How to Create Recycling Business Plan Efficiently in 2024

- Last Updated: February 21, 2024

- A well-crafted recycling business plan is crucial for financing, attracting investors, and driving the company’s growth and success.

- Analyzing the market is essential to identifying key opportunities, differentiating from competitors, and establishing a sustainable customer base.

- Developing a clear sales and marketing strategy with defined target markets help you build building brand awareness.

Starting a recycling business without a sound plan is like a sitting duck waiting to be shot. But thankfully, you are here so that you can get a guiding light for your new venture.

There is no doubt that the recycling services industry is on an upswing as it was valued at $57.69 billion in 2021 and is expected to touch the $90 billion mark by 2028 .

So first, let us show you what a recycling business plan is and how it will help you before moving on to its components.

Table of Content

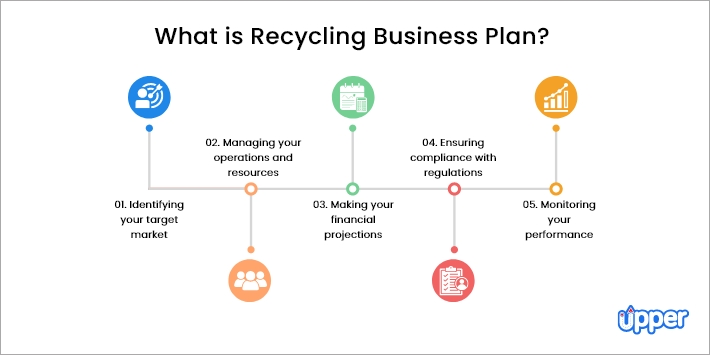

- What is Recycling Business Plan?

How to Develop a Recycling Business Plan?

What is recycling business plan .

Recycling business plan is a comprehensive document that outlines the goals, objectives, strategies, and financial projections of your business. In simple words, think of it as your pole star that will show you a way out of the dark.

Having such a well-developed plan can serve as a roadmap to guide your company’s operations and ensure better efficiency.

Why is it important to construct for your recycling business?

Whether you are starting a new business or already associated with the recycling industry, developing a robust business plan is essential for achieving organizational goals. Below is why you must construct one for your business.

1. Identifying your target market

Firstly, it enables you to identify and analyze your target market to help you understand the needs of your potential customers so that you can precisely serve what they want.

This precision will give you a competitive edge over your competitors who are scattering their efforts all over the place.

2. Managing your operations and resources

A business plan provides you with clarity about your operations, like how the daily waste collection process should take place and what tasks will be carried out by your team in a timely manner.

This will ensure that everything is properly aligned along with the right set of instructions for doing them. As a result, your recycling business can run smoothly.

3. Making your financial projections

A recycling business plan includes financial projections for at least the first year of operation. This projection gives you an idea about the funding you need for your business to take off. In short, it assists you to develop your financial plan as well.

Once you have projections ready, it also provides you with a roadmap for achieving your revenue and profitability goals. In other words, you can say, it gets your numbers right.

4. Ensuring compliance with regulations

As a business owner, you cannot provide your services legally without complying with the rules set by the jurisdiction in your area.

This is where it is crucial to develop a business plan that gives you an overview of the regulations and requirements for operating a recycling business in your service area.

Doing it right before starting your recycling business ensures that you have complied with all applicable regulations. This means you can avoid hefty fines as well as mitigate potential risks.

5. Monitoring your performance

A recycling business plan gives you detailed insights by serving as a baseline for monitoring your performance and progress. This allows you to come up with your strategies and operations accordingly and make informed decisions to optimize your recycling process.

Creating a plan is one of the initial steps when it comes to starting a new recycling business. But, how will you develop it efficiently? For that, let’s discuss its components in the next section..

Business owners should include 10 main components while developing a business plan. Let us talk about them one by one.

1. Industry overview

This section gives you a gist of the recycling industry and the market trends that are driving its growth. It typically includes information such as:

Size and growth of the industry

This section should provide an overview of the recycling industry’s size and growth trends. You can include statistics on the amount of waste generated, the percentage of waste that is currently being recycled, and projections for future growth.

Key market segments

Target market segments mean the sections of the whole industry which you are eying to target. For example – commercial or residential waste. Identify your target market segments and provide information on the size of each segment and its growth potential.

Competitive landscape

Analyze the major players (aka competitors) in your region, including their market share, strengths, and weaknesses. Also, identify any new entrants or potential competitors that may affect your business.

The legal and regulatory environment

Provide an overview of the legal and regulatory environment in which your business will operate. This gives you an idea of any permits or licenses required to operate a recycling business.

2. Executive summary

An executive summary is like a quick overview of your overall business plan. Here are some key elements to include:

- Services: Give an overview of the services that your recycling business will offer and the types of waste you will recycle.

- Target market: Describe the target market for your recycling business, including demographics, geography, and the size of the market.

- Financial projections: Summarize your financial projections for the first few years of operation, including revenue, expenses, and profit margins.

3. Mission statement

The mission statement is all about your company’s primary focus and what it aims to achieve. A well-crafted mission statement can serve as a guiding principle for all the decisions made at your business.

Thus, it should communicate the essence of the company’s business, values, and culture, including recycling problems and solutions . However, when creating a mission statement, it is important that you keep it clear and concise.

4. Services and pricing

Following a statement, you can describe the recycling services that you want to provide and how much you will charge for each of them. Hence, it should include a breakdown of the costs associated with any of your services as well as any pricing plans you offer.

For example , you could charge a flat fee for a specific service such as curbside recycling pickup. Or, wherever possible, you can charge variably based on the volume of materials being recycled.

5. Operational plan

It outlines the day-to-day activities that are essential to run your business. It gives details on:

- How your business will function?

- How it will meet its goals and objectives?

- What processes and precautions will everyone need to follow?

This will ensure that your daily efforts produce the maximum output toward your desired goals. As an additional benefit, it also saves recycling companies from inconsistencies that happen when a reliable plan is not set.

When deciding your operational plan, it is wise to add software to your process that will relieve you of much of your daily burden. One such recycling waste collection route planning software is Upper, which helps you plan routes for your waste collection team so that they can reach their destinations in a minimum time.

Get Optimized Routes for Waste Collection

Now, finding an optimized routes for waste pickups is a matter of seconds. That’s right, you can easily get them using the Upper Route Planner in less than a minute.

6. Job roles and responsibilities

This outlines the key positions within your business and the responsibilities associated with each of them. One of its purposes is to provide a clear understanding of the organizational structure of your company.

Here are some examples of job roles and responsibilities that can be included in a recycling business plan:

- Chief Executive Officer (CEO): The CEO is responsible for providing direction for the company while overseeing all aspects of its operations and ensuring that it achieves its objectives.

- Operations Manager: The Operations Manager is responsible for overseeing the day-to-day operations, managing staff, coordinating with customers, and ensuring that all equipment and facilities are properly maintained.

- Sales and Marketing Manager: A person who can develop marketing strategies to promote the services, identify new business opportunities, and build relationships with key customers.

- Customer Service Representative: The person should be responsible for providing customers with information about the company’s services, answering questions, and resolving any issues or concerns that arise.

- Recycling Technician: The Recycling Technician is responsible for sorting, processing, and preparing recyclable materials using recycling technologies for reuse.

