- Browse All Articles

- Newsletter Sign-Up

SupplyChain →

No results found in working knowledge.

- Were any results found in one of the other content buckets on the left?

- Try removing some search filters.

- Use different search filters.

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Elsevier - PMC COVID-19 Collection

COVID-19 pandemic related supply chain studies: A systematic review

Priyabrata chowdhury.

a School of Accounting, Information Systems and Supply Chain, RMIT University, Melbourne, Australia

Sanjoy Kumar Paul

b UTS Business School, University of Technology Sydney, Sydney, Australia

Shahriar Kaisar

Md. abdul moktadir.

c Institute of Leather Engineering and Technology, University of Dhaka, Dhaka 1209, Bangladesh

Associated Data

The global spread of the novel coronavirus, also known as the COVID-19 pandemic, has had a devastating impact on supply chains. Since the pandemic started, scholars have been researching and publishing their studies on the various supply-chain-related issues raised by COVID-19. However, while the number of articles on this subject has been steadily increasing, due to the absence of any systematic literature reviews, it remains unclear what aspects of this disruption have already been studied and what aspects still need to be investigated. The present study systematically reviews existing research on the COVID-19 pandemic in supply chain disciplines. Through a rigorous and systematic search, we identify 74 relevant articles published on or before 28 September 2020. The synthesis of the findings reveals that four broad themes recur in the published work: namely, impacts of the COVID-19 pandemic, resilience strategies for managing impacts and recovery, the role of technology in implementing resilience strategies, and supply chain sustainability in the light of the pandemic. Alongside the synthesis of the findings, this study describes the methodologies, context, and theories used in each piece of research. Our analysis reveals that there is a lack of empirically designed and theoretically grounded studies in this area; hence, the generalizability of the findings, thus far, is limited. Moreover, the analysis reveals that most studies have focused on supply chains for high-demand essential goods and healthcare products, while low-demand items and SMEs have been largely ignored. We also review the literature on prior epidemic outbreaks and other disruptions in supply chain disciplines. By considering the findings of these articles alongside research on the COVID-19 pandemic, this study offers research questions and directions for further investigation. These directions can guide scholars in designing and conducting impactful research in the field.

1. Introduction

Business organizations have faced huge challenges due to unprecedented disease outbreaks in recent decades. The scope of the challenges faced by these organizations largely depends on the severity of the outbreaks in question. A widespread public health incident such as an epidemic or pandemic can have substantial negative impacts on businesses and supply chains, including reducing their efficiency and performance ( Guan et al., 2020 , Ivanov, 2020a , Sodhi, 2016 ), and propagating disruptions across the supply chains (known as ripple effects) that affect their resilience and sustainability ( Ivanov, 2020b , Ivanov and Dolgui, 2020a ). Supply chains have encountered many severe disease outbreaks in the recent past; thus far, the World Health Organization (WHO) reported 1438 epidemics just between 2011 and 2018 ( Hudecheck et al., 2020 ). However, the current COVID-19 pandemic is unique. It has had even more severe, diversified, and dynamic impacts than that of previous epidemic outbreaks such as the 2003 SARS epidemic or the 2009 H1N1 epidemic ( Haren and Simchi-Levi, 2020 , Koonin, 2020 ). A report published by Fortune magazine on 21 February 2020, before the WHO reclassified the COVID-19 outbreak as a pandemic on 11 March 2020, revealed that due to the COVID-19 pandemic, 94% of the Fortune 1000 companies were facing disruption in their supply chains ( Fortune, 2020 ). Moreover, unlike other previous outbreaks, this pandemic has impacted all the nodes (supply chain members) and edges (ties) in a supply chain simultaneously ( Gunessee and Subramanian, 2020 , Paul and Chowdhury, 2020a ); hence, the flow of the supply chain has been disrupted substantially. For example, the demand for necessary items such as personal protective equipment (PPE), ventilators, and dried and canned foods has increased. Meanwhile, supply, transportation, and manufacturing face numerous challenges that reduce their capacities. These include border closures, lockdown in the supply market, interruption in vehicle movements and international trade, labor shortage, and the maintaining of physical distance in manufacturing facilities ( Paul and Chowdhury, 2020a , Amankwah-Amoah, 2020b ). Due to these multidimensional impacts on supply chains, along with other economic and financial challenges ( Dontoh et al., 2020 ), the pandemic is likely to have a severe effect on world international trade. For example, the world trade organization (WTO) announced that world trade may decline by 13–32% in 2020 due to the COVID-19 crisis ( WTO, 2020 ).

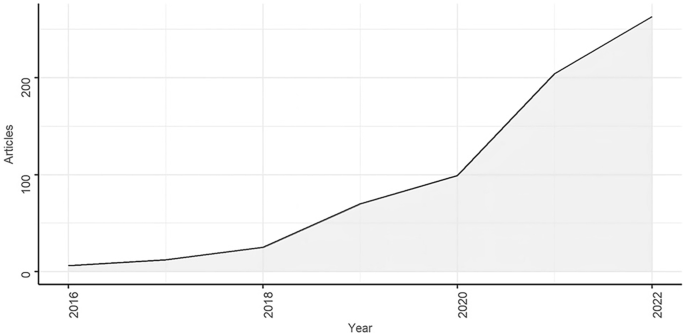

Given the severe impact of the COVID-19 pandemic on supply chains, scholars have increasingly turned their attention to the topic. As a result, a significant amount of research on the COVID-19 pandemic in supply chain disciplines has been published since 2020. With the topic becoming more and more important for researchers, it is worth reporting the current state of the literature and outlining future research opportunities at this early stage—in part, to help scholars avoid doing repetitive research in this area ( Chowdhury and Paul, 2020 , Iyengar et al., 2020 ). A systematic literature review can help summarize what we know, how we know it, and what can be done so that, going forward, supply chains can better deal with the impacts of this pandemic ( Tranfield et al., 2003 ). Accordingly, we synthesize here the results of published articles and sketch research agendas that can contribute to the existing body of knowledge in this domain, to provide practitioners and policymakers with better insights in managing the impacts of COVID-19 pandemic. In particular, in this study, we advance the supply chain literature by answering the following research questions.

- i. What are the main themes and contents of the published research on the COVID-19 pandemic in supply chain disciplines?

- ii. What are the opportunities for future research on the COVID-19 pandemic in supply chain disciplines?

To the best of our knowledge, this is the first literature review of studies on the COVID-19 pandemic in supply chain disciplines. Although several review articles on the impacts of disease outbreaks have been published recently, none of them specifically focuses on research on the COVID-19 pandemic in supply chain disciplines. For example, previous literature reviews have synthesized findings concerning the impacts of epidemics (in general) on logistics ( Dasaklis et al., 2012 ), the effects of past epidemics on supply chains ( Queiroz et al., 2020 ), and the causes of panic buying during an epidemic or pandemic ( Yuen et al., 2020 ). In contrast to these studies, our study focused on published articles related to the COVID-19 pandemic in supply chain disciplines. Although the COVID-19 pandemic is an extraordinary supply chain disruptions ( Ivanov, 2020b , Ivanov and Dolgui, 2020b ), we have also reviewed the literature on prior epidemic outbreaks and other disruptions to enhance our findings and to outline unique research opportunities. The findings can help scholars to conduct impactful research on the effects of the COVID-19 pandemic in the supply chain area, while also helping practitioners and policymakers understand what we already know on this topic so that they can deal with the actual impacts of the COVID-19 pandemic on the global supply chain. This study also explores the methodologies, contexts, and theoretical lenses used in the studies on COVID-19 pandemic in supply chain disciplines. We expect it can assist academics with issues of research design, such as deciding on the most appropriate methodology and context, in future studies.

The remainder of this paper is organized as follows. Section 2 provides the review methodology for the systematic literature review. The articles themselves are analyzed in section 3. Section 4 provides a review of studies on prior epidemic outbreaks and other disruptions in supply chain disciplines. Based on the analysis and findings, further research opportunities are discussed in section 5. Finally, section 6 concludes the paper.

