- My presentations

Auth with social network:

Download presentation

We think you have liked this presentation. If you wish to download it, please recommend it to your friends in any social system. Share buttons are a little bit lower. Thank you!

Presentation is loading. Please wait.

BIM Building Information Modeling

Published by Prosper Dean Modified over 6 years ago

Similar presentations

Presentation on theme: "BIM Building Information Modeling"— Presentation transcript:

Course: e-Governance Project Lifecycle Day 1

Copyright 2002 Prentice-Hall, Inc. Chapter 4 Automated Tools for Systems Development 4.1 Modern Systems Analysis and Design Third Edition Jeffrey A. Hoffer.

Lecture Nine Database Planning, Design, and Administration

The Software Product Life Cycle. Views of the Software Product Life Cycle Management Software engineering Engineering design Architectural design.

Computer Systems & Architecture Lesson Software Product Lines.

Enterprise Architecture

The BIM Project Execution Planning Procedure

Introduction to BIM BIM Curriculum 01.

Database System Development Lifecycle © Pearson Education Limited 1995, 2005.

Overview of the Database Development Process

Systems Analysis – Analyzing Requirements. Analyzing requirement stage identifies user information needs and new systems requirements IS dev team.

Information Integration in Construction. Construction information In construction, architects, engineers, planners, contractors, facility managers....

Publish Your Work BIM Curriculum 04. Topics External Collaboration Sharing the BIM model Sharing Documents Sharing the 3D model Reviewing

Assessing the influence on processes when evolving the software architecture By Larsson S, Wall A, Wallin P Parul Patel.

13 Step Approach to Network Design Steps A Systems Approach 8Conduct a feasibility Study 8Prepare a plan 8Understand the current system 8Design.

Unit 18: CADD in Construction Lesson Objective Be able to explain the use of Building Information Modelling in buildings.

Chapter 4 Automated Tools for Systems Development Modern Systems Analysis and Design Third Edition 4.1.

Smart Home Technologies

Unit – I Presentation. Unit – 1 (Introduction to Software Project management) Definition:- Software project management is the art and science of planning.

Application of the ISO for BIM Xenia Fiorentini, Engisis.

About project

© 2024 SlidePlayer.com Inc. All rights reserved.

- AU Overview

- On-demand sessions

A Case Study of BIM Design for a Smart City with the Architecture, Engineering & Construction Collection

Description, key learnings.

- Learn how to construct the BIM implementation for an urban project

- Learn how to apply a BIM workflow with the AEC Collection on a complex urban project

- Learn how to create an InfraWorks model assembled from Civil 3D modelization

- Discover the benefits of BIM for building the future smart city

AB 204-6 Flagship BIM Case Study: Designing and Building the New CENTCOM HQ

Apr 04, 2012

450 likes | 862 Views

AB 204-6 Flagship BIM Case Study: Designing and Building the New CENTCOM HQ . Major Patrick Suermann Steve Cline Air Force Center for Engr and Env. Burns & McDonnell.

Share Presentation

- which walls

- multiple stakeholders

- centcom project overview

- milcon plan

- autocad mep

Presentation Transcript

AB 204-6 Flagship BIM Case Study:Designing and Building the New CENTCOM HQ Major Patrick Suermann Steve Cline Air Force Center for Engr and Env. Burns & McDonnell The views expressed in this presentation are those of the author and do not reflect the official policy or position of the US government or the Department of Defense.

JICCENT HQ and HQ CENTCOM The views expressed in this presentation are those of the author and do not reflect the official policy or position of the US government or the Department of Defense.

Class Description and Key Points • Class Description • This session will discuss the new premiere building for the Department of Defense's most dynamic Command—Central Command. This LEED-Silver facility will be the first of its kind on Mac Dill AFB. Building on design efficiencies gleaned from the facility's fraternal twin, the JICCENT HQ, this building offers a myriad of lessons learned when moving to a BIM-based approach for a design-bid-build project with multiple stakeholders • Key Learning Points • Compare 2-D traditional design with a BIM-based approach • Realize the benefits and challenges of moving to BIM in the federal government • Apply anecdotal knowledge to future BIM-based design and construction • Understand BIM in relation to LEED®, collaboration, ATFP, and security concerns • Learn about the current state of the art for future shifting client expectations

Introductions & Roles Patrick C. Suermann, PhD, PE, LEED® AP • AFCEE MILCON PM, BIM SME Background: BSCE USAFA 1997 MSCM Texas A&M University 2003 PhD University of Florida 2009 Project Role: • Initial BIM (and LEED?) Consultant • Transitioned to AFCEE PM and admin oversight

Introductions & Roles Steve Cline, PE, LEED® AP • BIM Implementation Leader • Senior Structural Engineer Background: BSCE Purdue University 2002 MSCE University of Illinois 2003 Project Role: • BIM Advisor

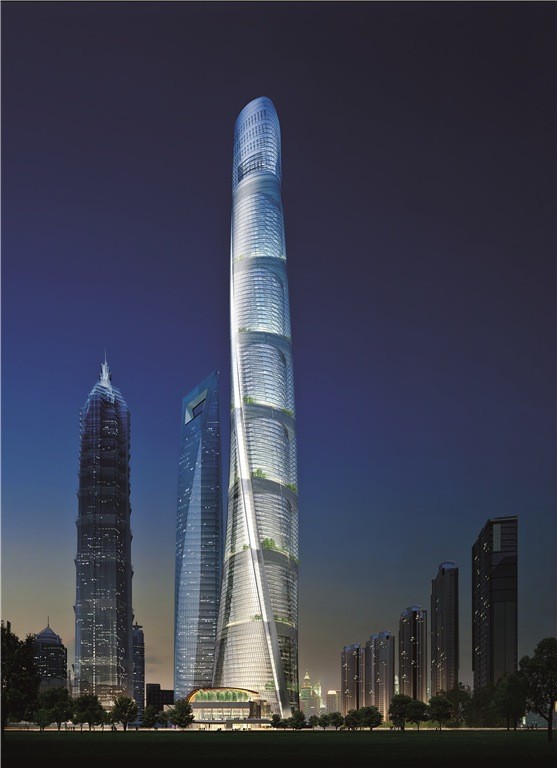

The CENTCOM Project Overview • CENTCOM Facts • Description: Four story structure with precast cladding • Usage: Central Command Headquarters • Location: Madill AFB • Square footage: 260KSF • Stakeholders: • CM: USACE-Mobile • A/E: Burns & McDonnell • GC: Clark Construction • Owner: CENTCOM

The CENTCOM Project Story • Original Plan: FY 2007 addition with FY 2008 alteration • Bids 4X programmed amount • Scopes combined to create new HQ building • Adjacent JICCENT building was used as basis for design graphic depicting steel prices OR demonstrating market conditions OR showing original plan for addition and alteration.

Existing Facility

Shifting to MILCON plan

Some Early Modeling – Notice same structure

JICCENT nearing completion

JICCENT/CENTCOM Comparison Highlights: JICCENT: $115M for 268KSF CENTCOM: $ 61M for 260KSF Deemed due to combo of factors: Market forces Repeat Partners BIM!

A Pathfinder Project – Determining the ‘Knowns’ "We know there are known known's: there are things we know we know. We also know there are known unknowns: that is to say we know there are things we know we don't know. But there are also unknown unknowns — the ones we don't know we don't know."

