- Open access

- Published: 13 August 2018

Bonded repair of composite structures in aerospace application: a review on environmental issues

- S. Budhe ORCID: orcid.org/0000-0002-3235-9232 1 ,

- M. D. Banea 1 &

- S. de Barros 1 , 2

Applied Adhesion Science volume 6 , Article number: 3 ( 2018 ) Cite this article

21k Accesses

60 Citations

Metrics details

Over the last two decades, the repair of existing engineering structures using fiber reinforced polymer composites has attracted a great attention by aerospace industry, as it is more economical than replacing new. With an increased use of composite material in aerospace field, it is thus essential to restore the structural integrity by repair of damaged part. Concerns regarding the long term durability of composite repair bonded joints have been a major obstacle for critical component of aerospace structures. This paper reviews the current research on the environmental durability of adhesive bonded repair of composite structures to focus on the durability concerns and suggestion on the research needed in this area. The most important environmental factors (moisture and temperature) are reviewed thoroughly and also combined environmental effect. Finite element methods used to predict the environmental influence on the composite bonded joints are briefly reviewed. Finally, the paper concludes with key findings, opportunities and future research topics in order to develop cost effective, better quality and reliable composite repair bonded joints.

Introduction

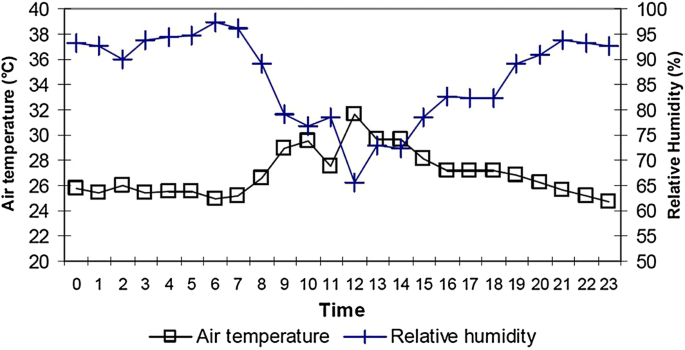

Outstanding properties of fiber reinforced polymer composite materials, lead to a wide application in all the sectors such as aerospace, automotive, marine, sports industries and even in the civil infrastructures, etc. Since the last decades, an enormous use of composite materials in the aerospace sector has caused an increasing need for repair technology of damaged component rather than replacement with a new component [ 1 , 2 , 3 , 4 ]. Composite structures in service experience damage that comes from the accidental impact and mechanical or environmental condition [ 5 , 6 ]. The main environmental threats are related to the effect of temperature and moisture absorption, which can affect the strength of composite structures and reduce their service life [ 4 , 7 , 8 ]. The temperature and moisture levels could vary throughout the day (see Fig. 1 ), from take off to the landing or vice versa, during seasonal change or geographical difference [ 9 ]. This cyclic temperature and moisture could even further deteriorate the structures and then lead to premature failure of the structure.

Daily air temperature and relative humidity variation in Johor Bahru, Malaysia [ 9 ]