7. Target market research

The process gives an in-depth analysis of the industry, competition, and potential customers. Thus, it is important to conduct thorough research using reliable sources and data. Let’s have a look at each of its components:

- Industry analysis: It provides an overview of the recycling industry, including its size, growth, and recycling trends as well.

- Competitor analysis: Here you identify your competition and their strengths or weaknesses. You can figure out information on their products, pricing strategies, marketing approaches, and market share.

- Customer analysis: Its purpose is to show you the buying behavior, pain points, and preferences of your target audience.

Pro tip: The better you know your audience, the more effective will be your market research. So, find out the demographics, psychographics, and needs and preference of your target audience in detail.

8. Sales and marketing strategy

A strategy outlines the specific tactics and approaches that you will use to promote your services, generate leads, and convert those leads into paid customers. Here are some of its key elements:

- Promotion channels: Here you identify specific channels for promoting your services and how you will use them. It includes digital marketing, social media, print media, events, and word-of-mouth marketing.

- Lead generation : This section describes the methods you will use to generate leads such as cold calling, email marketing, SEO, and PPC advertising.

- Sales/Conversion approach: It tells you how you will close more sales and generate more revenue. If you have any unique selling proposition (USP) that makes you stand apart, you can describe it in this part.

9. Financial projections

It is crucial step as it provides an overview of the expected financial performance of the company in the short term and long term. This also serves as a goal to achieve for your entire team so that you keep on growing financially every year.

Here is an example to give you a better idea of a financial projection:

- Revenue: $500,000

- Cost of services provided: $250,000

- Gross profit: $250,000

- Operating expenses: $100,000

- Net income: $150,000

10. SWOT analysis

SWOT stands for Strengths, Weaknesses, Opportunities, and Threats. It is a strategic planning tool that helps you identify and analyze internal and external factors that can affect the operations and profitability of your business.

Here’s a breakdown of each component of the SWOT analysis:

- Strengths: These are internal factors that give you an advantage over other recycling businesses. It includes your business’s core competencies, unique selling points, financial stability, and other resources.

- Weaknesses: These are internal factors that put your business at a disadvantage compared to its competitors. It can be a lack of resources, inexperienced staff, poor infrastructure, etc.

- Opportunities: These are external factors such as emerging trends, changes in regulations, new markets, or partnerships that your business can capitalize on to improve its operations and profitability.

- Threats: These are external factors that can negatively impact your business’s operations and profitability. It can be market competition, economic downturns, changing regulations, natural disasters, etc.

By conducting a SWOT analysis, you will have a better understanding of what to capitalize on (strengths and opportunities) as well as figure out weaknesses and potential threats.

To identify your target market, you need to consider factors such as location, demographic, and behavior. Determine the type of recyclables products that are in demand and the consumers who are likely to use recycling services.

The startup costs for a recycling business can range from $10,000 to $20,000, depending on the size and type of operation.

One should establish a strong marketing strategy that promotes your services and highlights the benefits of recycling in order to attract more clients. Additionally, you can use social media platforms, local advertising, and community outreach to raise awareness of your business.

The success of a recycling business can be measured through various metrics such as revenue growth, customer retention rate, and the volume of recyclables collected and processed.

All in all, a recycling business plan is a crucial roadmap that outlines your company’s mission, services, target market, sales and marketing strategy, financial projections, and operational plan.

A well-crafted plan can help you secure financing, attract clients and guide your business toward sustainable growth and profitability. So, go through these all components before you start your recycling business because it is worth all the effort. In case you want to streamline your waste collection process, it is recommended to use software like Upper. You can explore its features by taking a 7 days FREE TRIAL .

Rakesh Patel, author of two defining books on reverse geotagging, is a trusted authority in routing and logistics. His innovative solutions at Upper Route Planner have simplified logistics for businesses across the board. A thought leader in the field, Rakesh's insights are shaping the future of modern-day logistics, making him your go-to expert for all things route optimization. Read more.

Sign Up Now!

Get weekly updates from Upper Route Planner.

Related Posts

Maximize Your Recycling Business Profit Margin with 7 Recyclable Materials

750+ Catchy Recycling Business Names: Know the Best Practices in Naming Your New Business

Latest Recycling Trends in 2024 That You Must Be Aware of

Recycling Reality Check: Addressing the Recycling Problems & How to Fix Them

How to Start a Recycling Business? – 11 Steps to Get the Desired Start

11 Advanced Recycling Technologies to Efficiently Recycle Global Waste

Sign Up with Upper Route Planner and automate your daily business process route planning, scheduling, and optimizing!

https://www.google.com/

https://www.upperinc.com/blog/recycling-business-plan/

www.google.com

Grab a FREE Trial of Upper

- Plan routes with hundreds of stops in a minute

- Schedule routes months in advance

- Collect reliable proof of delivery

- Track drivers live for real-time updates

- Experience unparalleled customer support

Grab a FREE Trial of Upper TODAY!

- Schedule routes in advance for weeks

- Collect proof of delivery to maintain accountability

- Experience 24/7 customer support

- Smart reporting to get real-time insights

Start A Wood Recycling Business - Business Ideas

Please note that the data provided in this article are estimates and may vary depending on various factors, and should not be considered as perfect or definitive.

Starting a wood recycling business requires a great deal of effort, dedication, and most importantly passion .

If you're interested in how to sell wood recycled products, or selling wood recycled products online, you can use this page as a guide for everything you'll need to know.

Startup Costs

Successful businesses, pros & cons.

Join our free weekly newsletter and get them right now.

- 4,818 founder case studies

- Access to our founder directory

- Live events, courses and recordings

- 8,628 business ideas

- $1M in software savings

Join our free newsletter to get unlimited access to all startup data. We just need your email:

Check your email

If there's a Starter Story account associated with that email you'll get an email with a link to automatically log in. The link will expire in 15 minutes.

Your existing password still works, should you want to log in with it later.

With Starter Story, you can see exactly how online businesses get to millions in revenue.

Dive into our database of 4,418 case studies & join our community of thousands of successful founders.

Join our free newsletter to get access now. We just need your email:

How to Start a Recycling Business

Importantly, a critical step in starting a recycling business is to complete your business plan. To help you out, you should download Growthink’s Ultimate Business Plan Template here .

Download our Ultimate Business Plan Template here

14 Steps To Start a Recycling Business :

- Choose the Name for Your Recycling Business

- Develop Your Recycling Business Plan

- Choose the Legal Structure for Your Recycling Business

- Secure Startup Funding for Your Recycling Business (If Needed)

- Secure a Location for Your Business

- Register Your Recycling Business with the IRS

- Open a Business Bank Account

- Get a Business Credit Card

- Get the Required Business Licenses and Permits

- Get Business Insurance for Your Recycling Business

- Buy or Lease the Right Recycling Business Equipment

- Develop Your Recycling Business Marketing Materials

- Purchase and Setup the Software Needed to Run Your Recycling Business

- Open for Business

1. Choose the Name for Your Recycling Business

The first step to starting a recycling business is to choose your business’ name. This is a very important choice since your company name is your brand and will last for the lifetime of your business. Ideally you choose a name that is meaningful and memorable. Here are some tips for choosing a name for your recycling business:

- Make sure the name is available . Check your desired name against trademark databases and your state’s list of registered business names to see if it’s available. Also check to see if a suitable domain name is available.