Burns & McDonnell: A “Known Known” • 100% Employee-Owned • FORTUNE Magazine’s 100 Best Companies to Work For • $1.1 Billion+ in 2008 Revenues • Founded 1898 • 3,000+ Employee-Owners • Energy Star rated HQ (working towards LEED Silver) High Performance Buildings (Fall 2009)

A New Vision for CENTCOM • Envisioned as a “flagship facility for all of the Department of Defense” – Lt. Col. Jay Beam • Project goals include: • Flexibility for changing mission • Staff comfort • Architecturally appealing • Sustainable • Innovative

Achieving the Vision • Synergistic Approach: • Bringing Designer, Owner, User and Facility Manager together • Utilize BIM to meet FM goals, compressed schedule • Sustainability through LEED Gold • Innovative goal of carrying BIM through to FM

2D Toolbox Drafting Tools Autocad Coordination / Clash Detection Careful cross-discipline drawing review Facility Management Tools As-Built Drawings O&M Manuals BIM Toolbox Modeling Tools: Revit Architecture 2008 Revit Structure 2008 AutoCad MEP 2008 Coordination / Clash Detection Tool: Navisworks Facility Management Tools: COBIE? FM Desktop? Comparing Toolboxes

Traditional 2D and BIM Processes Compared • Access to Information • Understanding of the Facility • Clash Detection • Level of Detail • Duplication of Data

Defining the Level of Detail • Critical for success of BIM as FM tool • BIM vs. 2D • The FM Software question • Start by thinking like a facility manager…

Model Progression Specification

Level of Detail: Thinking like Mike Lilya • Focus on creating flexible space: • Which walls have SCIF or STC ratings? • Are there critical MEP or Structural components in the wall? • What VAV box serves this space and where is it located?

Level of Detail: 2D vs. BIM Approach

A BIM Set Apart: Describing the Level of Detail • Architectural and Structural models included • Wall stud sizes • Parameter for final paint • STC and SCIF ratings • Architectural precast • Fall protection system False Joints in Precast Piles

A BIM Set Apart: Describing the Level of Detail • AND MORE… • Wall placards • Fire ratings listed • Finish codes on ALL walls • Wall finish tied to room schedule • Handrails modeled • T.P. dispenser modeled with Bobrick model number!

A BIM Set Apart: Describing the Level of Detail • Mechanical model included: • ALL pipes and fittings (except connections to faucets!) • Diffusers • Return Air Grills • All ducts • VAV boxes • Air handling units

A BIM Set Apart: Describing the Level of Detail • Electrical components: • Light fixtures • Electrical panels • Communication antennas • Switches? • Electric feeder?

A BIM Set Apart: Describing the Level of Detail • So what wasn’t modeled?: • Thermostat and wiring • Structural connections • Electrical conduits smaller than 1.5”

CENTCOM BIM Highlighting Mechanical

Lessons Learned: Level of Detail • Extremely high LOD for FM • Hard to budget • Clearly define LOD early on

Lessons Learned: Comparing 2D vs. BIM Labor Hours Time Graphic by: Patrick MacLeamy, FAIA

Clash Detection & Collaboration

Clash Detection Resolved Clash Piping Vs. Structural CLASH!

Clash Detection & Collaboration Initial Clash Report March 2008

Clash Detection & Collaboration December 2008 Clash Report

Clash Detection & Collaboration Final Clash Report

Lessons Learned: Sharing the Model • Valuable at multiple stages • Clients able to make better informed decisions • Can have unforeseen consequences

Achieving LEED Goals • LEED Gold • 25% Energy Reduction • Ultra Low-Flow fixtures and sensors • Daylight Controls • 42 LEED Credits

The Next Phase: Construction Model Elements With No Fabrication Model Clark Construction Burns & McDonnell Design Team Facility Manager Fabrication Models: Steel, HVAC, Electrical, Plumbing, Fire Protection Design Intent Model As-Built Model Facility Management Model COBIE Spreadsheet With Matching Element IDs

Lessons Learned: Choosing the FM Platform • Choose the FM platform upfront • Investigate compatibility with BIM platform • Identify how the FM tool will be utilized • Bi-direction integration with BIM Archibus™? FM Desktop™? Maximo™?

Envisioning the Future of BIM • FM integration better defined • Level of detail standards • More content available • Contractors participating earlier

BIM and IPD • Subcontractors onboard Day 0 • Participating in modeling • Sharing risk / reward Construction Photo 8/28/09 BIM (Constructed elements highlighted)

Class Description and Key Points Class Description This session will discuss the new premiere building for the Department of Defense's most dynamic Command—Central Command. This LEED-Silver facility will be the first of its kind on Mac Dill AFB. Building on design efficiencies gleaned from the facility's fraternal twin, the JICCENT HQ, this building offers a myriad of lessons learned when moving to a BIM-based approach for a design-bid-build project with multiple stakeholders Key Learning Points Compare 2-D traditional design with a BIM-based approach Realize the benefits and challenges of moving to BIM in the federal government Apply anecdotal knowledge to future BIM-based design and construction Understand BIM in relation to LEED®, collaboration, ATFP, and security concerns Learn about the current state of the art for future shifting client expectations

- More by User

Designing a Portable Shader Library for Current and Future API's

Designing a Portable Shader Library for Current and Future API's David Gosselin 3D Application Research Group Outline Introduction & Motivation Demos Case Study: ATI’s demo shader format Design Goals Artist’s Interface Texture Definitions Vertex and Index Buffers Sub-shaders and Passes

1.07k views • 51 slides

Building a Winning Infrastructure for Distance Education: A Case Study

Building a Winning Infrastructure for Distance Education: A Case Study Stuart Varden Kitty Daniels Susan Feather 2002 OSRA Conference St. Louis, MO February 21, 2002 Overview Web and Database Support Stuart Varden Faculty Support Kitty Daniels Testing in an Online Course: A Challenge

932 views • 41 slides

Charles F. Hurley Building Case Study

Charles F. Hurley Building Case Study B.J. Mohammadipour Bureau of State Office Buildings Hurley Building Built in 1971 Poured concrete construction Department of Employment and Training & Group Insurance Commission 6 floors office plus 2 level parking garage

901 views • 17 slides

LEED for Municipalities: An Overview and Guidelines for Implementation

LEED for Municipalities: An Overview and Guidelines for Implementation Contents Overview Green Building USGBC LEED Making the Business Case Examples in the Industry Case Study City of Boulder Process Funding and Allocation Consultant Process Recommendations Next Steps

879 views • 42 slides

The Case Study

CASE REPORT Design Execution Reporting. The Case Study. The case may be an individual, an event, a policy, etc. e.g., a case of deafness and SMT (Harvey Lillard). Types of case studies. Case reports in the larger scheme of things:. Randomized clinical trial Cohort study

1.49k views • 66 slides

Case Study Presentation: Too Far Ahead of the IT Curve?

Case Study Presentation: Too Far Ahead of the IT Curve?. Catherine De La Torre-Martinez Dr. Minder Chen Bus 550 California State University Channel Islands November 3, 2009. Case Study Presentation Too Far Ahead of the IT Curve?.

5.63k views • 11 slides

The Effects of Coyote Removal in Texas: A Case Study in Conservation Biology

The Effects of Coyote Removal in Texas: A Case Study in Conservation Biology . Adapted from activity by Margaret Carroll Department of Biology Framingham State College . National Center for Case Study Teaching in Science website; http://ublib.buffalo.edu/libraries/projects/cases/case.html .

2.04k views • 23 slides

Malaria Case Study

Malaria Case Study. Arlín Toro Rafael Tosado Cole Benton. Malaria Case Studies. Potential Courses. Study Aspect. Case Scenario. Resources/Activity. Maps Basic concepts Malaria Life Cycle Travelers info. WHO, CDC, NIH. Case1 Malaria prophylaxis and control. Gen. Biology

1.99k views • 64 slides

CASE STUDY. © LOUIS COHEN, LAWRENCE MANION & KEITH MORRISON. STRUCTURE OF THE CHAPTER. What is a case study? Generalization in case study Reliability and validity in case studies What makes a good case study researcher? Examples of kinds of case study Why participant observation?

2.09k views • 32 slides

Design Patterns Case Study: Designing A Document Editor

Design Patterns Case Study: Designing A Document Editor. Tech Lunch Bill Kidwell. The Plan Design Patterns: Elements of Reusable Object-Oriented Design. Review the Case Study in the book 7 Design Problems Discuss each design problem Review their solution Where do we agree? Disagree?