2. Review methodology

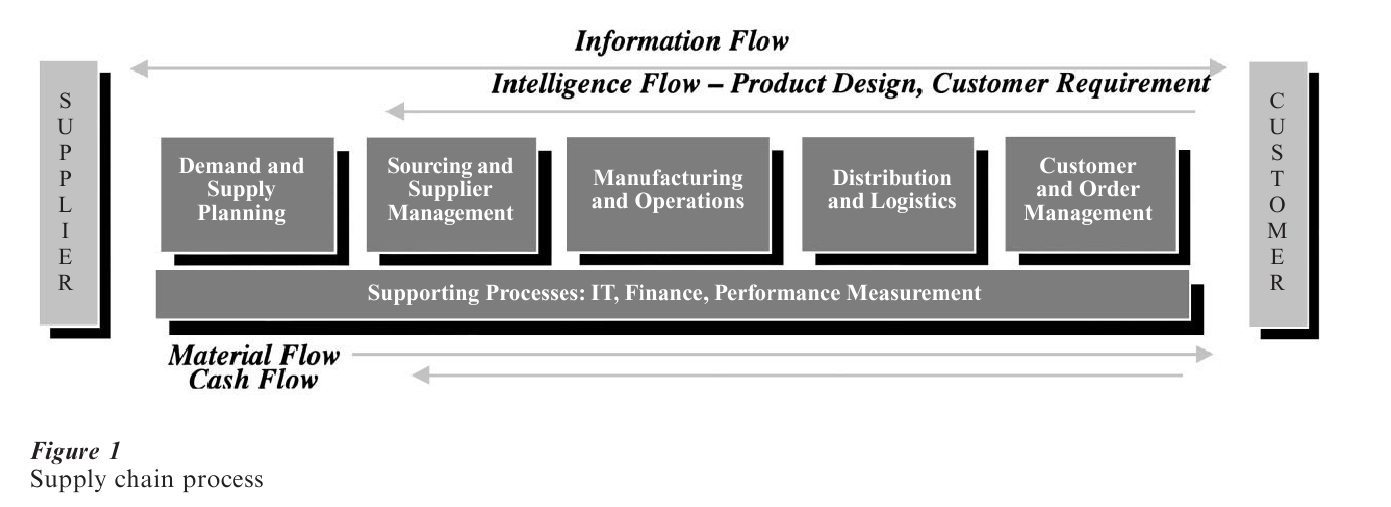

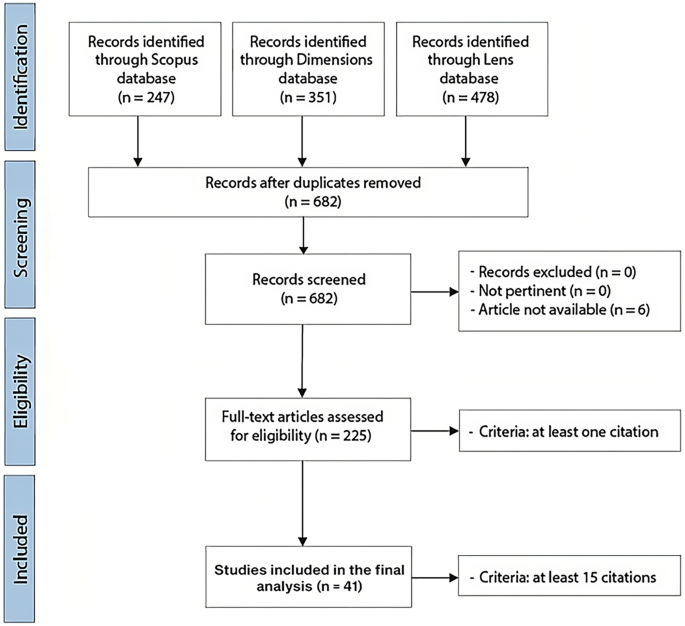

In this review paper, we followed a systematic literature review (SLR) approach. SLR has proven to be a rigorous framework for literature reviews ( Tranfield et al., 2003 ), and we illustrate in Fig. 1 the search methodology we undertook for this study. First, the research theme was finalized to conduct the literature search ( Cooper et al., 2018 ). Second, multiple research databases (Scopus, Google Scholar, and the Web of Science) were used to search for relevant articles. We considered different types of articles, including research articles, opinion pieces, short notes, discussion papers, review articles, and letters to the editor published in scholarly journals. Finally, we conducted a reference check of the included articles to enrich the final list of articles. We considered articles published online, including articles in the press and pre-publication versions of articles, up through our 28 September 2020 cut-off date.

Search methodology for finalizing the articles for analysis.

As depicted in Fig. 1 , initially we searched in Scopus using the keywords “supply chain” and “COVID-19” or “SARS-COV-2” or “coronavirus” both for articles and review papers published since 2020 in English. The search yielded 198 results. We then excluded the irrelevant results by reading titles, abstracts, and full papers; this process excluded 142 articles, leaving 56 papers from the Scopus database. The inclusion criteria were: (i) articles focused on the supply chain in relation to the COVID-19 pandemic, and (ii) both the search terms “supply chain” and “COVID-19”, “coronavirus”, or “SARS-COV-2” appeared in the body text. The exclusion criterion was one or more keywords only appearing in reference lists without being discussed in the body text. Then, to enhance the search results we repeated our search in Google Scholar and the Web of Science, and also conducted reference checks of our 56 identified articles. In the process, we identified a further 77 articles; but 38 of these were removed because they duplicated our findings from the previous search. We then read, in full, the remaining 39 articles, of which we included 18 for further consideration and excluded 21 based on the exclusion criterion mentioned before. Finally, we checked the references of the additional 18 articles, and no further articles were identified. The entire process yielded a total of 74 articles for our analysis.

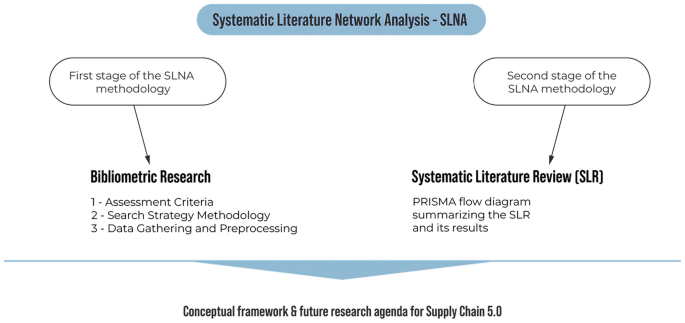

These 74 articles are systematically reviewed and analyzed to synthesize the themes investigated and other aspects, such as the methodologies, contexts, and theories used in these studies. Furthermore, this study analyzes the studies from two closely related fields on prior epidemic outbreaks and other disruptions in supply chain disciplines to provide unique future research opportunities. Similar to the studies on the COVID-19 pandemic in supply chain disciplines, main themes and methodologies, contexts and theories used in the articles on these two fields are explored. Finally, this study discusses future research opportunities and outlines potential research questions by considering the research findings on COVID-19 and studies on prior epidemics and disruptions in supply chain disciplines. The framework of the analysis process of this systematic review paper is illustrated in Fig. 2 .

Framework of the analysis process.

3. Analyzing the reviewed articles on the COVID-19 pandemic in supply chain disciplines

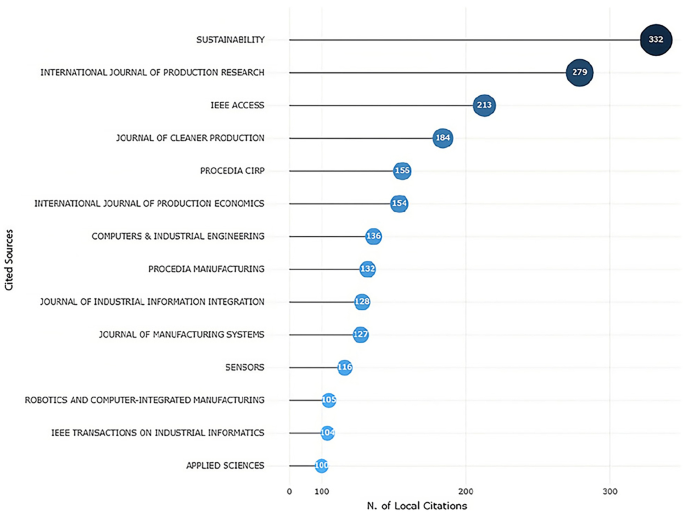

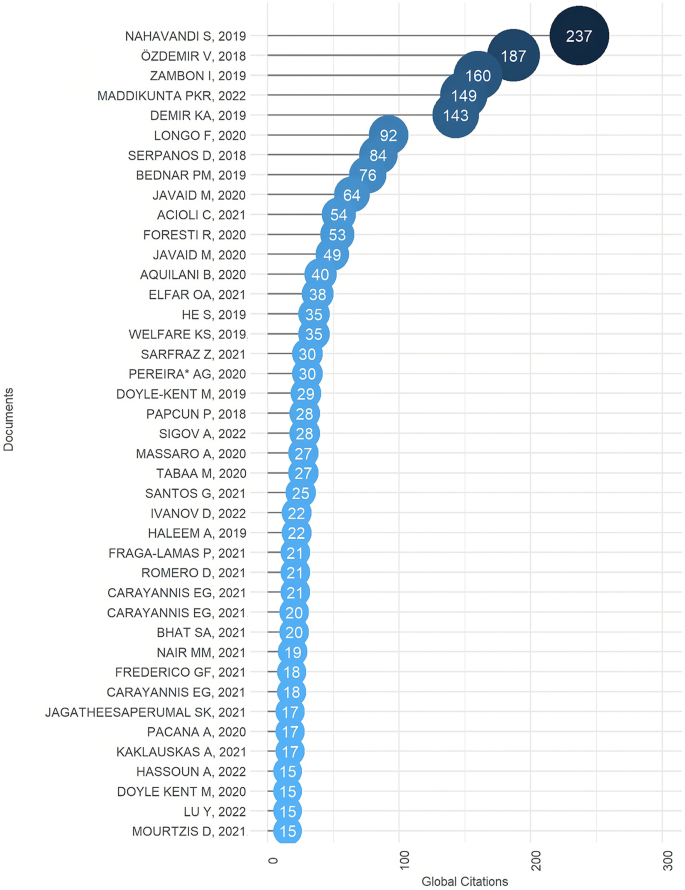

This section investigates the methodologies, contexts, and theoretical underpinnings used in the 74 articles identified through our search methods. It synthesises the main themes investigated in these studies. However, a descriptive analysis is conducted to provide the selected articles' general landscape before this. The analysis uncovers journals that have extensively publish research on the COVID-19 pandemic in supply chain disciplines and the leading subject areas in these articles. The distribution of the identified articles by different source titles, as presented in Table 1 , shows that a wide variety of journals have contributed to the literature in this domain.

Articles by source title.