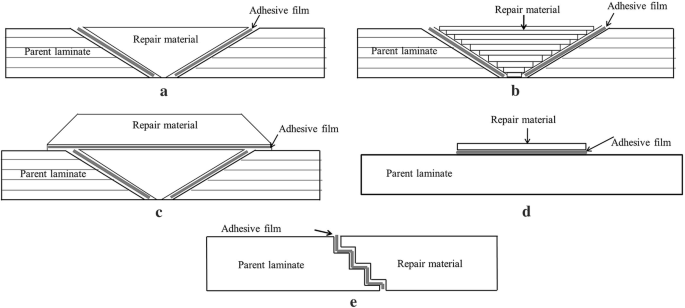

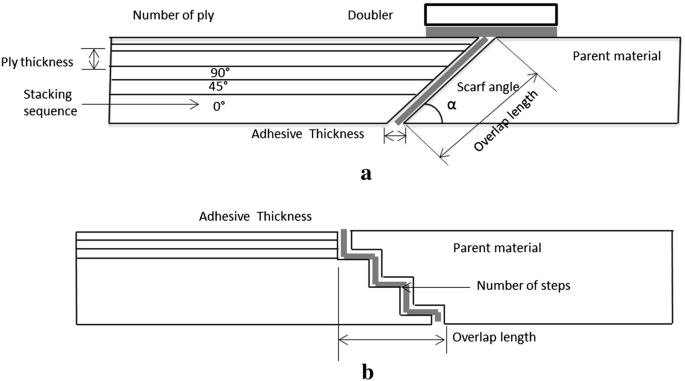

Composites are increasingly being used to repair both metallic and non-metallic (composite) structures. There are different types of composite repair bonded joints availables as shown in Fig. 2 . The most common types of repairs carried out with composite materials in the aerospace industry are external bonded patch repair and scarf repair. Both repair techniques differ from each other in terms of manufacturing and application point of view. The scarf repair joints require a special equipment to remove the considerable amount from parent material, so it is preferably used for thick laminate composite. On the other hand, external patch repair is relatively simple and faster, hence it is widely used in aircraft to keep an airplane in serviceable condition. Considerable experimental and numerical studies have been conducted to optimize the geometrical parameters of external patch repair and scarf repair joints for the better performance of the composite repair [ 10 , 11 , 12 , 13 , 14 , 15 , 16 , 17 ]. However, designing an optimum scarf and patch repair of a composite structures is complex due to an unpredicted environmental condition during service period.

Type of composite repair bonded joints, a scarf repair, b stepped scarf repair, c scarf doubler bonded repair, d patch repair, e stepped lap repair

The application of adhesively bonded joints is widely used for the composite repair in aerospace structure because of the design flexibility, more fatigue resistant and higher damage tolerance than the other joining methods. Adhesive bonding method is already a well matured and developed process and was reviewed by many authors [ 18 , 19 , 20 , 21 , 22 ]. Many researchers [ 23 , 24 , 25 , 26 , 27 , 28 , 29 , 30 ] studied the performance of adhesively bonded joints under the influence of different geometry and material parameters. Adhesive bonded repair in composite components are well established and developed in the aeronautical industry [ 31 , 32 , 33 ]. However, it is mainly restricted to the secondary structural component, due to the limit imposed by the fail-safe criteria.

Most of the composite repair systems in civil aircraft are implemented “in field” only and based on the cured-in-place (CIP) approach. This “in field” composite repair system introduces severe restrictions compared to those used in manufacturing plant such as: use of an autoclave, drying and curing methods, storing adhesive and composite laminate repair material, curing temperature etc. Bonded joints between the structure being repaired and the repair patch and the bonding agent (repair adhesive material) is the most critical part in terms of strength and durability of the repair. Many researchers conducted short term tests subjected to environmental condition by changing a number of variables such as the adhesive material, composite patch material, patch geometry, curing temperature etc. in order to determine the performance of repair bonded joints and optimize the joints [ 4 , 34 , 35 , 36 , 37 , 38 , 39 , 40 , 41 ]. The main challenge is how to give an assurance of these repair joints for long term operation throughout their service life. This difficulty is caused by possible degradation of joint strength due to exposure to unpredicted environmental (predominantly) condition, specially moisture and temperature. To ensure that repair designs using bonded assemblies have an acceptable lifespan, the interaction of adhesive, composite and bonded joints with the service environments is required.

This review paper summarizes the research on the environmental issues mainly moisture and temperature on composite, adhesive and bonded joints, which help to set the moisture and temperature (design and selection of repair material) limit for the maximum performance of composite repair. Combined effect of moisture and temperature on the composite bonded joints is also discussed. Finally, in the conclusion section, several scientific challenges and prospects have been discussed in order to develop cost effective and high performance composite repair systems.