- Keep it simple . The best names are usually ones that are easy to remember, pronounce and spell.

- Think about marketing . Come up with a name that reflects the desired brand and/or focus of your recycling business.

2. Develop Your Recycling Business Plan

One of the most important steps in starting a recycling business is to develop your business plan. The process of creating your plan ensures that you fully understand your market and your business strategy. The plan also provides you with a roadmap to follow and if needed, to present to funding sources to raise capital for your business. Your business plan should include the following sections:

- Executive Summary – this section should summarize your entire business plan so readers can quickly understand the key details of your recycling business.

- Company Overview – this section tells the reader about the history of your recycling business and what type of recycling business you operate. For example, are you a recycling collection center, plastic, metal, glass, or a paper recycling business?

- Industry Analysis – here you will document key information about the recycling industry. Conduct market research and document how big the industry is and what trends are affecting it.

- Customer Analysis – in this section, you will document who your ideal or target customers are and their demographics. For example, how old are they? Where do they live? What do they find important when purchasing products or services like the ones you will offer?

- Competitive Analysis – here you will document the key direct and indirect competitors you will face and how you will build competitive advantage.

- Marketing Plan – your marketing plan should address the 4Ps: Product, Price, Promotions and Place.

- Product : Determine and document what products/services you will offer

- Prices : Document the prices of your products/services

- Place : Where will your business be located and how will that location help you increase sales?

- Promotions : What promotional methods will you use to attract customers to your recycling business? For example, you might decide to use pay-per-click advertising, public relations, search engine optimization and/or social media marketing.

- Operations Plan – here you will determine the key processes you will need to run your day-to-day operations. You will also determine your staffing needs. Finally, in this section of your plan, you will create a projected growth timeline showing the milestones you hope to achieve in the coming years.

- Management Team – this section details the background of your company’s management team.

- Financial Plan – finally, the financial plan answers questions including the following:

- What startup costs will you incur?

- How will your recycling business make money?

- What are your projected sales and expenses for the next five years?

- Do you need to raise funding to launch your business?

Finish Your Business Plan Today!

3. choose the legal structure for your recycling business.

Next you need to choose a legal business structure for your recycling business and register it and your business name with the Secretary of State in each state where you operate your business. Below are the five most common legal structures:

1) Sole proprietorship

A sole proprietorship is a business entity in which the business owner and the business are the same legal person. The owner of a sole proprietorship is responsible for all debts and obligations of the business. There are no formalities required to establish a sole proprietorship, and it is easy to set up and operate. The main advantage of a sole proprietorship is that it is simple and inexpensive to establish. The main disadvantage is that the owner is liable for all debts and obligations of the business.

2) Partnerships

A partnership is a legal structure that is popular among small businesses. It is an agreement between two or more people who want to start a recycling business together. The partners share in the profits and losses of the business. The advantages of a partnership are that it is easy to set up, and the partners share in the profits and losses of the business. The disadvantages of a partnership are that the partners are jointly liable for the debts of the business, and disagreements between partners can be difficult to resolve.

3) Limited Liability Company (LLC)

A limited liability company, or LLC, is a type of business entity that provides limited liability to its owners. This means that the owners of an LLC are not personally responsible for the debts and liabilities of the business. The advantages of an LLC for a recycling business include flexibility in management, pass-through taxation (avoids double taxation as explained below), and limited personal liability. The disadvantages of an LLC include lack of availability in some states and self-employment taxes.

4) C Corporation

A C Corporation is a business entity that is separate from its owners. It has its own tax ID and can have shareholders. The main advantage of a C Corporation for a recycling business is that it offers limited liability to its owners. This means that the owners are not personally responsible for the debts and liabilities of the business. The disadvantage is that C Corporations are subject to double taxation. This means that the corporation pays taxes on its profits, and the shareholders also pay taxes on their dividends.

5) S Corporation

An S Corporation is a type of corporation that provides its owners with limited liability protection and allows them to pass their business income through to their personal income tax returns, thus avoiding double taxation. There are several limitations on S Corporations including the number of shareholders they can have among others. Once you register your recycling business, your state will send you your official “Articles of Incorporation.” You will need this among other documentation when establishing your banking account (see below). We recommend that you consult an attorney in determining which legal structure is best suited for your company.

Incorporate Your Business at the Guaranteed Lowest Price

We are proud to have partnered with Business Rocket to help you incorporate your business at the lowest price, guaranteed.

Not only does BusinessRocket have a 4.9 out of 5 rating on TrustPilot (with over 1,000 reviews) because of their amazing quality…but they also guarantee the most affordable incorporation packages and the fastest processing time in the industry.

4. Secure Startup Funding for Your Recycling Business (If Needed)

In developing your recycling business plan, you might have determined that you need to raise funding to launch your business. If so, the main sources of funding for a recycling business to consider are personal savings, family and friends, credit card financing, bank loans, crowdfunding and angel investors. Angel investors are individuals who provide capital to early-stage businesses. Angel investors typically will invest in a recycling company that they believe has high potential for growth.

5. Secure a Location for Your Business

There are a few things to consider when looking for a location for your recycling business. First, think about the type of recycling company you want to start. Do you want to recycle paper, plastic, metal, or glass? You may have different facility requirements depending on the type of material you’ll be recycling.

Next, you’ll need to consider the size of your operation. How much space do you need for your recycling equipment and materials? Will you be able to expand your business in the future? Finally, you’ll need to think about where your customers are located. You’ll want to choose a location that is convenient and easy for them to access.

When you’ve considered all of these factors, you’ll be able to narrow down your search for a location for your recycling business. Once you’ve found a few potential locations, you can contact the property owners and ask about leasing or purchasing options.

6. Register Your Recycling Business with the IRS

Next, you need to register your business with the Internal Revenue Service (IRS) which will result in the IRS issuing you an Employer Identification Number (EIN).

Most banks will require you to have an EIN in order to open up an account. In addition, in order to hire employees, you will need an EIN since that is how the IRS tracks your payroll tax payments.

Note that if you are a sole proprietor without employees, you generally do not need to get an EIN. Rather, you would use your social security number (instead of your EIN) as your taxpayer identification number.

7. Open a Business Bank Account

It is important to establish a bank account in your recycling business’ name. This process is fairly simple and involves the following steps:

- Identify and contact the bank you want to use

- Gather and present the required documents (generally include your company’s Articles of Incorporation, driver’s license or passport, and proof of address)

- Complete the bank’s application form and provide all relevant information

- Meet with a banker to discuss your business needs and establish a relationship with them

8. Get a Business Credit Card

You should get a business credit card for your recycling business to help you separate personal and business expenses. You can either apply for a business credit card through your bank or apply for one through a credit card company.

When you’re applying for a business credit card, you’ll need to provide some information about your business. This includes the name of your business, the address of your business, and the type of business you’re running. You’ll also need to provide some information about yourself, including your name, Social Security number, and date of birth.

Once you’ve been approved for a business credit card, you’ll be able to use it to make purchases for your business. You can also use it to build your credit history which could be very important in securing loans and getting credit lines for your business in the future.

9. Get the Required Business Licenses and Permits

To start a recycling business, you will need a business license and a permit to operate a recycling center. You may also need a permit to collect recycling materials from businesses and residences. Check with your local business licensing office to determine the specific requirements for your area.