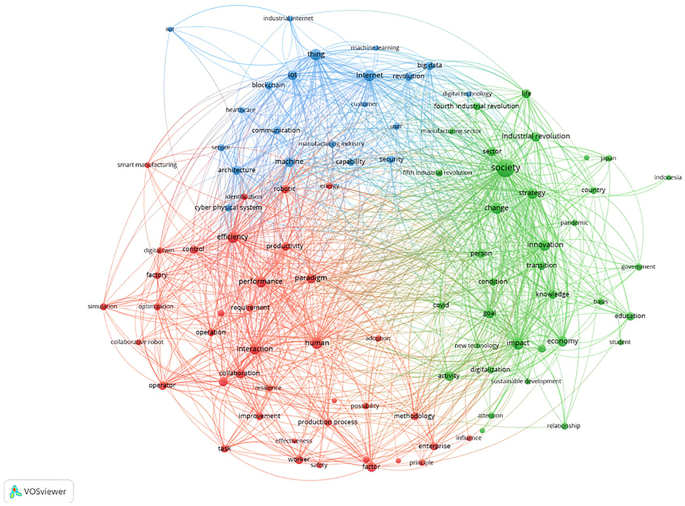

The selected articles’ different subject areas are presented in Fig. 3 , and show that business, management, and accounting, environmental science, engineering and decision sciences are at the top of the list. The other descriptive analyses of the selected articles are presented in Appendix A ( supplementary material ), which includes the affiliated countries of the authors (Table A1), the affiliated institutions of the authors (Table A2), the authors’ names (Table A3) and word art showing the different keywords used in the articles (Fig. A1). The description of each paper is presented in Appendix B ( supplementary material ).

Subject areas in the analyzed articles.

3.1. Methodologies used

This subsection analyzes the reviewed articles in terms of the methodologies their authors use. For this purpose, we divided the articles into several categories, including empirical (e.g., studies involving interviews, case studies, focus groups, the Delphi technique, and surveys), quantitative (e.g., studies involving mathematical models, simulations, analytical modeling, and multi-criteria decision-making (MCDM) method), literature reviews (e.g., reviews, analytical reviews, and systematic or structured reviews), and researchers’ opinions (opinion pieces, commentaries, and discussion articles). Table 2 shows the breakdown of methodologies used in the reviewed articles.

Research methodologies used in the reviewed articles.

The analysis reveals that the largest number of articles (31 out of 74) relied on researchers’ opinions as their main method of investigation. More specifically, at the start of COVID-19, researchers provided their perspectives and opinions on the potential impacts of and responses to this pandemic. Among the 31 articles that used researchers’ opinions, 25 of them used the perspective or viewpoint of the researchers themselves, while four of them were discussion and two were conceptual papers. The prevalence of opinion pieces is understandable, considering the sudden occurrence and huge impact of the pandemic, and also the limited time that researchers had to collect and analyze relevant data. However, this pattern also suggests that further research is required, with real-world data, to understand the pandemic’s impacts in different contexts, and to formulate strategies to address them.

Quantitative methods were the second-largest category, accounting for 27 of the 74 reviewed articles. Among the various quantitative techniques, seven studies used simulation modeling to predict the effects of the COVID-19 pandemic and to demonstrate the need for real-time visibility and structurally adaptable supply chains during a pandemic. Six studies used mathematical modeling techniques, including game-theoretical modeling ( Gupta et al., 2020 , Ivanov and Dolgui, 2020b , Kargar et al., 2020 ), mixed-integer linear modeling ( Lozano-Diez et al., 2020 ), stochastic optimization ( Mehrotra et al., 2020 ), and non-linear modeling ( Paul and Chowdhury, 2020a ). One of the studies ( Lozano-Diez et al., 2020 ) adopted an integrated mathematical and simulation model to recommend ways to reduce the shortage of medicines. Among the remaining articles, five studies used analytical modeling, nine relied on secondary data analysis including principal component analysis and cluster analysis, and one study applied stepwise weight assessment ratio analysis, which is one of the MCDM methods.

Literature reviews were used as the main research methodology in ten articles. Among them, five were simple review papers that did not employ systematic search and analysis methods. One of these articles ( Iyengar et al., 2020 ) acknowledges this limitation explicitly. Four other literature review articles used a systematic or structured approach in analyzing the articles. However, none of them is confined to the COVID-19 literature specifically. These studies summarize the literature from broad perspectives, considering the supply chain resilience modeling literature published between 2017 and 19 and its implications for COVID-19 ( Golan et al., 2020 ), the effects of past epidemics such as influenza, cholera, Ebola, malaria, and smallpox ( Queiroz et al., 2020 ), the use of AI in the agri-food supply chain ( Vaio et al., 2020 ), and the reasons for panic buying during a health crisis ( Yuen et al., 2020 ). One article ( Craighead et al., 2020 ) used an analytical review to investigate the theoretical underpinnings of response plans formulated by managers during health crises.

Only six of the studies that we reviewed used empirical methods in their research. Among them, three studies are qualitative, using a case study method in collecting and analyzing the data. The other three studies were survey-based and used descriptive statistics to report the findings. The lack of empirical studies confirms that researchers, thus far, have had limited opportunities to collect and analyze real-world data. However, the empirical studies are expected to reveal important supply chain issues and difficulties faced in different contexts, since the pandemic has caused unique challenges for supply chains.

3.2. Context of the studies

This section systematically analyzes the contexts brought into focus by the articles included in our review. The contexts are presented in terms of the location, type, and size of the industries considered in these articles.

3.2.1. National context

The reviewed articles were categorized according to the national contexts on which they focused ( Table 3 ). National context is an important factor for developing customized strategies for dealing with COVID-19, given that different countries have experienced different infection rates and adopted different lockdown strategies to manage the pandemic situation. Hence the industries in those countries faced contrasting challenges. The countries are also classified as developed (D) and developing/emerging (E) economies in our analysis, based on a recent report published by the United Nations ( United Nations, 2019 ). Among the 74 reviewed articles, three narrowed their scope to a particular region: two focused on South Asian countries, such as India and Bangladesh ( Majumdar et al., 2020 ), and the other investigated the context of central European countries, such as Poland, Hungary, the Czech Republic, and Slovakia ( Veselovská, 2020 ). Five studies considered multiple countries from various continents to demonstrate the global supply chain effects of the COVID-19 pandemic: comparisons included China, New Zealand, the United States, Vietnam, Nigeria, Malaysia, Kazakhstan, Jamaica, and Mongolia ( Guan et al., 2020 ); India, the United States, Germany, Singapore, and the United Kingdom ( Nikolopoulos et al., 2020 ); Brazil, India, the United Kingdom, and the United States ( Okorie et al., 2020 ); the United States and the United Kingdom ( Handfield et al., 2020 ); and the global context of many countries ( Xu et al., 2020a ). In terms of a specific country, four articles center on Canada and India, three on the United States, and one each on Australia, Brazil, Hong Kong, Ghana, Iran, Ireland, Mexico, Russia, and Turkey.

The national contexts on which the reviewed articles focused.

3.2.2. Industry context

Our analysis reveals that the major focus of existing research was on the food and healthcare supply chain. This finding makes intuitive sense, given that the healthcare industry is experiencing a major surge in demand, while a severe disruption has been observed in the food supply chain as it struggles to provide everyday essentials and meet high consumer demand. Among the 74 reviewed articles, 30 did not explicitly mention the industries under consideration.

As mentioned previously, the food and healthcare supply chains have received significant attention, with each of these two sectors being addressed in 16 and 14 articles respectively. Six articles reflected multiple industry sectors, such as service, production, transportation, construction, agriculture, and grocery sectors ( Veselovská, 2020 ); transportation, equipment, retail, fast moving consumer goods, food, apparel and technology sectors ( van Hoek, 2020 ); automobile and earth-moving equipment sectors ( Handfield et al., 2020 ); aviation and tourism sectors ( Ibn-Mohammed et al., 2021 ); healthcare, food, clothing, retail, automobile, airline and high-tech industry sectors ( Xu et al., 2020a ); and automobile, personal computer, and home furnishing sectors ( Ishida, 2020 ). Among the rest of the articles, one each focused on the industries of service, oil, electronics, automotive, clothing, retail, aviation, toilet paper manufacturing, and ship-breaking. Table 4 shows a breakdown of the industry sectors in our reviewed articles. It is worth mentioning that only four articles ( Craighead et al., 2020 , Gurbuz and Ozkan, 2020 , Quayson et al., 2020 , Reardon et al., 2020 ) out of the 74 reviewed articles addressed issues faced by SMEs; the rest focused on large industries.

A breakdown of the industry sectors in the reviewed articles.

3.3. Theories used

Although a variety of theoretical frameworks may give rise to strategies for overcoming the challenges of a pandemic ( Craighead et al., 2020 ), the majority of the published studies are not based on any underpinning theory. The analysis reveals that only five articles on COVID-19 and the supply chain are theoretically grounded in this sense. The tenets of the theory of constraint are used in one study to formulate a pandemic management plan ( Baveja et al., 2020 ). Dynamic system theory is used as a methodological principle in another article to design the digital twin necessary for disruption management ( Ivanov and Dolgui, 2020c ). Yet another article ( Ivanov, 2020b ) uses information control and communication theory to explain the relations between resilience and viability. In order to create value for customers, Mollenkopf et al. (2020) used a service-dominant logic paradigm to prepare a supply chain response plan to the current food crisis. The behavioral decision theory is used to understand how organizations behave and make decisions during ambiguous events such as the COVID-19 pandemic ( Gunessee and Subramanian, 2020 ).