1.39k views • 52 slides

Designing quantitative studies

Designing quantitative studies. Dr. Aidah Abu Elsoud Alkaissi An-Najah National University Faculty of Nursing. T he research design of a study spells out the basic strategies that researchers adopt to develop evidence that is accurate and interpretable.

1.08k views • 76 slides

Designing and Managing Fisheries Data Systems that Support the NOAA Data Quality Act: A Case Study Using the Hawaii Long

Designing and Managing Fisheries Data Systems that Support the NOAA Data Quality Act: A Case Study Using the Hawaii Longline Observer Program. Karen Sender and Janet Pappas NOAA Fisheries - Pacific Islands Fisheries Science Center Honolulu, Hawaii FIS Conference 2003 18 November 2003.

1.1k views • 91 slides

Method and Validation basics —HPLC case study Hua YIN (Assessor)

Method and Validation basics —HPLC case study Hua YIN (Assessor). Outline. HPLC methodology Content of HPLC test procedure System Suitability Testing (SST) - Relative Response Factor (RRF) Validation of HPLC method case study. Information Sources.

1.84k views • 34 slides

Designing Inputs, Outputs, and Controls

Designing Inputs, Outputs, and Controls . Final Exam . Chapters 1 to 12 and 14 and 15(5 th Edition) 20 multiple choices 3 or 4 short questions OO diagram Use Case Class Sequence. Overview.

961 views • 53 slides

Chapter 9 Building a New Venture Team

Entrepreneurship: Successfully Launching New Ventures, 2/e Bruce R. Barringer R. Duane Ireland. Chapter 9 Building a New Venture Team. Case Study – BrainyBunch. Founded in 2008 - a pioneer in International Islamic Montessori - focus : M ontessori and English.

2.02k views • 41 slides

To Case Study or Not to Case Study, That is the Question.

To Case Study or Not to Case Study, That is the Question. COM 304 Research & Writing Methods Dr. Feigenbaum Week 5 A Valentine’s Day Themed Lecture. Lecture Summary. What is a case study? Is a case study right for me? How do I select a case study?.

794 views • 30 slides

Eating Disorder Unfolding Case Study

Eating Disorder Unfolding Case Study. Linda Manfrin-Ledet , DNS, APRN Amanda Eymard , DNS , RN, CNE Scott Bellanger , BSN, RN. Review Materials Prior to Unfolding Case Study.

1.36k views • 47 slides

AXEON N.V CASE STUDY

AXEON N.V CASE STUDY. Group C2 : Fabio Ferla Capanni Livia Gulomjon Sobirov Fehim Alper Konuk Andrea Rodriguez piñero. 12th of November 2008. Question 1. What do you feel about the initial analysis? Was there, in your opinion, anything wrong with it?

2.99k views • 14 slides

Case Study: An Online Bookstore

Case Study: An Online Bookstore. Introduction. Case study of Online bookstore Divided into two parts Business-to-client (B2C) Business-to-business(B2B) Three fundamental pieces Client-side scripting – JavaScript Server-side scripting – ASP which generates XML Database.

1.65k views • 125 slides

Use Case Realizations

Use Case Realizations. Topics. Design Patterns and the Use Case Controller Use Case Realization Designing with Sequence Diagrams Object Responsibility Developing a Multilayer Design Approaches to Data Access Layer Designing the View Layer Designing with Communication Diagrams

1.69k views • 50 slides

Warlord Case Study review and giant bonus with 100 items

Warlord Case Study Review - (FREE) Bonus of Warlord Case Study. Ultimate Review of Warlord Case Study and Download (FREE) 2 Giant Bonus Of Warlord Case Study: https://crownreviews.com/warlord-case-study-review/ Warlord Case Study – The earth-shattering revelation that you need to launch your own product Warlord Case Study is a detailed case study with in-depth explanation created by Steven to show the exact way to build your income online with product creation. https://crownreviews.com/warlord-case-study-review/ Warlord Case Study, Warlord Case Study review, Warlord Case Study review and bonus, Warlord Case Study review discount, Warlord Case Study review and bonus, Warlord Case Study reviews and bonuses, Warlord Case Study ultimate review, Warlord Case Study review and coupon, Warlord Case Study review demo, Warlord Case Study review biggest bonus, Warlord Case Study review demo product, Warlord Case Study review demo in action

2.7k views • 8 slides

- Login

- Join the community

Case Studies

Real stories from real bim people, sichuan road and bridge sets new benchmark for regional smart highways, implementation, advertisement.

- English (200)

- Spanish (69)

- Italian (2)

- Russian (2)

- Portuguese (3)

- Project (171)

- Implementation (46)

- Research (2)

- Collaborative initiative (5)

- BIM Implementation (214)

- 3D / VDC (70)

- Corporate (4)

- Planning & Budgeting (33)

- Facility Management (6)

- Lean & Industrialized construction (22)

- Collaborative Processes & Tender (22)

- Software - Hardware (13)

- Sustainability (8)

- Strategies (41)

- Classification (3)

- Edification (62)

- Infrastructures (68)

- Territory (3)

- Project (151)

- Operation (15)

- Asset Management (13)

- Construcción Offsite (15)

- Workflows (41)

- Protocols (14)

- United Arab Emirates (9)

- Argentina (2)

- Austria (1)

- Australia (3)

- Bosnia and Herzegovina (1)

- Belgium (2)

- Bolivia (3)

- Switzerland (3)

- Germany (5)

- Dominican Republic (2)

- Finland (2)

- France (11)

- Hong Kong (2)

- Hungary (2)

- Ireland (1)

- Jamaica (1)

- Kazakhstan (2)

- Lebanon (1)

- Morocco (2)

- Malaysia (2)

- Netherlands (1)

- Portugal (1)

- Saudi Arabia (4)

- Singapore (2)

- Ukraine (1)

- United Kingdom (26)

- United States (54)

- Vietnam (5)

BIM Models with LOD 300 for the Hotel Project in USA

Precast Wall Panel Detailing - Perth Police Station

Elm Street Hotel & Apartments - BIM for Modular Construction

BIM Coordination Services for Healthcare Project in Boston

Case Study – Architectural BIM for Multi-family Residential Apartment in Florida

Case Study: MEP BIM services for Industrial Manufacturing in Texas

BIM Consulting & BIM Models Implementation for 12 high-rise buildings

Point Cloud to As-built Model of a Coffee Chain Outlet, USA

Comsa Digitizes Renovation of Century-old Bridge in Cabrianes, Barcelona

BIM Coordination Services for Warehouse Project in California

Using Bi in the BIM verification process

Modular MD Hospital Project by MaRS BIM

BIM Modeling Saved Time, Delivered Efficiency for the Project

Recover Password

Indicate the email with which you created your account in bimcommunity, do not have an account yet join the community now, it's free, thank you for subscribing to the newsletter.

Embracing BIM in its totality: a Total BIM case study

Smart and Sustainable Built Environment

ISSN : 2046-6099

Article publication date: 13 September 2022

Issue publication date: 23 April 2024

Building information modeling (BIM) is mostly limited to the design phase where two parallel processes exist, i.e. creating 2D-drawings and BIM. Towards the end of the design process, BIM becomes obsolete as focus shifts to producing static 2D-drawings, which leads to a lack of trust in BIM. In Scandinavia, a concept known as Total BIM has emerged, which is a novel “all-in” approach where BIM is the single source of information throughout the project. This paper's purpose is to investigate the overall concept and holistic approach of a Total BIM project to support implementation and strategy work connected to BIM.

Design/methodology/approach

Qualitative data were collected through eight semi-structured interviews with digitalization leaders from the case study project. Findings were analyzed using a holistic framework to BIM implementation.

The Total BIM concept was contingent on the strong interdependences between commonly found isolated BIM uses. Four main success factors were identified, production-oriented BIM as the main contractual and legally binding construction document, cloud-based model management, user-friendly on-site mobile BIM software and strong leadership.