10. Get Business Insurance for Your Recycling Business

There are various types of insurance necessary to operate a recycling business. Some business insurance policies you should consider for your recycling business include:

- General liability insurance : This covers accidents and injuries that occur on your property. It also covers damages caused by your employees or products.

- Auto insurance : If a vehicle is used in your business, this type of insurance will cover if a vehicle is damaged or stolen.

- Workers’ compensation insurance : If you have employees, this type of policy works with your general liability policy to protect against workplace injuries and accidents. It also covers medical expenses and lost wages.

- Commercial property insurance : This covers damage to your property caused by fire, theft, or vandalism.

- Business interruption insurance : This covers lost income and expenses if your business is forced to close due to a covered event.

- Professional liability insurance : This protects your business against claims of professional negligence.

Find an insurance agent, tell them about your business and its needs, and they will recommend policies that fit those needs.

11. Buy or Lease the Right Recycling Business Equipment

Depending on the type of recycling business you operate, you may need a variety of equipment. For instance, you will need a recycling truck, a compactor, and a baler. You may also need a shear, shredder, and a conveyor belt. You can purchase these items new or used. Used equipment is usually cheaper but you may have to do more maintenance, which leads to greater ongoing costs. You can find all of these items at your local recycling center or online.

12. Develop Your Recycling Business Marketing Materials

Marketing materials will be required to attract and retain customers to your recycling business. The key marketing materials you will need are as follows:

- Logo : Spend some time developing a good logo for your recycling business. Your logo will be printed on company stationery, business cards, marketing materials and so forth. The right logo can increase customer trust and awareness of your brand.

- Website : Likewise, a professional recycling business website provides potential customers with information about the products and/or services you offer, your company’s history, and contact information. Importantly, remember that the look and feel of your website will affect how customers perceive you.

- Social Media Accounts : establish social media accounts in your company’s name. Accounts on Facebook, Twitter, LinkedIn and/or other social media networks will help customers and others find and interact with your recycling business.

13. Purchase and Setup the Software Needed to Run Your Recycling Business

A computer is necessary to manage your business operations. You will need word processing software to create letters and invoices, accounting software to track expenses and income, and a contact management system to keep track of customers and suppliers. There are many different options for each type of software, so be sure to research the best options for your business needs.

14. Open for Business

You are now ready to open your recycling business. If you followed the steps above, you should be in a great position to build a successful business. Below are answers to frequently asked questions that might further help you.

Additional Resources

Recycling Mavericks

How to Finish Your Ultimate Business Plan in 1 Day!

How to start a recycling business faqs, is it hard to start a recycling business.

There is no one-size-fits-all answer to this question, as the difficulty of starting a recycling business will vary depending on factors such as the location of the business, the amount of competition in the area, and the type of recycling services offered. However, with a solid business plan and good marketing strategy, it is definitely possible to start a successful recycling business.

How can I start a recycling business with no experience?

There are a few ways to start a recycling business with no experience. You can start by becoming familiar with the recycling process and learning about the different types of recycling. You may also want to network with other business owners and get advice from them. Finally, you can attend trade shows and events related to recycling to learn more about the industry.

What type of recycling business is most profitable?

There is no definitive answer to this question as it largely depends on the specifics of the recycling business. However, certain types of recycling companies may be more profitable than others. For example, a recycling business that specializes in collecting and recycling metals may be more profitable than a business that specializes in collecting and recycling plastic. Additionally, a recycling business that processes and recycles materials on-site may be more profitable than a business that requires materials to be shipped off-site for processing. Ultimately, the most profitable recycling businesses are those that are able to generate the most revenue while incurring the least amount of expenses.

How much does it cost to start a recycling business?

It typically costs around $10,000 to start a recycling business. There are a few things you'll need to get started, such as a vehicle to transport the materials, recycling bins, and advertising. You'll also need to pay for a business license and zoning permit from your local government.

What are the ongoing expenses for a recycling business?

A recycling business usually incurs ongoing expenses for transportation, labor, and supplies. The cost of transportation may vary depending on the distance involved. Labor costs will also depend on how many workers are needed and how long they work. The cost of supplies will include things like bags, gloves, and sorting equipment.

How does a recycling business make money?

A recycling business can make money in a few ways. One way is by charging customers for the service of recycling their materials. Another way is by selling the recycled materials to companies that need them. Recycling businesses can also make money by getting grants from local or state governments.

Is owning a recycling business profitable?

There are a number of reasons recycling can be a profitable business .

First, there is a rising demand for recycled materials. Companies are increasingly environmentally conscious and look for new ways to reduce their carbon footprint.

Second, recyclers can charge to collect materials and then sell recycled materials for a profit. Recyclable materials are often preferred by commercial customers because they can be more sustainable and require less energy and money to process than raw materials.

Finally, the recycling industry is becoming increasingly automated. There is less labor required to operate a recycling business. As a result, recycling businesses are becoming more cost-effective.

All of these factors together make owning a recycling business a lucrative venture. If you are looking to start a business that is both profitable and environmentally friendly, then a recycling business may be the perfect option for you.

Why do recycling businesses fail?

There can be a few reasons why most recycling businesses fail. Recycling businesses can fail if they are not able to effectively collect and process materials, or if they are unable to find buyers for their recycled products. Additionally, recycling businesses can be unsuccessful if they are not financially well-managed and operated. While there are many reasons recycling businesses can fail, there are also many ways to overcome these challenges and create a successful recycling operation.

Other Helpful Business Plan Articles & Templates

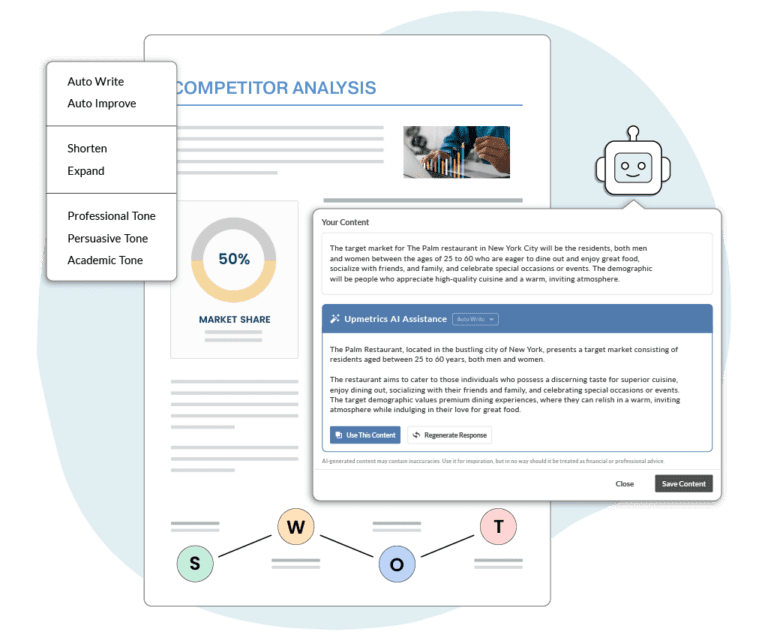

Upmetrics AI Assistant: Simplifying Business Planning through AI-Powered Insights. Learn How

Entrepreneurs & Small Business

Accelerators & Incubators

Business Consultants & Advisors

Educators & Business Schools

Students & Scholars

AI Business Plan Generator

Financial Forecasting

AI Assistance

Ai Pitch Deck Generator

Strategic Planning

See How Upmetrics Works →

- Sample Plans

- WHY UPMETRICS?