On the other hand, several studies suggest conducting research grounded by theoretical lenses. For example, Craighead et al. (2020) urge scholars and managers to use theoretical lenses to better understand the supply chain phenomena in play during a pandemic like COVID-19. Their study discusses how ten well-established and emergent theories, such as (i) the awareness–motivation–capability framework, (ii) event systems theory, (iii) game theory, (iv) institutional theory, (v) prospect theory, (vi) real options theory, (vii) resource dependence theory, (viii) resource orchestration theory, (ix) structural inertia, and (x) tournament theory, can all be used productively in this connection. Another study ( Ketchen and Craighead, 2020 ) further suggests the use of the resource orchestration theory in future research on the COVID-19 pandemic; this could provide valuable insight into how organizational resources could be deployed for enhancing various capabilities, such as online distributions, and how such deployment may affect performance during the disruption. Similarly, Ivanov and Dolgui, 2020b , Queiroz et al., 2020 also urge researchers to conduct studies underpinned by operations research/management theories, such as network theory, complexity theory, graph theory and systems dynamics theory as well as empirical theories such as contingency theory, resource/knowledge-based views, dynamic capabilities models, and information processing theory.

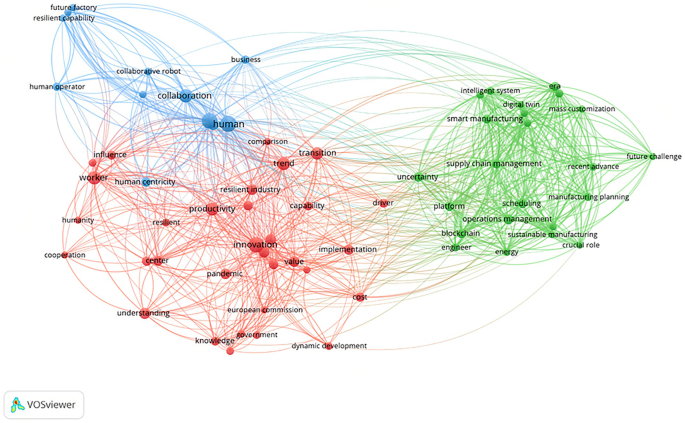

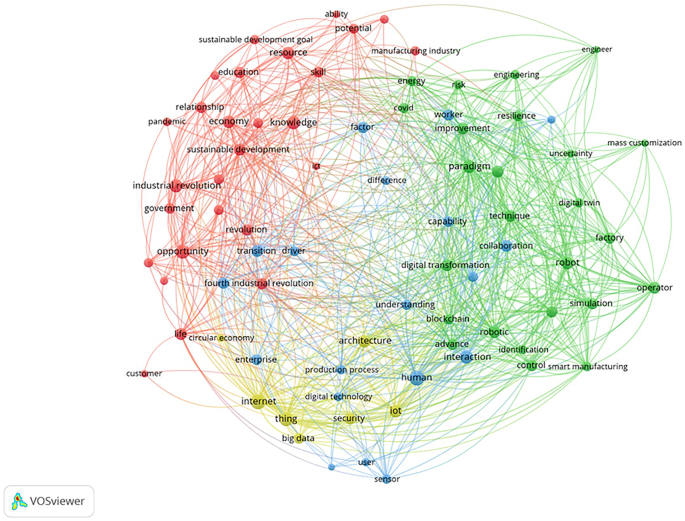

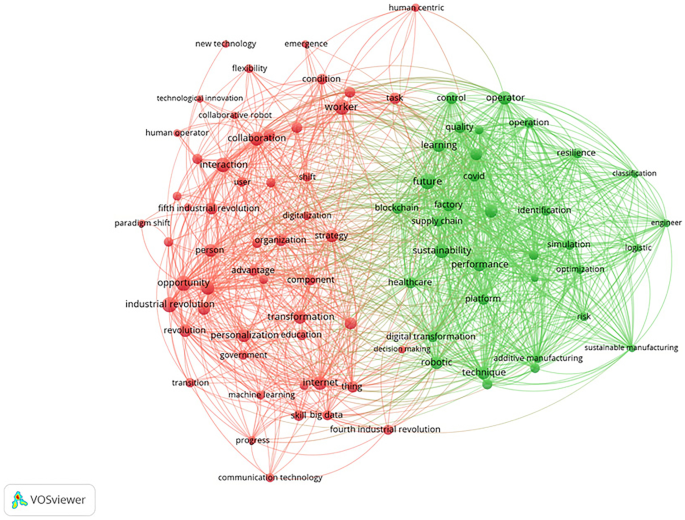

3.4. Main themes in the existing research: A synthesis

Our analysis revealed that these studies focus on four broad areas (see Fig. 4 ). While several articles discuss only one of these four themes, others touch on two or more of the four themes. Among the themes, exploring and reporting the various impacts of COVID-19 on supply chains is the most frequently discussed, appearing in 60 articles. Many of these articles (47) also discuss and report potential resilience strategies to reduce the impacts and to enable affected firms to make a quick recovery. Thirteen (13) of the included articles discuss the role of technology in the implementation of resilient strategies. Finally, 17 of the articles discuss issues of sustainability in light of the COVID-19 pandemic. The following sub-sections summarize each of these four themes.

Themes of the reviewed articles.

3.4.1. Impacts of the COVID-19 pandemic

The majority (60) of the reviewed articles discuss the impacts of COVID-19 on supply chains. The reviewed articles report several impacts of COVID-19 related to various supply chain areas, as outlined in Table 5 .

List of impacts of the COVID-19 pandemic on supply chains.

In the area of demand management, researchers mention demand fluctuation and firms’ ability to manage such changes in demand. COVID-19 has affected the pattern of consumers’ purchasing behavior for both essential and non-essential products ( Hakovirta and Denuwara, 2020 , Mollenkopf et al., 2020 ). The demand for essential products (e.g., food, medicine and ventilators) increased sharply ( Paul and Chowdhury, 2020a , van Hoek, 2020 ), leading to temporary product shortages ( Deaton and Deaton, 2020 , van Barneveld et al., 2020 ). Further, there have been delays in delivering products to customers via online and traditional distribution channels ( Ivanov and Das, 2020 ), causing the loss of security concerning essential items, such as food ( Siche, 2020 ). The reasons for such demand spikes include panic buying, uncertainty about the future, and stockpiling behaviors ( Hobbs, 2020 , Richards and Rickard, 2020 ). One study ( Yuen et al., 2020 ) explored the causes of such panic buying and found that several factors, such as perceived threats, fear of the unknown, the copying of others’ behavior, and other social psychological factors are in play. As a solution, one study ( Zhu and Krikke, 2020 ) suggests that information that may lead to panic buying should not be disseminated to the public. At the same time, non-essential products have seen downward demand, because the income of customers has declined and they prefer to save money for an uncertain future ( Abhishek et al., 2020 , Chiaramonti and Maniatis, 2020 ). More generally, many industries, including aerospace, tourism, oil, gas, and apparel, are bearing the brunt of this extraordinary crisis ( Majumdar et al., 2020 ). The sudden fluctuation in demand creates ambiguity and uncertainty for supply chains, affecting both forecasting and decision-making ( Gunessee and Subramanian, 2020 ). Moreover, this also affects the price of the products. While the price of the essential products has increased ( Farias and Araújo, 2020 ), the price of non-essential products has declined.

In the area of supply management, governments have imposed full or partial lockdowns around the world, restricting vehicle movements to control the spread of the virus; such measures have substantially affected suppliers’ ability to deliver products on time to customers ( Ivanov and Das, 2020 ). In the modern globalized world, companies are sourcing materials from all parts of the globe. Even if the direct suppliers of a company are from the domestic market, its tier 2 or tier 3 suppliers are likely to be located overseas. As a result, the sudden closure of international suppliers’ operations, in line with local restrictions created by lockdowns, have caused supply disruptions for manufacturers.

In the production management area, suppliers' failures create severe production disruptions and backlog for companies ( Richards and Rickard, 2020 ). Moreover, the production capacity of the companies has been reduced due to several policy decisions, such as reduced office hours and having employees work on alternative days to maintain social distancing in the office ( Leite et al., 2020 ). Because of these social distancing and safety measures, employees have been unable to work full time, causing a workforce shortage ( Trautrims et al., 2020 ). Moreover, limited operations in the factory also resulted in the obsolescence and impairment of machinery and capital assets ( Dente and Hashimoto, 2020 ).

In the areas of transportation and logistics management, different modes of transportation, including ocean shipping, air freight, trucking, and rail, have all been disrupted because of the restriction in vehicle movement ( Gray, 2020 ). These transportation disruptions have created delays and negatively affected the smooth flow of products ( Chiaramonti and Maniatis, 2020 ), while also disrupting international trade ( Deaton and Deaton, 2020 ). Distribution and logistics patterns are shifting rapidly. While for many years physical channels were the main distribution mode, the pandemic has forced many companies to shift their business fully online, or to undertake a blended online-offline model. Moreover, physical distribution channels are either closed or have limited operations due to the restrictions ( Dente and Hashimoto, 2020 ). Despite the efforts of companies to increase their capacity in the area of online sales, the loss or limited operations of physical channels has caused huge negative impacts on the flow of supply chains. Moreover, the sudden surge in online sales also outstripping the ability of the supply chains to cope. For example, while some retailers have developed ‘dark-warehouses’—a distribution center designed to serve online customers exclusively—others are struggling to quickly implement logistical solutions to meet the new demand ( Mollenkopf et al., 2020 ).

The COVID-19 pandemic has also impacted supply chain relationship management. The limited scope of social interactions among supply chain partners is reported in one study ( Baveja et al., 2020 ). This decline in interactions causes information incompleteness, which can lead to information ambiguity and a lack of clarity and precision ( Gunessee and Subramanian, 2020 ). Moreover, this has reduced supplier engagement, making it harder for companies to develop a collaborative approach by integrating all the parties involved ( van Hoek, 2020 ). Opportunistic behaviors might also increase, as Gupta et al. (2020) noted, and non-disrupted suppliers may charge higher prices if they see that other suppliers have been affected by disruptions.