Originality/value

A unique case is studied where BIM is used throughout all project phases as a single source of information and communication platform. No 2D paper drawings were used on-site and the Total BIM case study highlights the importance of a new digitalized construction process.

- Building information modeling

- Digitalization

- BIM on-site

Disney, O. , Roupé, M. , Johansson, M. and Domenico Leto, A. (2024), "Embracing BIM in its totality: a Total BIM case study", Smart and Sustainable Built Environment , Vol. 13 No. 3, pp. 512-531. https://doi.org/10.1108/SASBE-06-2022-0124

Emerald Publishing Limited

Copyright © 2022, Oliver Disney, Mattias Roupé, Mikael Johansson and Alessio Domenico Leto

Published by Emerald Publishing Limited. This article is published under the Creative Commons Attribution (CC BY 4.0) licence. Anyone may reproduce, distribute, translate and create derivative works of this article (for both commercial and non-commercial purposes), subject to full attribution to the original publication and authors. The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode

1. Introduction

The benefits of using 3D models and BIM (building information modeling) are widely reported in research ( Azhar, 2011 ; Sacks et al. , 2018 ; Volk et al. , 2014 ). Despite this, site work in construction projects is still dominated by paper in the form of 2D drawings and other design information ( Davies and Harty, 2013 ). These 2D drawings are created from BIM at a specific moment in the whole construction process and the information in them remains mostly the same as before BIM existed ( van Berlo and Natrop, 2015 ). For decades drawings have been criticized for containing redundant information, requiring a large effort to produce and maintain changes, having to manually take off construction information and not reflecting the current state of the building ( Eastman et al. , 1974 ). Yet they continue to be used during the construction phase as the main source of information.

Previous studies have largely been concerned with BIM in the design phase, which is widely used and the benefits for communication, coordination and clash detection are generally accepted ( Davies and Harty, 2013 ; Zaker and Coloma, 2018 ). So far little attention has been given to BIM throughout the whole construction process because implementation in the production phase has been limited. The lack of adoption in the production phase has been previously linked to issues surrounding the legal status of BIM in construction projects, cost and technology limitations ( Eadie et al. , 2013 ; Englund and Grönlund, 2018 ). With BIM's unclear legal status, it is common to see conventional 2D drawings applied in parallel to support the construction process, even in so-called “BIM projects” ( Davies and Harty, 2013 ; Calderon-Hernandez and Brioso, 2018 ; Koseoglu and Nurtan-Gunes, 2018 ). Two parallel processes exist creating, translating and maintaining both 2D paper documents and BIM, which leads to extra costs, errors and delays ( Davies and Harty, 2013 ). Due to current rules, regulations and contract forms, BIM is far from becoming a standard on its own as 2D drawings are usually legally binding. In this context, BIM becomes obsolete and is not fully trusted or used on construction sites as it becomes a parallel information source often disconnected from the construction documents and drawings. As such, despite significant investment in creating BIM for projects, the potential benefits are not realized due to the simultaneous provision of 2D drawings. Ultimately, this is hindering the leap towards a more digitalized construction process, especially in the construction phase.

Succar (2009 , p. 357) defines BIM as “a set of interacting policies, processes and technologies generating a methodology to manage the essential building design and project data in digital format throughout a building's life-cycle.” Still, as previously mentioned BIM is often limited to the design phase and the term “BIM” has come to have many different associated meanings ( Davies and Harty, 2013 ). More recently Cousins (2017) discusses an approach known as Total BIM where projects strive to embrace BIM in its totality. Total BIM projects are 100% digital where no paper drawings are produced at any project stage. BIM and its connected databases are the repository and carrier of information along all project phases (planning, design, construction and operation). Traditionally a huge amount of work goes into creating 2D drawings, where many are unused. In Total BIM, information is presented in a different way (directly connected to BIM), which enables designers to focus their time on constructability rather than drawing ( Cousins, 2017 ).

This paper presents and investigates the overall concept and approach of a Total BIM project. This differs compared with traditional and “semi-BIM” projects, since in a Total BIM project no parallel processes exist creating and maintaining both 2D drawings and BIM. The case study is notable for its complexity compared to other advanced BIM projects which are often found in the infrastructure sector, and usually for rebaring work. The case study is a real-world office and laboratory construction project (Celsius in Uppsala, Sweden) where BIM was embraced in its totality – Total BIM. In the Celsius project, the demands and requirements of 2D drawings as legal documentation were superseded and BIM was recognized as the contractual document. BIM was actively used in all phases of the project by every actor, including on-site where workers extracted construction information from mobile BIM software.

This paper is organized as follows. It begins with a brief review of previous attempts at BIM focused projects which highlights common challenges and limitations. This is followed by our research methods. Interview findings are presented in four parts, according to the four main categories of the BIM implementation framework: ecosystem, strategy and innovation, organizing and technology . These findings are discussed in relation to traditional and previous leading BIM projects and the challenges and opportunities of the Total BIM approach are considered. Finally, conclusions are drawn focusing on key success factors with an “all-in” BIM approach with implications for both practitioners and researchers in this area.

2. Background and related work

In construction projects, the benefits of using BIM to communicate the designer's intent are limited when the final stage of information delivery is still dominated by paper drawings ( Davies and Harty, 2013 ). There have been some previous attempts at pushing towards full implementation of BIM in the construction phase. In 2014, Czmock and Pękala (2014) reported a case study of an office complex in Warsaw, designed with the help of BIM, while 2D CAD files were secondary. The design process was estimated to be 10% faster and 80% more accurate than traditional methods ( Czmock and Pękala, 2014 ). Czmock and Pękala (2014) concluded that BIM helps eliminate collisions, manage changes, order accurate quantities of materials, saves time and money. However, the use of BIM was limited to the design stage. 2D paper drawings had to be produced from the model because it was required by Polish law to use these on the construction site.

The designers of the Thames Tideway Tunnel project in 2017 (a large sewage system in London) aspired to eliminate 2D drawings and for all stakeholders to focus on a single source of design truth, the BIM model ( Gaunt, 2017 ). They considered a model-based delivery approach much more efficient than producing 2D drawings but were required to produce them anyway as they were the legally binding construction documents. Therefore, BIM implementation was limited to the design phase. Gaunt (2017) states that savings realized by implementing BIM in the design phase are insignificant to the potential of that in the construction phase. They found that skill levels, engagement and software must improve for a more holistic BIM approach to occur. Even though using BIM in the Thames Tideway Tunnel project created savings in the design phase additional effort and expense were required to produce 2D drawings in parallel for the construction phase, limiting the potential benefits and value of BIM.

In 2013, the Röfors bridge project in Sweden was realized without using traditional drawings. Agreements were established that gave BIM the same legal status as “construction specifications”, thereby placing them above “drawings” according to the General Conditions of Contract. The model was accessible on-site via tablets. However, due to limitations with BIM-viewer software at the time, site workers were not able to extract accurate measurements and specific information from the model. To solve this issue, the project had a structural engineer on-site to create Production-Oriented Views (POVs) from the model in consultation with the construction workers ( Johansson and Roupé, 2019 ). The views contained measurements, dimensions, sections, object information and were color-coded, but were essentially just screenshots taken from the BIM and not interactive ( Figure 1 ). These views were uploaded to a shared model repository that could be accessed on tablets to complement BIM. Whilst an innovative concept at the time, creating the POVs required additional resources and workers were not able to extract the information from the model themselves. Therefore, extra demands were placed on the project organization.

For the Norwegian Oslo airport expansion project, completed in 2017, a detailed BIM was created in the design phase. It was estimated that 50,000 paper drawings and documents were needed to carry out the reinforcement work ( Mershbock and Nordahl-Rolfsen, 2016 ). Instead, they decided to adopt an on-site BIM approach using Tekla BIMsight software but only for the placement of the reinforcement, rather than the whole project. As Mershbock and Nordahl-Rolfsen (2016) note the project represents an early implementation of on-site BIM, where practical examples are rare and often limited by IT capabilities and available resources.