Background: bonded repair

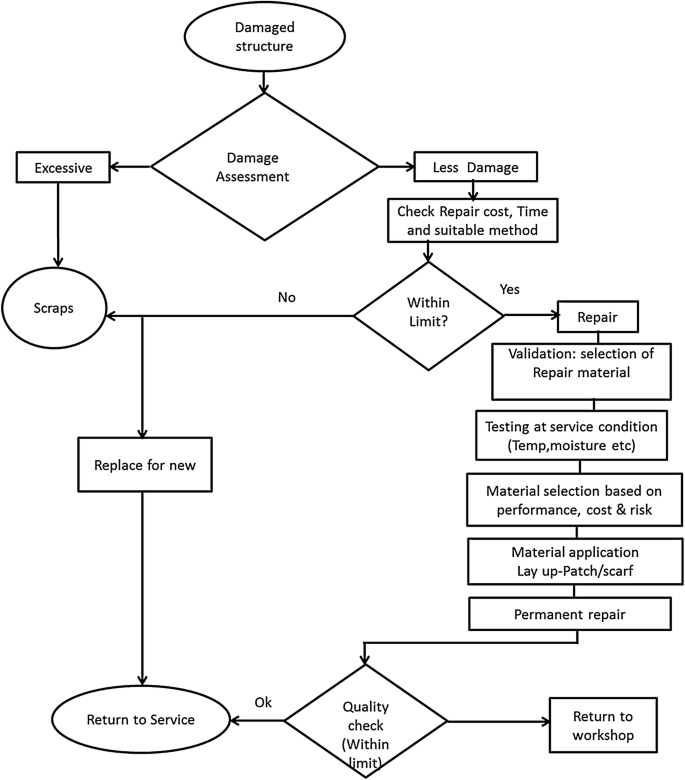

Bonded composite repair of damaged structures have seen significant growth since the introduction of the composite repair system. The frequency of minor accidental damages during the operational life of the structure is high and their repair operations have a significant impact on the maintenance costs. Figure 3 summarizes the principal steps to follow for the repair of a damaged structure or component. If the material damage is not extensive, structural repair is the best solution as replacing the entire component is not cost-effective in many cases [ 42 , 43 ]. However, it is required to follow an exhaustive process to validate the repaired component, and if the component does not fulfil the structural requirements, then it is replaced by a new one.

Flow chart for the repair of a damaged structure made of composite

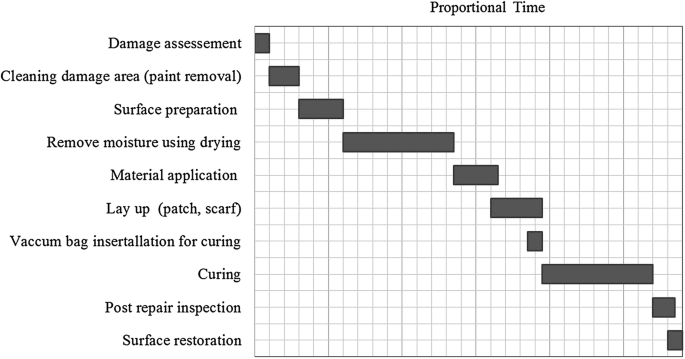

Figure 4 shows a chart which indicates the usual repair process and the time required to complete the activity. Usually a drying procedure is required before application of the repair patch to remove all the moisture in the skin absorbed during the service period of the aircraft [ 2 , 4 , 44 ]. The damage location is then cleaned and the repair laminates are placed. The repair patch/scarf is then cured on top of the original parent structure (aircraft part) using a heating blanket under vacuum, as unavailability of autoclave in “in field” composite repair system. It is clearly seen that the drying and curing process activity is taking more time compared to the other activities in the repair process. Drying time increases the repair costs dramatically, not only because of the energy wasted in the process, but also due to the lost revenue during this extended repair time and aircraft downtime [ 4 , 34 ]. Different trends in the mechanical performance of the composite bonded joins are observed with respect to the moisture content level and the adhesive material. Typical repair procedures recommend implementing a drying step before bonding. Currently, more attention is to reduce the drying time and curing temperature also, as both could reduce repair time and better performance of composite repair.

A summary of repair procedure of composite repair with time

Industry concerns

In recent years, the aerospace industry has acknowledged the need for standardized bonded repair process due to heavy use of composite material in aircraft, almost 40–50% of the volume in new aircrafts (i.e. Boeing 544) entering into service. Composite materials are widely used in both primary and secondary structural components, but industries are not well prepared to tackle the maintenance and repair of the secondary structural component of aircraft.

The current trends in aircraft operations are showing an increasing demand for lower operational and maintenance costs. However, durability concerns remain an obstacle to the application of composite repair in primary structure of aerospace components because of safe limit criterion. Many researchers [ 8 , 45 , 46 , 47 , 48 ] focused on durability and presented some trends, but it is difficult to generalize as it depends on a number of factors such as material properties, environmental conditions, manufacturing process and exposure time, etc. Hence proper selection of design parameters and process is a very important and requires a basic data base in order to obtain an optimum performance of the composite repair system. In order to meet these requirements, there are some obstacles such as availability of the autoclave system for curing, storage of repair adhesive material at particular condition and other facility for the composite bonded repair on site (field). Lack of complete long term data in the presence of environmental conditions, imposes a complete drying of components which ultimately lead to more repair time. In some instances, a compromise between the drying temperature and time for the curing of the damaged structure provided the best suitable combination. It is in the airliner’s best interest to produce a good quality repair in the most efficient way possible, namely by ensuring the implementation of a robust and low cost repair process.

