Resume Worded | Proven Resume Examples

- Resume Examples

- Engineering Resumes

7 Quality Engineer Resume Examples - Here's What Works In 2024

As technology pervades every area of life, quality engineers are necessary, in high demand, and with the right education, experience, and skills, you can quickly move up. this guide will cover how to compile your quality engineer resume, with templates and examples that you can replicate yourself, as well as needed skills in the industry..

Quality Engineers work to ensure that the quality of a product lacks defects or problems. This could include devising tests, working closely with suppliers or other staff and creating documentation. While Quality Engineers typically work within manufacturing or production, a Quality Assurance (QA) Engineer is slightly different and works within software and technology to test websites or apps for bugs. As a Quality Engineer, you might take a linear path from Quality Engineer to Senior Quality Engineer. Or, you could pursue other higher level roles such as, Senior R&D Quality Engineer, Principal Supplier Quality Engineer, Quality Systems Engineer, or Senior Manufacturing Quality Engineer. Because Quality Engineering is a highly technical field, it is important to have at least a Bachelor’s degree in either industrial, production, mechanical engineering, or lab/science. However, if you don’t have a degree now, it’s possible to start as a technician or production operator, and then go back to school and eventually become a Quality Engineer. Ideally, you will need strong analytical, critical thinking, team working, and communication skills.

Quality Engineer Resume Templates

Jump to a template:

- Quality Engineer

- QA (Quality Assurance) Engineer

- Senior Quality Engineer

- Supplier Quality Engineer

Jump to a resource:

- Keywords for Quality Engineer Resumes

Quality Engineer Resume Tips

- Action Verbs to Use

- Bullet Points on Quality Engineer Resumes

- Related Engineering Resumes

Get advice on each section of your resume:

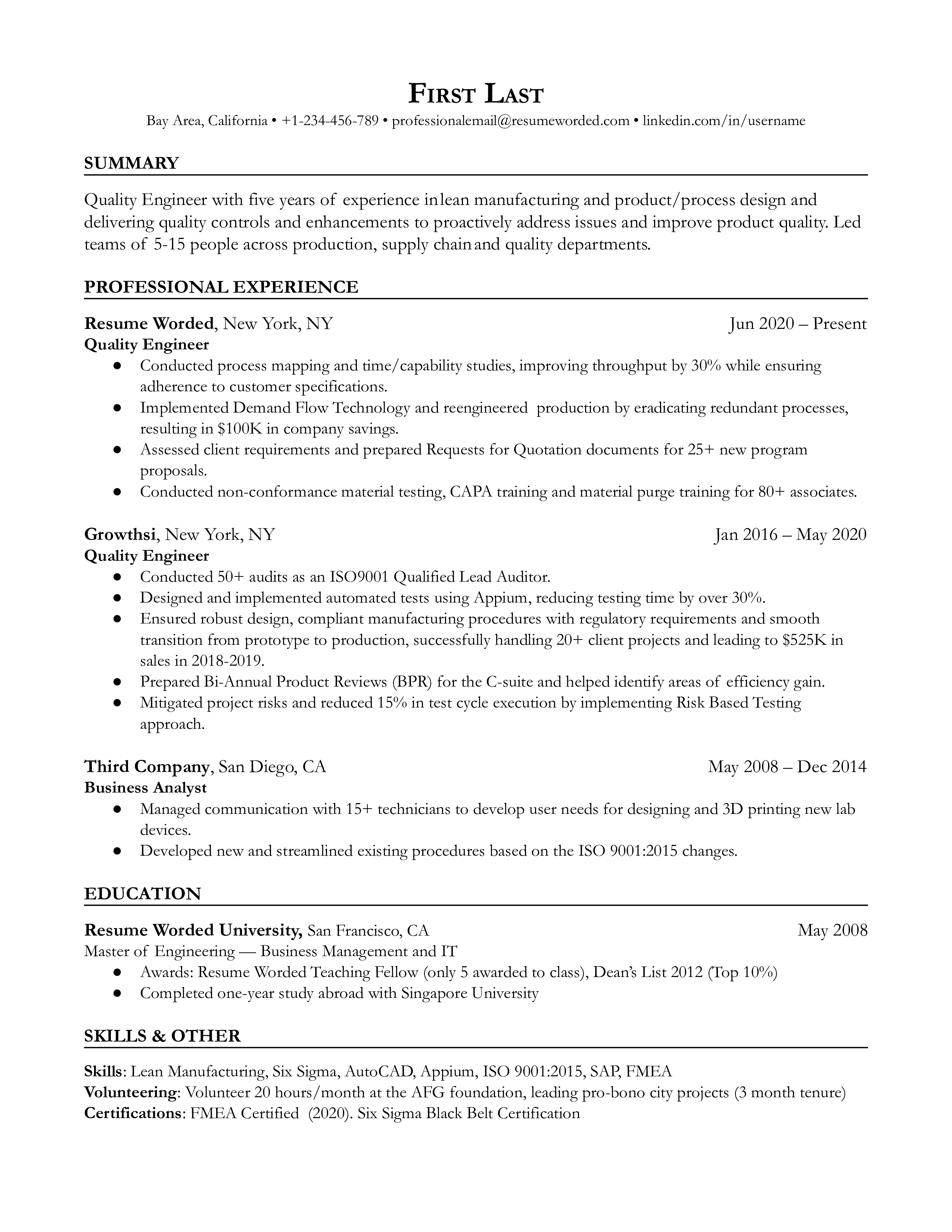

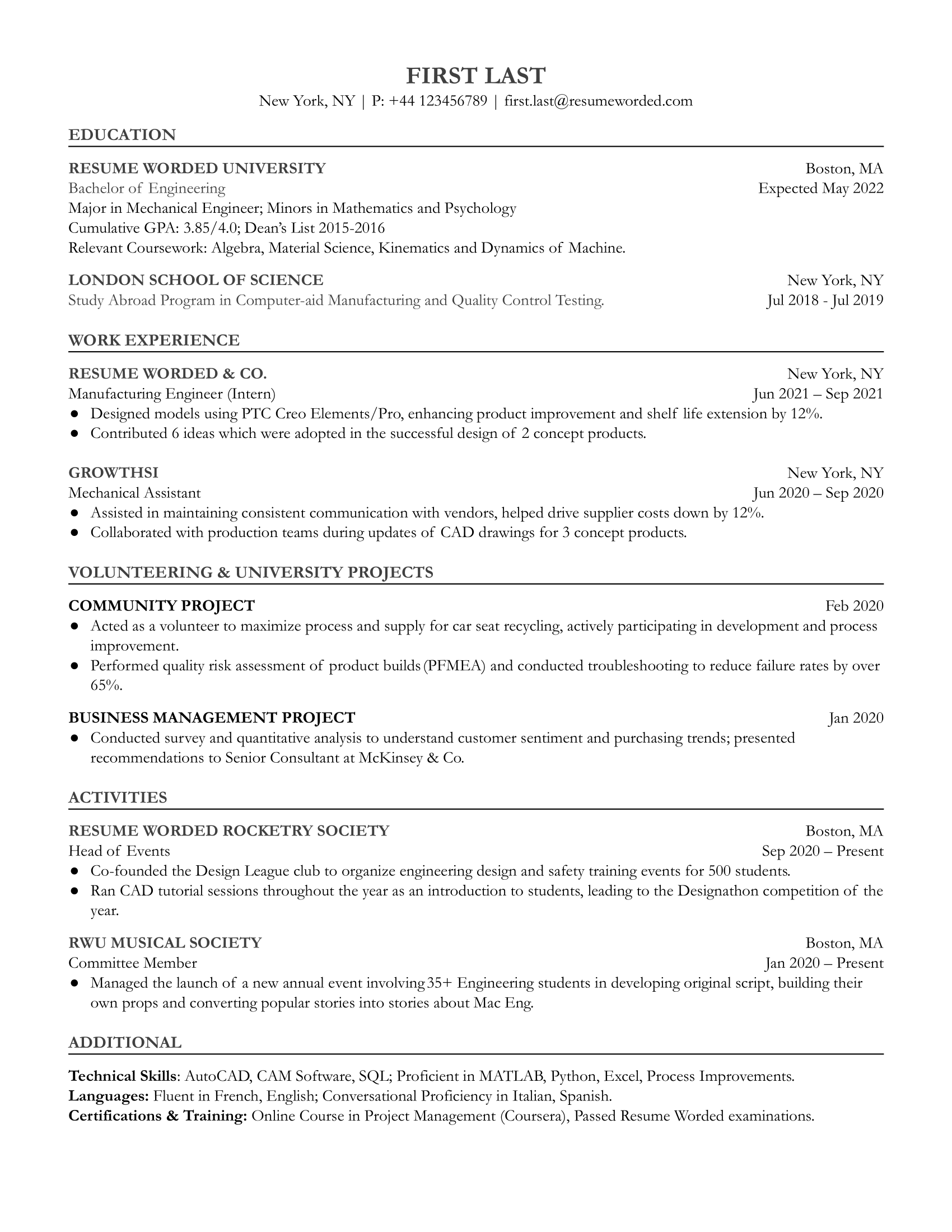

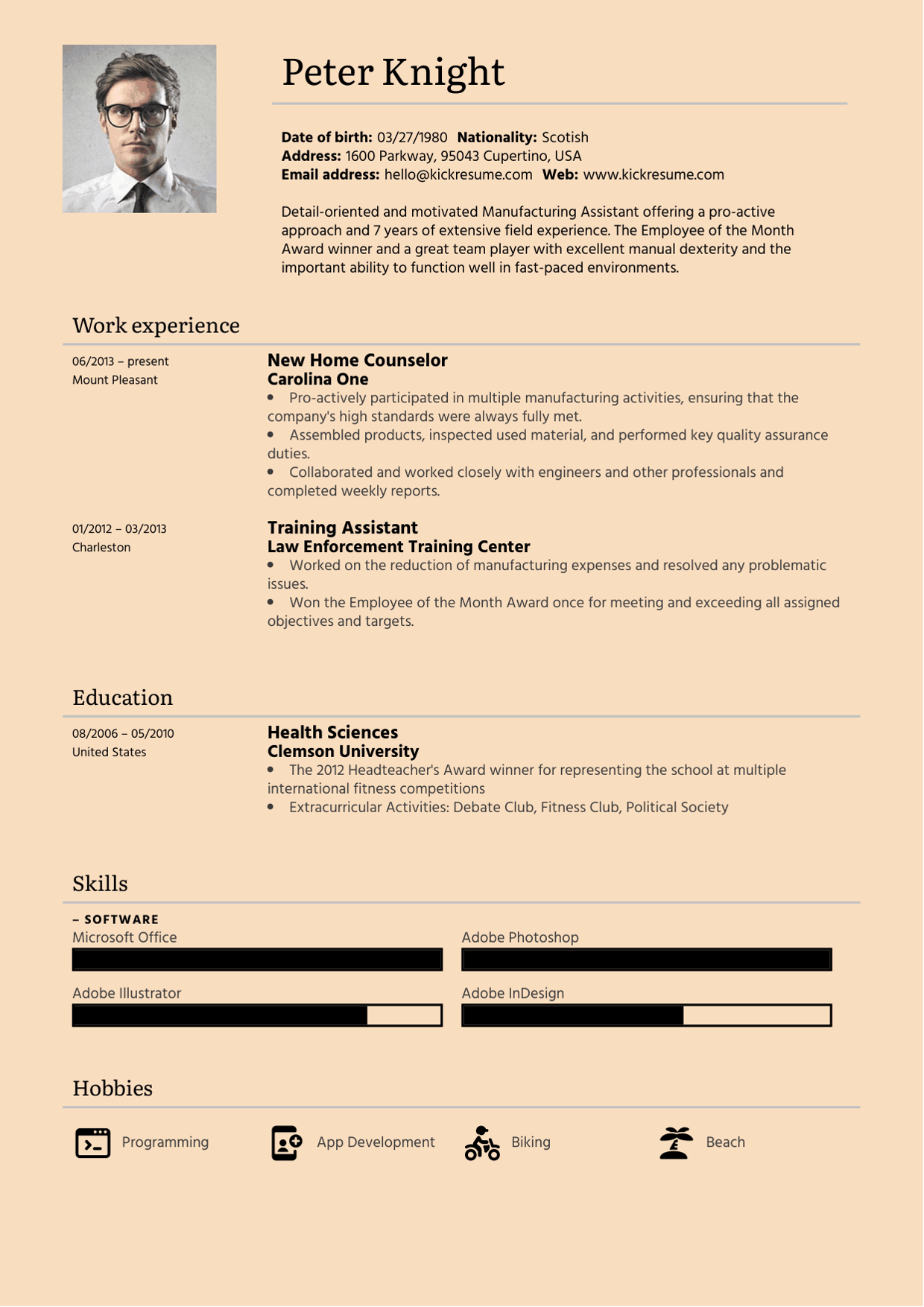

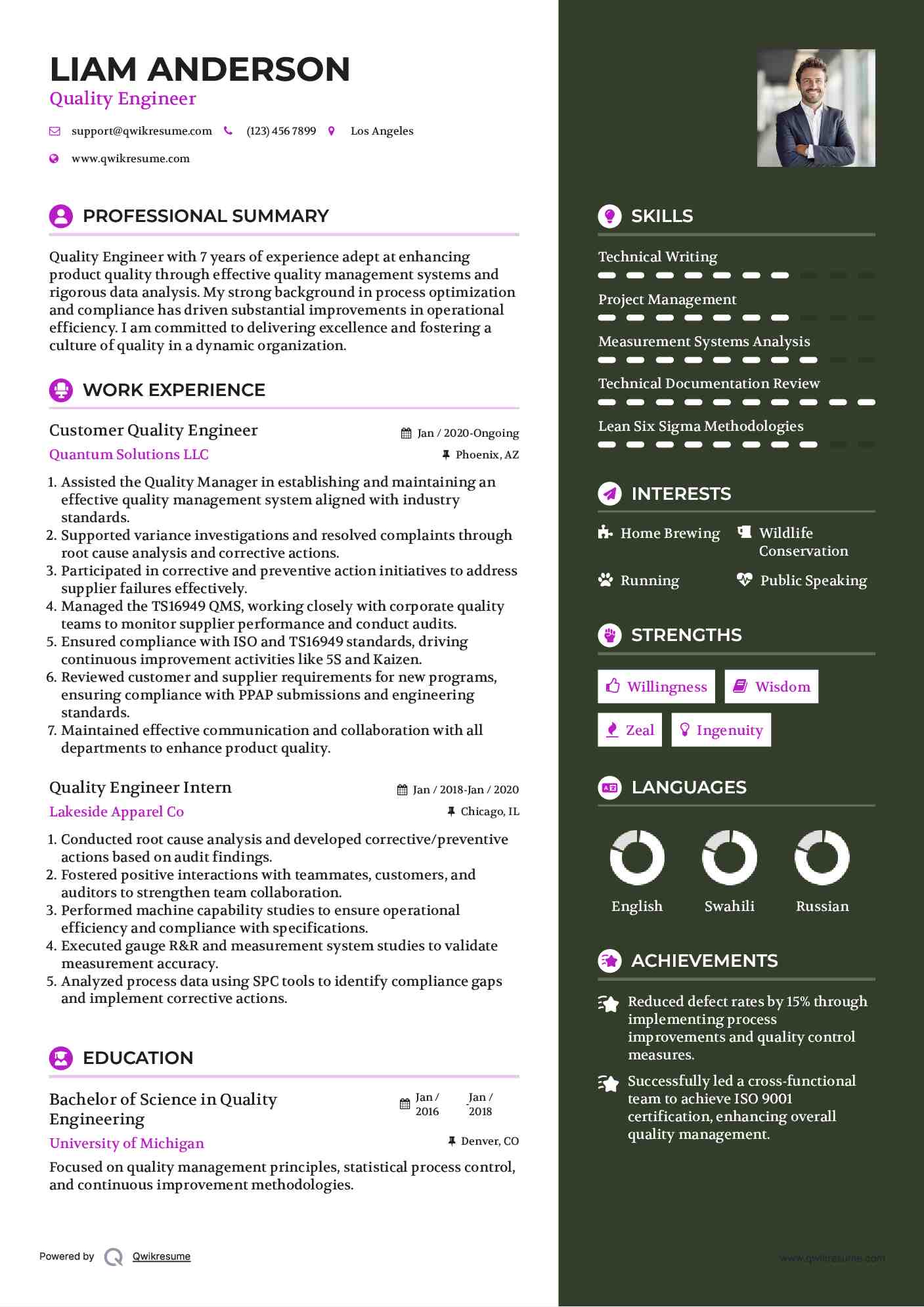

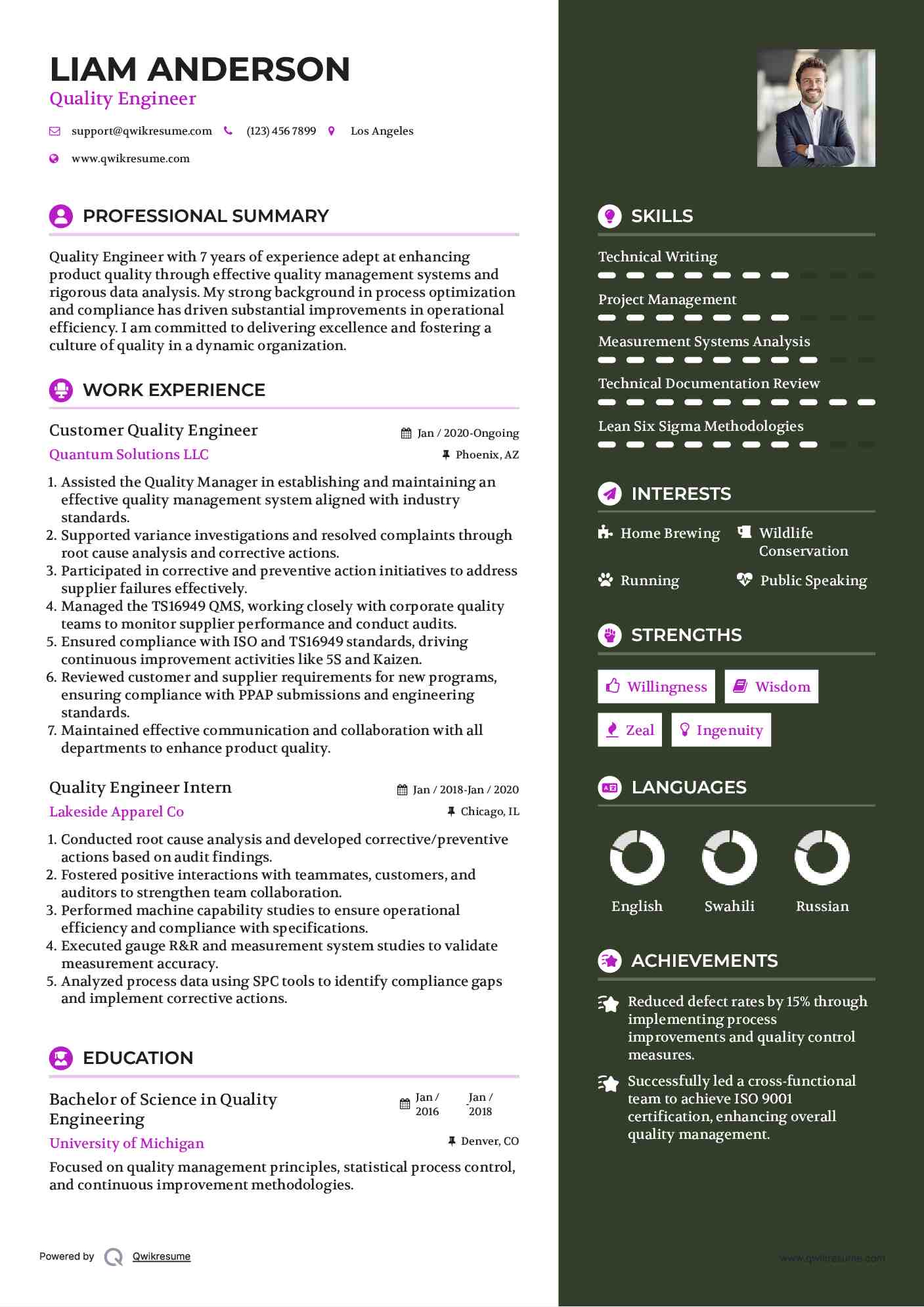

Template 1 of 7: Quality Engineer Resume Example

Quality engineers are professionals responsible for ensuring the safety and quality of manufactured products for a company. They monitor regulations and standards, run various tests, define test criteria, and provide documentation of their findings. Quality engineers will work with several cross-departmental colleagues such as people on the design and manufacturing teams to ensure products are meeting all expectations. When something is wrong in the manufacturing process, it’s the quality engineer's job to troubleshoot the issue and solve it. To land a role as a quality engineer, you will need a bachelor’s degree in a relevant field such as engineering. Hiring managers will look for someone with testing and manufacturing knowledge. Good candidates for this role typically have previous experience as a manual tester, mechanical supervisor, or manufacturing engineer. Moreover, companies will look for someone with relevant skills such as proficiency in lean manufacturing, process optimization, and Six Sigma project management.