Recently in Scandinavia some projects have begun to be realized using the 3D model as the legally binding and contractual document on the construction site ( Nohrstedt, 2017 ). The Slussen project in Stockholm, is the rebuilding of the 1930s junction between Södermalm and Gamla stan. The project started in 2019 and the completion date is scheduled for 2025. It was decided to only use 3D models in the project and not to use 2D paper drawings because the creation and handling of the latter wastes time ( Cousins, 2017 ). The intention was to deploy “BIM kiosks” on-site to access the 3D model and virtual reality to help stakeholders visualize the project ( Cousins, 2017 ). Working digitally was expected to eliminate creating and keeping up to date 15,000 paper drawings ( Cousins, 2017 ). As more than 40 different contractors were involved in the project, working in BIM was identified as an easier and faster method for a common way of working. However, this was not the plan from the start and some early work in the project occurred using 2D printed drawings ( Cousins, 2017 ). In the Slussen project, they used a single source of information and synchronized construction data with design data to reduce the information gaps that often occur in traditional projects.

Construction began on the Smisto Hydropower plant in Norway in 2015. In the project they aimed to only use the 3D model for design and construction as they found “drawingless” execution to be worth pursuing ( Gaunt, 2017 ). A year into the project, by working with Revit, Civil 3D Navisworks and other software they were able to deliver BIM to the contractor without preparing any 2D drawings ( Smith and Hansen, 2016 ). Significant improvements over traditional processes were found including, no need to establish or maintain complete drawings, which reduced possible sources of error ( Smith and Hansen, 2016 ).

The Norwegian Randselva Bridge project was a recent winner of the Tekla Global BIM awards 2020 for best BIM project. It was constructed entirely without drawings where IFC models were predominantly used for construction and is the longest bridge to be built without drawings to date ( Rybus, 2022 ; Ulvestad and Vieira, 2021 ). Although in its infancy several reasons were given for working with BIM and “drawingless” design. The main ones were that it is easier to understand the scope of the work, solve clashes, parametric design, BIM looks the same in any country, facilitates the procurement process and to prepare for more automation in the future ( Ulvestad and Vieira, 2021 ). Rebars were modeled in Tekla and were directly ordered from the model, eliminating the need for manually made bar bending schedules ( Ulvestad and Vieira, 2021 ). Early in the project they focused on who would use the model and what information they would need to extract from it ( Ulvestad and Vieira, 2021 ). The aim was to be left with an as-built model that can be used as a digital twin. The project showed that it was possible to perform projects in this way, and that it may even be the preferred method in the future for large complex projects ( Rybus, 2022 ). Despite this there were still software challenges, Solibri did not have its own cloud solution and it was difficult to assign data to geometry through simple annotations using the available BIM viewers ( Rybus, 2022 ).

The above examples are some of the current most advanced BIM projects throughout Scandinavia and beyond. Yet the implementation of BIM is often limited. 2D drawings are produced in parallel creating unnecessary work, structural engineers were also needed on-site to create POVs for construction as the software did not support taking measurements. In addition, the examples mostly concern infrastructure projects and the use of Tekla, which is designed to support a 3D model-based approach for rebar and steel structures. For example, the Röfors bridge project used Tekla and at the time it would likely not have been possible to use alternatives like Revit.

Technology (software, interoperability and standardization) is a limiting factor in the drive towards using BIM in all stages of a construction project because as shown in the cases above additional work methods are required. Other obstacles highlighted by Sundqvist et al. (2020) include model quality, on-site education, technical support and user-friendliness of software. The availability of regular 2D drawings introduces another common problem, as workers then tend to fall back on traditional (non-BIM) ways of working during times of high-pressure ( Sundqvist et al. , 2020 ). Contractual concerns also exist such as who controls the entry of data into the model, who is responsible for inaccuracies and keeping the BIM up-to-date, licensing issues, model ownership and costs ( Azhar, 2011 ). Costs are often given as a reason for limited BIM use in projects, specifically for training workers in the use of new technology ( Czmoch and Pękala, 2014 ; Eadie et al. , 2013 ). These issues are just some of the reasons why BIM use is limited today. Existing research reflects this where BIM is developed during the design phase and from the model construction drawings are created. The benefits cease to transfer fully over into the construction phase as BIM has limited use, does not have legally binding status and could therefore not be fully trusted as a single source of information. One of the core issues has been the inability for workers to take measurements directly from mobile BIM software on-site, which results in a mixed-mode (digital and paper-based) way of working. Using a BIM based approach can eliminate the use of 2D paper drawings, which are expensive, take a lot of effort to produce, print, maintain, update as well as risk using wrong or out-of-date documents ( Koseoglu and Nurtan-Gunes, 2018 ).

This paper draws on a Total BIM case study to discuss an approach where BIM was embraced in its totality during the entire project from design and construction to the operation of the facility. Unlike the examples outlined above it was unique as it was a complex office and laboratory building rather than an infrastructure project. The infrastructure projects described above have mainly been concrete and rebar structures with limited multidisciplinary construction teams and primarily using a Tekla model-based approach. The case project, on the other hand, had many different disciplines and 40 sub-contractors with more than 300 individuals, which collaborate and coordinate on the construction site using BIM as the single source of information. This created demands on a new novel, innovative and digitalized production-oriented construction process, which is studied in this paper. The paper therefore contributes to the understanding of implementing and embracing BIM in its totality from design and construction to the operation of the facility. In contrast to other case studies and literature ( Calderon-Hernandez and Brioso, 2018 ; Czmock and Pękala, 2014 ; Davies and Harty, 2013 ; Eadie et al. , 2013 ; Englund and Grönlund, 2018 ; Koseoglu and Nurtan-Gunes, 2018 ; Sacks et al. , 2018 ), which focus more on a “Hybrid-BIM” approach, i.e.i.e. usage of BIM in order to produce 2D-drawings for construction. This paper focuses on Total BIM or “building-without-traditional-2D-drawings” and how it was implemented and used during the Celsius project. The Celsius case is unique, as it was a true Total BIM project, as BIM became the single source of information during the whole project.

The following sub-sections introduce the case-study, the Celsius project, and how data were collected and analyzed.

3.1 Case study

Our approach was to focus on a case study as a “force of example”, drawing on specific lessons learnt from a unique project ( Flyvbjerg, 2006 ). This research investigates a BIM case project that strived to embrace BIM in its totality by implementing BIM technologies in all stages of the project to produce an office and laboratory building in Uppsala Science Park, Sweden. The building covered 12,000 square meters over 6 floors, with a project budget of roughly 45 million Euros, and was certified with LEED Platinum. Design work on the project started in 2017, construction began in 2018 and work was completed in November 2020. The project named Celsius was selected for this research due to the international recognition it received as the winner of the 2020 buildingSMART Award for its innovative and digitalized construction process. Notably, it was also the top-rated construction project in Sweden for project quality based on worker feedback in a survey conducted after the project was complete. The project was unique as BIM was legally binding, production-oriented BIM was created during the design and site workers produced the construction information they needed themselves on-site on mobile devices ( Figure 2 ). The project was also delivered within time and under budget.