Environmental parameters

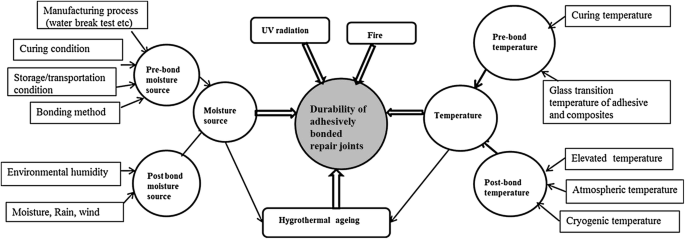

The main environmental threats are related to the effect of temperature and moisture absorption, which can affect the strength of the composite structures and reduce their service life. In composite bonded joints, as in those used for repairs, the amount of moisture uptake by the composite structures depends on a number of factors such as: composite laminate, adhesive material, exposure conditions (temperature, humidity), exposure time, etc. [ 49 , 50 , 51 , 52 , 53 ]. The most important environmental parameters and their sources which are directly and indirectly associated with the durability of bonded joint performance are discussed below (Fig. 5 ).

Environmental factor and their sources which influencing the durability of adhesively composite bonded joints

- Temperature

The adhesives used in aerospace applications experience a wide range of temperature from cryogenic (− 55 °C) at high altitude to elevated temperature (200 °C), when travelling at mach 2 or above, during its service period. There has been a growing demand by industries, particularly in the aerospace industry for the adhesives to withstand high and low temperatures. Adhesive systems that can resist high temperature and high strength includes epoxies, silicones, phenolics, polyimides, bismaleimides and ceramics, etc. [ 19 ]. However, due to the polymeric nature of adhesives, the variation of the mechanical properties of the adhesives with temperature is generally the most important factor to consider when designing a bonded joint.

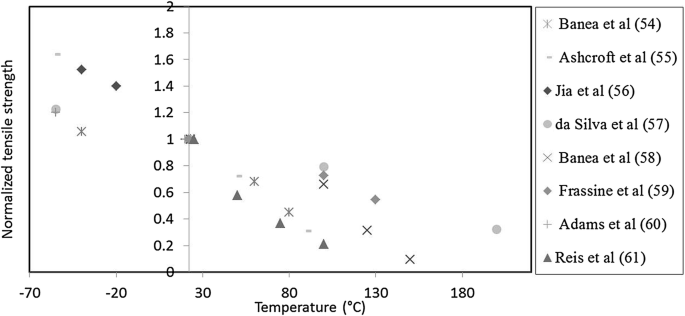

Figure 6 shows the tensile strength variation of adhesive with respect to the temperature for different adhesives [ 54 , 55 , 56 , 57 , 58 , 59 , 60 , 61 ]. The tensile strength values are normalized with respect to the value obtained at room temperature 22 °C for respective adhesives. It is clearly seen that the strength decreases at elevated temperature while at lower temperature, it increases with respect to the room temperature. At lower temperature adhesive get brittle in nature and at higher temperature the softening of adhesive takes place [ 54 , 56 , 57 , 58 , 62 ]. A similar trend was observed for all the adhesives, only the strength value differs and it depends on adhesive chemical properties. Retaining the maximum strength of the joints at both high and low temperatures is difficult as the adhesive behavior changes with respect to temperature. Therefore, the mechanical properties of the adhesive need to be measured from low to high temperature ranges, which can assure the performance of the composite repair for the specified temperature range.

Temperature dependent tensile strength properties of structural adhesives, test results from Refs. [ 54 , 55 , 56 , 57 , 58 , 59 , 60 , 61 ]

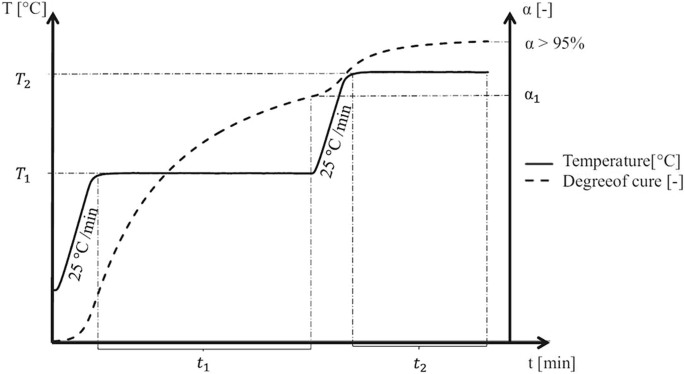

The strength of the adhesive is closely related to the glass transition temperature, T g , which is highly dependent on the cure temperature of the adhesive [ 57 , 59 , 63 , 64 , 65 ]. Curing at high temperature for short period improves the T g , which ultimately reduces the composite repair time. But, high initial curing temperature leads to a higher void formation, affecting the mechanical performance of the joint [ 50 , 63 , 66 ]. Cebrain et al. [ 67 ] proposed a dual step curing at isothermal stages (Fig. 7 ) which ensures a low void formation and thus maintaining a good mechanical performance. The overall processing time could be reduced from 4 h for the recommended cure cycle to 30 min with a cure cycle based on a dual step heating process, which accelerates the curing process. This dual step curing approach can reduce the void formation, which is essential in order to ensure the quality of adhesion, as a poorly cured adhesive is a critical issue for aeronautics industry.