Customer Success Stories

Business Plan Course

Small Business Tools

Strategic Planning Templates

E-books, Guides & More

- Sample Business Plans

- Manufacturing & Wholesale

Recycling Business Plan

Environmental benefits, high demand, and a recurring profit model make starting a recycling business a lucrative and rewarding profession.

Anyone can start a new business, but you need a detailed business plan when it comes to raising funding, applying for loans, and scaling it like a pro.

Need help writing a business plan for your recycling business? You’re at the right place. Our recycling business plan template will help you get started.

Free Business Plan Template

Download our free business plan template now and pave the way to success. Let’s turn your vision into an actionable strategy!

- Fill in the blanks – Outline

- Financial Tables

How to Write a Recycling Business Plan?

Writing a recycling business plan is a crucial step toward the success of your business. Here are the key steps to consider when writing a business plan:

1. Executive Summary

An executive summary is the first section planned to offer an overview of the entire business plan. However, it is written after the entire business plan is ready and summarizes each section of your plan.

Here are a few key components to include in your executive summary:

Introduce your Business:

- This section may include the name of your recycling business, its location, when it was founded, the type of recycling business (E.g., paper recycling, metal recycling, glass recycling, tire recycling), etc.

Market opportunity:

Products and services:.

- For instance, you may include collection & sorting, material processing, manufactured products from recycled materials, sustainable waste management solutions, etc.

Marketing & Sales Strategies:

Financial highlights:, call to action:.

Ensure your executive summary is clear, concise, easy to understand, and jargon-free.

Say goodbye to boring templates

Build your business plan faster and easier with AI

Plans starting from $7/month

2. Business Overview

The business overview section of your business plan offers detailed information about your company. The details you add will depend on how important they are to your business. Yet, business name, location, business history, and future goals are some of the foundational elements you must consider adding to this section:

Business Description:

- Paper recycling business

- Plastic recycling business

- Metal recycling business

- E-waste recycling business

- Glass recycling business

- Tire recycling business

- Construction & demolition recycling business

- Explain where your business is located and why you selected the place.

Mission statement:

Business history:.

- Additionally, If you have received any awards or recognition for excellent work, describe them.

Future goals:

This section should provide a thorough understanding of your business, its history, and its future plans. Keep this section engaging, precise, and to the point.

3. Market Analysis

The market analysis section of your business plan should offer a thorough understanding of the industry with the target market, competitors, and growth opportunities. You should include the following components in this section.

Target market:

- For instance, government agencies, commercial & industrial businesses, residential customers, manufacturing & industrial facilities, or educational institutions would be an ideal target audience for a commercial recycling business.

Market size and growth potential:

Competitive analysis:, market trends:.

- For instance, sustainable fleets have a booming market; explain how you plan on dealing with this potential growth opportunity.

Regulatory environment:

Here are a few tips for writing the market analysis section of your recycling business plan:

- Conduct market research, industry reports, and surveys to gather data.

- Provide specific and detailed information whenever possible.

- Illustrate your points with charts and graphs.

- Write your business plan keeping your target audience in mind.

4. Product and Services

The product and services section should describe the specific services and products that will be offered to customers. To write this section should include the following:

Describe your products & services:

Mention the recycling products& services your business will offer. This list may include

- Collection & sorting services

- Material processing

- Manufactured products from recycled materials

- Composting services

- Waste audits & consulting

- Education & awareness programs

Quality measures:

- This may include material sorting & contamination control, compliance with environmental regulations, product quality standards, continuous improvement & innovation, etc.

Additional Services:

In short, this section of your recycling plan must be informative, precise, and client-focused. By providing a clear and compelling description of your offerings, you can help potential investors and readers understand the value of your business.

5. Sales And Marketing Strategies

Writing the sales and marketing strategies section means a list of strategies you will use to attract and retain your clients. Here are some key elements to include in your sales & marketing plan:

Unique Selling Proposition (USP):

- For example, comprehensive recycling solutions, advanced recycling technologies, or collaborative partnerships could be some of the great USPs for a professional recycling company.

Pricing Strategy:

Marketing strategies:, sales strategies:, customer retention:.

Overall, this section of your recycling business plan should focus on customer acquisition and retention.

Have a specific, realistic, and data-driven approach while planning sales and marketing strategies for your recycling business, and be prepared to adapt or make strategic changes in your strategies based on feedback and results.

6. Operations Plan

The operations plan section of your business plan should outline the processes and procedures involved in your business operations, such as staffing requirements and operational processes. Here are a few components to add to your operations plan:

Staffing & Training:

Operational process:, equipment & machinery:.

- Explain how these technologies help you maintain quality standards and improve the efficiency of your business operations.

Adding these components to your operations plan will help you lay out your business operations, which will eventually help you manage your business effectively.

7. Management Team

The management team section provides an overview of your recycling business’s management team. This section should provide a detailed description of each manager’s experience and qualifications, as well as their responsibilities and roles.

Founders/CEO:

Key managers:.

- It should include, key executives(e.g. COO, CMO.), senior management, and other department managers (e.g. general manager, operations manager, sales & marketing manager.) involved in the recycling business operations, including their education, professional background, and any relevant experience in the industry.

Organizational structure:

Compensation plan:, advisors/consultants:.

- So, if you have any advisors or consultants, include them with their names and brief information consisting of roles and years of experience.

This section should describe the key personnel for your recycling services, highlighting how you have the perfect team to succeed.

8. Financial Plan

Your financial plan section should provide a summary of your business’s financial projections for the first few years. Here are some key elements to include in your financial plan:

Profit & loss statement:

Cash flow statement:, balance sheet:, break-even point:.

- This exercise will help you understand how much revenue you need to generate to sustain or be profitable.

Financing needs:

Be realistic with your financial projections, and make sure you offer relevant information and evidence to support your estimates.

9. Appendix

The appendix section of your plan should include any additional information supporting your business plan’s main content, such as market research, legal documentation, financial statements, and other relevant information.

- Add a table of contents for the appendix section to help readers easily find specific information or sections

- In addition to your financial statements, provide additional financial documents like tax returns, a list of assets within the business, credit history, and more. These statements must be the latest and offer financial projections for at least the first three or five years of business operations.

- Provide data derived from market research, including stats about the industry, user demographics, and industry trends.

- Include any legal documents such as permits, licenses, and contracts.

- Include any additional documentation related to your business plan, such as product brochures, marketing materials, operational procedures, etc.

Use clear headings and labels for each section of the appendix so that readers can easily find the necessary information.

Remember, the appendix section of your recycling business plan should only include relevant and important information supporting your plan’s main content.

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks and automatic financials make it easy.

This sample recycling business plan will provide an idea for writing a successful recycling plan, including all the essential components of your business.

After this, if you still need clarification about writing an investment-ready business plan to impress your audience, download our recycling business plan pdf .

Related Posts

EV Charging Business Plan

Renewable Energy Business Plan

10 Key Components of a Business Plan

Best AI Business Plan Generator Tools

Good Milestones for a Business

Steps to Create a Business Plan Presentation

Frequently asked questions, why do you need a recycling business plan.