Several of the impacts described in the studies are not related to a particular area of the supply chain, but rather linked to the entire supply chain management area. The activities in a supply chain are interconnected; hence, disruption in one of the functions leads to a ripple effect encompassing other functions ( Gunessee and Subramanian, 2020 , Ivanov and Dolgui, 2020b ). This finding suggests that overall operations are disrupted when one segment does not function properly ( Queiroz et al., 2020 ). The combination of these effects on demand, supply, production, transportation, logistics, and relationships can cause the total collapse of supply chains ( Yuen et al., 2020 ). Moreover, supply chain partners, including manufacturers and their suppliers and distributors, may keep their facility centers closed or limit their operations, in line with government policies and guidelines ( Quayson et al., 2020 ).

In the performance or financial management area, reductions in supply chains’ financial performance ( Ivanov and Das, 2020 ) and overall cash inflow ( Hakovirta and Denuwara, 2020 ) are reported in the reviewed articles. Two studies ( Guan et al., 2020 , Ivanov, 2020a ) also investigate how these losses increase or decrease based on other factors, such as restriction measures and their duration. The findings suggest that the extent of financial losses largely depends on the number of countries placing the lockdown or restriction measures into effect, and the duration of such measures rather than their strictness ( Guan et al., 2020 ). The extent of losses also depends on the timing of facilities’ closing and reopening at the different levels of a supply chain ( Ivanov, 2020a ). As a result of such performance reductions, the overall global gross domestic product is expected to decrease by 12.6 percent in 2020, which may rise to 26.8 percent because of the global lockdown ( Guan et al., 2020 ).

The final set of impacts reported in the articles is related to sustainability management. In general, researchers found that the sustainability focus (both social and environmental) has been negatively affected, as companies struggle to survive ( Sharma et al., 2020a ). Likewise, creating a healthy and safe working environment has been given less priority since the pandemic began ( Trautrims et al., 2020 ). Companies are also less committed to developing green and low-carbon energy ( Hosseini, 2020 ). Furthermore, because of the transportation delays and demand variations, businesses dealing with food or other perishables are often left with large amounts of unsellable products and waste ( Dente and Hashimoto, 2020 , Trautrims et al., 2020 ). Moreover, transportation and labor crises would significantly increase recyclable materials and products. For example, Rahman et al. (2021) suggest that in the ship-breaking industry alone, there are expected to be around 300 million gross tonnages of recyclable material generated in the next five years, which would cost around $20 billion if they are not recycled.

In addition to citing these impacts, many of the studies that we reviewed agreed these impacts are likely to be long-lasting ( Ivanov, 2020b , Ivanov, 2020a , Ivanov and Das, 2020 , Veselovská, 2020 ). As such, Gunessee and Subramanian (2020) report that COVID-19 affects almost all existing supply chain decisions and suggests developing better strategies for resilience.

3.4.2. Resilience strategies

In the pre-COVID-19 era, in studies about supply chain resilience strategies, if researchers considered issues related to an epidemic or pandemic, they focused on a specific disruption scenario such as one involving supplier selection ( Golan et al., 2020 ). However, these studies remained silent about the “unknown unknowns” of a pandemic like the current COVID-19 crisis, neglecting to consider, for example, how the effects of a disrupted node might be propagated throughout the supply chain. As a result, supply chains are not as resilient as they should be. In response to the current vulnerability, several studies (47) suggested various strategies for minimizing the impacts of COVID-19, recovering from the current pandemic, and preparing for future pandemics. By closely reviewing the arguments presented in these articles, we identified the range of strategies that have been proposed. To this end, we focused on three main dimensions of supply chain resilience, namely preparedness, response, and recovery ( Chowdhury and Quaddus, 2016 ). A strategy is considered effective for preparedness if it is preemptive for future disruption readiness; for the response, if it can help members of the supply chain respond quickly to minimize the immediate impacts; and for recovery, if it can help the supply chain return to its original or even a better state ( Chowdhury and Quaddus, 2016 , Ponomarov and Holcomb, 2009 ). Table 6 summarizes the resilience strategies proposed in the articles we reviewed, and indicates which of the three dimensions of supply chain resilience they aim to enhance.

Resilience strategies for managing the impacts of the COVID-19 pandemic.

During the current pandemic, shortages of essential food products and medicines are widely reported. To minimize the impacts of this problem and to ensure the supply of essential products, various strategies have been suggested in the literature. Among them, ramping up production early by taking rapid decisions, to minimize shortfalls, is suggested in various studies ( Lozano-Diez et al., 2020 , Mehrotra et al., 2020 , Veselovská, 2020 ). In this connection, the optimal timing for ramping up production is a critical consideration, and should be determined by analyzing relative costs and benefits ( Mehrotra et al., 2020 ). Further, supply chains can allocate resources from non-priority areas, and re-direct staff from non-critical activities while also hiring students and retired persons to accelerate their response ( Leite et al., 2020 ).

Supply chains may also need to increase their production capacity ( Paul and Chowdhury, 2020a ). Given that pandemic-caused spikes in demand are for the short run, researchers have proposed building temporary capacities by removing non-essential operations, rather than increasing the permanent capacities ( Leite et al., 2020 ), and using distributed manufacturing systems ( Shokrani et al., 2020 ). In general, establishing geographically-dispersed manufacturing facilities with the necessary logistical supports is considered effective as a proactive readiness strategy. At the same time, acknowledging the need to increase production capacities, a number of the studies have suggested strategies for modifying product features, such as their basic quality and size, to serve more customers with existing resources ( Paul and Chowdhury, 2020b ). To improve the responsiveness and diversified needs of the supply chain, some studies proposed redesigning and improving logistics, such as redesigning production facilities and diversifying their locations to accommodate emergency items, especially PPE items ( Rowan and Laffey, 2020 ), and improving transportation routes for this purpose. The implementation of faster delivery modes, such as air transport, has also been recommended ( Deaton and Deaton, 2020 ). Generally, the demand for services from the various entities involved in the supply chain will peak at different points; hence, resource sharing among these entities has been proposed, as a strategy for minimizing the impacts and recovering from this extraordinary disruption ( Mehrotra et al., 2020 ).

It is neither practical nor possible to increase production if there is a shortage of raw materials. In their study, Paul and Chowdhury (2020a) reported that an Australian hand sanitizer company had to stop the production process due to a lack of raw materials. As a response to such issues, several studies suggested strategies for increasing upstream resilience. For example, Ivanov & Dolgui (2020a) proposed enhancing visibility by mapping supply networks, to predict potential disruptions and their consequences. This mapping can be useful for formulating node/supplier-specific strategies. Another recommendation is for supply chains to diversify suppliers across different locations, to avoid production breakdowns while a given location is under lockdown ( van Hoek, 2020 ). Moreover, the use of emergency sourcing at times of crisis has been suggested as a strategy for responding to and recovering from the impacts of the COVID-19 outbreak ( Paul and Chowdhury, 2020b ).

Strategies related to logistics and supply chain restructuring, including location and size, have been proposed both as a way of minimizing current impacts and as a way of ensuring a more resilient supply chain in the post-COVID-19 era. Several studies ( Cappelli and Cini, 2020 , Deaton and Deaton, 2020 , van Hoek, 2020 ) have suggested nearshoring or back shoring production facilities to increase domestic capabilities for dealing with the COVID-19 pandemic. In the pre-COVID-19 era, many firms adopted the offshoring strategy and set up production plants with necessary logistic supports in developing countries to minimize production costs. However, COVID-19 shows that during a pandemic it is harder to transport products from various locations. Therefore, even if companies decide to outsource products from overseas, they will still need to strike a balance between domestic production and international trade to reduce vulnerability ( Deaton and Deaton, 2020 ). Designing short supply chains by reducing the number of partners can also be effective in accelerating recovery and preparing for the next disruption ( Farias and Araújo, 2020 ). Other studies suggested improving IT capability in supply chains. The popularity and requirements of mobile services have increased substantially, with consumers now preferring to receive services at their doorstep ( Choi, 2020a , Richards and Rickard, 2020 ). Hence, firms should now use home delivery, online sales, and mobile services; and by the same token, digitalization and the use of information technology are required to monitor the supply chain and to reduce the impacts of disruption ( Ibn-Mohammed et al., 2021 , van Hoek, 2020 ). Several disruptive technologies such as cloud computing, 3-D printing, Internet of Things (IoT), artificial intelligence (AI), and big data analytics are suggested in this regard. Further, with the current social distancing measures, only a limited number of employees can work in the factory. To boost the production capacity despite limited staff, researchers have suggested automating the production system such that it can function with less human intervention ( Ivanov and Das, 2020 ). Moreover, in line with the safety measures, it is recommended that companies develop and implement contactless payment systems, especially at the retail store level ( Mollenkopf et al., 2020 ). Likewise, to deal with the shortage of capital for purposes of restructuring the supply chain and digitalization, Deaton and Deaton (2020) proposed easing capital flow.