Two step heating (curing) process [ 67 ]

Advanced adhesive can sustain the higher temperature in structural application but difficulties arise during composite repair where the high temperature properties need to be restored. Hence the curing temperature of the adhesive should be as low as possible around 177 °C, above which may risk as the auto-ignition temperature for the aviation fuel can be attempt [ 63 ]. Aerospace industries demand for lower curing temperature of adhesive as the repair takes place “in field” condition and composite repair systems need to cure at room temperature [ 35 , 36 ]. Table 1 presents the curing temperature of most used adhesives in aerospace and space application structures. The adhesives that can be stored at ambient temperature and cured at low temperature, with short cycle time, could be ideal for bonded repairs.

- Composite materials

An increasing use of fiber reinforced polymer (FRP) composites in large structural applications and development of polymer-matrix composite (PMC) materials with additional qualities requires a better understanding of the thermal and mechanical response at wide temperature range before application in aerospace and space structural.

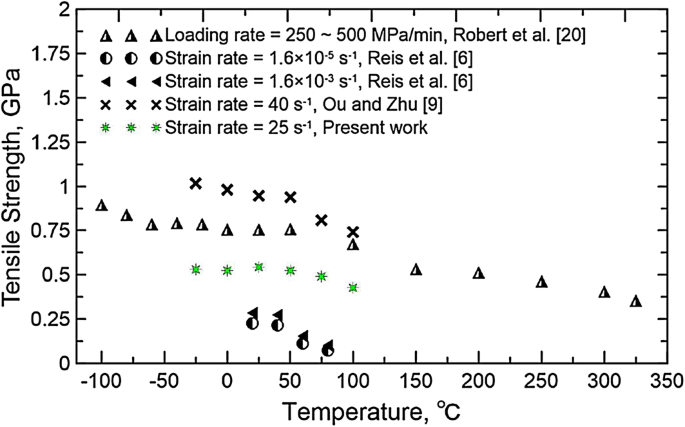

In recent years, more experimental research was carried out into the effect of temperature on the mechanical properties of composite materials. Figure 8 shows the trend of tensile strength of GFRP specimens at different temperatures [ 74 ]. The results of these studies show a decrease in strength at higher temperatures while the strength increases at lower temperatures. The reduction is caused by the softening of the resin matrix when its T g is reached or near the test temperature [ 75 , 76 , 77 ]. This would weaken the interfaces between fibers and matrices and decrease the resistance of matrices during deformation [ 78 , 79 , 80 ]. But, thermal exposure up to temperatures below the T g is in fact advantageous for FRP composites and adhesives as a result of further post-curing [ 81 ]. Di Ludovico et al. [ 82 ] replaced the conventional resin matrix with an innovative epoxy with higher T g , in order to avoid failure at lower T g . On contrary, Takeda et al. [ 83 ] found that tensile strength increased with temperature for the thin graphite/epoxy cross-ply composite laminates, but decreased slightly for the thicker laminates at 80 °C. Patch thickness should be considered carefully during the design of bonded repair joints. Many researchers shows an improved strength of FRP composites at low temperature and a possible explanation for improved strength is FRP matrix embrittlement and matrix hardening [ 84 , 85 , 86 , 87 ]. The composite behavior at low temperatures depends to a large degree on the type of polymer matrix and its sub-zero mechanical properties.

Tensile strength of FRP composite coupon with respect to different temperature [ 74 ]

Fiber reinforced polymer composites are sensitive to temperature variations as a result of induced thermal stresses between the fibers and polymer matrix [ 88 ] which arises due to their distinct thermal expansion coefficients. Researchers [ 85 , 87 , 89 , 90 ] stated that the difference in contractions of fiber and matrix on cooling is also suspected to increase the residual stresses at the fiber/matrix interface, and then result in local micro-cracking and reduced tensile strength. Also at elevated temperatures, differential thermal expansion of fiber and matrix may lead to the formation of microcracks at the fiber/polymer interface [ 91 , 92 ]. The magnitude of the residual stresses is proportional to the difference in curing and operating temperatures of the composite material [ 93 ]. The effect of a thermal environment on the residual mechanical performance was evaluated and found both the flexural and shear strength decreased and became more pronounced at prolonged exposure time due to weakening of the interface [ 94 ]. In order to utilize the full capability of the advanced and new composites, its behavior under high and low temperature conditions and stress must be studied in detail.