A business plan is an essential tool for anyone looking to start or run a successful recycling business. It helps to get clarity in your business, secures funding, and identifies potential challenges while starting and growing your business.

Overall, a well-written plan can help you make informed decisions, which can contribute to the long-term success of your recycling company.

How to get funding for your recycling business?

There are several ways to get funding for your recycling business, but self-funding is one of the most efficient and speedy funding options. Other options for funding are:

- Bank loan – You may apply for a loan in government or private banks.

- Small Business Administration (SBA) loan – SBA loans and schemes are available at affordable interest rates, so check the eligibility criteria before applying for it.

- Crowdfunding – The process of supporting a project or business by getting a lot of people to invest in your business, usually online.

- Angel investors – Getting funds from angel investors is one of the most sought startup options.

Apart from all these options, there are small business grants available, check for the same in your location and you can apply for it.

Where to find business plan writers for your recycling business?

There are many business plan writers available, but no one knows your business and ideas better than you, so we recommend you write your recycling business plan and outline your vision as you have in your mind.

What is the easiest way to write your recycling business plan?

A lot of research is necessary for writing a business plan, but you can write your plan most efficiently with the help of any recycling business plan example and edit it as per your need. You can also quickly finish your plan in just a few hours or less with the help of our business plan software .

How do I write a good market analysis in a recycling business plan?

Market analysis is one of the key components of your business plan that requires deep research and a thorough understanding of your industry.

We can categorize the process of writing a good market analysis section into the following steps:

- Stating the objective of your market analysis—e.g., investor funding.

- Industry study—market size, growth potential, market trends, etc.

- Identifying target market—based on user behavior and demographics.

- Analyzing direct and indirect competitors.

- Calculating market share—understanding TAM, SAM, and SOM.

- Knowing regulations and restrictions

- Organizing data and writing the first draft.

Writing a marketing analysis section can be overwhelming, but using ChatGPT for market research can make things easier.

How detailed should the financial projections be in my recycling business plan?

The level of detail of the financial projections of your recycling business may vary considering various business aspects like direct and indirect competition, pricing, and operational efficiency. However, your financial projections must be comprehensive enough to demonstrate a complete view of your financial performance.

Generally, the statements included in a business plan offer financial projections for at least the first three or five years of business operations.

What key components should a recycling business plan include?

The following are the key components your recycling business plan must include:

- Executive summary

- Business Overview

- Market Analysis

- Products and services

- Sales and marketing strategies

- Operations plan

- Management team

- Financial plan

Can a good recycling business plan help me secure funding?

Indeed. A well-crafted recycling business will help your investors better understand your business domain, market trends, strategies, business financials, and growth potential—helping them make better financial decisions.

So, if you have a profitable and investable business, a comprehensive business plan can certainly help you secure your business funding.

What's the importance of a marketing strategy in a recycling business plan?

Marketing strategy is a key component of your recycling business plan. Whether it is about achieving certain business goals or helping your investors understand your plan to maximize their return on investment—an impactful marketing strategy is the way to do it!

Here are a few pointers to help you understand the importance of having an impactful marketing strategy:

- It provides your business an edge over your competitors.

- It helps investors better understand your business and growth potential.

- It helps you develop products with the best profit potential.

- It helps you set accurate pricing for your products or services.

About the Author

Upmetrics Team

Upmetrics is the #1 business planning software that helps entrepreneurs and business owners create investment-ready business plans using AI. We regularly share business planning insights on our blog. Check out the Upmetrics blog for such interesting reads. Read more

Plan your business in the shortest time possible

No Risk – Cancel at Any Time – 15 Day Money Back Guarantee

Popular Templates

Create a great Business Plan with great price.

- 400+ Business plan templates & examples

- AI Assistance & step by step guidance

- 4.8 Star rating on Trustpilot

Streamline your business planning process with Upmetrics .

Business Plan for Investors

- Bank/SBA Business Plan

- Operational/Strategic Planning Services

- L1 Visa Business Plan

- E1 Treaty Trader Visa Business Plan

- E2 Treaty Investor Visa Business Plan

- EB-1 Business Plan

- EB-2 NIW Business Plan

- EB-5 Business Plan

- Innovator Founder Visa Business Plan

- Start-Up Visa Business Plan

- Expansion Worker Visa Business Plan

- Manitoba MPNP Visa Business Plan

- Nova Scotia NSNP Visa Business Plan

- British Columbia BC PNP Visa Business Plan

- Self-Employed Visa Business Plan

- OINP Entrepreneur Stream Business Plan

- LMIA Owner Operator Business Plan

- ICT Work Permit Business Plan

- LMIA Mobility Program – C11 Entrepreneur Business Plan

- USMCA (ex-NAFTA) Business Plan

- Franchise Business Plan

- Landlord business plan

- Nonprofit Start-Up Business Plan

- USDA Business Plan

- Cannabis business plan

- Ecommerce business plan

- Online boutique business plan

- Mobile application business plan

- Daycare business plan

- Restaurant business plan

- Food delivery business plan

- Real estate business plan

- Business Continuity Plan

- Pitch Deck Consulting Services

- Financial Due Diligence Services

- ICO whitepaper

- ICO consulting services

- Confidential Information Memorandum

- Private Placement Memorandum

- Feasibility study

- Fractional CFO

- How it works

- Business Plan Examples

Recycling Company Business Plan Sample

AUG.26, 2013

Recycling company business plan for starting your own business?

If you are considering starting up your own recycling company, you should know that the business opportunities available are as wide-ranging and varied as the tons of stuff that we dispose of every day. Starting a recycling company business does not require you to hold technical knowledge, you can start it with a small team and with less funding. You can start it at any scale and can expand or narrow down your offerings whenever you want.

To start any business, it is important to follow the proper procedure. First, you will have to develop a business plan . To learn how to write a recycling proposal, you can take help from this provided sample. This is a business plan for a recycling company named ‘Greenworks Recycling Center’. This business plan would also be helpful in writing scrap metal business plan .

Executive Summary

2.1 the business.

Greenworks Recycling Center will be a recycling company owned by Ardon John in New York. The primary aim of the business will be to recycle and reuse plastic waste materials. Our recycling company will focus to recycle plastic wastes like plastic containers, bottles, polythene, polybag, plastic boxes, packets, sheets, and the like, and turn them into useful products. The business will offer a wide range of services and products for the ease of its customers.

2.2 Management of recycling company

To start a plastic recycling business, you must have strong management skills. Adequate planning is necessary to ensure flawless management. There is no better way to plan out every aspect of your company than developing a recycling company business plan pdf like the one offered here.

A relevant business plan such as a business plan for e waste recycling company can also help you write your strategic plan.

In this recycling business proposal, we will guide you on all the major aspects of a strong business plan. This business plan is written for investors as Ardon needed funding to set up his recycling business.

2.3 Customers of recycling company

Our customers and the people who will benefit from our products and services are expected to belong to both ends of the supply chain. Our customers will belong to almost all work domains as plastic recycling is required in many diverse areas nowadays. However, our potential and recurring customers are identified as follows:

- Commercial Businesses

- Residential Community

- Industrial and Manufacturing Units

- Government

2.4 Business Target

Our target is to become the most trustworthy and reliable choice for our target customers whenever they need recycled and reused plastic materials.