Along with implementing restructuring strategies, supply chains need to develop new supply chain partnerships to smooth the flow of products and services ( Veselovská, 2020 ). For example, while a company re-shores its production facility, it may need to find and build partnerships with new suppliers to ensure locational proximity. Improved supply chain relationships and collaborations can also safeguard companies from negative impacts, allowing for quick recovery as well as preparation for future events ( Hobbs, 2020 , Paul and Chowdhury, 2020a , Sharma et al., 2020a ). Being connected drives supply chain partners to meet the requirements of each other; they can thereby reduce the impacts of disruptions. Knowledge management via sharing important information, ideas, and expertise ( Jabbour et al., 2020 ), as well as synchronization of strategic processes ( Sharma et al., 2020a ), are also reported as helpful in dealing with the impacts of COVID-19. Such information and knowledge exchange can reduce information ambiguity, which is a significant problem for businesses during a pandemic or any other major disruption ( Gunessee and Subramanian, 2020 ). The integration of shops and warehouses at various levels—such as central, state and district-level warehouses—is also necessary for maintaining responsiveness to and meeting demand during a pandemic ( Singh et al., 2020 ). Focusing on the example of toilet paper, one study ( Paul and Chowdhury, 2020b ) suggested horizontal collaboration among similar types of producers at a national level to ensure the supply of necessary products during this crisis ( Paul and Chowdhury, 2020b , Paul and Chowdhury, 2020b ). Along with steps taken to bolster relationships, a focus on strengthening contracts is also helpful, to prevent supply chain partners from engaging in opportunistic behaviors in the future ( Gupta et al., 2020 ).

While developing resilience strategies, supply chains need to ensure real-time flexibility, or dynamic responses ( Hobbs, 2020 , Ivanov and Dolgui, 2020c ). Proactive and flexible strategies can help make supply chains less sensitive to external disruptions ( Ivanov and Das, 2020 ). Focusing specifically on low-demand items, Chiaramonti and Maniatis (2020) urged firms to reduce the price of products, this being a common economic strategy for managing demand reduction. Several strategies for increasing sustainable practices have also been suggested, given the importance of sustainability for supply chain resilience. For example, the implementation of all appropriate safety measures for the workforce can reduce the probability of the spread of COVID-19 and help ensure the continuity of production/operations ( Rizou et al., 2020 ). Moreover, the cancellation of unauthorized subcontractors ( Majumdar et al., 2020 ), the production of renewable and bio-based energy ( Chiaramonti and Maniatis, 2020 ) and the development of automated waste treatment processes ( Sharma et al., 2020b ) are suggested for the post-COVID-19 era. At the same time, several studies ( Choi, 2020a , Kumar et al., 2020 , Majumdar et al., 2020 ) recognized the need for support from stakeholders such as non-government organizations (NGOs) and the government to help organizations handle the impacts of the COVID-19 pandemic; hence, researchers have called for support and subsidy schemes.

In short, developing and implementing a holistic, resilient response plan, which integrates multiple strategies, is crucial—as emphasized in a number of the studies we reviewed ( Baveja et al., 2020 , Ivanov, 2020b , Jabbour et al., 2020 , Leite et al., 2020 ). In the post-COVID-19 era, a viable supply chain, which is simultaneously agile, resilient, and sustainable, is essential, not just to recover from the current crisis but also to prepare well for the next pandemic or other major disruption ( Ivanov, 2020b ).

3.4.3. The role of technology in implementing resilience strategies

Researchers have suggested using a number of technologies, such as digital twins, industry 4.0, 3-D printing technology, artificial intelligence and mobile service operation, for managing supply chains during and after COVID-19 pandemic. Thirteen (13) of the papers we reviewed discussed the use of technology in implementing resilience strategies. They focused on low-tech solutions to the problem of obtaining sufficient quantities of medical equipment in healthcare supply chains ( Armani et al., 2020 ); applications of digital supply chains and industry 4.0 ( Deshmukh and Haleem, 2020 , Ivanov and Dolgui, 2020c , Kumar et al., 2020 , Okorie et al., 2020 , Quayson et al., 2020 ); the use of additive manufacturing methods, such as 3-D printing technology, to meet the extra demand for ventilators and personal protective equipment (PPE) ( Iyengar et al., 2020 , Larrañeta et al., 2020 , Novak and Loy, 2020 ); the use of mobile service operations to bring service directly into people’s homes ( Choi, 2020a ); the use of a drone or hybrid truck-drone for ensuring on-time and contactless delivery ( Quayson et al., 2020 , Singh et al., 2020 ); and the use of artificial intelligence for developing sustainable business models ( Vaio et al., 2020 ). Several studies also suggested that modern and emergent technologies may be helpful for managing the impacts of COVID-19, both during and after the pandemic ( Gurbuz and Ozkan, 2020 , Okorie et al., 2020 ).

With the supply chains for medical products such as PPE and ventilators being especially critical during the COVID-19 pandemic, researchers have suggested the use of 3-D printing technology, one of the concepts of additive manufacturing, to manufacture products for medical/healthcare supply chains ( Iyengar et al., 2020 , Larrañeta et al., 2020 , Novak and Loy, 2020 ). These studies have argued that the use of such technology can help the medical/healthcare supply chains most, given the surge of demand for PPE, ventilators, and other medical equipment during the pandemic. 3-D printing techniques, among other technologies, can help companies design and manufacture those products quickly.

3.4.4. The COVID-19 pandemic and supply chain sustainability

During the COVID-19 pandemic, sustainability practices have been substantially affected. Seventeen (17) of the studies that we reviewed discussed several issues under different dimensions of sustainability. Several of these studies considered environmental and social sustainability along with economic dimensions, including job loss, health and safety issues, the problem of domestic violence, social and health inequality ( Hakovirta and Denuwara, 2020 , Ibn-Mohammed et al., 2021 , Sharma et al., 2020a , Sharma et al., 2020b , van Barneveld et al., 2020 ), the pandemic’s impact on the labor market ( van Barneveld et al., 2020 ), modern slavery risk ( Trautrims et al., 2020 ), the dominant power of a few select brands, ethical violations by organizations ( Majumdar et al., 2020 ), compliance with labor laws and social standards ( Sharma et al., 2020c ), and the broader social cost of the pandemic ( Jabbour et al., 2020 , Queiroz et al., 2020 ).

Several other studies considered issues of environmental sustainability vis-à-vis the current pandemic. These include reversal of the progress that has been made toward embracing green and low-carbon methods of energy generation ( Hosseini, 2020 ); the environmental impact of the life cycle of pharmaceutical products, which has increased during pandemic progress ( Yu et al., 2020 ); the pandemic’s impacts on waste flows, resource use and air pollution ( Dente and Hashimoto, 2020 , Sharma et al., 2020c ); the implementation of environmental sustainability policies ( Amankwah-Amoah, 2020a ); the recyclability of end-of-life products ( Rahman et al., 2021 ); and the increase in medical, plastic, and food waste ( Sharma et al., 2020b ) . Other researchers have suggested that the COVID-19 pandemic will have both positive and negative impacts on environmental sustainability, since both companies and the general population are expected to be more committed to sustainability in the post-COVID-19 era ( Dente and Hashimoto, 2020 , Sarkis et al., 2020 ). The positive environmental impacts include better air quality, low carbon dioxide and greenhouse gas emissions, a decline in energy use, and a decrease in environmental pollution ( Dente and Hashimoto, 2020 , Ibn-Mohammed et al., 2021 , Sarkis et al., 2020 , van Barneveld et al., 2020 ). Table 7 indicates how the studies we reviewed have considered different dimensions and issues of supply chain sustainability in the light of the COVID-19 pandemic.

Dimensions and issues of sustainability vis-à-vis the COVID-19 pandemic.

4. Review on prior epidemic outbreaks and disruptions in supply chain disciplines

In this section, we reviewed the articles related to prior epidemic outbreaks and other disruptions in supply chain disciplines, and explored how they might provide unique research opportunities.

4.1. Research on prior epidemic outbreaks

A recent review article ( Queiroz et al., 2020 ) synthesizes the impacts of epidemics—including the COVID-19 pandemic—on logistics and supply chains by reviewing 32 articles. To make our review more streamlined and holistic, we also looked at existing studies on epidemic outbreaks in supply chain disciplines to analyze their main contributions and findings, as well as methodology, industry and country context, and theories used. To find articles, we searched Scopus using the keywords ‘epidemics’ and ‘supply chain management’. Then we read the title, abstract, and full text to select the articles relevant to supply chain disruptions during epidemic outbreaks. Finally, we shortlisted 25 relevant articles, discussing their main finding below and presenting a summary of each article in Table C1 in Appendix C ( supplementary material ).

The majority of the articles (24 out of 25) focused on the different aspects of supply chain resiliency as strategies for managing disruptions. These articles broadly focus on two major areas: (1) allocating resources to increase supply chain capabilities during large-scale disruptions; and (2) redesigning logistics and supply chain networks to reduce vulnerability. In the first area, articles have highlighted resource shortages as a major obstacle during an epidemic ( Enayati and Özaltın, 2020 , Liu et al., 2020 , Parvin et al., 2018 , Rachaniotis et al., 2012 , Savachkin and Uribe, 2012 , Sun et al., 2014 ). Consequently, these studies offered various strategies for allocating minimal or further resources, such as controlling transportation costs and equitable policies ( Savachkin and Uribe, 2012 ); undertaking threshold policy for inventory balancing; optimal area-based trans -shipment policy and planning horizon ( Parvin et al., 2018 ); increasing capacity to manage disruptions ( Hessel, 2009 , Sun et al., 2014 ); implementing cost-sharing contracts ( Mamani et al., 2013 ) or coordinating contracts ( Chick et al., 2008 ); and appropriate capacity setting and the minimum budget ( Liu et al., 2020 ). These studies mostly looked at the influenza epidemic, while a few were focused on outbreaks of ebola and malaria ( Büyüktahtakın et al., 2018 ). Most of the studies have healthcare and pharmaceutical supply chain as their context.