We're just getting the template ready for you, just a second left.

Tips to help you write your Quality Engineer resume in 2024

obtain a certificate in six sigma green belt.

Six Sigma Green Belt is a set of project management techniques quality engineers can use to optimize processes and ensure fewer errors are made. You can get a certification to show you understand the principles of Six Sigma and can use them in this role.

Showcase your ability to manage projects and budgets simultaneously

A big piece of the quality engineer's job is to make sure manufacturing projects are being completed efficiently and within the budget. For this reason, you should highlight any experience you have optimizing manufacturing processes that resulted in saving money or time for the company.

Skills you can include on your Quality Engineer resume

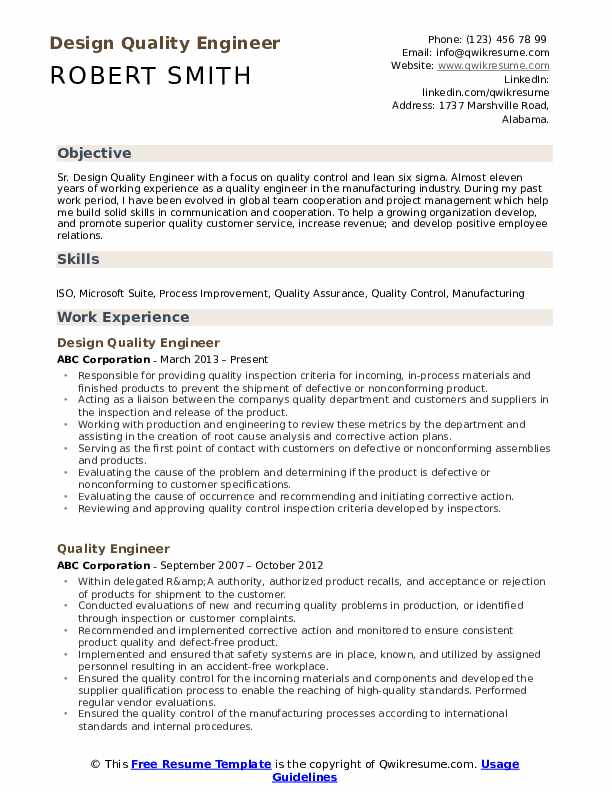

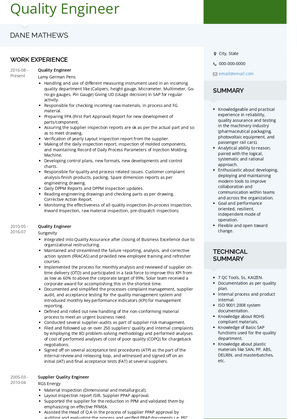

Template 2 of 7: quality engineer resume example.

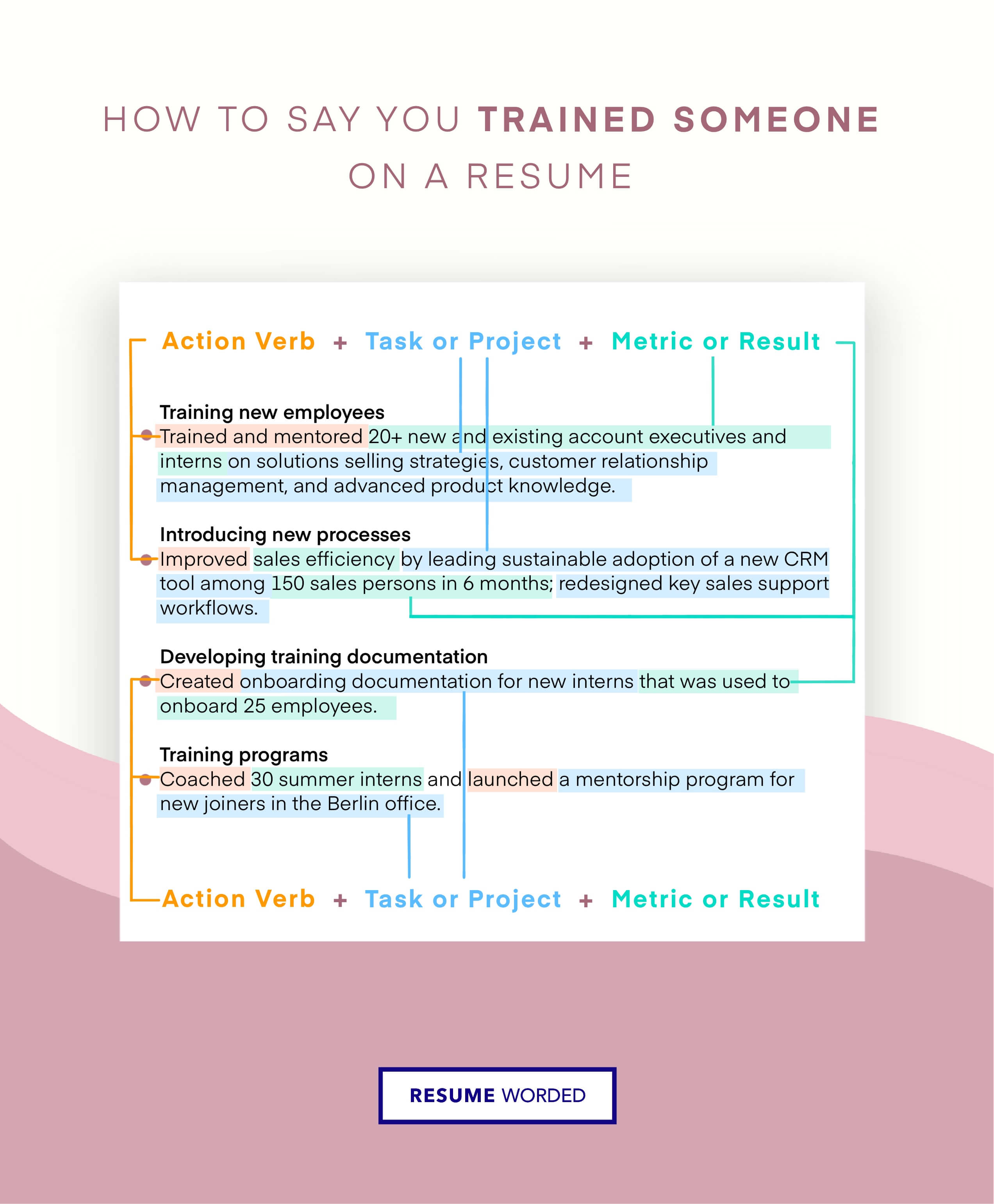

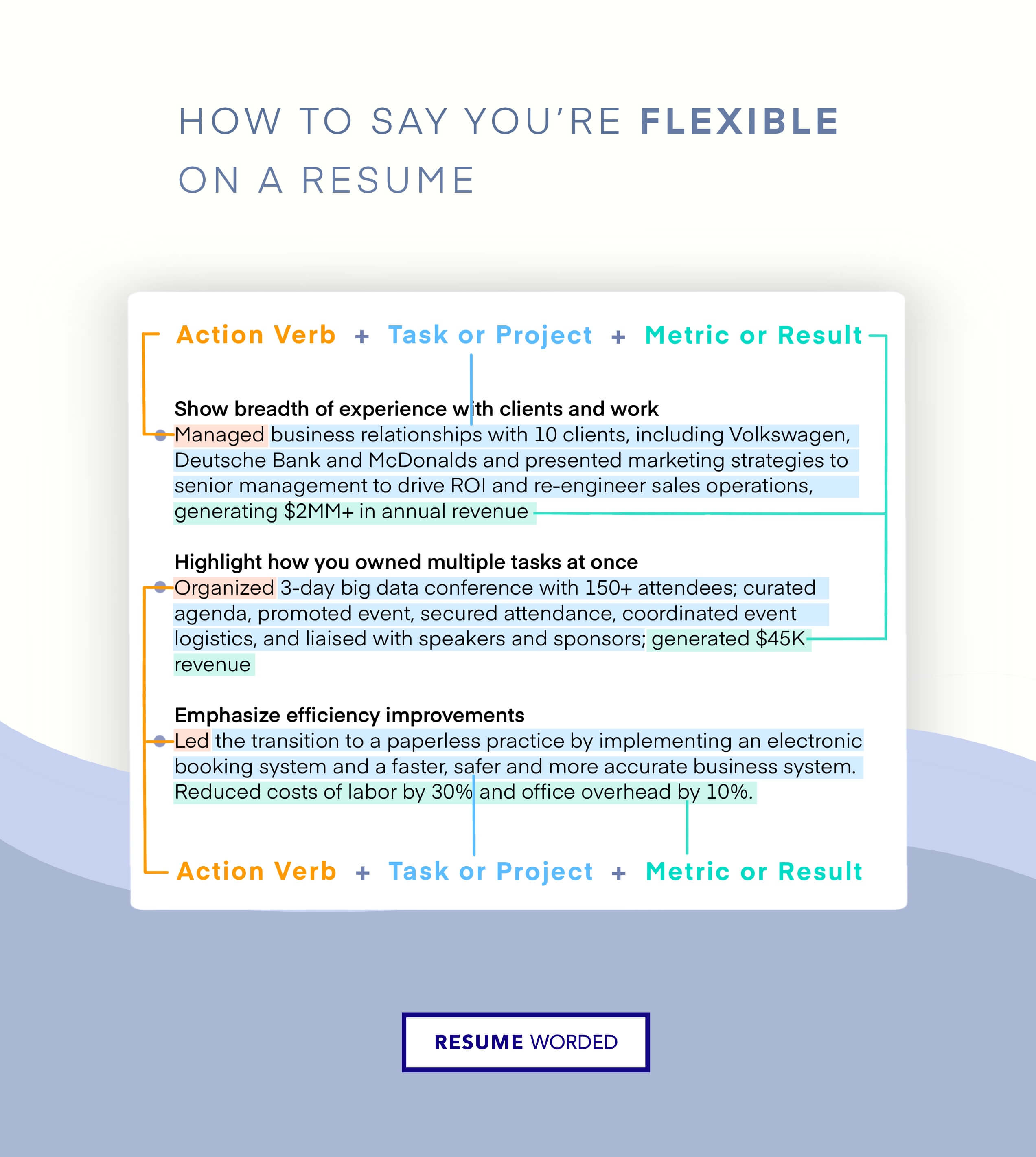

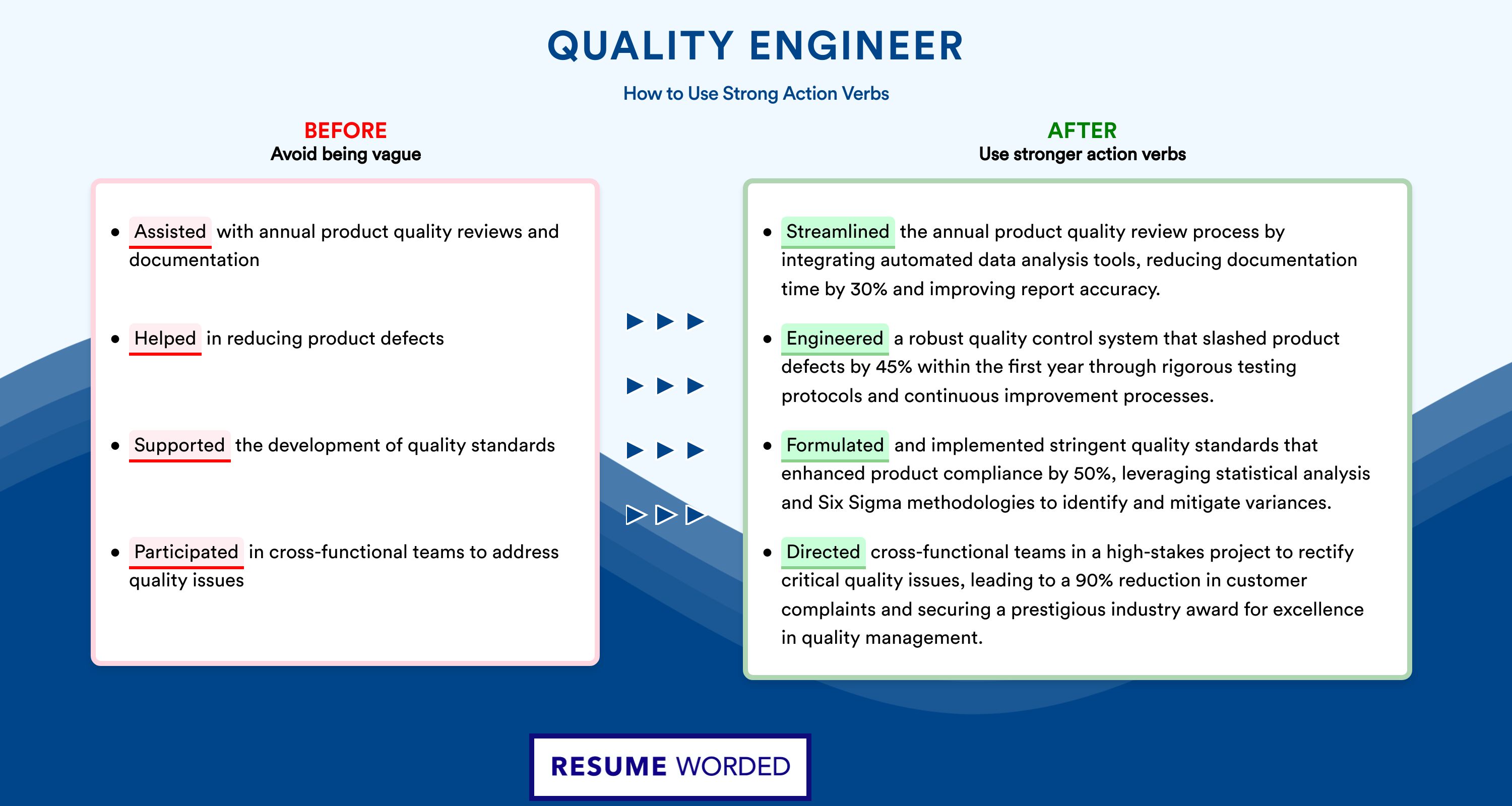

A Quality Engineer is responsible for making sure that all of the engineering or manufacturing processes are moving smoothly and that high standards are maintained. As a Quality Engineer, you should be a technical and data driven person, and able to express your professional accomplishments using clear metrics. You should also use your resume bullet points to convey your technical and managerial skills.

Good use of metrics which relate to ensuring quality and quality engineering

Using clear metrics allows hiring managers to see what you are capable of achieving. This resume says, “Implemented Demand Flow and re-engineered production by eradicating redundant processes, resulting in $100K in company savings.” Use examples to show your ability to help the company save money and be efficient. Make it clear how the company will benefit by hiring you.

Bullet points using action verbs with Quality Engineer skills

Remember to start a bullet point with a verb that will make a statement. You might use something like, “Implemented,” “Mitigated,” or “Conducted” to convey your hard analytical skills that are essential as a Quality Engineer. Make sure to follow these strong verbs with clear results using numbers or specific outcomes that you attained.

Template 3 of 7: QA (Quality Assurance) Engineer Resume Example

Quality Assurance Engineers are different from Quality Engineers because they are focused on computer software. They generally have degrees in Computer Science or Computer Engineering and focus on making sure that the code is up to standard, passes tests and is free from bugs. This is a career path where being highly educated with a Master’s or other certifications will often give you an advantage. You can also emphasize your vast technical skills in your bullet points and skills section.

Tips to help you write your QA (Quality Assurance) Engineer resume in 2024

identifies hard skills relating to quality assurance.

As a Quality Assurance Engineer, you are expected to have hard skills that are rooted in software development and programming. For example, this resume says, “Created over 100 individual test programs in C++.” Using examples like this are one way to provide proof of your experience using different programs and software. You can replicate this in your skills section and your bullet points.

Highlight advanced education that complements Quality Assurance experience

Engineering is a field where specialized education is highly regarded and expected. However, not everyone will have a Master’s degree, and if you do, this is something you will want to emphasize and draw attention to in your resume. You could also include a minor if you received one or any certifications that you have earned in your field.

Skills you can include on your QA (Quality Assurance) Engineer resume

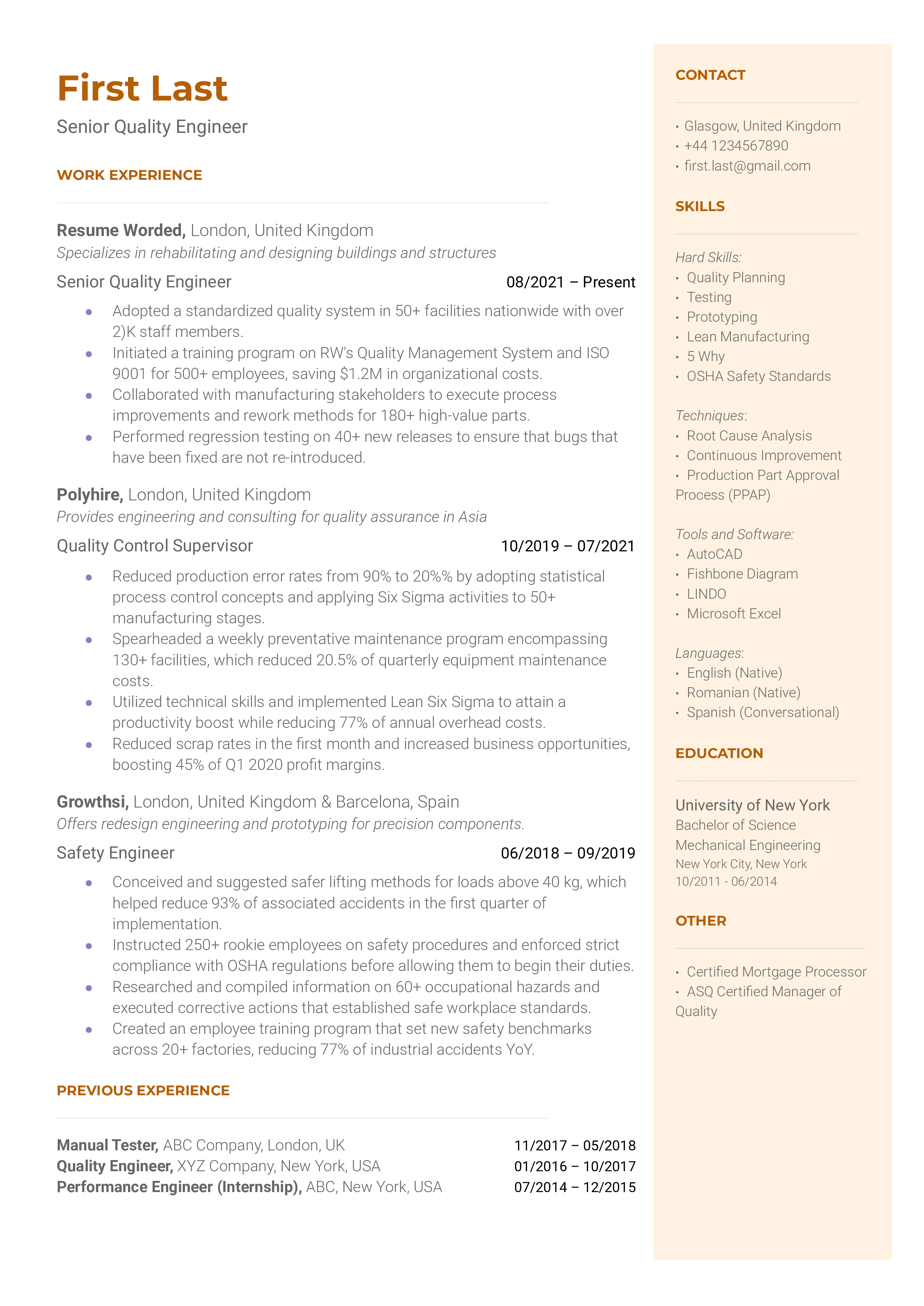

Template 4 of 7: senior quality engineer resume example.