3.2 Data collection and analysis

Primary data is gathered from qualitative semi-structured interviews. The interviewees were selected due to their role, knowledge and responsibilities within the project for planning, strategy and implementation of the Total BIM concept, both during design and construction. Additional data was gathered from informal discussions, presentations and question and answer sessions. Prior to commencing the interviews, the virtual design construction (VDC) strategist provided an extensive project presentation, which helped form the initial interview questions. The first interview was with the VDC on-site engineer, which occurred during construction of the project in March 2020 and lasted approximately one hour. After the project was complete six further interviews were held with the VDC strategist totaling eight to ten hours. The VDC strategist was involved in both the design and construction phases of the project. One interview with the VDC strategist focused on the Celsius case in relation to the four main categories of the holistic research framework to BIM implementation ( Figure 3 ) (Bosch et al. , 2016; Sundquist et al. , 2020 ). An additional interview was conducted after project completion with the design and construction project management leader, lasting 70 min. A further interview was also conducted with the site manager for the Celsius project, focusing on production planning and scheduling using production-oriented BIM. All interviews were semi-structured with open-ended questions to gather insights from the respondents ( DiCicco-Bloom and Crabtree, 2006 ; Yin, 2009 ). In this paper we apply a holistic research framework by Bosch-Sijtsema et al. (2016) and Sundquist et al. (2020) where the main framework categories are ecosystem, technology, strategy and innovation, and organizing. Analysis of the interviews occurs from a socio-technical point of view and investigates the contributing factors throughout the whole project for the BIM concept used. These results are presented as a loosely guided framework to serve a purpose for discussion. Findings were allocated where the authors deemed most appropriate, but many elements overlap categories and therefore, are not limited to the category that they are presented in.

4. Findings

In the Celsius project, no traditional 2D paper drawings were used on-site. Workers extracted the construction information they needed directly from BIM-viewer software (StreamBIM) on mobile devices. They created their own interactive and dynamic production-oriented views containing the information they needed to conduct and plan their work on the construction site. In this context, they created measurements, sections, and extracted information directly from the BIM using StreamBIM on mobile phones or tablets. Further into the construction project they also started using the phone's camera and StreamBIM as a communication platform for design and construction issues, question handling, “as-is” and “as-built” communication between the design team, construction workers and sub-contractors. To achieve this BIM was embraced in its totality and used as the information source and platform throughout the whole project. To support this new novel innovative and digitalized construction process, many different aspects had to be accounted for and addressed. To present the different interconnected aspects the overall concept and holistic approach of the project are presented in Tables 1–4 .

4.1 Ecosystem

The ecosystem category refers to the existing environment where BIM developments were introduced such as, standards, laws, regulations and requirements, which act as boundary conditions for the digital construction process. Additionally, implementing the Total BIM concept affected how the project environment and ecosystem were managed. In Table 1 the most important findings within this category are presented.

4.1.1 Standards

Standardized codes and names were used for objects and object information in BIM. These were added in the design phase and used in both pre-production and production. When standardized information was missing from manufacturers and suppliers, it was manually added whilst focusing on how it would be used later in the process (e.g. weight, responsible sub-contractor, etc.). By eliminating paper drawings, BIM became the carrier of information. All construction information had to be contained in BIM and readily accessible for those carrying out the work. This made it clear how construction should occur, which reduced on-site discussions about how to build. During the design there was also a strong focus on how the information would be used in production.

IFC files were used as standard throughout the project. Designers used them to exchange models, sub-contractors received them as part of the bidding process package, and they were later used in production as the source data for StreamBIM. IFC files were used due to their interoperability between different software.

4.1.2 Laws, regulations, requirements

BIM was the contractual and legally binding construction document and had a higher legal status than drawings throughout the project. Designers worked to produce a high-quality BIM, which was used in the tendering process with sub-contractors as well as during the construction process. It was the main information carrier in the project and no printed drawings were used. The high-quality BIM reflected more accurately what and how construction should occur. All objects in the model had coded information attached, which resulted in the BIM being legally more descriptive than 2D drawings.

Working with BIM and to not revert to using paper drawings were keys requirement of the project. Designers and sub-contractors that refused to use BIM were excluded from the project (which occurred once during design and once during sub-contractor tendering). However, those with weaker BIM competencies but eager to engage in the concept were invited into the project to “fix the problem” together with the construction management (CM) company and to learn the necessary skills.

The high-quality BIM had flexible levels of detail and was developed with site workers in accordance with their needs to carry out construction. In some cases, sub-contractors with specialist knowledge further developed plans (e.g. adding sections for vents, where designers were not sure about the machines the sub-contractors had available). Routines and guidelines were developed to reach efficient levels of design for construction to occur smoothly and accurately.

The CM company was not only responsible for the design and construction process but also responsible for supporting BIM on the construction site and ensuring that workers had sufficient knowledge to use the mobile BIM-viewer software efficiently. The process for change orders was clear. These were also handled through the mobile BIM-viewer software. Changes and backups were automatically logged and saved to the cloud to ensure that data was secure. Any changes made to the BIM in the design phase were communicated during the weekly design meetings.

The CM company pushed the use of BIM throughout the project and managed the bidding process. It was decided that the client would own the BIM as they were the ones paying for it to be developed. This guaranteed them future access for facility management and if the BIM needed to be updated. A few months after the project was complete, final BIM updates occurred and the client received an accurate “as-built” digital twin.

4.2 Technology

The technology category refers to the technological components and interoperability where BIM developments were introduced such as, software, hardware and supporting IT system. In Table 2 the most important technology related findings are presented.

4.2.1 Technological components

Cloud-based BIM was used throughout the project providing access to a single source of up-to-date information for both designers and site workers. Designers could be certain that they were always working with an up-to-date version of BIM and avoided having to send or retrieve files from each other. Designers worked to produce a production-oriented BIM that facilitated the needs of site workers. During construction BIM was retrieved from the cloud and accessible on mobile devices by using mobile BIM viewer software (StreamBIM), ensuring that they were always working with the latest version, even after weekly updates occurred.

Site workers had full access to BIM on-site through the StreamBIM software, which had a user-friendly interface for measuring, sectioning and creating 3D views ( Figure 2 ). Workers created the views that they needed to perform their work on-site. iPads were used in teams to provide mobile access to BIM, allowing workers to always have the construction information and views with them. The same device was used for communication, design markups, inspection documentation, as-built documentation and checklists for controls such as safety. It was important that all information was accessible in one application rather than requiring workers to keep switching to different ones. Therefore, the creation of “drawings” was transferred to on-site where construction workers created their own production-oriented views in StreamBIM, rather than designers providing them with 2D drawings. This also helped to ensure that only relevant views were created and 2D drawings were not necessary.

Working digitally and using StreamBIM improved how information was handled. By communicating through StreamBIM information was connected between users and the model. This communication was more transparent than traditional means (e.g. a replacement for emails where information chains are commonly lost and broken or outdated files are shared). User requests were also automatically logged, and users had access to what they needed. By linking information exchange to the model, it was easier to flag any problems by marking areas on the model, attaching photos and adding descriptions. This helped the receiver to quickly decipher the problem and provide quick solutions. Construction progress was monitored by taking photos in StreamBIM using mobile devices, which documented the project whilst it was being built. In this way the design team, construction workers and the different sub-contractors could communicate construction issues, raise questions, create “as-is” and “as-built” documentation and prepare and plan their work before they arrived at the construction site. Wi-Fi was installed across the construction site as it was essential to have fast and reliable Internet connectivity to access data and information in StreamBIM.

During the design phase, data was stored in the cloud by using the Revit plugin RTV Tools to create automatic export schedules (every night) for saving, updating and legally archiving IFC files. SimpleBIM was also scripted to trim, color coordinate and clean IFC files from Revit, Tekla and ArchiCAD. During the construction phase weekly BIM updates occurred and were uploaded to the cloud every Friday. Site workers then had access to them at the start of the following week.

4.2.2 Interoperability

To accomplish the CM company's vision, it was established early in the design phase that a cloud-based design process would be used. Since most of the design team worked and designed in Autodesk Revit, they recognized Autodesk 360 as an interoperability and collaboration platform. Design teams were able to work efficiently together in one place through cloud-based BIM, with automatically synchronized data and information (other software such as Tekla and Solibri was also used where IFC files were exchanged between programs). Work occurred live in BIM, which required good communication and strong project leadership to communicate changes (e.g. if an architect moves a wall, who else is affected).