Our financial targets to meet for the first three years of our launch are demonstrated below:

Company Summary

3.1 greenworks recycling center owner.

This Greenworks Recycling Center will be owned by Mr. Ardon John. Ardon Jack completed his master’s in environmental sciences a few years back. After his academic career, he pursued a manager position in a noteworthy recycling company. Recently, he left his job to start his own business of recycling plastic materials to create environmentally friendly products.

3.2 Why the recycling company is being started

Ardon noticed that as the environmental movements began to take hold on a national scale, recycling started to be viewed as a personal manifestation of helping the environment. So, he decided to bring innovation to existing modes through his intellect and knowledge. Therefore, he decided to start his own recycling business to fully implement the great ideas he had.

3.3 How the recycling company will be started

Step1: Plan Out Everything

To learn how to start your own recycling company, first, you will have to make a business plan. To help you in creating a business plan we are providing a recycling company business plan . For opening a recycling business, you can take help from this business sample or go through other business plans like greentech consulting business plans to get an idea of what to include when planning for a startup.

Step2: Branding

The next step is to get your company and its values and services recognized by customers. For this purpose, Greenworks Recycling Center will make a brand that people can trust. Defining the brand is important as it enables you to introduce a good image of your business to your customers. It also helps you create a space for yourself in the market.

Step3: Physical Space

The next step is establishing the physical presence of the business and for this purpose, Ardon decided to buy a large place in the outskirts of New York. To set up his recycling company, he acquired land that had shades, a closed space, large rooms, and a technical room. After acquiring the space, he got the machinery installed there.

Step4: Online Presence

A wider audience can be attracted through online channels so establishing an online presence is a must if you start a business nowadays. Ardon decided to make a mobile-friendly app, website, and social media page for his business to reach out to a wider audience.

Step5: Advertisement

Marketing is the most important thing for the promotion of the business. Ardon will develop a thorough plan for the advertisement of his business. In later sections, we will document the sales strategy developed by Ardon.

Marketing is the most important thing for the promotion of the business. Ardon will develop a thorough plan for the advertisement of his business.

Services of recycling company

Your business plan of recycling company must include the services that you will provide to your targeted customers. You may have many plastic recycling business opportunities, but you have to choose the ones that are in the most demand in your target location.

For starting a recycling company, you can follow this guide on how to open a recycling business to figure out what the market for the business looks like and what services are ideal to be included in your startup. This business plan sample can also aid in writing other business plans such as business plan for a distilled business.

Following are the services that will be provided by our Greenworks Recycling Center Company:

- Plastic material retrieval

This will be the main service offered by us. We will retrieve plastic material from solid waste and process it for recycling or reuse. Plastic is of distinctive types and it usually has joint material attached to it. Our company will segregate plastic consisting of different polymers, strengths, and qualities.

- Waste Awareness Services

To ensure that our customers send the right materials to be recycled, we will spread information about the materials that can be recycled and the ones that cannot be. This information will be distributed every time we enter into a partnership with a company or an organization.

- Dumpster and Container Rental Services

Our customers will be able to take advantage of our low-cost dumpsters and containers that they can rent out for a short period.

- Plastic Sale

The plastic materials we purchase and retrieve will be sold to local buyers and the ones from other states. We will try to make recycled plastic material buyers a permanent customer group for the business.

Marketing analysis of recycling company

Excellent work.

excellent work, competent advice. Alex is very friendly, great communication. 100% I recommend CGS capital. Thank you so much for your hard work!

To learn how to start up a recycling business, you should have an excellent understanding of your target market. You can gain this understanding by doing an extensive market analysis as a part of yourmarketing plan for recycling business. This analysis should look into current market trends as well as compare them with past trends. The same marketing plan can be used for business plan for an e waste recycling company.

Your recycling business model should also analyze the rates of similar services in the market. If you don’t know how to open a recycling business company and how to price your offerings then you can take help from this business plan.

This business plan can also be used to make other business plans like electronic recycling business plan and waste paper recycling business plan.

5.1 Market Trends

According to IBIS World, the recycling industry holds a market size of $77 Billion in the United States, employing almost 70,961 people. The industry is continuously in demand as more and more people adopt recycling in their life. So, opening a plastic scrap recycling business is a very smart move as the demand will only increase.

5.2 Marketing Segmentation

The potential customers of Greenworks Recycling Center are divided into the following groups:

5.2.1 Commercial Businesses

Our commercial customers will range from smaller retail businesses to urban skyscrapers with high-volume waste streams. We will provide permanent, temporary, and need-based trash removal and recycling services.

5.2.2 Residential Community

Residential customers have a variety of materials to be recycled. Some households generate enough trash making it economically feasible for the resident to utilize a larger commercial-sized trash container for weekly trash service.

5.2.3 Industrial and manufacturing

Industrial customers frequently require roll-off dumpsters, compactors, trash containers, and waste plastic recycling equipment. Industrial customers are expected to contact us for scrap metal hauling and redemption, cardboard and waste paper recycling, construction and demolition debris collection, and trash disposal.

5.2.4 Government

Our company will also provide trash and recycling services to government buildings and organizations.

5.3 Business Target

- To provide a green way of disposing of trash to our customers

- To earn a net profit margin of up to $70k per month by the end of the fifth year

- To achieve and maintain a CSAT score above 92%

5.4 Product Pricing

Our prices will be economical as compared to our competitors. We aim to provide the best services at a nominal rate.

Marketing Strategy

To start a recycling company, you must develop the best business plan with an impressive sales strategy. A strong marketing strategy is needed to attract a wider audience. To gain attention in the market among your competitors, you need to highlight your competitive advantages.

This is a business plan developed for Greenworks Recycling Center by a business consultancy firm. You can use this business plan to write other business plans like shoe business plan . You can learn a lot from here if you are even making a skateboard store business plan .

6.1 Competitive Analysis

- Our custom programs will ensure that you have the right containers, schedules, and operations.

- We’ll implement green cleaning practices by using eco-friendly and non-toxic recycling operations.

- Through our website and user-friendly mobile app, our customers would be able to book our services remotely.

6.2 Sales Strategy

- We’ll use online channels like Google Local ads service and social media to attract a wider audience.

- We’ll provide free waste pick-up services for one month to our first ten customers.

- We’ll offer a 30% discount on specialized recycling services for the first month of our launch.

6.3 Sales Monthly

6.4 Sales Yearly

6.5 Sales Forecast

Personnel plan

The success of an eco-conscious business such as a recycling business depends not only on its services but also on the values and behavior of its workforce. So, you have to be very careful when you are hiring employees in your company. You also need to be very diligent in background checks when hiring for these positions.

This business plan for a plastic recycling company has all the detail regarding the employment practices of a recycling service business. The same personnel plan can be used for starting a paper recycling plant.

7.1 Company Staff

The list of employees, necessary for the business to function, includes:

- 1 CEO/ Manager

- 6 Recycling Plant Personnel

- 1 Operations Executive

- 1 Technician to upkeep the recycling machinery

- 1 Accountant

7.2 Average Salary of Employees

Financial plan.

It is essential to manage your operations timely and efficiently to earn recycling business profit. A detailed financial analysis is necessary to ensure that your business is not getting into a loss. The recycling companies business plan must contain all the financial information to help analyze how to direct cash flows to earn revenue.

