement tool. It was first used by Toyota and is quickly gaining popularity in industry today. Companies must start to view problems as opportunities for improvement. The A3 Report format allows the entire problem identification, clarification, analysis and resolution steps to be documented on one single sheet of paper.

What is A3 Problem Solving

The name “A3” is actually derived from a standard European paper size similar to 11” by 17”. The A3 Report is based upon the Plan, Do, Check, Act (PDCA) Method. The PDCA process is sometimes referred to as the Deming Wheel or Deming Circle. The A3 Report incorporates this basic premise to problem solving and continuous improvement.

Why Implement A3 Problem Solving

Some problem solving tools involve numerous pages of information, multiple charts and graphs and lengthy reports. The A3 Report format can be used to more effectively communicate all of the pertinent information with greater visual impact. While the A3 Report is an effective communication tool, it is actually much more valuable as a problem solving and critical thinking tool that can be used to drive continuous improvement. The A3 Report fosters a problem solving / continuous improvement mindset within the participating team members. It is an excellent tool for managers and supervisors to share problem solving techniques with their teams. With resources being limited, completion of a formal A3 Report may not be applicable to every problem. Its use should be determined based upon the size of the problem and its impact on the business or organization. The A3 Report and the A3 way of thinking are valuable tools for Lean initiatives and for integrating a problem solving culture throughout the organization.

How to Implement A3 Problem Solving

The A3 Report usually consists of multiple steps following a PDCA structure of Plan, Do, Check, Act. The number of steps can vary due to the different formats being used for the A3 Report. The exact number of steps used is not as important as the end result. The A3 Report can utilize various forms depending upon the organizations needs and preferences. The following paragraphs provide information regarding the basic steps and some tools used to complete the A3. One thing that all of the forms seem to have in common is that they follow the PDCA problem solving process. The basic steps and where they fall into the PDCA structure are listed below:

- Define the Problem:

The first step is to define the problem or identify the need for improvement:

- Define the ideal state, the operational standard or the desired condition

- Describe the current situation or status

- How is the current status different from the desired state or operational standard?

- What value will be realized by completion of the A3 exercise?

- Containment:

In some A3 formats, a section is included for immediate countermeasures or containment actions. The purpose of containment is to prevent further problems from occurring or prevent the current problem from causing negative effects to other processes, products or departments.

- Breakdown the Problem:

Next, the team should breakdown or further define the problem. Ask any relevant 5W (What, When, Where, Who, Why) and 2H (How, How many / How often) questions. There also may be more than one issue contributing to the problem or more detail required to properly address the problem. Prioritize the issues and identify the point of occurrence or escape point.