In the area of redesigning logistics and supply chain networks, several articles studied methods for optimizing such networks. These studies suggested several strategies which include reconfiguration of facility location for food distribution ( Ekici et al., 2014 ); designing/redesigning a distribution and logistics network for minimizing the total cost of vaccine supply, when considering the demand backlogs, vaccine shortage, and losses due to an Influenza outbreak ( Hovav and Herbon, 2017 , Orenstein and Schaffner, 2008 ); building isolated areas for animal slaughtering and establishing centrally controlled slaughterhouse facilities ( Khokhar et al., 2015 ); and the use of dynamic logistics concepts for distribution network design, especially for medical products and resources ( Liu and Zhang, 2016 ). One of the studies also suggested the use of flow-down of products to the lowest level in the network, and the permitting of sufficient warm-up to avoid the end of horizon effects for vaccine distribution, to prepare for the potential impacts of an epidemic, (e.g. vaccine shortages, transportation delays, and product losses during distribution, storage, and/or transportation) ( Chen et al., 2014 ). Although not focused on commercial supply chains, Dasaklis et al. (2012) confirmed the importance of logistics operations and their efficient management for handling epidemic disruptions such as polio, smallpox, cholera, and HIV.

Other articles that suggested resilience strategies mainly focused on mitigating the immediate effects of the epidemic. Given that majority of the reviewed articles (16 out of 25) focused on pharmaceutical supply chains, a shortage in product supply was a common obstacle. As a result, these studies highlighted a few strategies to increase immediate product supply. These strategies include the use of emergency sourcing from unaffected parts of the world ( Anparasan and Lejeune, 2018 , Dasaklis et al., 2012 ); use of emergency operations and logistics such as new transportation modes ( Huff et al., 2015 ); use of backup suppliers and contract agreement ( Shamsi et al., 2018 ); outsourcing drugs from third parties to improve access, as well as the use of improved ordering policy, lead time, safety stock and replenishment policy ( Dasaklis et al., 2012 , Paul and Venkateswaran, 2020 ); and use of piggybacking, enabling satellite drug storage facilities, and removing barriers to local and regional trade ( Min, 2012 ). Studies also considered collaborative strategies, such as the design of coordination mechanisms among stakeholders to manage financial losses and increase product availability ( Anparasan and Lejeune, 2018 , Mohan et al., 2009 ), and the use of coordinated supply chains to manage logistics systems more efficiently ( Majić et al., 2009 ). One study suggested training to ensure that staff are capable of handling the immediate impacts of epidemic disruptions and are better equipped to deal with critical infrastructure ( Huff et al., 2015 ).

Several papers discussed the impacts of an epidemic on supply chains; however, we found only one article that mainly focused on the impacts of an influenza outbreak using a literature review-based case study ( Alders et al., 2014 ): it was focused on village poultry production, and listed several impacts of the influenza outbreak, such as adverse effect on employees and increased food insecurity. Several other impacts that were covered in other studies include the shortage of medical items, delays in transportation and distribution, unavailability of skilled manpower, demand backlogs, resource shortage, disruption in the logistics system, market and economic losses, and supply disruptions.

We observed that sixteen articles developed mathematical models. The mathematical models include linear or non-linear programming, integer or mixed-integer programming, game-theoretic modeling, and stochastic programming. Among other articles, four are conceptual studies, two are reviews, and one each used survey, secondary data analysis, and system dynamic model. Concerning the contexts of these studies, diverse national contexts were considered. However, the majority of the articles considered pharmaceutical/medicinal supply chains. We also noticed that among the twenty-five articles, only one study considered SMEs ( Khokhar et al., 2015 ), and no study used theories for conceptualizing or investigating the problems. Table C1 in Appendix C ( supplementary material ) presents details about the relevant epidemic outbreaks, findings, methodology, context, and theories used.

5. Research on supply chain disruptions

Research on disruption management has received increased attention in the recent past ( Bier et al., 2020 ). With the increase in the numbers of available articles, several studies have also rigorously or systematically reviewed the published literature in this area and summarized the current knowledge. To avoid repetition while comprehensively reporting the state of the literature, we carefully identified and thoroughly reviewed 15 review articles that rigorously synthesize and report the findings of studies published until 2019 (presented in Table D1 in Appendix D under supplementary material ). To ensure rigor and comprehensiveness, we also searched Scopus for articles published since 2020 using the keyword ‘supply chain disruption’, and found and reviewed another 26 articles (presented in Table D2 in Appendix D under supplementary material ). The main observations of the review are described as follows.

Several studies investigated the potential types of disruptions in a supply chain, and ranked them in order to understand which disruptions could be the most critical ( Fan and Stevenson, 2018 , Fartaj et al., 2020 , Ho et al., 2015 ). These studies detailed how various types of disruptions may occur, such as natural disruptions including earthquakes, floods, cyclones, and extreme weather; man-made and discrete events including disease, labor strikes, port/traffic congestion, theft, and fire; system failure including machine or technology breakdown, utility failure, and obsolescence; and financial disruptions including fluctuation of exchange rates and bank interests, and import/export restrictions. While such a wide variety of disruptions have been identified, the literature also suggests that such disruptions are difficult for a supply chain to predict given that they occur suddenly. As such, a recent study suggested adding agility to the data in predicting supply chain disruptions ( Brintrup et al., 2020 ).

Assessments of disruptions show that the relative criticality of disruption depends on the context (both industry and country); because of this, different studies produced different rankings. For example, two recent studies looked at the transportation disruptions of two industries in Bangladesh: one pharmaceutical ( Paul et al., 2020 ) and the other automotive ( Fartaj et al., 2020 ). Several disruption assessment tools have been developed to support practitioners ( Snyder et al., 2016 ), as it has been found they tend to underestimate disruptions if proper assessment tools are not available ( Tang, 2006 ). While several studies assessing the disruption factors can be found in various contexts, these studies mostly identified or assessed disruption factors for a particular area/activity in a supply chain such as supply, demand, production, or transportation ( Fartaj et al., 2020 ). However, thus far, research identifying or investigating supply chain network-wide disruptions (i.e., assessing all disruptions simultaneously across various areas in a supply chain) is limited ( Baryannis et al., 2019 , Greening and Rutherford, 2011 ). For example, a recent review ( Duong and Chong, 2020 ) reported that 64.9 percent of studies reviewed consider either supply disruptions or demand disruptions.

Several studies investigated and reported the impacts of supply chain disruptions ( Ivanov et al., 2017 ), since Hendricks and Singhal (2003) confirmed a decrease in shareholder value, Hendricks and Singhal (2005a) reported a decrease in stockholder return, and Hendricks and Singhal (2005b) reported a decline in operating income, return on asset, and return on sales due to supply chain disruptions. These studies have confirmed the negative impacts of supply chain disruptions on several financial and non-financial performance indicators including, but not limited to, financial performance, supply chain performance, productivity, brand value, and reputation ( Bier et al., 2020 , Duong and Chong, 2020 , Greening and Rutherford, 2011 , Paul et al., 2016 ). However, the impacts of disruptions on supply chains differ based on differences in the network structures such as density, centrality, network tie, and structural holes ( Greening and Rutherford, 2011 ). Moreover, disruptions cause structural dynamics leading to a ripple effect in the supply chain ( Bier et al., 2020 , Duong and Chong, 2020 , Ivanov et al., 2017 , Xu et al., 2020b ). This ripple effect intensified with the complexity of supply chains ( Birkie and Trucco, 2020 ). Given that majority of the studies in this area investigated disruptions in each area/function of a supply chain in isolation, it is still not clear how disruptions in one area are propagated to another in a supply chain ( Ho et al., 2015 , Snyder et al., 2016 ). A recent study, comparing the impacts of disruptions in the upstream and downstream part of supply chains, reports that the latter has more impacts on supply chain performance than the former ( Olivares-Aguila and ElMaraghy, 2020 ).

The formulation of appropriate strategies for managing disruptions such as supply, demand, production, and transportation disruptions was the main focus of a vast number of studies ( Albertzeth et al., 2020 , Wu et al., 2020 ). These strategies include supply chain planning for disruptions, response plans for minimizing impacts, and action plans for quick recovery.

As a preparedness plan, various supply chain and logistics network design-oriented strategies such as network redesign ( Fattahi et al., 2020 , Fattahi and Govindan, 2020 , Tolooie et al., 2020 ), optimal network design ( Yan and Ji, 2020 ), supply chain flexibility ( Shekarian et al., 2020 ), and careful selection of facility locations ( Sundarakani et al., 2020 ) are suggested. A recent systematic review article examines various logistics and supply chain network types, such as hub-and-spoke, cross-docking, pick-up and delivery, and hybrid network design and evaluates their effectiveness for disruption management ( Esmizadeh and Parast, 2020 ). While each network has its advantages, the hub-and-spoke network with flexibility (also known as routing flexibility) was more effective for disruption management. The research and development (R&D) investments are also important for identifying and preparing for potential disruptions ( Parast, 2020 ). In particular, upstream supply disruptions formalized processes for supplier selections, lot sizing, and scheduling ( Mohammadi, 2020 ) along with optimum inventory level ( Islam et al., 2020 ). For downstream demand disruptions, demand planning is effective as it can reduce the disruptions in the downstream supply chain via proactive strategies ( Swierczek, 2020 ). Moreover, supply chain coordination is critical for managing demand disruptions ( Zhao et al., 2020 ). To enhance supply chain coordination with the downstream supply chain members, a linear quantity discount contract is more effective than a revenue-sharing contract ( Zhao et al., 2020 ).