Adhesive joints

The influence of temperature on the strength of adhesive joints is an important factor to consider in the design of adhesive joints. The strength of adhesive joints at different temperature depends on the coefficients of thermal expansion (CTE), cure shrinkage of adhesive and properties of the adhesive and adherend. Many researchers [ 95 , 96 , 97 , 98 , 99 , 100 ] studied the temperature effect on the composite bonded joint strength. Generally adhesive joints strength degrades at higher temperature and improves at lower temperatures. The quasi-static tensile behavior of adhesively-bonded double-lap joints, composed of pultruded GFRP laminates and an epoxy adhesive, was investigated under temperatures ranging between − 35 °C and 60 °C. The highest strength was obtained at 40 °C due to a statistical size effect caused by the smoothing of the normal tensile and shear stress peaks [ 97 ]. At temperatures above T g , strength and stiffness decreased following the trend of the thermomechanical behavior of the adhesive [ 97 , 98 ]. It would be beneficial to select the adhesive and composite patch material with higher glass transition temperature, which allow a better performance of the repair joint at higher temperature too.

Temperature variations (thermal cycle) are among the most important environmental factors that may affect the durability of adhesively bonded joints for aerospace applications. Sousa et al. [ 95 ] studied the effects of thermal cycles on adhesively bonded joints between pultruded glass fibre reinforced polymer. The maximum performance reduction of Elastic Polymer-GFRP joints occurred after 150 thermal cycles, when the ultimate load and stiffness decreased by 18% and 22%, respectively. Little changes occurred with additional thermal cycles, which were partly attributed to the occurrence of post-cure phenomena in the elastic polymer adhesive during exposure at higher temperatures [ 95 ]. A small number thermal cycles would be advantageous to the joint as an occurrence of post-cure. Residual thermal stresses are induced at higher temperature of the joint due to the CTE mismatch between the adhesive and the adherends [ 101 ]. The higher temperatures facilitate polymer chain mobility and lead to some degree of relaxation of these stresses. However, when cooling the joint, the stress relaxation is reflected in an increased interfacial stress between the substrate and adhesive layer.

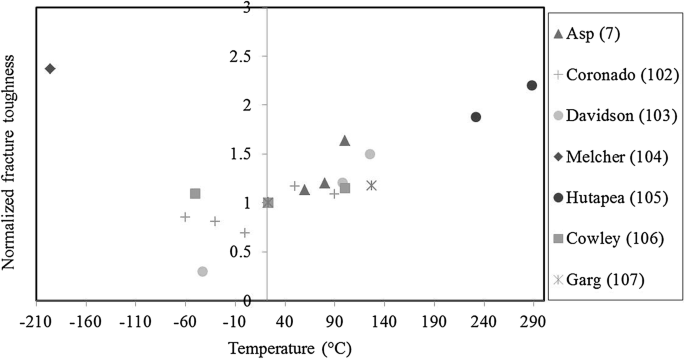

Fracture toughness of the composite laminate bonded joints is widely used to predict the performance of composite bonded joints under different temperature condition. It has generally been found that there is an increase in fracture toughness, G IC , with increasing temperature while at lower temperature decreases with respect to the room temperature under mode I tensile loading (DCB specimens) as shown in Fig. 9 [ 7 , 102 , 103 , 104 , 105 , 106 , 107 ]. The fracture toughness values are normalized with respect to the value obtained at room temperature 22 °C. An increase of the matrix ductility, an increment in the amount of fiber bridging and fiber breakage are the most common explanation for the improvement in fracture toughness [ 103 , 105 , 107 , 108 , 109 , 110 ]. On the other hand, if test temperature is above the T g , the fracture toughness decreases due to the loss of adhesion between the fibers and the matrix (Rubbery state), but below the T g , it was observed an increase in G IC due to strongest bond strength between the fiber and the matrix [ 108 ]. While, Russell et al. [ 111 ] suggested that the decrease was likely related to both residual stress states in the matrix around the fiber and to the fibers constraining the size of the adhesive. In pure mode II tests, however, do not exhibit the same trend, some of the authors observed a decrease G Ic , while some found increased values with respect to the test temperature [ 5 , 103 , 106 , 111 ]. A small number of results for the mixed mode I–II behaviour have been published, but still there is not a clear consensus about the trend of fracture toughness value with the effect of temperature under mixed loading [ 7 , 111 , 112 ].