Evaluating the startup costs are also important for your financial plan. In your financial plan, you must identify when and how you’ll cover your investment amount with the earned profits. It would also help you to analyze your yearly expenses to determine the possibilities of reducing them. To know how to make an accurate financial plan and which projections to include in it, you can see this business plan. Here we’re providing the detailed financial plan made for Greenworks Recycling center.

The financial plan of this sample can also be used to write jewelry business plan .

8.1 Important Assumptions

8.2 break-even analysis.

8.3 Projected Profit and Loss

8.3.1 profit monthly.

8.3.2 Profit Yearly

8.3.3 Gross Margin Monthly

8.3.4 Gross Margin Yearly

8.4 projected cash flow.

8.5 Projected Balance Sheet

8.6 business ratios.

- Is the recycling business profitable?

Yes, if you start recycle business after doing proper planning, it can be immensely profitable.

- Which recycling business is most profitable?

The wastepaper recycling business is the most profitable. A paper recycling business proposal is necessary for starting a business in this domain. You can also consider the start up plastic recycling business as it is a strong contender for the most profitable recycling businesses.

- How do I start a recycling business?

A recycle company business plan is needed to start a recycling business. Along with this a strong operations and marketing strategy is also needed.

- Why recycling is not profitable?

The only reason behind a recycling business not yielding the desired profits can be inaccurate planning. If you follow the stepwise guide given in this business plan recycling company, your business is not likely to get into a loss.

Download Recycling Company Business Plan Sample in pdf

OGSCapital’s team has assisted thousands of entrepreneurs with top-rate business plan development, consultancy and analysis. They’ve helped thousands of SME owners secure more than $1.5 billion in funding, and they can do the same for you.

Add comment

E-mail is already registered on the site. Please use the Login form or enter another .

You entered an incorrect username or password

Comments (0)

mentioned in the press:

Search the site:

OGScapital website is not supported for your current browser. Please use:

How to start a waste recycling business

Table of Contents

Different kinds of waste recycling

Waste paper and cardboard, plastic recycling, metal recycling, electronic devices, wood recycling, glass recycling, clothing and textiles, bricks and inert waste recycling, regulations, how to register your waste recycling business, making a business plan, start-up costs, finding partners, useful contacts, environment agency, department for environment, food and rural affairs, chartered institute of waste management, the environmental services association, manage your finances with a simple app.

As the world continues to put a greater emphasis on environmental issues, there are more opportunities for businesses to cater to those needs.

It’s not just government agencies that must commit to environmental standards, nowadays there are many more upsides for businesses that choose to go green, whether it’s for regulatory purposes or just part of building a socially conscious public image.

All this means that waste recycling looks to be a promising career prospect going forward. In this guide, we’ll cover everything you’ll need to know about how to start a waste recycling business, including:

- Different kinds of waste recycling

- Managing your finances

First of all, let’s talk about what we actually mean by “waste recycling” because it can cover a lot of different areas that you can cover as a business.

Most paper and cardboard is completely recyclable. In the UK alone, several million tonnes of it are discarded every year, so recycling it is big business and great news for the environment.

Plastic waste is a huge environmental problem at the moment. Because it doesn’t break down naturally, any plastic that ends up in landfills or oceans is going to be there for a long time.

Metal is by far one of the most robust when it comes to recycling. Because it doesn’t lose any of its quality during the process, all kinds of metal can be recycled over and over again for different purposes.

Waste of electrical and electronic equipment (WEEE) recycling became mandatory in 2014 with the introduction of WEEE regulations.

The regulations prevent electronic devices from ending up in landfills where the materials and batteries become more dangerous as they degrade. It covers pretty much all electronic devices, but you’ll mainly be dealing with things like computers, monitors, mobile phones, radios, TVs and electrical tools.

Wood is an incredibly versatile material for recycling. It can be easily reshaped and reused or turned into mulch for building materials

Glass is another material that is perfect for recycling. It’s all completely reusable and never loses its quality, so it can be recycled pretty much endlessly into products that are as good as brand new.

Clothing has become a much larger issue in recent years. As the general public has started to catch on to the real environmental cost of “fast fashion”, there has been a real push to prevent the mountains of old clothing from filling up landfills.

Luckily, around half of textiles that go into making clothes can be recycled.

Finally, a lot of waste from construction sites can be recycled into usable materials for other construction products.

Rubble can be ground down into building materials, while old bricks can be reused for different projects or turned into brick chips for landscaping.

Starting a waste recycling business involves adhering to regulations set out by the Waste Framework Directive and Environmental Protection Act.

Under their regulations, both you and every business you work with:

- Have a ‘Duty of Care’ requiring them to ensure their waste is disposed of safely and properly even after it has been passed on to another party.

- Must ensure waste is transferred only to another authorised person.

- Must transfer a written description of the waste so that the new carriers can properly perform their own Duty of Care.

- Planning consent from their local authority or council. This can be difficult because local residents often protest waste projects in their area.

For a full picture of the regulations you need to follow, and how to get them, get in touch with these government agencies:

- Department for Environment, Food and Rural Affairs.

- The Environment Agency.

- Driver and Vehicle Licensing Agency – for vehicle licenses.

- The Chartered Institute of Wastes Management and the Environmental Services Association – for training courses about Duty of Care and permits.

As a recycling business, you’ll need to register with HMRC for the proper license. The license applies to any business that plans to:

- Transport waste (a carrier).

- Buy, sell, or dispose of waste (a dealer).

- arrange for someone else to buy, sell, or dispose of waste (a broker).

Registration costs £154, but operating without registration could lead to a fine of up to $5,000

When you register, you’ll need all of the following:

- Names and dates of birth of the organisation’s executives, owners, directors or partners.

- Details of any environmental offences they’ve committed.

- A way to pay (for example, a debit or credit card).

When you register, HMRC will tell you whether your registration is upper or lower tier. Upper-tier registrations need to be renewed every 3 years for £105. You don’t need to renew if it’s a lower-tier registration.

If any of your registration details change, you’ll need to contact the Environmental Agency to update your registration. You need to update them within 28 if any of the following things happen:

- Your organisation’s contact details change

- Your organisation’s management changes

- Someone in management is convicted of an environmental offence

- Your organisation changes what it does, for example, you’re registered as a waste carrier but start acting as a waste broker as well. This change will cost an additional £40.

Your details need to be updated within 28 days.

You’ll need to apply for entirely new registration if:

- your business structure has legally changed, like changing from a sole trader to a limited company

- you’re changing from a lower tier to an upper-tier registration

A new registration will cost another £154.

The guidance we’ve mentioned is specific to England, there are slightly different processes depending on where you live in the UK:

- Northern Ireland

Any business that plans to use, recycle, treat, store, or dispose of waste also needs a specific permit from the Environmental agency .

Once again, there are different issuing bodies for each region of the UK:

Both the registration process and permit application can be a little confusing, and the penalties for not getting it perfect are severe, so it’s probably a good idea to contact the Environmental Agency directly to make sure you’re doing everything right.

Every business should begin with a detailed business plan. It’ll clearly outline all your main goals while giving you step by step guidance on how to achieve those goals.

Not only that, your business plan will be useful if you’re trying to secure investors. Whether you’re applying for a bank loan or working with a private individual, a business with a well-made plan is going to be a much safer bet for them.

At the very basic level, every business should be made up of:

- Market research