Strategies are also developed for reducing impacts and quick recovery when supply chains experience a disruption ( Birkie and Trucco, 2020 ). Four strategies such as collaboration, redundancy, flexibility and agility are the main suggestions for managing disruptions ( Shekarian and Parast, 2020 ). Among these four, various collaboration practices are frequently suggested in the literature and are considered the most appropriate strategy for managing disruptions ( Shekarian and Parast, 2020 , Wu et al., 2020 ). A recent review ( Duong and Chong, 2020 ) identified seven collaboration practices that were used by commercial supply chains for responding and recovering from supply chain disruptions: (i) contractual and economics practices; (ii) joint practices; (iii) relationship management; (iv) technological and information sharing practices; (v) governance practices; (vi) assessment practices; and (vii) supply chain design (integrated operations). The necessity of ensuring visibility in supply chains through gathering, processing, and sharing information among the partners is highlighted in the disruption management literature ( Messina et al., 2020 , Tao et al., 2020 ). Having timely information about second-tier suppliers from immediate suppliers is also important for disruption management ( Yoon et al., 2020 ).

Other redundancy strategies typically considered for disruption management include inventory or capacity buffers, backup suppliers, flexibility strategies such as dual or multiple sourcing, and product and process flexibility ( Albertzeth et al., 2020 , Choi, 2020b , Gaur et al., 2020 , Ivanov et al., 2017 ). While redundancy strategies are suggested more frequently than flexible strategies ( Ivanov et al., 2017 ), the latter is applicable across various types of supply chains ( Gaur et al., 2020 , Tao et al., 2020 ). For example, flexibility in the procurement plan by considering sourcing, pricing, consumption, and delivery pattern is effective for managing the impacts of disruption in cruise ship supply chains ( Rodrigue and Wang, 2020 ). Ensuring agility –the ability to respond rapidly to disruptions by quickly modifying product development cycle time, lead time, and customer services – is also suggested in the literature. In fact, the ability to respond rapidly (agility) is more effective than long-term or fundamental changes (flexibility) in reducing the effect of a disruption ( Shekarian et al., 2020 ). Due to the sudden nature of disruptions, risk acceptance ( Albertzeth et al., 2020 ) and risk transfer such as undertaking insurance are also suggested ( Fan and Stevenson, 2018 ).

With such strategies in place and supply chains’ involvement in business continuity management ( Azadegan et al., 2020b ) and relevant business continuity programs ( Azadegan et al., 2020a ), supply chains can contain the damage of disruptions. However, in formulating the strategies, these studies mostly ignored complexity in supply chain network structures and investigated disruptions and network structure separately; hence, the disruption-structure-interfaces remain unclear ( Bier et al., 2020 ). Similar to disruption identification, assessment, and impact analysis, strategies were developed by considering disruptions in only one area of supply chains ( Duong and Chong, 2020 , Paul et al., 2016 ). As such, firms use different strategies to manage supply, demand, and production during a major disruption ( Tang, 2006 , Tang and Musa, 2011 ). Of the disruptions in various areas of supply chains, demand disruptions received the greatest attention for strategy development ( Shekarian and Parast, 2020 ). This may be because demand disruptions have greater impacts or are more closely linked to revenue than other disruptions ( Olivares-Aguila and ElMaraghy, 2020 ).

One of the common observations in almost all of the literature review articles is that studies on supply chain disruptions predominantly used a quantitative modeling approach ( Baryannis et al., 2019 , Bier et al., 2020 , Duong and Chong, 2020 ). The quantitative modeling approach includes mathematical, simulation, and analytical modeling. Looking at the high amount of research using quantitative modeling or management science models, the main focus of four review articles ( Fahimnia et al., 2015 , Ivanov et al., 2017 , Paul et al., 2016 , Snyder et al., 2016 ) was to synthesize the quantitative models used for managing supply chain disruptions. These studies suggested that there has been rapid development of quantitative modeling for supply chain disruptions and these models are used widely for a variety of purposes such as evaluating disruptions, developing strategic decisions under disruptions, and assessing various disruption management strategies (including recovery strategies). However, these studies mostly considered single disruption, i.e., supply or demand or production or transportation, compared to dual or multiple disruptions when designing recovery models ( Paul et al., 2016 ).

6. Research opportunities

The analysis of the articles reveals abundant opportunities for research on the COVID-19 pandemic in the context of supply chains. While several articles have been published since the COVID-19 pandemic began, studies that are systematic, methodologically sound, and well-grounded in theoretical tenets are still scarce. Based on the thematic synthesis of the articles provided in Section 3 and considering existing literature on prior epidemic outbreaks and other disruptions in supply chain management disciplines, in this section, we suggest some key areas that still need to be investigated. Table 8 highlights key future research questions and opportunities in different areas.

Summary of research questions and opportunities.

6.1. Impact focus

Several studies have discussed, as reported in Section 3.4.1 , the impacts of the COVID-19 pandemic on supply chains. Earlier research on epidemic outbreaks and other disruptions also reported several impacts on the operations in supply chains. However, no study thus far comprehensively explored all the potential short-term, medium-term, and long-term impacts of disruptions, including COVID-19 pandemic or other epidemics, on a particular supply chain (whether a supply chain for a high-demand or a low-demand item) to guide policymakers in this regard. Given that the impacts of a pandemic like COVID-19 are different for different types of products ( Paul and Chowdhury, 2020b ), future studies should explore these impacts by considering various product types. Prior studies on disruptions indicate that the impacts of disruption are likely to vary due to differences in network complexity, such as the number of nodes and edge (ties), network characteristics such as high vs low density and network ties, and structural holes ( Bier et al., 2020 ). Therefore, the impacts of the COVID-19 pandemic should be explored with consideration for the complexity in the network structures. Reviewing the literature on COVID-19 pandemic, epidemics and other disruptions, we observe that there is a lack of articles investigating supply chain network-wide impacts, considering all potential disruptions simultaneously ( Baryannis et al., 2019 , Duong and Chong, 2020 , Greening and Rutherford, 2011 ). As such, the complex relationships between the impacts of the COVID-19 pandemic and how disruptions propagated throughout the supply chain is not yet clear ( Xu et al., 2020b ) and should be investigated. Investigating the relationships between the impacts, such as revealing the cause group and effect group, would also enable understanding of the most critical impacts; this would provide information to aid prioritization of the resilience strategies.

The literature on epidemic outbreaks and COVID-19 pandemic suggest that the sudden spikes in demand and reduction of production capacity are likely to cause a huge bullwhip effect for supply chains ( Ivanov and Dolgui, 2020b ). Hence, we suggest research questions on this issue to better understand these impacts. The research also should be carried out to investigate the impacts on SMEs as the previous studies in this area mostly ignored SMEs. For example, our review of 25 studies on epidemics and 26 studies on other disruptions published in 2020 shows that only one article in each category has considered SMEs along with large firms. Likewise, we found that only four studies thus far have discussed the implications of the COVID-19 pandemic on SMEs. Yet small firms are the companies that have been most substantially impacted by this pandemic ( Quayson et al., 2020 ). Another study ( Ketchen and Craighead, 2020 ) stressed that it is hard to conceptualize the full impacts on SMEs without proper investigation. Hence, further studies are needed to understand the effect of the COVID-19 pandemic on SMEs, which are the most common type of business in the world and the main contributor to economies worldwide ( Chowdhury et al., 2019 ).

6.2. Resilience focus

As noted in Section 3.4.2 , studies have also outlined several resilience strategies designed to deal with the impacts of the COVID-19 pandemic. Some of the resilience strategies we found in Section 3.4.2 are also suggested in previous studies on epidemic outbreaks or other supply chain disruptions. For example, resource allocation, restructuring supply chains, and developing collaboration and relationships are suggested in the research on COVID-19, other epidemics, or supply chain disruptions. This denotes that some of the existing strategies to improve supply chain resilience can be useful during a global crisis like the current pandemic. However, it is also clear that the current COVID-19 pandemic has severely impacted almost all supply chains, highlighting the vulnerability of supply chains and requiring better resilience strategies. Therefore, further investigations are needed to understand the extent and how the strategies provided in previous studies helped supply chains handle issues related to COVID-19 and the best combination of strategies to deal with the impacts of the pandemic. Hence, by considering the findings and strategies suggested in studies on epidemics and other disruptions, we suggest several research questions that need to be explored to develop better resilience strategies for managing the impacts.

We noticed that most articles on disruptions only investigate one strategy in their studies ( Snyder et al., 2016 ). However, a single strategy may not be able to safeguard supply chains from all impacts of a pandemic and ensure a quick recovery. Hence, selecting an optimal combination of strategies that can ensure better resilience is important and should be explored. In this regard, future studies should map impacts using the strategies, i.e., outline which strategy can deal most effectively with which impact. A study of this sort can help policymakers to formulate a recovery plan. Our analysis of the studies on COVID-19 revealed that most of the studies focus on high-demand essential and medical products, as reported in Section 3.3.2. A similar observation is also noted from the review of studies on prior epidemic outbreaks, as discussed in Section 4.1 . Low-demand items, such as textiles, oil, and automobiles, are bearing the brunt of this pandemic as sales of these products—and thus cash inflow and profit—have decreased substantially ( Majumdar et al., 2020 ). Given that customized strategies are needed by firms in various industries ( Ishida, 2020 ), future studies exploring how supply chains for these low-demand items can survive during this pandemic, and recover in the post-COVID-19 era, are needed. As complexity-disruption-interfaces are not explored in the previous studies, we also suggest considering this in future studies on designing resilience strategies.