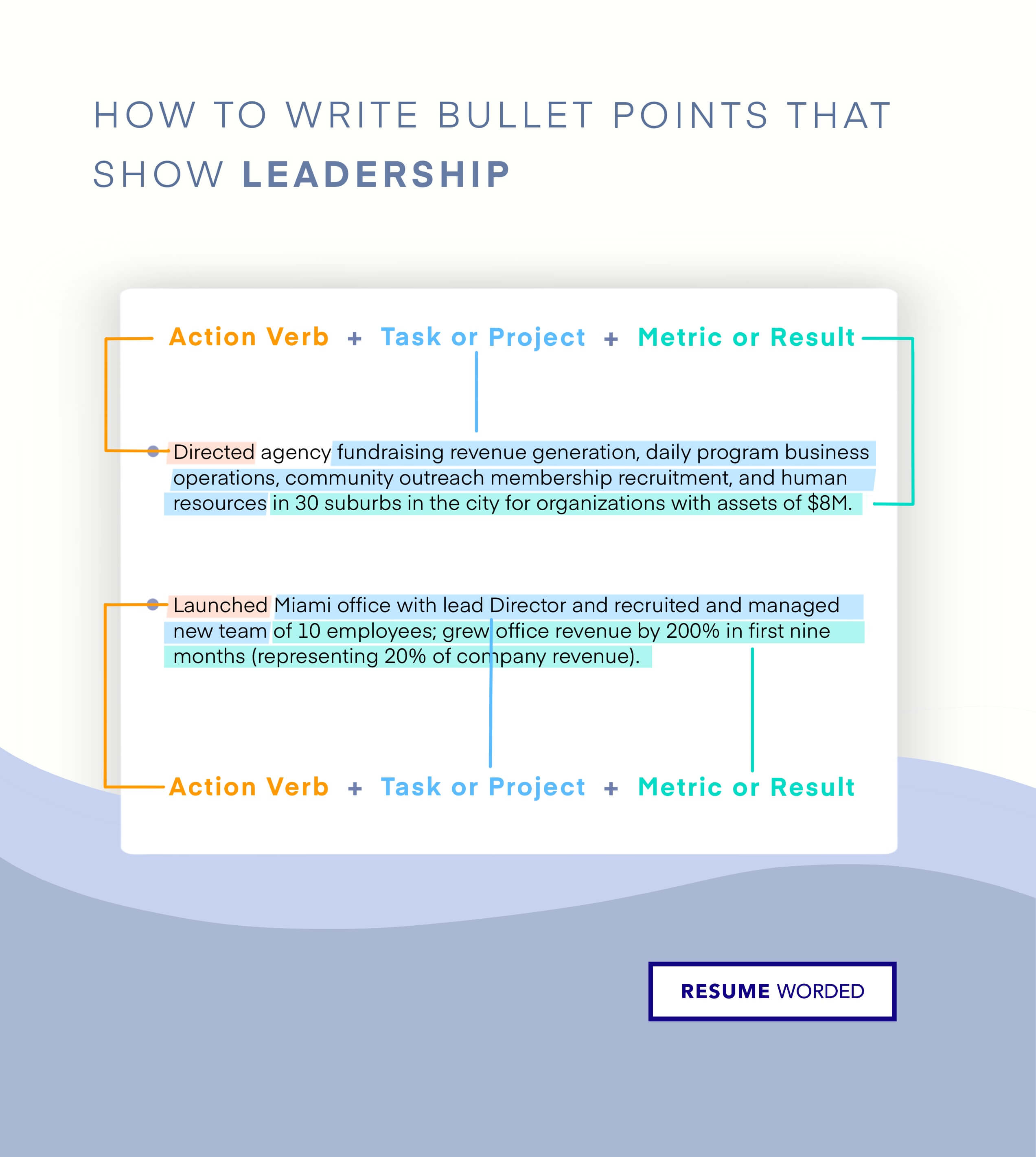

A senior quality engineer oversees many aspects of the QA testing and verification process in an organization. Quality testing ensures that every product a company produces is effective and in good working order before it reaches the customer. As a senior quality engineer, you support this process by creating and identifying quality testing measures, tracking and presenting testing results, and overseeing a group of junior engineers. To become a senior quality engineer, you will need progressive experience in a related field and demonstrated leadership abilities. Hiring managers will look for a candidate with a bachelor's degree in a related field, such as mechanical engineering. They will also look for someone with several years of experience in relevant roles such as prior positions as a safety engineer, quality control supervisor, or quality engineer. As this is a senior role, ideal candidates will demonstrate superb communication and management skills.

Tips to help you write your Senior Quality Engineer resume in 2024

show your ability to enforce workplace safety standards.

As a senior quality engineer, you will oversee testing measures that happen in the manufacturing setting. As such, you need to be well-versed on workplace safety standards and how to enforce them. You should be OSHA certified and demonstrate your ability to enforce workplace safety standards on your resume.

Highlight examples of improving processes

Senior quality engineers may be asked to improve current quality testing standards to optimize the process leading to better business metrics. For this reason, you should highlight any experience you have executing process improvements and what impact it made.

Skills you can include on your Senior Quality Engineer resume

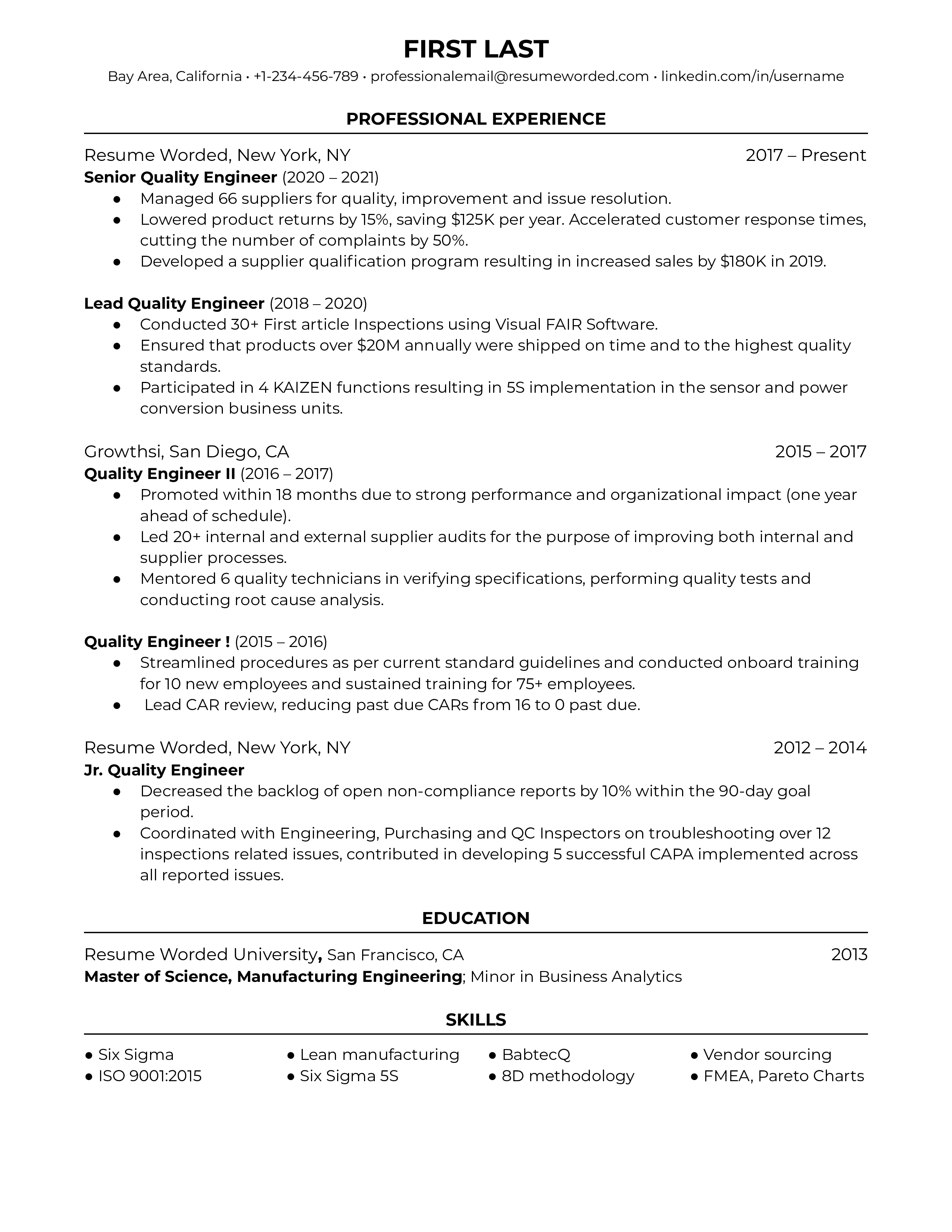

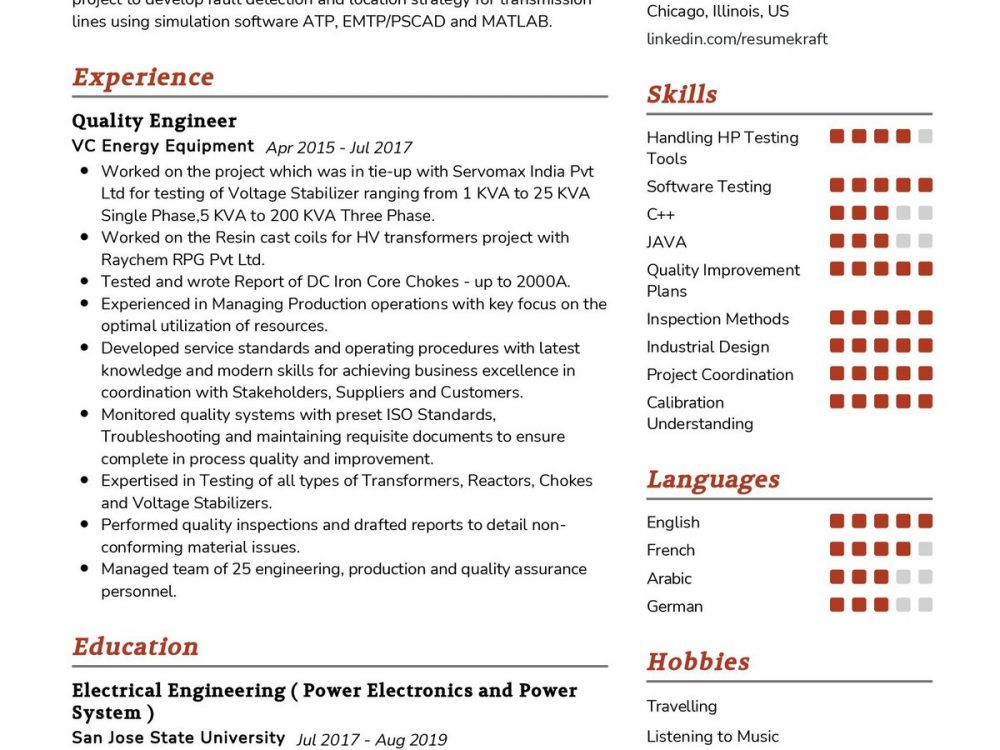

Template 5 of 7: senior quality engineer resume example.

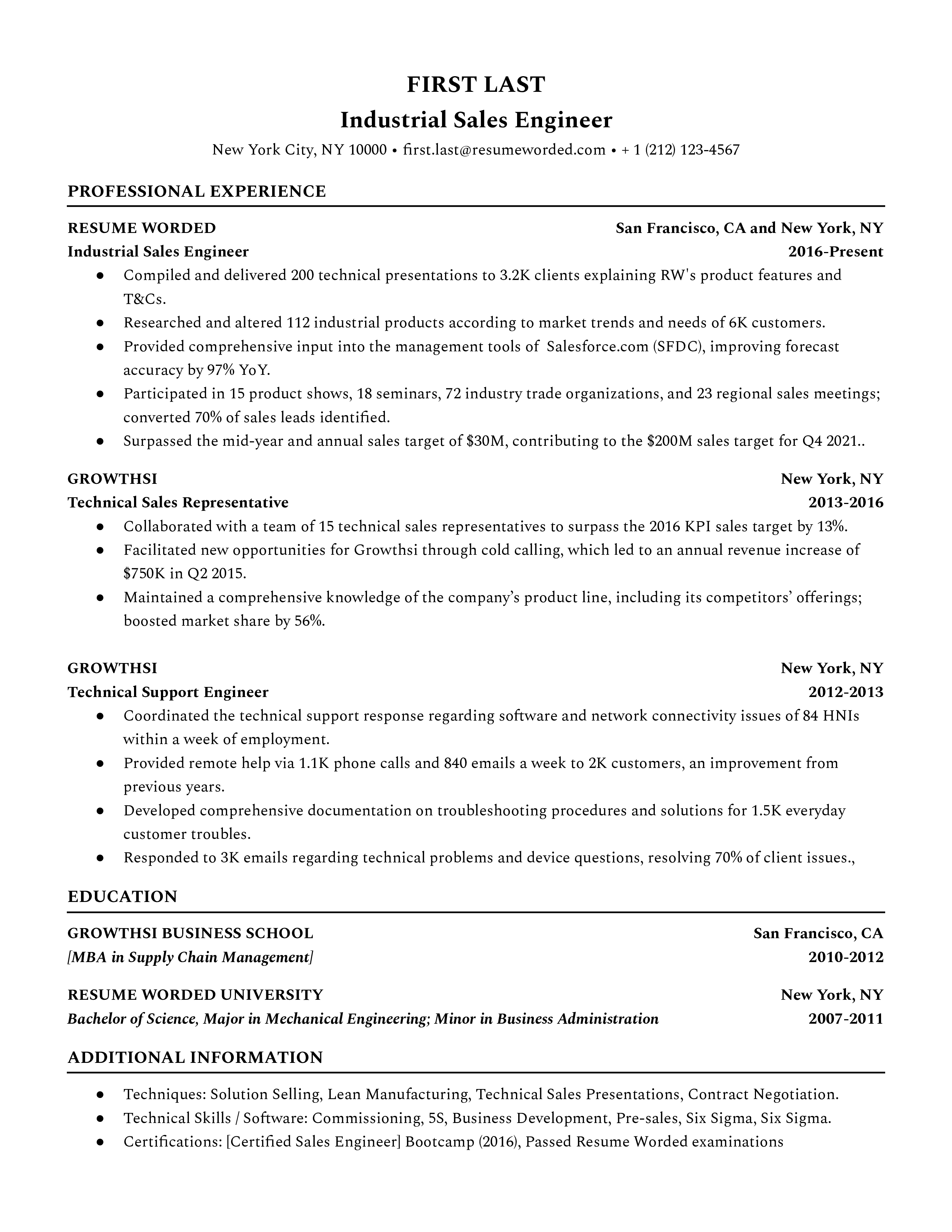

Senior Quality Engineers are higher level Quality Engineers. In addition to testing products and finding defects, they often have managerial responsibilities with managing teams, guiding, and training other employees. If you already have management or training experience, make sure to make this evident on your resume. Also, prioritize your experiences where you have held similar skills or roles — this will show that you are prepared.

Adapt to the specific Quality Engineer role

Make sure that you are adapting each version of your resume to fit the specific job that you’re applying for. If you had previous jobs with different titles, try to match them as much as possible to your next position. In this resume, each previous job has some variation of the words, “Quality Engineer” in the title.

Show leadership experiences in your previous Quality Engineering jobs

As you begin to take on senior level positions, employers will also be looking for leadership initiatives, in addition to your technical expertise. This resume uses the examples, “Managed 66 suppliers,” “Mentored 6 quality technicians,” and “Promoted within 18 months.” Make sure you are able to blend your metrics and achievements, with specific leadership examples.