Instead of having to search through different documents, drawings, applications or menus, site workers were able to quickly access the information they needed for construction with a single press of a button within the StreamBIM application. Object information was custom filtered to the sub-contractor's discipline and interest, where templates were created to provide them with direct easy access to what they needed. In StreamBIM it was also possible to create custom reference planes, in custom views. These reference planes could be duplicated on the construction site (e.g. chalk lines on slabs, walls, etc.), enabling and helping workers to accurately measure where to assemble the building components and building parts. Both horizontal and vertical reference planes helped the alignment between the virtual and the real world. Workers were able to fully customize the process to fit their own construction information needs, e.g. dimensions, measurements, product information etc.

4.3 Strategy and innovation

The strategy and innovation category refers to the business value of BIM in terms of costs, productivity and performance. The Total BIM concept affected strategy work, cost structures, productivity and performance related to the project. In Table 3 , the most important strategy and innovation related findings are presented.

4.3.1 Costs

The focus on BIM shifts the cost structure in the project. Extra demands were placed on creating high-quality production-oriented BIM that can be used as a single source of information in the construction phase. This increased design costs from 11% to 13% of the project total. The entire project still came in 2% (€900k) under budget despite additional unexpected costs (€1200k) for piling early in the project.

Most site workers had not worked directly from BIM before so there were additional costs for educating and supporting them. There were also extra costs for IT in the project such as StreamBIM licenses (supporting 300+ users), Wi-Fi across the site, BIM kiosks with large TV screens and shared mobile devices (e.g. iPads). The costs associated with these were absorbed into the budget for construction costs. However, as construction information was delivered digitally, there were no printed documents in the project. This resulted in savings as there were no costs for printing, re-printing or maintaining drawings.

It was easier to make budget adjustments for cost changes in the project as quantity data from BIM was linked to the same Excel sheet that sub-contractors had used to submit their bids. Therefore, as new project conditions arose, quantity lists were scaled, and cost changes were clear.

Logistics costs in the project decreased due to reducing the number of deliveries to the construction site by 80% compared to a similar project in the same area. This was possible as BIM supported earlier quantity data calculations in the project and therefore facilitated better planning. The CM company implemented a logistics hub where deliveries were sent through before arriving at one of the four designated zones on the construction site.

4.3.2 Productivity, performance

An aim the CM company had before the project started was for construction to occur in the way that designers intended and with fewer errors. They were able to achieve this in the Celsius project by developing BIM to the standard that was required for it to be used in the construction process. Eliminating unbudgeted changes was a key factor in completing the project two months ahead of schedule. Since site workers were more accurately able to produce what designers intended, waste was reduced due to less guesswork, mistakes and changes. They also considered prefabrication as a way to further reduce waste in the future, which is made possible by more detailed planning, earlier in the project.

BIM was the single source of information in the project from design to construction. The vision was to work more efficiently by replacing the process of using drawings (e.g. measuring, guesswork, interpretation errors and searching for information) with a single source of information (cloud-based BIM) and eliminating duplication work (producing drawings). BIM was used on-site rather than many versions of different drawings, eliminating “information islands” and disconnected information sources commonly found in traditional projects. For elements that were hard to illustrate using 3D, 2D digital “mega” PDF's were created which were connected to BIM. This was used for some of the electrical work and some overviews of floorplans in the project.

4.4 Organizing

The organizing category refers to methods, processes, ways of working with BIM and cooperation with BIM between firms. The Total BIM concept affected business processes and organizational structures. In Table 4 the most important findings within this category are presented.

4.4.1 Methods and processes

The CM company was responsible for teaching sub-contractors how to use the BIM viewer software when they arrived at the project. VDC and IT support were on-site to ensure that technical issues were solved, and workers were provided with the knowledge they needed. Site workers were initially introduced to the BIM based work method and tools with an introductory presentation. A self-learning and supportive environment were encouraged when using StreamBIM.

By digitizing construction information, access and user-friendliness were improved over traditional 2D documents. Information, data and requirements were linked to the model, resulting in easier navigation. By working in this way, all information became transparent amongst stakeholders, as everything was derived from the cloud, which improved on-site coordination. There was no conflicting construction information as BIM was the single source of information. Users had access to the cloud, ensuring that they were always working on the latest version, rather than having to deal with multiple versions as commonly found with paper drawings. This was seen by the CM company as an important step forward, which was highlighted with an example from a previous project, where an outdated IFC file had been sent to a manufacturer for a glass façade.

StreamBIM was the single tool for handling production related tasks rather than closed e-mail chains, etc. which increased collaboration between site workers, designers, and management due to a more integrated process. Within StreamBIM workers could raise questions and highlight problems, which were ideally resolved within 24 h. The BIM approach in this instance also eliminated the need to come up with costly on-site solutions since problems were solved by the design team rather than construction workers. Increased effort spent on design helped to improve work conditions on-site, since at an early stage in the project more focus was put on constructability. Furthermore, the extra effort in the design stage improved data quality, which made it possible to make more informed data-driven decisions.

Celsius was a project where sub-contractors were provided with quantity take-off lists, sub-divided IFC files and technical documents taken from BIM. This shifted costs away from sub-contractors to the project as they saved time by not having to measure details. The result of this was that more bids were received, and they were easier to evaluate as they were more even, which eased concerns that elements had been missed or forgotten about. Fewer questions were also raised during the bidding process. However, some sub-contractors continued trying to take their own measurements from BIM as they did not read or understand the attached documentation, which may lead to losses. If a sub-contractor refused to use BIM, they were excluded from the project.

By not giving the workers the opportunity to use traditional drawings, they were forced to use new digital working methods, which some were reluctant to do at first but positive about by the end of the project (others were happy that a project was finally being done this way). Initially some site workers were hesitant to embrace BIM. However, at the end of the project a survey was conducted, and it was the top-rated construction project in Sweden for project quality based on worker feedback, with many comments directed towards using BIM in production and using StreamBIM as a communication platform. Thus, highlighting the shift in attitude from project start to end.

4.4.2 Cooperation with BIM between firms

The CM company was behind the vision to implement BIM throughout the whole project with guidelines and requirements supported by the client. The CM company was also responsible for ensuring the project's success.

By working with cloud-based BIM information was accessible on demand, provided access had been granted. As StreamBIM contained all information needed for production sub-contractors were able to see what other disciplines were working on, which helped facilitate communication and coordination on-site.

In the design stage, weekly co-located meetings took place. During these meetings work occurred live on the model, issues were resolved, and updates were communicated (integrated concurrent engineering (ICE) methodology). Workshops were also held by the CM company to engage designers early in the project to work with the BIM approach, which was crucial to achieving the goal of production-oriented model-based design. One design company was excluded from the project as they refused to work with BIM based delivery.

Sub-contractors engaged in the BIM approach by using mobile devices and integrated cameras for communication, coordination, administration, information handling, question-answer handling, case/issue management and controls/protocols. Site workers took the initiative to use these tools, which were simple and easy to use in the StreamBIM software.

5. Discussion

The Celsius case is an example of a project where BIM was totally embraced throughout the design and construction phase, which after completion provided the client with a digital twin for facility management. What is unique about this case is the extent that BIM was used during production, where site workers were able and required to extract construction information directly from BIM. Establishing BIM as the contractual and legally binding construction document as well as excluding 2D paper drawings was key to achieving this. In this case cloud-based BIM became the single source of information and communication platform for the project. To support this new novel, innovative and digitalized construction process, many different aspects had to be addressed and accounted for during the project. The holistic BIM approach, implemented by the CM company throughout the project united commonly found fragmented BIM uses into an approach where BIM was embraced in its totality, shifting focus towards creating and using production-oriented BIM.

5.1 Embracing BIM in its totality “Total BIM”

Although many of the individual BIM elements applied in the Celsius project are exotic, such as having BIM as the legally binding document, no 2D paper drawings, and constructing directly from BIM, they are actually not unique. Instead, what truly sets it apart is using them all together in a single project. There are some previous attempts from practice at using BIM in this way in production, but mainly within Scandinavia and often limited to infrastructure projects. What makes the Celsius case special is the shift towards production-oriented BIM, incorporating all the elements described within a single project, fully embracing BIM. By adopting this approach site workers were able to construct directly from BIM, creating the drawings and views themselves that they needed to conduct the work.