Fracture toughness with respect to the temperature [ 7 , 102 , 103 , 104 , 105 , 106 , 107 ]

It was shown in the literature that there are many mechanisms such as: matrix deformation (G m ), fibre bridging (G b ), fibre fracture (G f ), and fibre/matrix interfacial debonding (G deb ) that contribute to increase or decrease of the fracture toughness, but still not confirmed about quantities of each mechanism. Activation of each mechanism depends on different parameters such as adhesive- adherend material properties, test temperature, curing temperature, glass transition temperature, moisture content, etc. Mixed trend of fracture toughness was observed over the temperature range under different loading condition. Hence, it is important to consider the glass transition temperature and the expected maximum temperature that can be reached by the composite structure during service period, while selection of adhesive and composite patch for repair.

Moisture primarily affects the resins and adhesives in FRP composites and bonded assemblies structures. Generally, the adhesive absorbs more moisture content than the composite laminate, matrix and interface in any composite structure. Each adhesive type absorbs moisture up to certain extent and its absorption rate and saturation limits are dependent on a number of factors such as exposure condition, exposure time, temperature and humidity level, etc. So, the moisture absorption data of each adhesive in different environmental condition for long duration are almost difficult to have. Instead of it, the worst possible, attack by the moisture on the adhesive is considered for the design purpose to maintain the safe design.

In general moisture can change adhesive properties through plasticization, swelling, cracking and hydrolysis phenomenon. Figure 10 shows the representative moisture curve of sorption, desorption and resorption level of particular adhesive [ 113 ]. Faster resorption and higher saturation limit in a subsequent cycle compared to previous one indicate a change in physical and chemical properties after a cycle of sorption and desorption. It has been reported that the penetration of the moisture into the polymer will increase the free volume by the swelling effect and cracking during moisture absorption [ 114 , 115 ]. A subsequent step, in resorption cycles, this free volume occupies the moisture in the resorption process which adds more moisture content and faster than the previous cycle. Desorption from highly moisture saturation tended to leave small residual moisture content, which could only be removed by heating at high enough temperature but blistering may occur [ 116 , 117 ]. So, for composite repair structure the knowledge of desorption, resorption and a saturation limit should be needed as the structure face higher impact than previous as proved by earlier studies.

Moisture curve of sorption, desorption and resorption level of adhesive [ 113 ]

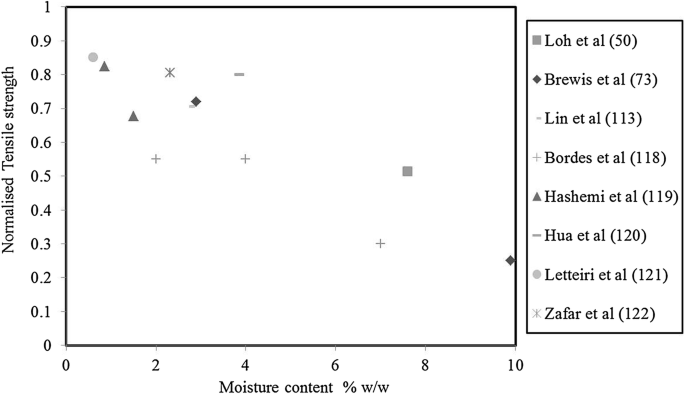

The effects of the moisture on the mechanical behavior of the epoxy system have been studied by many researchers [ 113 , 118 , 119 , 120 , 121 ]. The detailed trend of tensile strength and elastic modulus is shown in Fig. 11 [ 50 , 73 , 113 , 118 , 119 , 120 , 121 , 122 ]. The possible reasons for the degradation of the strength are plasticization, decreasing the values of the glass transition temperature, stress generation due to the swelling of the system and a possible chemical degradation [ 113 , 114 , 118 , 123 , 124 ]. The lower percentage of moisture in the adhesive won’t be a major issue as long as post-cure will absorb during curing process, but void content may introduced. It was noted that the glass transition temperature, T g value decreased with moisture (plasticise the epoxy) and softening of the adhesive [ 73 , 121 , 125 , 126 , 127 , 128 ]. Therefore, it is important to have the moisture absorption history of the adhesive, which is going to use for repair and its mechanical behaviour and also consider moisture accumulation by the adhesive during the storage in freezer.