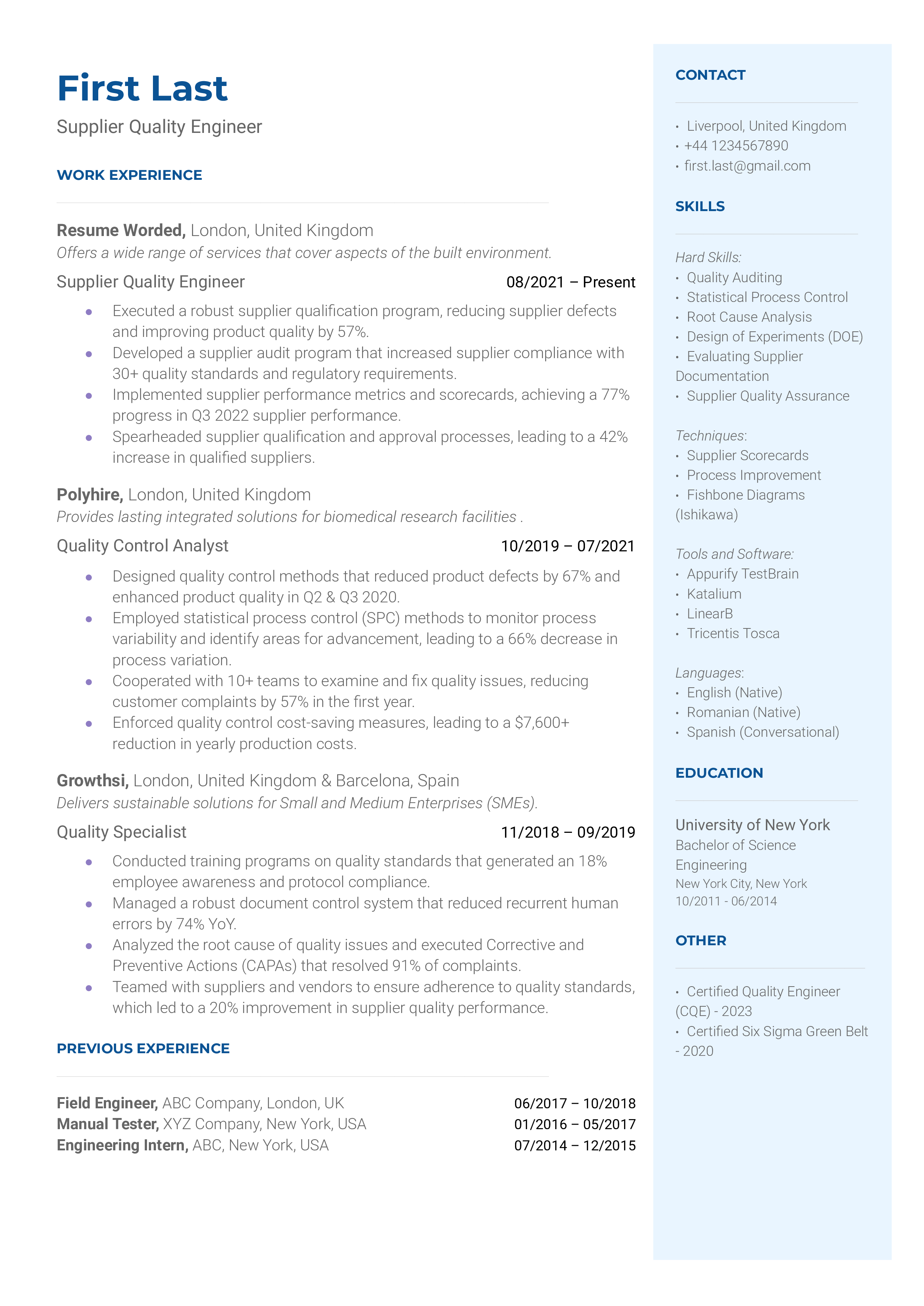

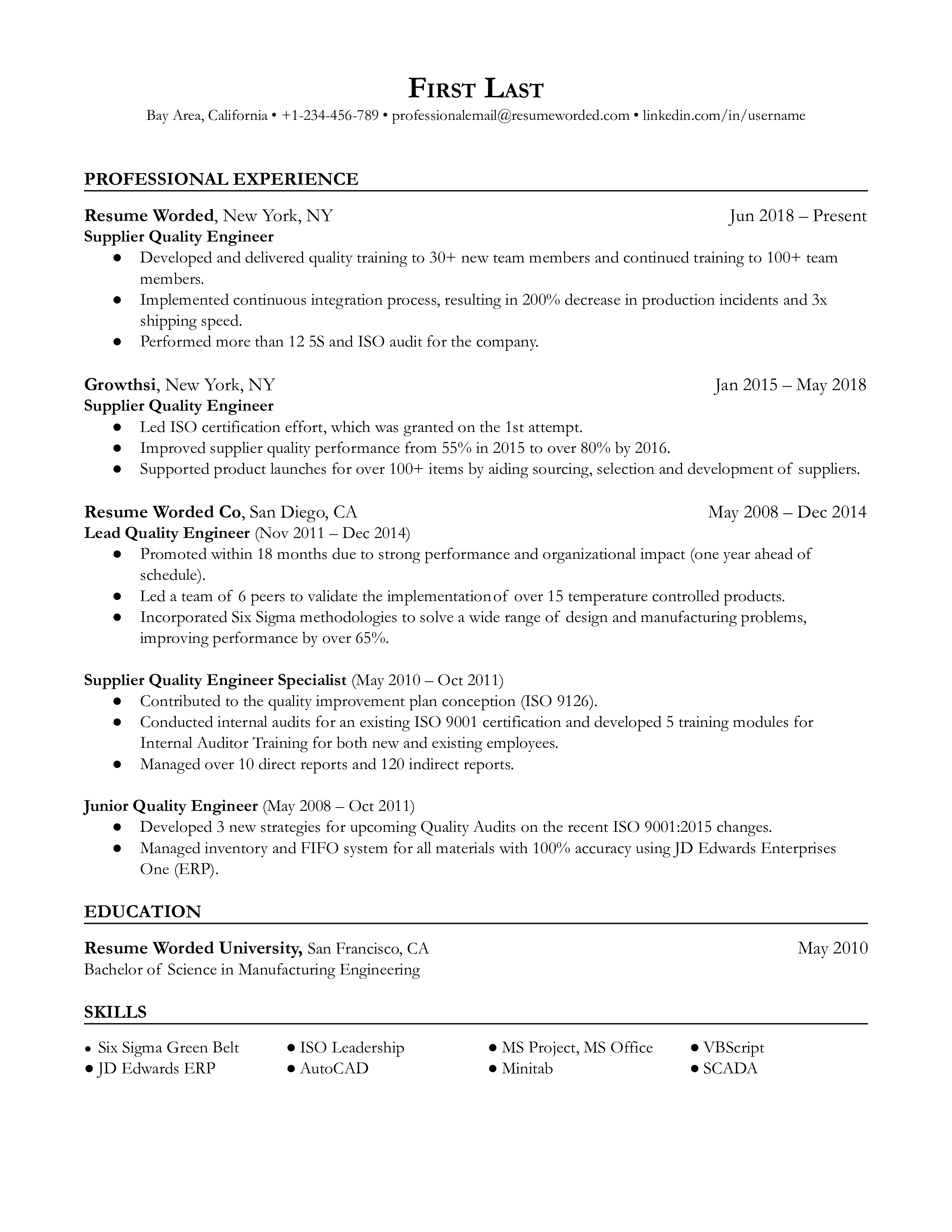

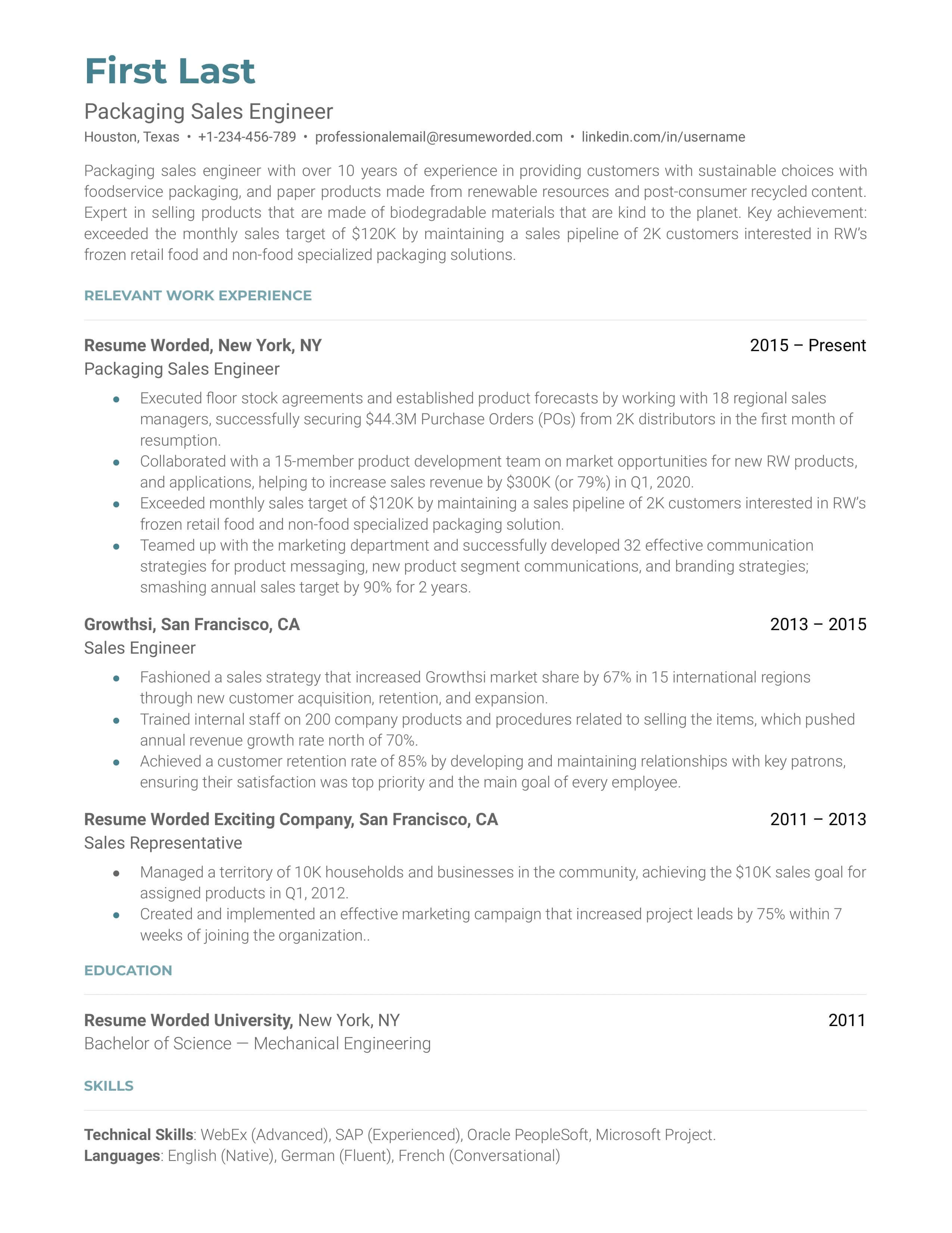

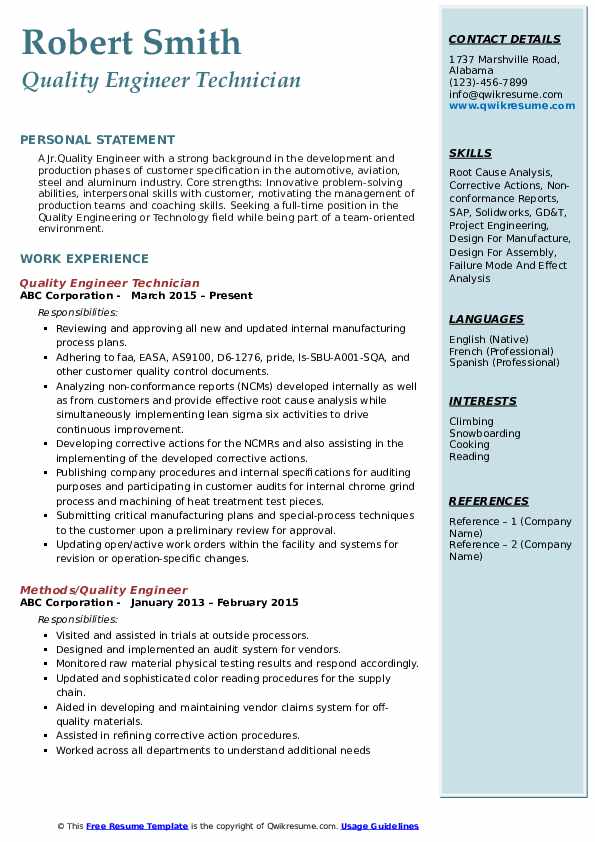

Template 6 of 7: Supplier Quality Engineer Resume Example

As a Supplier Quality Engineer, you're the vital connection between a company and its suppliers, ensuring goods meet the company's high standards. It's a role that requires a mix of technical know-how and relationship building skills. There's been a recent shift in this role towards more data-driven decision making. So when you're preparing your resume, you should ensure it demonstrates not only your skills in quality assurance and supplier management, but also your ability to interpret and analyze data. Remember, it's not just about showcasing your technical competence. Highlight your soft skills too. The best Supplier Quality Engineers are communicators, collaborators, and problem-solvers.

Tips to help you write your Supplier Quality Engineer resume in 2024

highlight industry-specific experience.

When you're drafting your resume, don't just list your previous roles. Instead, highlight how this experience is relevant to the industry you're applying within. If you've worked with suppliers from the same or similar sector, make that stand out. It shows you understand the unique challenges and standards of that industry.

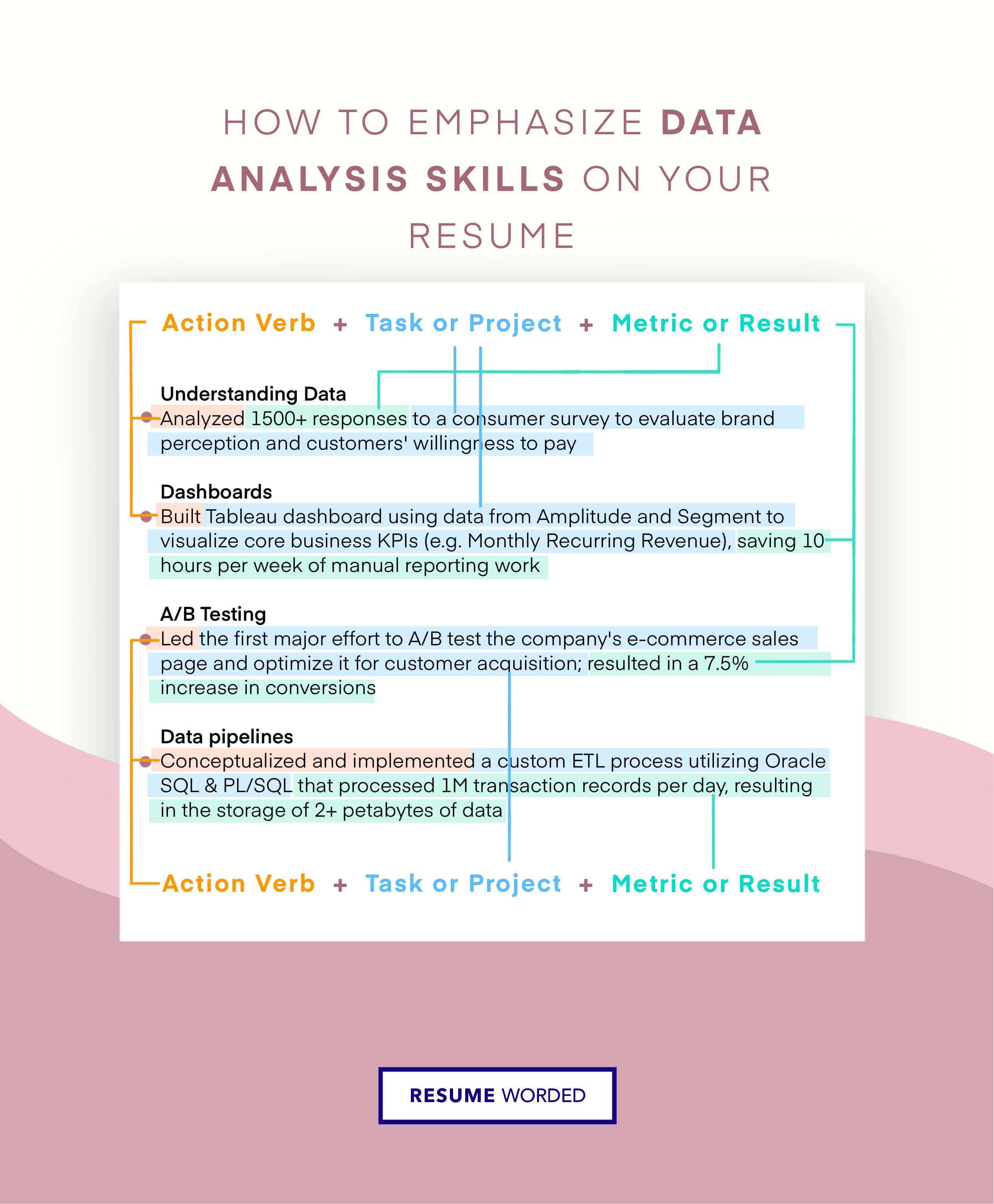

Showcase data analysis skills

The role of a Supplier Quality Engineer is increasingly data-driven. Therefore, make sure your resume clearly demonstrates your ability to interpret and analyze data. This could be through highlighting specific data analysis projects you've led, or relevant certifications you've achieved.

Skills you can include on your Supplier Quality Engineer resume

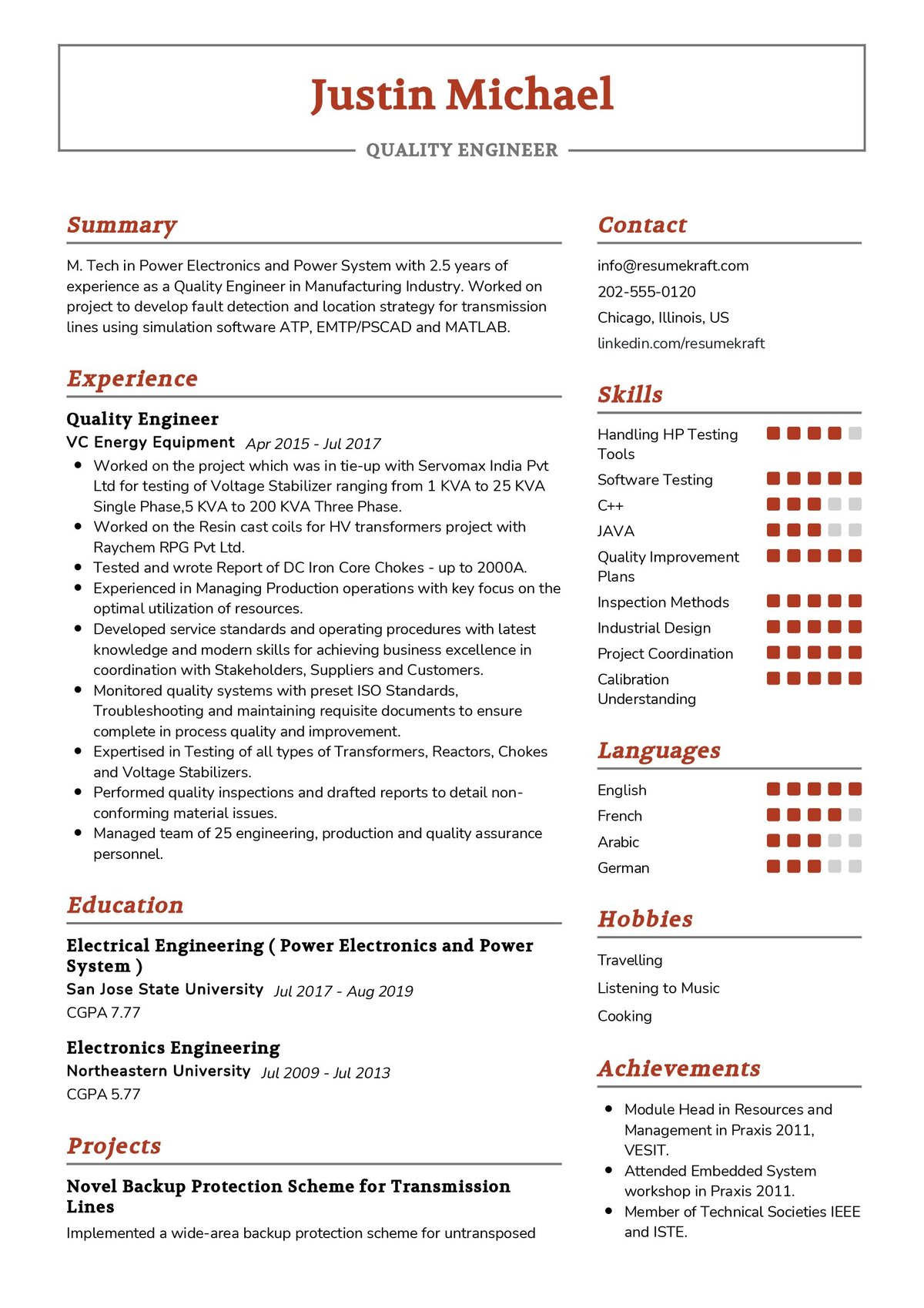

Template 7 of 7: supplier quality engineer resume example.

Supplier Quality Engineers work with logistics, supply chain management, and manufacturing. They ensure that all products meet company, industry, and government standards and lack any defects. To advance in this field, it’s important to show your strong technical and analytical skills through previous roles, using numbers and specific examples to quantify your proven results.

Strong use of skills relating to Supplier Quality Engineer skills

You must have strong technical qualifications to succeed in specialized and technical fields like Quality Engineering. Look at job descriptions and see what programs and software employers will expect you to know. If it’s listed in the description, make sure to include it in your skills section or throughout your bullet points.

Show substantial experience in Quality Engineering

When you have 10+ years of experience, you’ll want to emphasize examples of leading teams, advancing, and training others. Also, make sure to highlight with metrics how you improved your team, department, or company as a whole. For example, like this resume, “implemented continuous integration process, resulting in 200% decrease in production incidents and 3x shipping speed.”

We spoke with hiring managers at top companies like Boeing, GE, and Lockheed Martin to get their insights on what makes a strong quality engineer resume. The tips below will help you create a resume that showcases your skills and experience in a way that will catch the attention of recruiters and hiring managers.