The CM company was behind the “all-in” BIM approach rather than a “half-in” or “mixed-mode” of working. Traditionally it is common that separate parallel processes exist where BIM is developed during the design stage, which is then used to produce 2D drawings. During this traditional process BIM becomes obsolete and replaced by drawings in the last stage of the design process, as they are the common legal and construction document. Trust is lost in BIM as it ceases to be regularly updated and workers lack the confidence to use it on the construction site as a single source of information. Instead, in Celsius they developed a high-quality BIM that could be used for construction. The process was supported by the CM company that was involved both during the design and construction of the project. By going “all-in” on BIM, efforts were focused on a single representation and single process, instead of the extra demands of creating drawings. By having a single representation (BIM), the burden of supporting two representations and processes is lifted and conflicts between them are no longer an issue. Workers were also not able to fall back on traditional methods as 2D paper documents did not exist. This led to new innovative work methods that had previously been attempted in the Röfors bridge project back in 2013, but were not effectively realized until Celsius. It is generally accepted that increasing BIM implementation in projects is an increasingly challenging task for stakeholders (e.g. going from BIM level 2 to 3) ( Succar, 2009 ). But, by focusing on a single representation, we question if the BIM approach in Celsius really is more challenging than current “mixed-mode” projects. It must be easier for both the design and the construction team to have a single source of information and representation that they can fully focus on and trust, rather than having two or more sources, which need to be cross-checked and updated throughout the process. These “mixed-mode” processes could cause expensive mistakes and construction errors, which was one of the main reasons why the CM company wanted to use BIM as the single source of information.

Software was crucial to the success of the Celsius project, most notably the use of StreamBIM on-site. Previous projects have been limited by software, such as the Röfors bridge project where workers could not extract construction information directly from BIM. Functionality and user-friendliness are crucial factors for site workers to be able to engage with BIM. StreamBIM provided this with simple but powerful viewing, sectioning, filtering and measuring functionalities, which enabled production-oriented views to be created on the fly by workers on-site. By having this application available on iPads and mobile phones, workers could take the process a step further by using cameras and software features for issue management and controls, supporting the feedback process. This cloud-based, production-oriented BIM became the communication platform for the project, where design teams, construction workers and the different sub-contractors could communicate construction issues, questions, maintain “as-is” and “as-built” documentation, and plan their work before they arrived at the construction site. Throughout construction, design teams continued to work on the model, reducing the need for on-site solutions. The cloud-based solution also ensured that workers were always using the most up-to-date version.

Site workers could use virtual reference planes in the digital model and compare them with real (physically painted) reference lines on the construction site. Since production-oriented views are created by site workers, they can take the measurements they need and relate them to the current state on the construction site and known reference objects or lines in the real world. They are no longer limited to the dimensioning provided to them by the design team, but instead have the possibility to take more measurements (in all directions) and more accurately. They also have more information available to them by working in 3D rather than with traditional 2D drawings, which may provide a more realistic visualization of the designer's intent ( Ghaffarianhoseini et al. , 2017 ). This enables them to carry out their work more efficiently, by extracting more accurate measurements and information from BIM.

Previous studies and BIM use have mostly been concerned with the design stage and the term BIM has come to have many different meanings ( Davies and Harty, 2013 ). Cousins (2017) discusses the concept known as Total BIM, where BIM is embraced in its totality. BIM is seldom used as the unique source of construction information or legal documentation, yet they were in Celsius. The case study findings further highlight the unique “all-in” BIM approach implemented by the CM company. We find that the Celsius project is one of the first to really embrace BIM in its totality – Total BIM, based on our understanding of Total BIM today. What sets it apart is integrated BIM use in a complex construction, throughout the whole construction process, including its use on-site and legally binding status, e.g. moving from BIM level 2 to level 3 ( Succar, 2009 ). It was also considered successful as the project was delivered within time, under budget, highly rated in worker surveys and BIM adopted in all project stages.

5.2 Challenges and competencies

Working with the BIM concept used in Celsius presents challenges. BIM object and product information are imported into BIM, which helps avoid design errors and helps during the bidding process. But sometimes it is difficult to track and make decisions early in the design process before the sub-contractor is decided. Standard, representative components are often available in the BIM authoring software but not always the actual ones that will be used on the construction site, which may affect clash detection due to different dimensions (e.g. this occurred in the Celsius project with sprinkler systems). The CM company stated that there needs to be an increased focus on having the specific product components in BIM that they are going to use and purchase during the construction stage and that is important to develop a standardized object library that can be reused in future projects.

Even if designers can produce a high-quality model there needs to be follow through from production, otherwise the concept fails. In Celsius the CM company was able to achieve this by being involved in all project stages. Additionally, the approach is reliant on the vision of the people involved, their engagement and leadership skills. Clear goals were set early in this project and communicated through workshops to get people onboard. Taking workers out of their comfort zone, getting them to try something new and trusting the vision required strong project management. By not producing paper drawings, workers had little choice but to engage with new technologies (e.g. StreamBIM) and by implementing it in this way the sub-contractors could not fall back on the traditional way of working with printed drawings.

A common concern is that small firms may be excluded from high-end BIM projects due to a lack of competencies and resources ( Dainty et al. , 2017 ). However, more bids were received compared to similar projects and Celsius simplified this process by providing firms with quantity data. The bidding process can be costly for small firms due to the time-consuming process of extracting quantities from 2D drawings, but in this case, it was made easier. A recent study has shown that quantity take-off and cost estimation using BIM is often 10 times faster and more accurate than the traditional drawing-based process ( Brohn, 2018 ). In the Celsius case the bidding sub-contractors could put the time and effort into production planning, to work smarter and more efficiently during construction, instead of performing time-consuming quantity take-off tasks. The on-site BIM viewer software with its user-friendly interface, all-in-one approach and filtering template feature aided the learning process of workers that were unfamiliar with BIM. The CM company also provided education and created a supportive learning environment on the construction site. Costs associated with the software licenses and training were included in the project budget, which again shifts the burden away from small firms. By the end of the project feedback was overwhelmingly positive towards the BIM approach. As competencies develop less training will need to be provided and more information can be found by users themselves. However, working in this manner is very dependent on the people involved. It was recognized in this project that they needed to document more and update manuals so that another person could take over if required. User engagement was a vital aspect of the project's success and those who failed to align with this vision were excluded, as was the case with one design company and one of the sub-contractors. Celsius challenges the general understanding of the effects on different stakeholders in high-end BIM projects, and as mentioned extra demands were placed on designers, project management and leadership. Implementing the Total BIM concept may also digitally disrupt the traditional way of working within construction projects as the transformative effects of digital work methods occur. Roles and responsibilities will be affected by using BIM as the contractual document, the single source of information and as a central communication platform. This paper has outlined some examples of this such as sub-contractors that were unwilling or unable to engage with the digital work methods and the added effort for designers to create a high-quality accurate design.

5.3 Project structure changes and legal aspects

Site workers were no longer the consumer of static 2D drawings but instead creators and consumers of information in BIM (drawings, views, sections, product information etc.). They were given the possibility to create 3D views, i.e. Production-Oriented Views (POVs), to display information in the most suitable way for themselves. In the future building design may focus on what is most suitable for the site worker, i.e. enabling seamless switching between interactive 2D and 3D views within BIM-viewer applications on-site. Concerns are often raised about transforming work methods, for example, increased mistakes and responsibility. However, this often assumes that the 2D world with paper drawings is perfect, when in fact many of these challenges already exist (mistakes measuring). One worker reflected on this upon project completion saying, “he had focused too much on what could go wrong instead of what could go right.” This shift from consumer to creator and producer on-site helps save time and expense. Extra effort is spent on creating a high-quality production-oriented BIM but consequently reduces the amount of expensive ad hoc solutions on-site.