Highlight your quality assurance expertise

Hiring managers want to see that you have a deep understanding of quality assurance principles and methodologies. Make sure to highlight your experience with:

- Quality management systems like ISO 9001, Six Sigma, or Lean

- Statistical process control (SPC) tools and techniques

- Root cause analysis and corrective action

- Quality auditing and inspection

For example:

- Implemented Six Sigma methodology to reduce defects by 35% and improve overall product quality

- Conducted root cause analysis on manufacturing issues, resulting in a 20% reduction in scrap rate

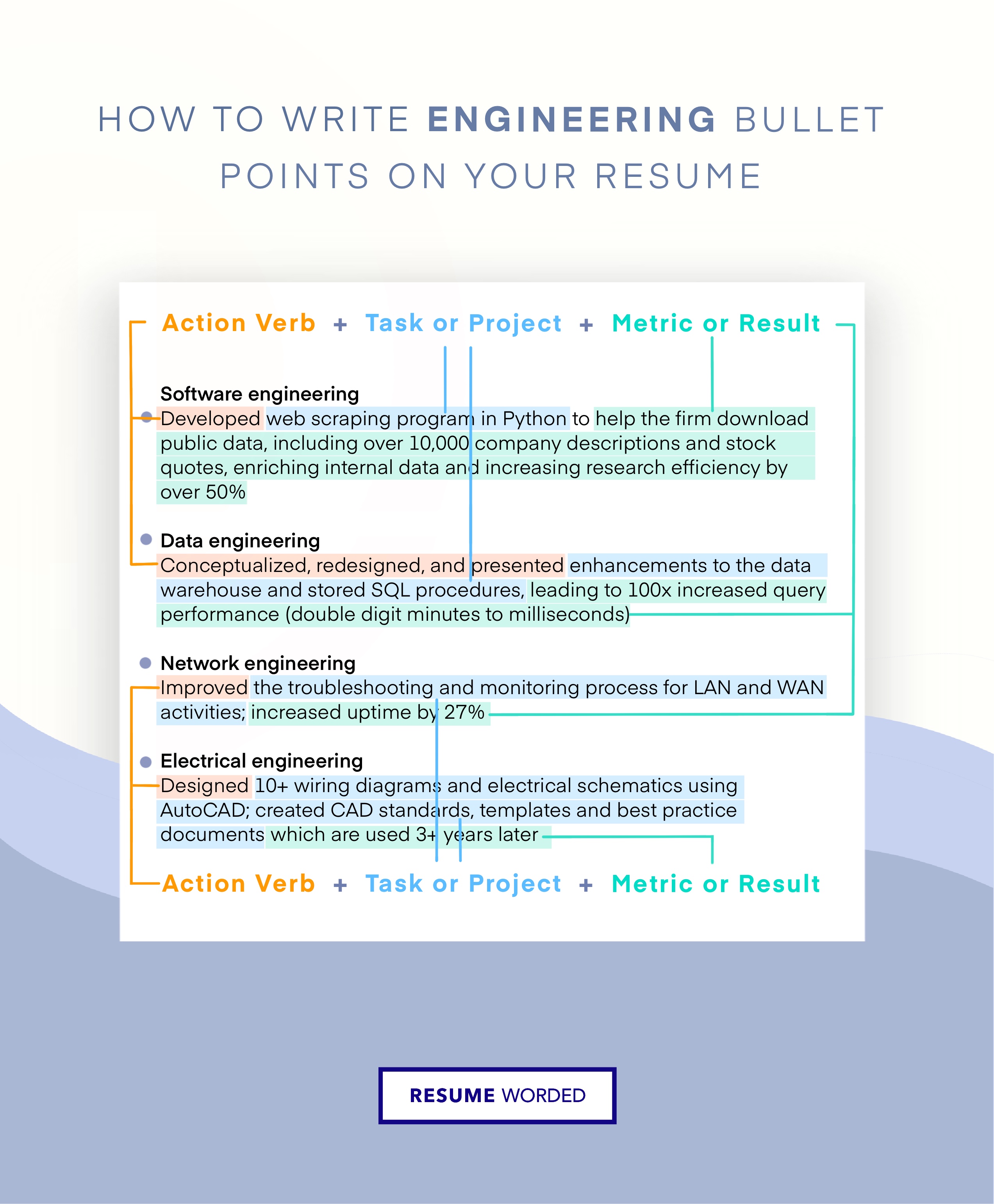

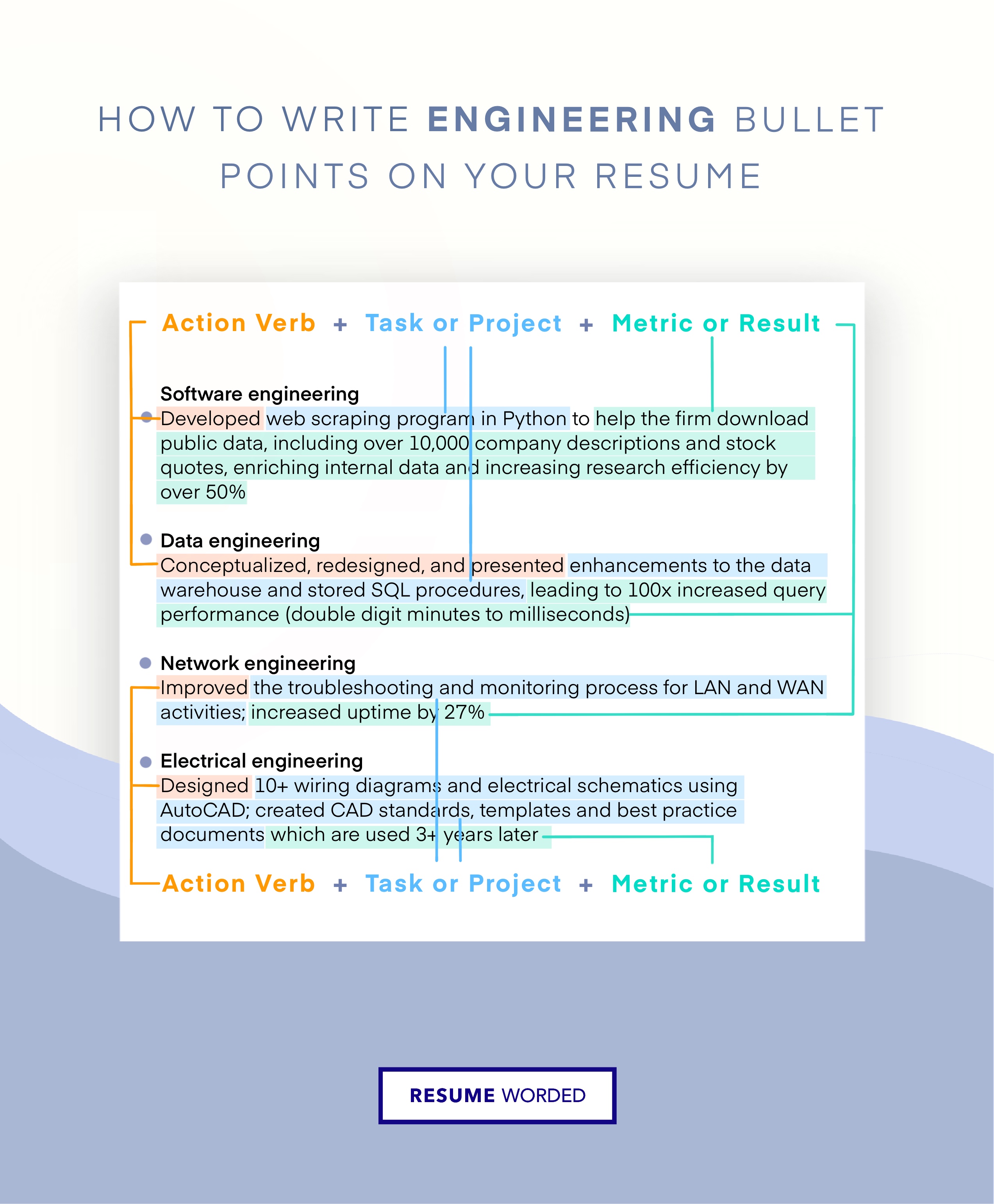

Showcase your technical skills

Quality engineers need a strong technical background to be effective in their roles. Highlight your experience with:

- CAD software like SolidWorks or AutoCAD

- Statistical analysis tools like Minitab or JMP

- Programming languages like Python or SQL

- Metrology and measurement systems

Avoid simply listing technical skills without context, like this:

- Skills: SolidWorks, Minitab, Python, CAD

Instead, provide specific examples of how you've used these skills:

- Used SolidWorks to design and simulate new product prototypes, reducing time to market by 15%

- Developed Python scripts to automate data collection and analysis, saving 10 hours per week

Demonstrate your problem-solving abilities

Quality engineers are often tasked with identifying and solving complex problems. Use your resume to showcase your problem-solving skills with specific examples, such as:

- Investigating product failures or customer complaints

- Collaborating with cross-functional teams to improve processes

- Implementing corrective actions to prevent recurring issues

For instance:

- Led a cross-functional team to investigate and resolve a critical product defect, preventing a potential recall and saving $500K in costs

- Analyzed customer complaint data to identify trends and implemented process improvements, reducing complaints by 30%

Quantify your impact

Whenever possible, use numbers and metrics to quantify the impact of your work. This helps hiring managers understand the scale and significance of your contributions. Consider including:

- Cost savings generated through process improvements

- Reductions in defect rates or customer complaints

- Improvements in yield, cycle time, or efficiency

Avoid vague statements like:

- Improved product quality and reduced waste

Instead, provide specific numbers:

- Implemented lean manufacturing techniques to reduce waste by 20% and improve yield by 15%

- Optimized inspection processes, reducing defect escape rate from 1.5% to 0.5%

Tailor your resume to the job description

One of the biggest mistakes job seekers make is sending a generic resume to every job posting. Instead, take the time to tailor your resume to each specific job description. This shows the hiring manager that you've done your research and are genuinely interested in the role.

Look for keywords in the job description that match your skills and experience, and make sure to include them in your resume. For example, if the job description mentions:

- Experience with FMEA (Failure Mode and Effects Analysis)

- Knowledge of GD&T (Geometric Dimensioning and Tolerancing)

- Familiarity with PPAP (Production Part Approval Process)

Make sure to include these specific terms in your resume if you have relevant experience.

Highlight your industry-specific experience

If you have experience in the same industry as the company you're applying to, make sure to highlight this on your resume. Hiring managers often prefer candidates who are already familiar with the specific challenges and regulations of their industry.

For example, if you're applying for a quality engineer position at a medical device company, you might include:

- Expertise in FDA Quality System Regulations (QSR) and ISO 13485

- Experience with design control and risk management for medical devices

- Familiarity with cleanroom protocols and sterile manufacturing processes

By showcasing your industry-specific knowledge, you demonstrate that you can hit the ground running and add value from day one.

Writing Your Quality Engineer Resume: Section By Section

header, 1. include your name and professional title.

Your header should prominently feature your full name at the top of your resume. Consider using a larger font size or bold text to make it stand out. Directly below your name, include your professional title or a brief phrase that encapsulates your expertise as a quality engineer.

Examples of effective professional titles for quality engineers:

- Certified Quality Engineer (CQE)

- Six Sigma Black Belt Quality Engineer

- Quality Assurance & Control Specialist

Avoid using generic or vague titles that don't highlight your specific skills:

- Quality Professional

2. Provide essential contact information

In addition to your name and title, your header should include key contact details so employers can easily reach out. Essential information to include:

- Phone number

- Professional email address

- Location (City, State)

- LinkedIn profile URL

Make sure your email address is professional, ideally [email protected] . Avoid outdated AOL or Hotmail accounts. You can also create a custom domain email to show tech-savviness.

John Doe, CQE Quality Engineer San Diego, CA | 123-456-7890 | [email protected] | linkedin.com/in/john-doe

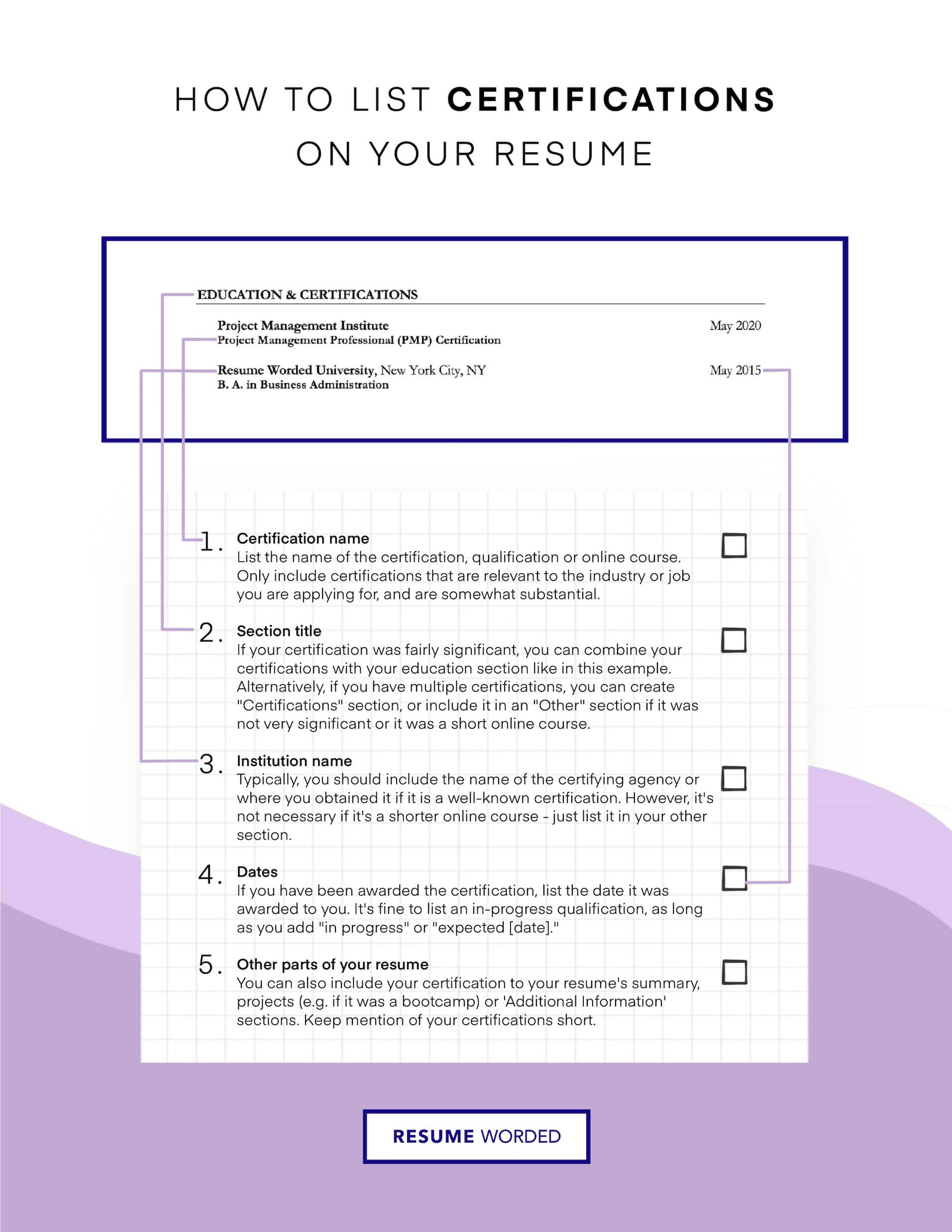

3. Showcase relevant certifications

As a quality engineer, certifications demonstrate your expertise and commitment to the field. If you have any relevant certifications, consider featuring them after your name to grab the hiring manager's attention.

Some valuable certifications for quality engineers include:

- ASQ Certified Quality Engineer (CQE)

- Six Sigma Black Belt or Green Belt

- Certified Quality Auditor (CQA)

- Certified Reliability Engineer (CRE)

However, avoid listing generic or irrelevant certifications that don't directly apply to quality engineering roles, such as:

- Project Management Professional (PMP)

Summary

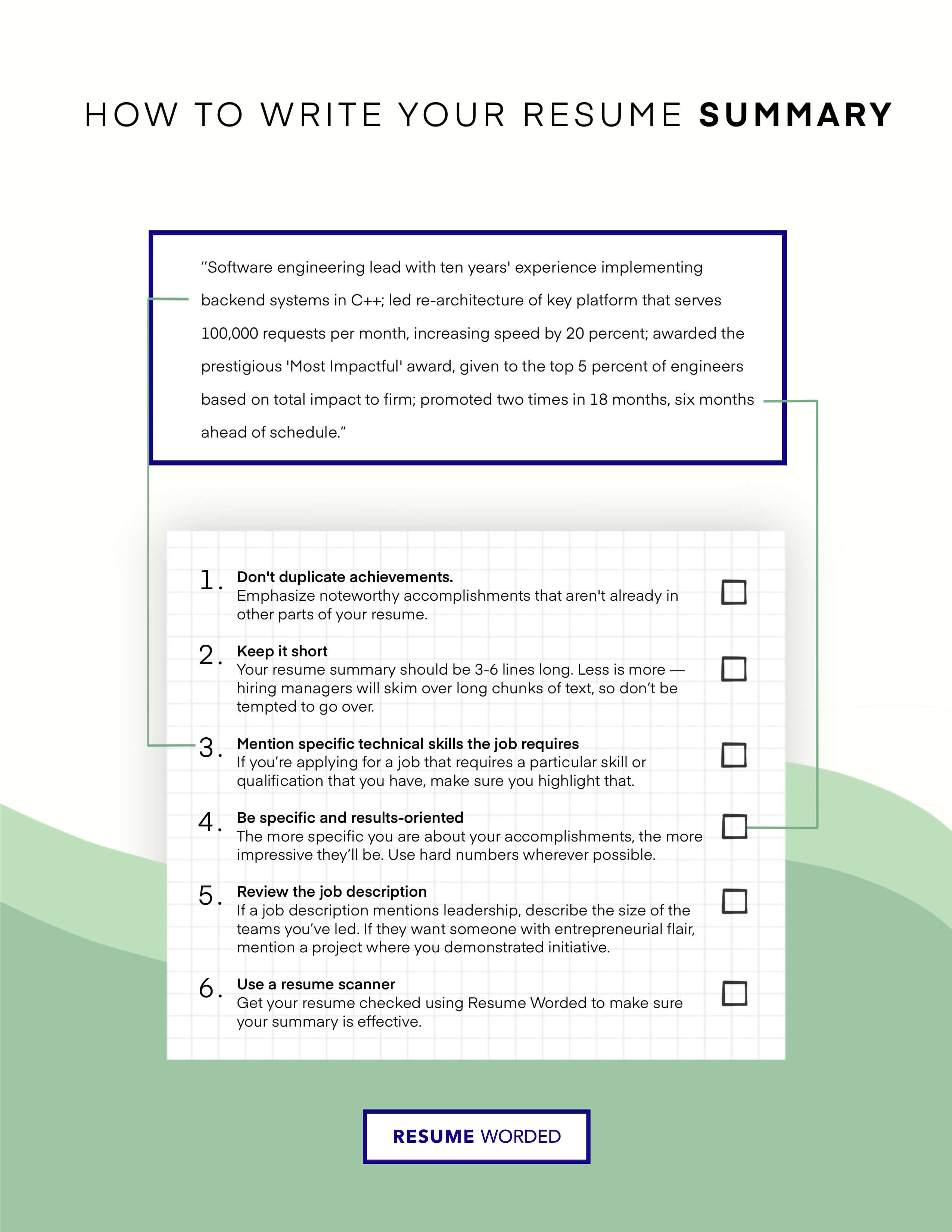

A resume summary for a Quality Engineer position is optional. It's a brief statement at the top of your resume that provides an overview of your professional background and key skills relevant to the role you're applying for. While a summary can be helpful in certain situations, such as when you're making a career change or have extensive experience, it's not always necessary. Avoid using an objective statement, as it's outdated and focuses on what you want rather than what you can offer the employer.

If you choose to include a summary, make sure it's concise, no more than a few sentences or a short paragraph. Tailor it to the specific Quality Engineer position and company, highlighting your most relevant qualifications and expertise. Remember, your resume itself is already a summary of your experience, so avoid repeating information that's already covered in other sections.

To learn how to write an effective resume summary for your Quality Engineer resume, or figure out if you need one, please read Quality Engineer Resume Summary Examples , or Quality Engineer Resume Objective Examples .

1. Showcase your quality assurance expertise

When crafting your Quality Engineer resume summary, focus on your key areas of expertise and how they align with the job requirements. Consider the following examples:

- Experienced Quality Engineer with a proven track record of success

- Hardworking and detail-oriented professional seeking a challenging role in quality assurance

Instead, be specific about your skills and experience:

- Quality Engineer with 5+ years of experience in developing and implementing quality control processes for automotive manufacturing

- Certified Quality Engineer (CQE) with expertise in Six Sigma methodologies and lean manufacturing principles

By highlighting your specific qualifications and areas of expertise, you demonstrate your value to potential employers and show that you're a strong fit for the role.

2. Quantify your achievements

To make your Quality Engineer resume summary more impactful, include quantifiable achievements that demonstrate the value you've brought to previous employers. Here's an example of a summary that lacks specific accomplishments:

Quality Engineer with experience in improving manufacturing processes and reducing defects. Skilled in problem-solving and collaborating with cross-functional teams.

Now, let's see how incorporating quantifiable results can strengthen your summary:

Quality Engineer with a track record of reducing manufacturing defects by 35% through the implementation of Six Sigma methodologies. Collaborated with cross-functional teams to optimize production processes, resulting in a 15% increase in efficiency and $500K in annual cost savings.

By providing specific, measurable achievements, you give employers a clear picture of the impact you can make in the Quality Engineer role.

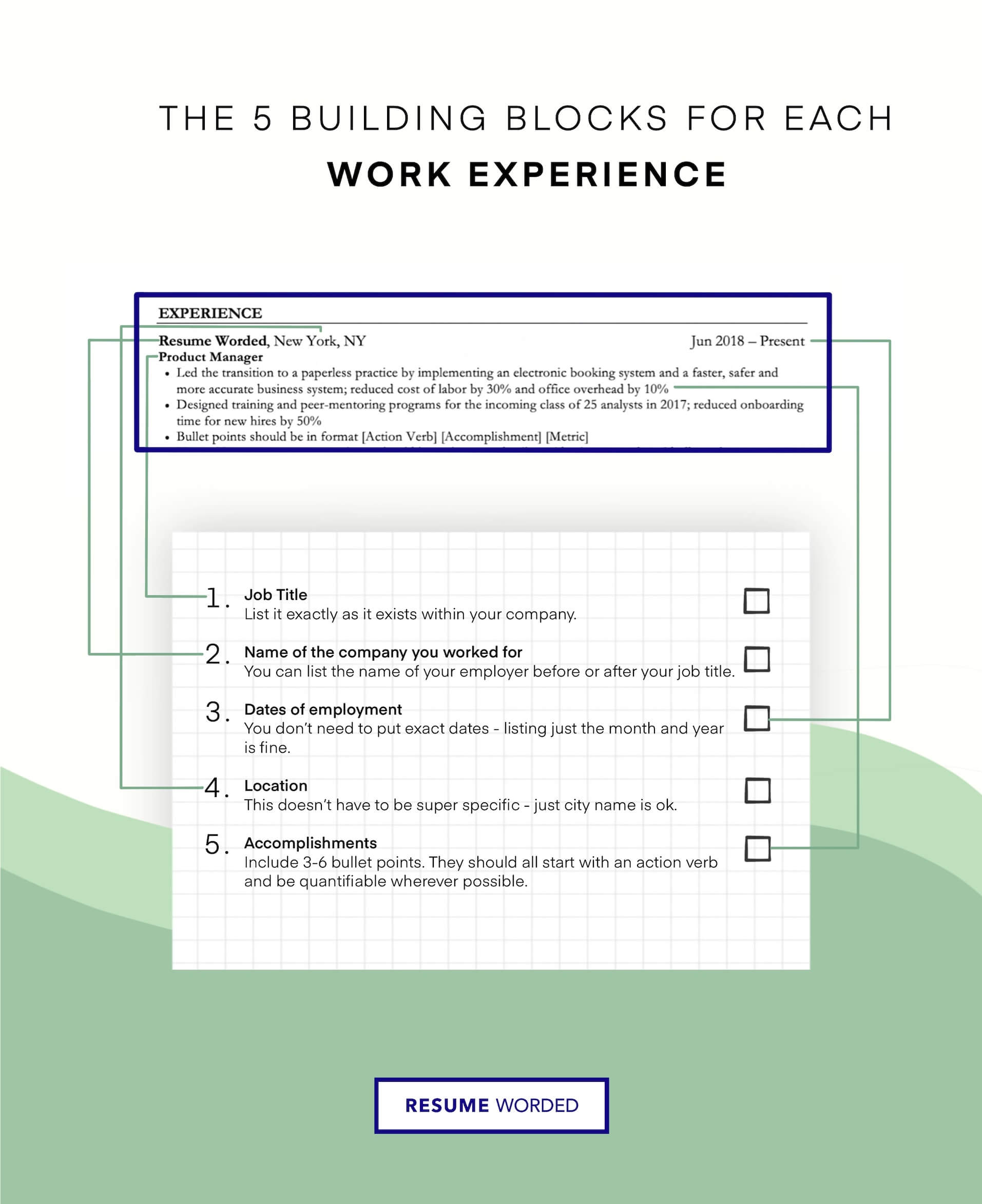

Experience

Your work experience section is the most important part of your quality engineer resume. It's where you show hiring managers how you've applied your skills to real-world projects and made an impact. Use these tips to write a compelling work experience section that will grab attention and land you interviews.

1. Highlight quality assurance tools and methodologies

Quality engineers rely on a variety of tools and methodologies to ensure products meet rigorous standards. Showcase your expertise by mentioning specific tools and approaches you've used, such as:

- Utilized Six Sigma methodologies to reduce defects by 35%

- Developed and executed test plans using Selenium and JMeter

- Performed root cause analysis using Ishikawa diagrams and 5 Whys

By highlighting your technical skills and problem-solving approaches, you demonstrate your ability to drive quality improvements and deliver results.

Not sure if your resume is highlighting the right tools and skills? Try our Targeted Resume tool to check if your resume matches a specific job description.

2. Quantify your impact with metrics

Numbers speak louder than words when it comes to your resume. Whenever possible, use metrics to quantify the impact of your work. Here are some examples:

- Reduced defect rate from 5% to 1.5% through improved testing processes

- Saved $500K annually by identifying and eliminating waste in the manufacturing process

- Increased first-pass yield by 12% through statistical process control

In contrast, here are some examples that lack specific metrics:

- Improved product quality through testing

- Reduced waste and increased efficiency

Metrics help hiring managers understand the scope and significance of your contributions. They also help your resume stand out from generic statements that could apply to any candidate.

When writing your bullets, focus on your most impressive, relevant achievements. Don't worry if you can't quantify everything. Pick your top 2-3 accomplishments per role and aim to have at least one metric for each position.

3. Tailor your examples to the job description

Quality engineering roles can vary significantly depending on the industry and specific position. To create a targeted resume, look for key skills and requirements in the job description and tailor your work experience examples accordingly.

For example, if the job emphasizes experience with ISO 9001 standards, you might include a bullet like:

Spearheaded successful ISO 9001:2015 certification audit, resulting in zero non-conformances and full compliance

If the job requires experience with lean manufacturing, you might say:

Implemented lean manufacturing principles to streamline production, reducing lead times by 20% and improving on-time delivery to 98%

By customizing your examples to the specific role, you show the hiring manager that you have the directly relevant experience they're looking for.

Our Score My Resume tool can help you optimize your resume to get past applicant tracking systems. It checks your resume against 30+ key criteria hiring managers look for and provides instant, expert feedback.

4. Show career growth and progression

Hiring managers love to see candidates who have progressed and taken on increasing responsibility throughout their careers. If you've earned promotions or advanced to roles with wider scope, make that clear in your work experience section.

One way to do this is by grouping multiple positions within the same company under one heading, like this:

ABC Manufacturing Senior Quality Engineer (2018-Present) Quality Engineer (2015-2018)

Then use your bullet points to show how your responsibilities and achievements grew with each role:

- Senior Quality Engineer: Led a team of 5 engineers to develop and implement new quality control processes, reducing scrap rate by 30%

- Quality Engineer: Designed and executed testing plans for new product launches, ensuring 98% first-pass quality

By highlighting your progression, you show that you have the drive and ability to succeed in roles with increasing responsibility and scope.

When describing your achievements, focus on the skills and experiences that are most transferable to the role you're targeting. Even if you're applying for a role in a different industry, you can frame your accomplishments in terms of the core quality engineering competencies they demonstrate.

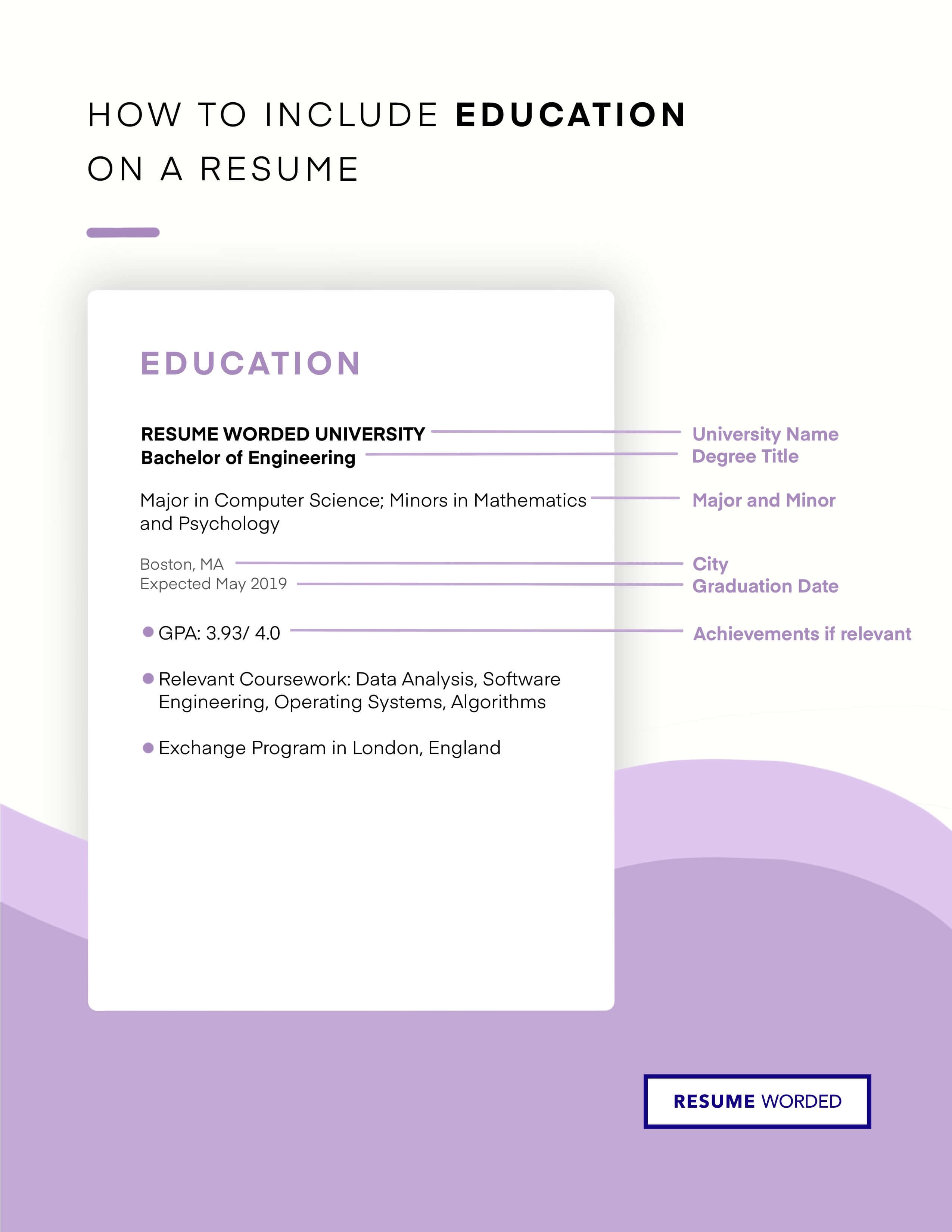

Education

Your education section is a vital part of your quality engineer resume. It shows employers that you have the necessary knowledge and skills to excel in the role. Use the following tips to make your education section stand out.

1. Include relevant coursework

If you're a recent graduate or have limited work experience, highlight relevant coursework that demonstrates your knowledge of quality engineering principles and techniques.

- Relevant Coursework: Quality Management, Statistical Process Control, Six Sigma, ISO 9001, Lean Manufacturing

Avoid listing generic courses that don't directly relate to quality engineering, such as:

- Relevant Coursework: English 101, Psychology 101, World History

2. Highlight your degree and major

Emphasize your degree and major, especially if it's directly related to quality engineering or a similar field.

Bachelor of Science in Industrial Engineering Purdue University, West Lafayette, IN GPA: 3.8/4.0

If your degree is in a different field, consider adding a brief explanation of how it relates to quality engineering.

3. Keep it concise for experienced professionals

If you have several years of experience as a quality engineer, your education section should be brief and to the point. Employers will be more interested in your professional achievements.

- M.S. in Quality Management, Arizona State University

- B.S. in Mechanical Engineering, University of Michigan

Avoid listing graduation dates if you're concerned about age discrimination. For example:

- B.S. in Industrial Engineering, Georgia Institute of Technology, 1985

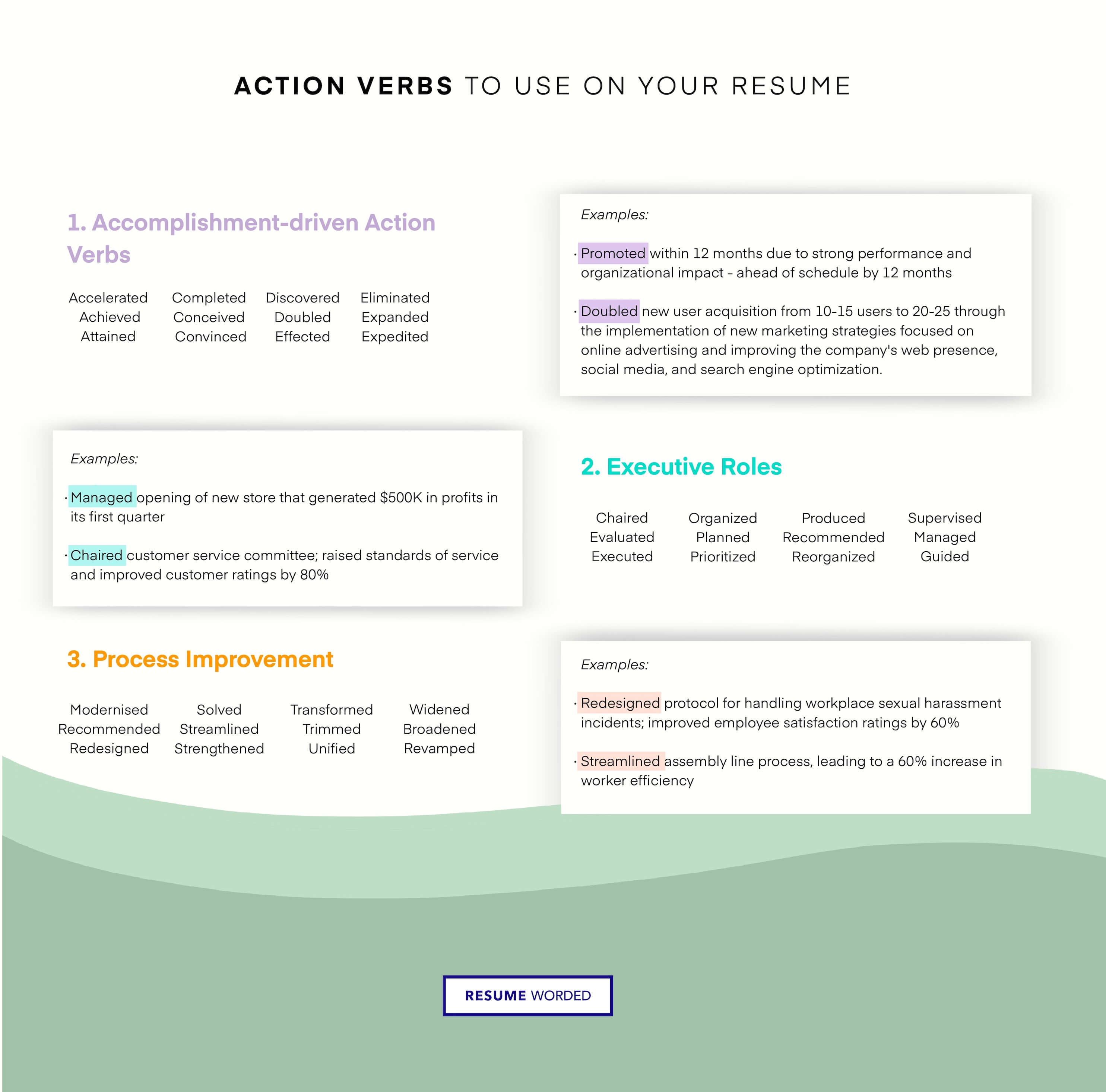

Action Verbs For Quality Engineer Resumes

Quality Engineers need to have experience testing and automating processes, developing procedures, and creating solutions to problems. You can emphasize these skills using your action verbs -examples: use Led and Managed to show your leadership skills. As you list your bullet points, remember to begin with an action verb. By doing this you are emphasizing what you’ve been able to achieve in other roles. Employers are looking for Quality Assurance Engineers that have proven results so use your action verbs to support this in your resume.

- Implemented

- Streamlined

For more related action verbs, visit Engineering Action Verbs .

For a full list of effective resume action verbs, visit Resume Action Verbs .

Action Verbs for Quality Engineer Resumes

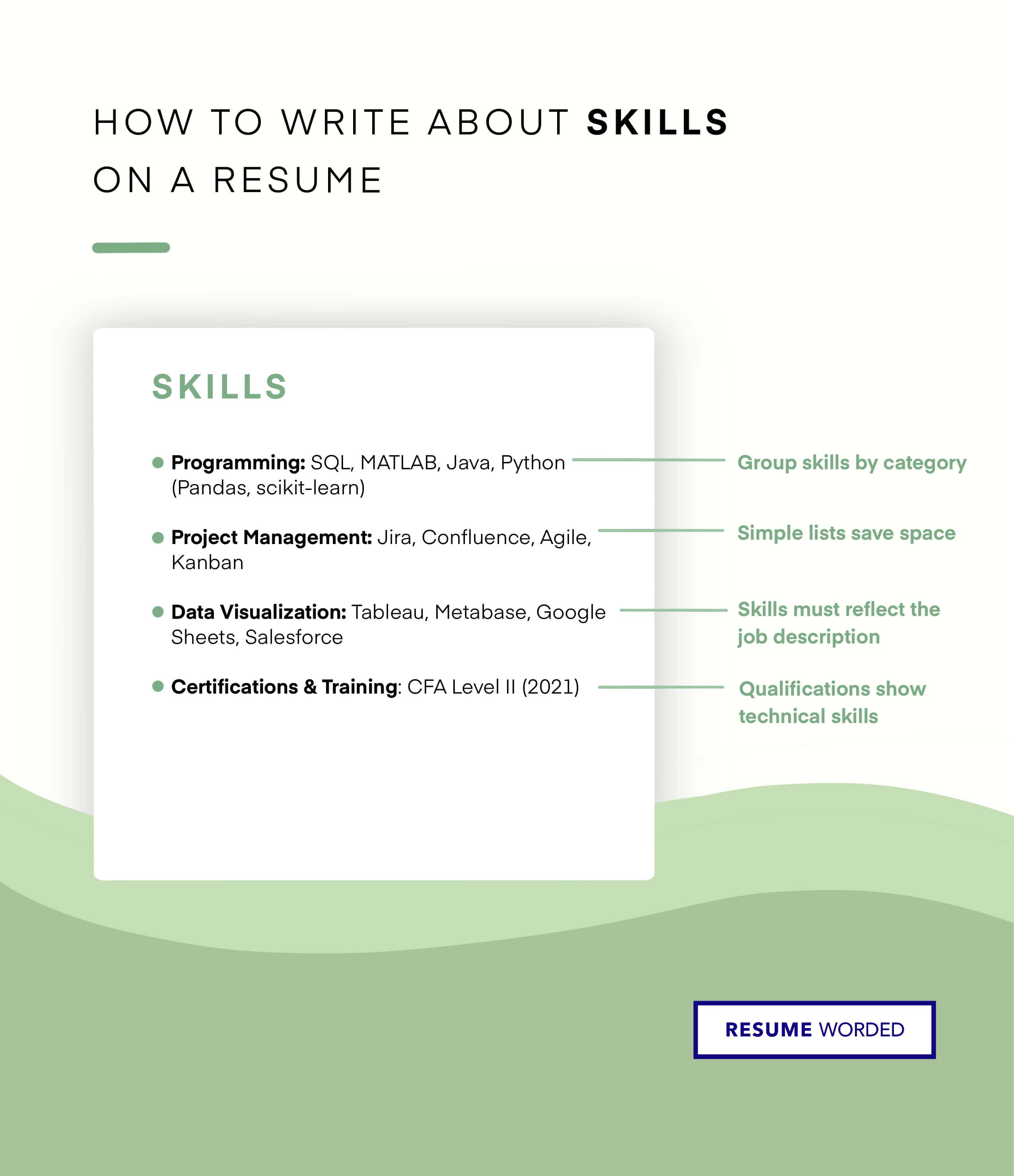

Skills for quality engineer resumes.

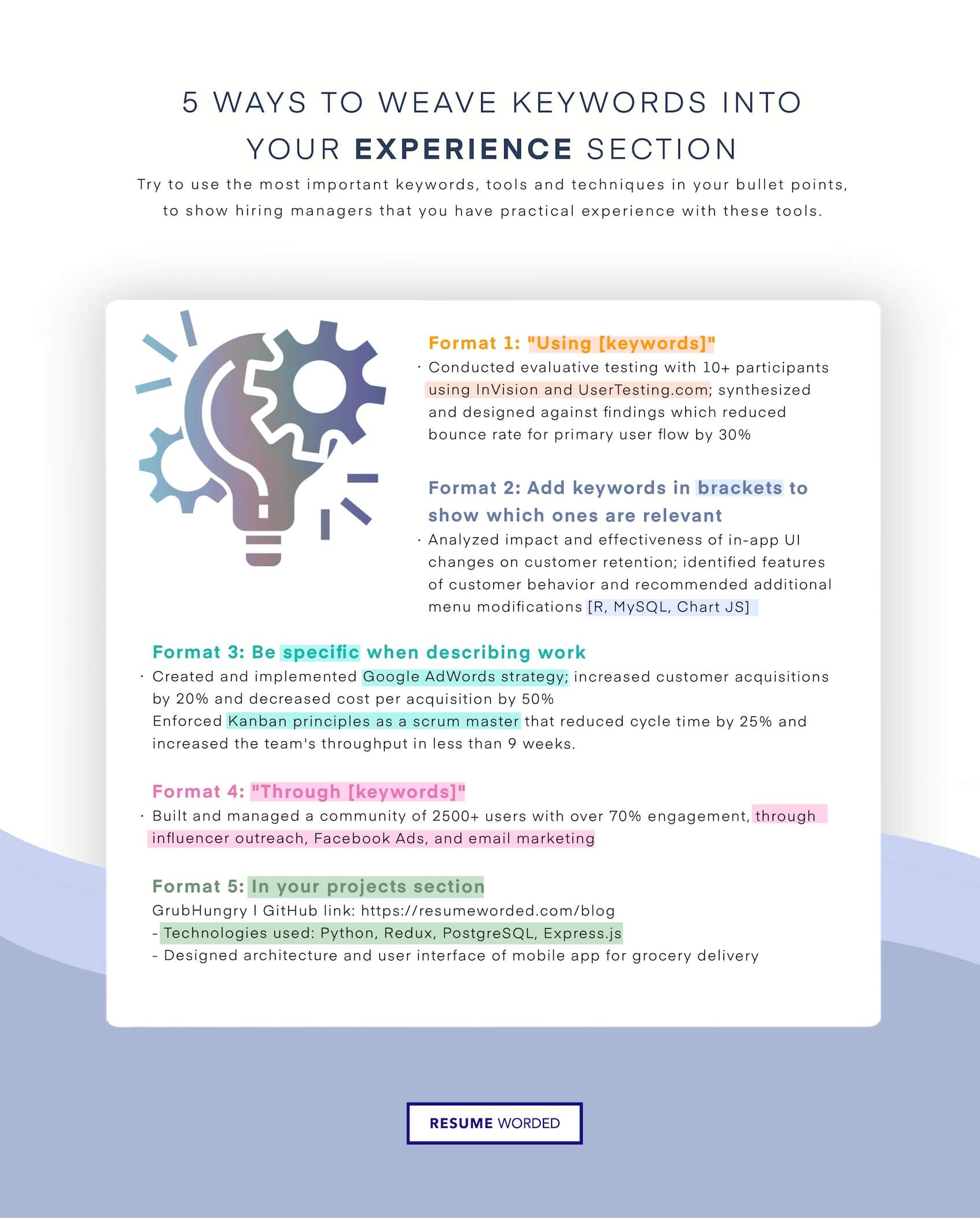

For Quality Engineer jobs, you will need to be skilled in programs or methodologies such as Six Sigma, Lean Manufacturing, AutoCAD and ISO 9001:2015. As you read through the job description carefully, you can include the skills that the company is looking for throughout your resume in your skills section or in your bullet points. You might say something like, “streamlined existing procedures based on the ISO 9001:2015 changes.” This will help you get through the Applicant Tracking System. This tracking system is typically an automated filter and as you use the specific words that the system is tracking, you will be more likely to be chosen by the system to move forward.

- Quality Management

- Failure Mode and Effects Analysis (FMEA)

- Quality Assurance

- Production Part Approval Process (PPAP)

- Advanced Product Quality Planning (APQP)

- Continuous Improvement

- Quality System

- Manufacturing

- Root Cause Analysis

- Statistical Process Control (SPC)

- Engineering

- Supplier Quality

- Lean Manufacturing

- ISO/TS 16949

- ISO Standards

Skills Word Cloud For Quality Engineer Resumes

This word cloud highlights the important keywords that appear on Quality Engineer job descriptions and resumes. The bigger the word, the more frequently it appears on job postings, and the more 'important' it is.

How to use these skills?

Resume bullet points from quality engineer resumes.

You should use bullet points to describe your achievements in your Quality Engineer resume. Here are sample bullet points to help you get started:

Created knowledge base of 80 internal resources, improving employee onboarding and reducing time spent per project on administrative tasks by 40%

Introduced standardized on-boarding templates and training program for 100+ new joiners; reduced employee on-boarding time from one month to just one week

Led 2 business analysts to automate repetitive process flows using Excel Macros / VBA and reduce analysis time by 10+ hours per week

Designed strategy for large-scale operational transformation initiative encompassing 1700+ full-time employees (FTEs), resulting in 500 FTE savings

Received Recognition Award for automating booking system, reducing required man-hours by 75%; promoted 6 months ahead of schedule

For more sample bullet points and details on how to write effective bullet points, see our articles on resume bullet points , how to quantify your resume and resume accomplishments .

Other Engineering Resumes

Industrial engineer.

Manufacturing Engineer

Packaging Engineer

- Software Engineer Resume Guide

- Software Developer Resume Guide

- Web Developer Resume Guide

- Programmer Resume Guide

- Front End Developer Resume Guide

- DevOps Resume Guide

- Full Stack Developer Resume Guide

- Java Developer Resume Guide

- Python Developer Resume Guide

- IT Manager Resume Guide

- Cyber Security Resume Guide

- Salesforce Resume Guide

- Quality Assurance Resume Guide

Quality Engineer Resume Guide

- Electrical Engineer Resume Guide

- System Administrator Resume Guide

- Scrum Master Resume Guide

- Civil Engineer Resume Guide

- Network Administrator Resume Guide

- Mechanical Engineer Resume Guide

- Manufacturing Engineer Resume Guide

- Network Engineer Resume Guide

- Node.js Resume Guide

- SQL Developer Resume Guide

- Integration Architect Resume Guide

- Engineering Manager Resume Guide

- Software Tester Resume Guide

- Service Technician Resume Guide

- Platform Engineer Resume Guide

- Automation Engineer Resume Guide

- C, C++, and C# Developer Resume Guide

- Technical Support Resume Guide

- Project Engineer Resume Guide

- Security Manager Resume Guide

- Electronic Technician Resume Guide

- System Engineer Resume Guide

- IT Specialist Resume Guide

- Packaging Engineer Resume Guide

- Oracle Resume Guide

- Planning Engineer Resume Guide

- Blockchain Resume Guide

- Cloud Developer Resume Guide

- ETL Developer Resume Guide

- SharePoint Developer Resume Guide

- Kafka Resume Guide

- Audio Engineer Resume Guide

- HVAC Resume Guide

- Industrial Engineer Resume Guide

- Maintenance Technician Resume Guide

- Solutions Architect Resume Guide

- Implementation Specialist Resume Guide

- Software Architect Resume Guide

- PHP Developer Resume Guide

- Biomedical Engineer Resume Guide

- Robotics Resume Guide

- Chief Digital Officer Resume Guide

- Innovation Resume Guide

- Security Analyst Resume Guide

- IT Auditor Resume Guide

- Director of Software Engineering Resume Guide

- Environmental Engineer Resume Guide

- Technology Director Resume Guide

- Director of Information Technology Resume Guide

- AWS Resume Guide

- Director of Engineering Resume Guide

- Materials Engineer Resume Guide

- UAT Tester Resume Guide

- Quality Engineer Resume Example

- QA (Quality Assurance) Engineer Resume Example

- Senior Quality Engineer Resume Example

- Supplier Quality Engineer Resume Example

- Tips for Quality Engineer Resumes

- Skills and Keywords to Add

- Sample Bullet Points from Top Resumes

- All Resume Examples

- Quality Engineer CV Examples

- Quality Engineer Cover Letter

- Quality Engineer Interview Guide

- Explore Alternative and Similar Careers

Download this PDF template.

Creating an account is free and takes five seconds. you'll get access to the pdf version of this resume template., choose an option..

- Have an account? Sign in

E-mail Please enter a valid email address This email address hasn't been signed up yet, or it has already been signed up with Facebook or Google login.

Password Show Your password needs to be between 6 and 50 characters long, and must contain at least 1 letter and 1 number. It looks like your password is incorrect.

Remember me

Forgot your password?

Sign up to get access to Resume Worded's Career Coaching platform in less than 2 minutes

Name Please enter your name correctly

E-mail Remember to use a real email address that you have access to. You will need to confirm your email address before you get access to our features, so please enter it correctly. Please enter a valid email address, or another email address to sign up. We unfortunately can't accept that email domain right now. This email address has already been taken, or you've already signed up via Google or Facebook login. We currently are experiencing a very high server load so Email signup is currently disabled for the next 24 hours. Please sign up with Google or Facebook to continue! We apologize for the inconvenience!

Password Show Your password needs to be between 6 and 50 characters long, and must contain at least 1 letter and 1 number.

Receive resume templates, real resume samples, and updates monthly via email

By continuing, you agree to our Terms and Conditions and Privacy Policy .

Lost your password? Please enter the email address you used when you signed up. We'll send you a link to create a new password.

E-mail This email address either hasn't been signed up yet, or you signed up with Facebook or Google. This email address doesn't look valid.

Back to log-in

These professional templates are optimized to beat resume screeners (i.e. the Applicant Tracking System). You can download the templates in Word, Google Docs, or PDF. For free (limited time).

access samples from top resumes, get inspired by real bullet points that helped candidates get into top companies., get a resume score., find out how effective your resume really is. you'll get access to our confidential resume review tool which will tell you how recruiters see your resume..

Writing an effective resume has never been easier .

Upgrade to resume worded pro to unlock your full resume review., get this resume template (+ 6 others), plus proven bullet points., for a small one-time fee, you'll get everything you need to write a winning resume in your industry., here's what you'll get:.

- 📄 Get the editable resume template in Google Docs + Word . Plus, you'll also get all 6 other templates .

- ✍️ Get sample bullet points that worked for others in your industry . Copy proven lines and tailor them to your resume.

- 🎯 Optimized to pass all resume screeners (i.e. ATS) . All templates have been professionally designed by recruiters and 100% readable by ATS.

Buy now. Instant delivery via email.

instant access. one-time only., what's your email address.

I had a clear uptick in responses after using your template. I got many compliments on it from senior hiring staff, and my resume scored way higher when I ran it through ATS resume scanners because it was more readable. Thank you!

Thank you for the checklist! I realized I was making so many mistakes on my resume that I've now fixed. I'm much more confident in my resume now.

Privacy preference center

We care about your privacy

When you visit our website, we will use cookies to make sure you enjoy your stay. We respect your privacy and we’ll never share your resumes and cover letters with recruiters or job sites. On the other hand, we’re using several third party tools to help us run our website with all its functionality.

But what exactly are cookies? Cookies are small bits of information which get stored on your computer. This information usually isn’t enough to directly identify you, but it allows us to deliver a page tailored to your particular needs and preferences.

Because we really care about your right to privacy, we give you a lot of control over which cookies we use in your sessions. Click on the different category headings on the left to find out more, and change our default settings.

However, remember that blocking some types of cookies may impact your experience of our website. Finally, note that we’ll need to use a cookie to remember your cookie preferences.

Without these cookies our website wouldn’t function and they cannot be switched off. We need them to provide services that you’ve asked for.

Want an example? We use these cookies when you sign in to Kickresume. We also use them to remember things you’ve already done, like text you’ve entered into a registration form so it’ll be there when you go back to the page in the same session.

Thanks to these cookies, we can count visits and traffic sources to our pages. This allows us to measure and improve the performance of our website and provide you with content you’ll find interesting.

Performance cookies let us see which pages are the most and least popular, and how you and other visitors move around the site.

All information these cookies collect is aggregated (it’s a statistic) and therefore completely anonymous. If you don’t let us use these cookies, you’ll leave us in the dark a bit, as we won’t be able to give you the content you may like.

We use these cookies to uniquely identify your browser and internet device. Thanks to them, we and our partners can build a profile of your interests, and target you with discounts to our service and specialized content.

On the other hand, these cookies allow some companies target you with advertising on other sites. This is to provide you with advertising that you might find interesting, rather than with a series of irrelevant ads you don’t care about.

Quality Engineer Resume Examples & Writing Guide for 2024

To land a job as a quality engineer, the first step is to create a compelling resume that catches the attention of employers.

Get ready to harness the power of quality control, process improvement, and problem-solving skills, as we navigate the intricacies of presenting your expertise on paper.

Whether you're a seasoned quality aficionado or just stepping into the world of quality engineering, this guide will equip you with the tools to showcase your abilities and land that dream role.

In this guide, we will teach you everything you need to know about writing a resume as a quality engineer. Keep reading to learn how to:

- Select a resume format that matches your experience level

- Write a resume summary that impresses employers

- Include key quality engineering skills on your resume

- Describe your responsibilities and accomplishments at previous jobs

- List your educational credentials correctly on your resume

- Elevate your quality engineer resume with relevant extra sections

- Find the best job search resources for quality engineers

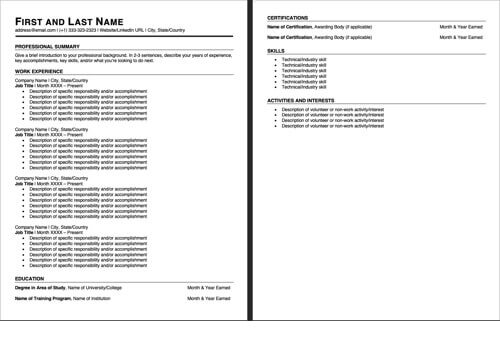

1. Select a resume format that matches your experience level

As a quality engineer, you will generally want to select a resume format that highlights your real-life professional experience . The best format for this purpose is the reverse-chronological resume , which focuses primarily on work experience.

In the reverse-chronological format, you will list your most recent job first, working chronologically backward from this point.

However, a format that focuses on work experience is not ideal for all applicants – especially those who have less than a year’s experience within the field. In this case, you can consider using one of the following alternative formats:

- The functional resume : Functional resumes focus on education, skills, and unpaid experience rather than formal work experience. This format is very well-suited by recent or soon-to-be college graduates who have extensive academic experience but limited employment examples.

- The hybrid resume: Hybrid resumes eliminate any central focus, instead spreading the emphasis of the document out more evenly between all sections. This format works well for applicants who have professional experience in other fields who are changing careers, as well as those who are working around gaps in their work histories.

Choose your preferred template and make your resume shine.

Try our AI Resume Writer and have your resume ready in minutes!

2. write a quality engineer resume summary that impresses employers.

A resume summary is a brief introductory statement at the start of your resume. In this summary, you should focus on including information that is highly valuable and eye-catching to employers, such as years of experience and notable accomplishments .

To demonstrate how to write an effective resume summary, we have included a weak example below, followed by a corrected example and explanation.

Incorrect quality engineer resume summary example

Experience Quality Engineer with a background in cosmetics manufacturing. Proven track record of increasing production output through optimized workflows that simultaneously reduce errors. Skills include product quality testing, quality assurance, quality auditing, and deep knowledge of compliance.

Why is this incorrect?

In this example, the applicant is far too vague when discussing their “proven track record.” When describing accomplishments, it is always better to show rather than tell, meaning you should use quantifiable figures and statistics when possible. Additionally, the applicant focuses too much on their various skills – these should be omitted and moved to a dedicated skills section.

Corrected quality engineer resume summary example

Resourceful Quality Engineer with 7+ years of experience with cosmetics manufacturing plants. Specialized in quality assurance and auditing, averaging a 65% decrease in production errors at 3 previous positions. Achieved a 40% increase in production output while maintaining a production error rate of less than 2% in most recent position.

Why is this correct?

In this corrected example, the applicant is much more explicit with the details they provide. An employer reading this will have much greater context around their skills and accomplishments, making them more likely to continue reading the rest of the document due to the impressive achievement detailed in this summary.

3. Include key quality engineering skills on your resume

As a quality engineer, your job will require you to not only have the technical know-how to ensure proper production standards are met but also a strong set of interpersonal abilities to effectively communicate with your company and team.

To show that you possess this full range of abilities , you should include both hard and soft skills on your quality engineer resume. Hard skills refer to your technical and learned abilities, while soft skills refer to your interpersonal ones.

Below are 10 ideas for both hard and soft skills that look great on a Quality Engineer’s resume:

The best quality engineer hard skills to put on your resume

- Process documentation

- Production reports

- Product testing

- Material & equipment inspection

- Developing quality management systems

- OSHA safety standards

- Quality control workflows

- Data analytics

- Improvement recommendations

- Quality assurance consultations

Effective soft skills to put on your quality engineer CV

- Clear communication (both verbal & non-verbal)

- Collaboration

- Critical & analytical thinking

- Attention to detail

- Thoroughness

- Organization

- Time management

- Active listening

- Strict adherence to deadlines

4. Make your quality engineer work experience section stand out

Crafting the ideal work experience section on a resume requires more than simply listing out your responsibilities at a previous job. You should aim to include as many specific and quantifiable details as possible, with an emphasis on key accomplishments that employers will find valuable.

Additionally, to keep this section organized, you should use bullet points to create your job descriptions. Each bullet point should contain one concise sentence and should ideally be no more than two lines of text.

However, for accomplishments that require extra contextual information, an additional sentence or line of text may be acceptable.

Here is an example of a work experience entry from a quality engineer resume

Mac’s Manufacturing, Birmingham, AL Quality Engineer April 2019 to January 2022

- Prepared annual product reviews for all basic products, improving production review efficiency by 20%.

- Supervised onsite product testing and performance, providing full performance reviews and recommendations for improvement monthly.

- Implemented 10 new quality assurance procedures, reducing product errors and malfunctions by 35%.

Find out your resume score!

5. List your educational credentials correctly on your quality engineer resume

To work in an engineering position, employers will almost always expect you to have a minimum of a bachelor’s degree in a related engineering program.

However, to make both your resume and yourself as a professional more competitive , you should also consider completing relevant certification programs as well. This is especially important for quality engineers, who may have an engineering degree that is not specialized in quality engineering.

Here is an example of a well-crafted education section on a quality engineer resume:

University of Central Florida, Orlando, FL B.S. in Engineering Graduated: 2016, Magna Cum Laude

Certifications

- Certified Quality Engineer — American Society for Quality (ASQ), 2020

6. Elevate your quality engineer resume with relevant extra sections

In the dynamic realm of quality engineering, standing out from the crowd is essential. That's why incorporating relevant extra sections into your quality engineer resume can make all the difference.

These additional sections provide valuable insights into your skills , achievements , and unique qualifications , helping you leave a lasting impression on potential employers.

One such extra section to consider is " Certifications and Training ," where you can showcase specialized courses and certifications that highlight your expertise in quality management systems or specific methodologies such as Six Sigma or Lean Manufacturing. This demonstrates your commitment to continuous improvement and keeps you ahead of the curve.

Here is an example of how to list extra sections in your quality engineer resume

Professional Affiliations and Memberships

- American Society for Quality (ASQ)

- International Quality Federation (IQF)

Volunteering Experience

- Assisted in building homes for low-income families, focusing on quality control and adherence to safety standards.

- Collaborated with a team of volunteers to complete construction tasks efficiently and effectively.

- Demonstrated strong attention to detail in ensuring the accuracy of measurements and the proper installation of materials.

7. Valuable job search resources for quality engineers

Locating the optimal career opportunity as a quality engineer involves more than just updating your resume. It's important to have a set of reliable job search tools at your disposal. Here are some of the most effective platforms for a quality engineer job search:

- Engineering.com : This niche job board caters specifically for engineers. On it, you can find a multitude of postings for quality engineers across different industries.

- Indeed : As one of the largest job search websites globally, Indeed offers a wide array of quality engineering positions. The platform allows you to filter by location, salary, and job type.

- LinkedIn : This professional networking site doubles as a resourceful job search platform. It offers an extensive range of job postings, including those for quality engineers, and allows you to directly connect with potential employers.

- Glassdoor : In addition to a robust job search feature, Glassdoor can also provide insights into the company culture, benefits, and employee experiences of potential employers.

Harness these resources for a more streamlined, effective job search. Ensure your resume is up-to-date and tailor your applications to fit each specific role. Persistence is key in the job hunt journey, so keep going — your ideal quality engineering role could be just a few clicks away!

Still looking for a job? These 100+ resources will tell you everything you need to get hired fast.

Quality Engineer Resume FAQ

Highlight technical skills like proficiency in quality control software, knowledge of ISO 9001, and statistical analysis. Also, emphasize soft skills such as problem-solving, communication, and attention to detail.

List your experiences in reverse chronological order. For each position, mention your job title, the company name, the period of employment, and bullet points describing your key responsibilities and quantifiable achievements.

If you're a fresh graduate or changing careers, an objective statement can clarify your career goals. If you're experienced, replace it with a summary statement that provides a snapshot of your skills and achievements.

Tailor your resume to the job description, use action verbs, and quantify achievements where possible. Also, highlight any awards, certifications, or major projects related to quality engineering.

It's typically not necessary to include references on your resume. Most employers will ask for them later in the process if needed.

Nikoleta Kuhejda

A journalist by trade, a writer by fate. Nikoleta went from writing for media outlets to exploring the world of content creation with Kickresume and helping people get closer to the job of their dreams. Her insights and career guides have been published by The Female Lead , College Recruiter , and ISIC, among others. When she’s not writing or (enthusiastically) pestering people with questions, you can find her traveling or sipping on a cup of coffee.

All engineering resume examples

- Aerospace Engineer

- CAD Designer

- Chemical Engineer

- Civil Engineer

- Electrical Engineer

- Mechanical Engineer

- Production Manager

- QA Engineer (Quality Assurance)

All quality engineer resume examples

Related quality engineer cover letter examples

Resume guides

How to write a professional resume summary [+examples], how to put your education on a resume [+examples], how to describe your work experience on a resume [+examples], let your resume do the work..

Join 5,000,000 job seekers worldwide and get hired faster with your best resume yet.

- Quality Engineer Resume Example

Resume Examples

- Common Tasks & Responsibilities

- Top Hard & Soft Skills

- Action Verbs & Keywords

- Resume FAQs

- Similar Resumes

Common Responsibilities Listed on Quality Engineer Resumes:

- Develop and implement quality control systems to ensure product and process compliance with customer and industry standards

- Monitor and analyze product and process performance to identify areas of improvement

- Develop and execute test plans and protocols to ensure product quality

- Investigate customer complaints and non-conformance issues

- Develop and implement corrective and preventive actions

- Develop and maintain quality documentation systems

- Develop and maintain quality metrics and reports

- Participate in internal and external audits

- Train and mentor other quality engineers

- Lead continuous improvement initiatives

- Analyze and interpret data to identify trends and root causes

- Develop and implement process control systems to ensure product and process compliance with customer and industry standards

Speed up your resume creation process with the AI-Powered Resume Builder . Generate tailored achievements in seconds for every role you apply to.

Quality Engineer Resume Example:

- Developed and implemented a new quality control system, resulting in a 25% reduction in defects and a 15% increase in customer satisfaction.

- Analyzed product and process performance data to identify areas for improvement, leading to a 20% increase in production efficiency and a 10% reduction in waste.

- Lead continuous improvement initiatives, resulting in a 30% reduction in non-conformance issues and a 20% increase in on-time delivery.

- Developed and executed test plans and protocols to ensure product quality, resulting in a 15% reduction in product recalls and a 10% increase in product reliability.

- Investigated customer complaints and non-conformance issues, leading to the implementation of corrective and preventive actions that resulted in a 20% reduction in customer complaints and a 15% increase in customer satisfaction.

- Participated in internal and external audits, resulting in a 100% compliance rate and a 10% increase in audit scores.

- Developed and maintained quality documentation systems, resulting in a 20% reduction in documentation errors and a 15% increase in documentation accuracy.

- Analyzed and interpreted data to identify trends and root causes, leading to the implementation of process control systems that resulted in a 25% reduction in defects and a 20% increase in production efficiency.

- Trained and mentored other quality engineers, resulting in a 30% increase in team productivity and a 15% improvement in team satisfaction scores.

- Quality control systems

- Data analysis and interpretation

- Process improvement

- Continuous improvement initiatives

- Test plan development and execution

- Root cause analysis

- Corrective and preventive actions

- Internal and external auditing

- Quality documentation systems

- Process control systems

- Team training and mentoring

- Customer complaint resolution

- Product reliability

- Production efficiency

- Waste reduction

- On-time delivery

- Compliance management

Top Skills & Keywords for Quality Engineer Resumes:

Hard skills.

- Statistical Process Control (SPC)

- Root Cause Analysis (RCA)

- Failure Mode and Effects Analysis (FMEA)

- Quality Management Systems (QMS)

- Six Sigma Methodology

- Lean Manufacturing Principles

- ISO 9001 Standards

- Quality Auditing

- Calibration and Metrology

- Design of Experiments (DOE)

- Supplier Quality Management

- Corrective and Preventive Action (CAPA)

Soft Skills

- Attention to Detail and Accuracy

- Analytical and Data-Driven Thinking

- Continuous Improvement and Process Optimization

- Teamwork and Collaboration

- Communication and Interpersonal Skills

- Problem Solving and Troubleshooting

- Time Management and Prioritization

- Adaptability and Flexibility

- Leadership and Mentoring

- Quality Assurance and Compliance

- Root Cause Analysis and Corrective Action

- Risk Management and Mitigation

Resume Action Verbs for Quality Engineers:

- Implemented

- Collaborated

- Streamlined

- Investigated

- Standardized

- Facilitated

- Troubleshot

Generate Your Resume Summary

Resume FAQs for Quality Engineers:

How long should i make my quality engineer resume, what is the best way to format a quality engineer resume, which keywords are important to highlight in a quality engineer resume, how should i write my resume if i have no experience as a quality engineer, compare your quality engineer resume to a job description:.

- Identify opportunities to further tailor your resume to the Quality Engineer job

- Improve your keyword usage to align your experience and skills with the position

- Uncover and address potential gaps in your resume that may be important to the hiring manager

Complete the steps below to generate your free resume analysis.

Related Resumes for Quality Engineers:

Quality engineer, automation test engineer, automotive quality engineer, qa engineer, software qa manager, software tester, automation tester, automotive test engineer.

Quality Engineer Resume: Sample and Free Template [2020]

Use these quality engineer resume sample bullets to create your resume and land your dream job. all of these can be accessed for free in our in-product quality engineer resume templates. explore them below., search quality engineer resume bullets for your resume:.

- Managed a $2M project to improve the process of a new, high speed data center

- Managed all phases of the design and development process for a new product

- Managed multiple project projects from inception to closeout, ensuring all deadlines and timelines are met

- Managed project to improve the accuracy of data and to reduce the number of errors

- Managed engineering and manufacturing teams for the design of a high-speed fiber optic network

- Managed projects from initiation through delivery, ensuring that the quality of work is maintained and meets the requirements of regulatory bodies

- Managed risk and identified opportunities to improve process performance and quality

- Managed, monitored and evaluated the quality of all work

- Managed an engineering change control process for a new system

- Managed over 100 projects and achieved a 95 percent on-time delivery

- Managed the implementation of a $2M project to upgrade the existing network infrastructure

- Managed a $10MM annual project to improve the reliability of a large-format printer

- Managed all phases of project from initial concept development, design and implementation to final production

- Managed over 100+ workflows and projects for the project

- Managed development of a quality system for the entire product portfolio

- Managed a team of 6 to 8 people in the development of a new software package for the company

- Managed all aspects of the production process from initial concept through completion of the final assembly

- Managed multiple projects and provided leadership to a staff of 15 engineers and technicians

- Managed daily operations of a multi-site manufacturing environment

- Managed an engineering group of 5 engineers and 3 supervisors

- Managed engineering change requests and provided technical guidance to the Engineering Department on all project changes

- Managed team of 5 employees and oversaw the day -to-. Responsive to customer service, problem- solving and quality control

- Managed an engineering group of 5 engineers and 3 support personnel in the development of a new process for the manufacture of a high speed laser

- Performed analysis of the data and developed a report to be used by the management

- Performed quantitative and graphical analysis of the statistical process and data

- Performed in depth analyses of the manufacturing processes and developed a comprehensive report to support the manufacturing process

- Performed data analysis and developed a comprehensive plan to implement the project in a

- Performed analysis of the performance and quality assurance data to identify areas of improvement and recommended corrective action

- Maintained and updated the PPAPS (Quality Management Process).

- Maintained a clean and safe working enviorement for the entire plant and its personnel

- Maintained the highest standards of customer satisfaction and service in a fast paced, high-volume environment

- Maintained all aspects of the company, from scheduling to production

- Maintained an inventory of all equipment and parts for the company

- Maintained production schedules and quality standards, monitored product performance

- Maintained all data for the department and maintained a high standard of quality and accuracy

- Maintained records of work performed and the progress made to ensure that corrective action is taken

- Maintained daily production schedule, and monitored quality of finished product

- Maintained an inventory of all equipment and parts for the department

- Maintained project schedules and budgets, managed projects through the project lifecycle

- Maintained daily production and test logs

- Maintained and updated the quality management database for all of the company's quality programs

- Maintained a high quality of product and customer relations by maintaining a high standard of quality

- Maintained a database of the number and types used in statistical analysis

- Maintained accurate and timely production of the following equipment

- Maintained high level of accuracy and quality

- Maintained accurate and timely data for the development of a project management tool to track the progress of projects

- Maintained an accurate, up keep of the plant

- Maintained daily production and inspection reports, performed weekly quality checks and maintained all production logs

- Maintained detailed project records and performed quality assurance testing of various products

- Maintained a high degree of quality assurance and reliability for the entire manufacturing process

- Maintained monthly and yearly production schedules for the plant and its employees

- Maintained and repaired various electrical equipment

- Maintained the PPAPS and PAP for all projects

- Maintained all aspects of the project including, design review and approval of all work, scheduling for the construction of all projects

- Maintained an inventory of raw material, parts and finished goods for the manufacturing of a wide range products

- Maintained daily production schedule and quality control for the company

- Maintained records of work completed and submitted to the project manager for review

- Maintained high standards of cleanness and safety in work areas, equipment storage methods and pallets

- Maintained 100% compliance with ISO 9000 and Quality Assessment Manual (SAMS).

- Maintained, repaired and tested various types of electrical components

- Maintained project schedule and ensured that all required tasks, including the development of project scope, milestones and schedules

- Maintained project schedule and ensured all required materials are ordered and received in a time sensitive manner

- Maintained daily production and material control records, ensuring compliance with all safety and health standards

- Maintained detailed project schedules for multiple projects, coordinated with project management to ensure deadlines are met

- Maintained production schedule and ensured all equipment is in proper working condition for production

- Assisted in the design and implementation of a prototype for the new product line

- Assisted with the design and implementation of a CNC machining system for the company

- Assisted the project team in identifying and implementing new process improvement initiatives

- Assisted customers with technical issues and resolved them in a professional manner

- Assisted engineers in the development of a process to improve the quality of a product

- Assisted engineering in the design and implementation of a variety test equipment

- Assisted Engineers in the design and implementation of a variety engineering projects

- Assisted engineers in the design and implementation of a novel, high-throughput process for the manufacture of a new, low cost product

- Assisted Project Managment with the development of a project management system for the development of a project manager for the implementation of a project manager for the development of a project manager

- Assisted Engineers in the development of new products and procedures for the manufacturing of new product lines

- Assisted clients in the development of a comprehensive plan to address their business and financial challenges

- Assisted project managers in the design and implementation of a variety engineering projects for the Department of Energy

- Assisted clients with the development of a comprehensive, cost effective and efficient process for the development of a comprehensive, and efficient

- Assisted clients with the development of a comprehensive plan for the implementation of a new system for the FFE

- Assisted in the creation of a product line for the first time in company history

- Assisted the project managers in identifying and implementing process changes to improve the project management system

- Assisted customers with purchasing and maintaining a clean, organized work environment

- Assisted engineers in the preparation of corrective action documents for the following Corrected and maintained all documentation for the project

- Assisted project manager with the implementation of a project to reduce the number of defects in a project

- Assisted customers with technical support and product knowledge related to products

- Assisted on the project to design and develop a data base for the development of a new product

- Assisted on the production of a new process for the manufacture of a product

- Assisted Engineers in the preparation of a variety engineering reports for the Department of Energy

- Assisted Production Engineers in the planning and implementation of manufacturing procedures, processes

- Assisted Engineering in the identification of a process and system problem

- Assisted clients with all phases of the project lifeprogramming process from initial start-up to project closure

- Assisted Engineers in the construction of a large industrial wastewater plant

- Assisted customer with their purchase of a vehicle and assisted with the installation of new vehicle

- Assisted with the design and implementation of a system to track the production of a variety products

- Assisted the PM with all phases of PPAPS and PMO activities

- Assisted engineers in the testing and troubleshoots of production machinery, including the testing and repair of production machines

- Assisted customers with the installation of new and replacement parts

- Assisted Project Manager in the design and implementation of a new process for the manufacturing of a novel polymer

- Assisted on the design and implementation of a statistical software package for the Department of Energy's National Grid

- Assisted and trained employees in the use of various types and methods to ensure the quality of products

- Assisted project manager in the design and implementation of a new process for the manufacturing of a high-pressure, liquid oxygen fuel system

- Assisted project manager with the design and development of a new system for the SPSS

- Assisted and supported the FFEA in developing a new FFEB program

- Assisted and supported the project manager in all phases of the design and construction process

- Assisted clients in the identification of root causes and solutions to prevent, detect or resolve problems

- Assisted a team of 5 Engineers in the design and development of a new process for the manufacturing of a novel product

- Assisted clients with the selection of their home improvement projects

- Assisted Engineering in the preparation of a report for an audit

- Assisted management with the preparation of statistical data for presentation to the board of education

- Perform calculations and reports for the analysis of statistical information and trends

- Perform analytical and technical research to develop statistical methods and procedures for the purpose of analyzing and reporting on the performance of various programs and services

- Perform on-going analysis of manufacturing process and product performance to determine root- cause of product failures

- Provided technical guidance and support to the Engineering, Manufacturing & Quality departments on the development of new processes and procedures

- Provided support to the Engineering and Manufacturing teams in developing new processes and systems for the manufacturing of high quality products

- Provided support to the Quality Engineer in developing and maintaining the Quality Management system

- Provided recommendations for improvement of the quality system and process improvement

- Provided oversight for the development of a comprehensive, cost effective corrective action program for the company

- Provided feedback to the Quality Control Department on corrective action procedures

- Provided analysis and recommendations for product design

- Provided design and development of a statistical model to evaluate the effectiveness of a new system for the department

- Provided detailed reports to management and senior leadership on the progress of projects and activities

- Provided input to the design and implementation of a system to track and monitor the quality of all product

- Provided technical assistance to the Engineering department in developing and testing new equipment for the company

- Provided support to the manufacturing and quality teams for all processes

- Provided leadership and guidance to the team in developing and maintaining a quality control program for the company

- Provided oversight for the implementation of a comprehensive, integrated process improvement plan for the company's manufacturing operations

- Provided feedback to the team on corrective action andor improvement opportunities

- Provided onsite engineering and project support for the design, development and delivery of a new product

- Provided input to the design and implementation of a process for the production line

- Provided detailed reports to the management and staff on all projects

- Provided support to the project manager and engineering staff to ensure the completion of all project requirements

- Provided reports to the Board of Directors and other management

- Provided solutions to the engineering, manufacturing and customer support teams to ensure the successful delivery of quality products

- Provided a variety of administrative and technical assistance to the Director of Operations and other senior management

- Provided engineering support to the development of a comprehensive, risk-management program for the US Air Force

- Developed and maintained a database of over 200 suppliers and vendors

- Developed process improvement strategies to reduce the amount of waste and increase productivity by 30% in the manufacturing of high quality parts

- Developed the design and implementation of a process to improve the quality of a product

- Developed new process and procedures for the production of a variety products

- Developed & executed a comprehensive process to identify and resolve issues with the product

- Developed policies and processes to mitigate risks, identify opportunities and implement solutions to mitigate risk

- Developed design and implementation of a process to improve the efficiency of a new product

- Developed procedures for the development of a system to monitor the performance of a system

- Developed procedures for the development of a process to improve the quality of a product

- Developed standard procedures for the manufacturing of high quality parts and assemblies

- Developed high performance manufacturing processes and systems for the production of high quality automotive parts

- Developed a new product that is now used in the industry

- Developed a new method to calculate the percentage of time that a given amount is processed by the company

- Developed new process for the development of a high speed digital camera

- Developed an APIQC system for the development of a new product for the production of a high speed liquid chromatographic analyzine

- Developed & executed a process for the removal of all hazardous waste from the plant

- Developed project plan for the implementation of a system to monitor the quality of all incoming and outgoing materials

- Developed project schedules for the entire plant, coordinated with engineering and manufacturing to ensure the plant was in good condition

- Developed and implemented a manufacturing system for the manufacture of industrial and consumer products

- Developed a new system for the FFEB to track and monitor all aspects of the project

- Developed, implemented and managed a statistical analysis of the data for a large, complex project

- Developed the process for creating and maintaining a quality system for the manufacturing of a wide variety products

- Developed process and procedures for the development of a high-performance manufacturing facility

- Developed an audit program for the company to review and audit all the processes

- Developed inspection procedures and test plans for the following inspection procedures

- Developed & implemented a manufacturing and engineering program for the company's new product development

- Developed analytical methods to measure the effectiveness of statistical analyses

- Developed procedures for the identification and resolution of all quality issues, identified root- cause and implemented corrective action

- Developed procedures and tools to support the development of process improvements and cost reduction

- Supervised and performed the analysis of data for a large scale project

- Supervised over 50 engineers and project management staff in the design, development and implementation of a new system for the company

- Supervised daily activities of the engineering team, ensuring all projects were completed on time and within budget

- Supervised the design of a computer-controlled instrument to evaluate the performance of a large-scale instrument

- Supervised daily operations of the manufacturing process, which involved quality assurance and process design

- Manage team of engineers and project management professionals to develop, implement and maintain the company's business process, procedures and policies

- Coordinated and supervised the development of a risk assessment and mitigation plan for the company

- Coordinated the development of a process for an electronic document control system

- Coordinated all aspects of the corrective action plan for all assigned projects

- Coordinated project activities with other engineering departments to meet deadlines and ensure quality of work

- Coordinated project with other engineering teams to identify and correct any issues