Normalised tensile strength at various levels of moisture uptake [ 50 , 73 , 113 , 118 , 119 , 120 , 121 , 122 ]

The moisture uptake by the composites is consist of polymer matrix, interface of matrix-fiber and very negligible by the fiber. Moisture absorption by the composite is mainly conducted by the diffusion mechanism. The other two mechanisms of moisture penetration into composite materials are capillary flow along the fiber/matrix interface and finally, percolating flow and storage of water in micro-cracks. These two damage-dependent mechanisms are increasing both the rate and the maximum capacity of moisture absorption in an auto-accelerative manner [ 51 , 129 , 130 , 131 ]. The degree of absorption depends on both matrix and fiber properties, matrix-fiber interface, fiber volume fraction, composite void content and epoxy resin curing agent ratio, etc. [ 132 , 133 , 134 ]. Moisture absorption by composite laminate during repair time is not only the concern but also the moisture that might be absorbed by uncured composites (prepreg) during storage. Finally, repair materials that are left uncovered during the multi-step process of bonded repairs may also absorb and trap atmospheric moisture.

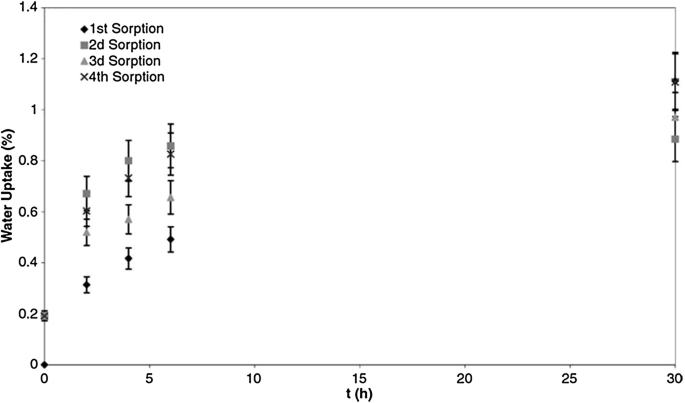

Figure 12 shows the moisture uptake during the first four absorption cycles. The moisture level and diffusivity of composites increases during each subsequent reabsorption cycles [ 51 ]. This behavior has been associated with the penetrant molecules can rearrange the polymer network, causing swelling of the material and micro-cracking occurring in the matrix during each sorption. As already mentioned, moisture absorption may induce irreversible changes to polymers and composites, such as chemical degradation, cracking and debonding [ 131 , 134 , 135 , 136 ]. Hence, topics such as the reversibility of the wet/dry cycle, the damage induced by the absorption process and the effect of this damage on the later stages of the absorption process and on subsequent cycles, are of practical interest and important for the composite repair applications. This data would help for proper selection of composite patch material in the composite repair.

Moisture sorption by Gr/Ep composite laminate in subsequent steps [ 51 ]

The influence of moisture absorption on mechanical properties of FRP composites is well documented in literature, regarding the tensile, interlaminar shear and flexural properties [ 122 , 132 , 137 , 138 , 139 , 140 , 141 , 142 ]. The absorbed moisture results in more detrimental effects on the mechanical properties of composite materials since the water not only interacts with polymer matrices, physically, i.e. plasticization, but it also attacks the fiber–matrix interface [ 143 , 144 , 145 ]. A reduction in strength and stiffness due to moisture absorption can be attributed to various damage mechanisms which can include matrix cracking, fibre/matrix interface, matrix plasticization/softening, stress generation due to swelling of the system, chemical degradation [ 122 , 138 , 139 , 146 , 147 ].

Akay et al. [ 8 ] reported that water uptake is also further detrimental to fibre–matrix adhesion strength. This has been supported by an increase of bare fibres on SEM inspections of fractured surfaces, which indicate a weak adhesion between matrix and fiber. Also strong mismatch in swelling behaviour between the matrix and the fibre was observed, which may introduce weak adhesion integrity [ 148 ]. The drying of FRP composites is compulsory but complete drying also lead to damage the FRP composite by introducing the micro-cracking during desorption, so it is important to consider the drying temperature and time, in order to avoid any damage caused by drying [ 149 ]. Presence of moisture in composites may affect the properties of the repair as it can cause an increase in bond line porosity and a decrease in joint strength.

The majority of the research papers recommend drying the composite substrates before bonding to prevent the diffusion of moisture from the substrate into the joint during repair cure cycle. For increased durability of composite materials, their capacity for sustained performance under harsh and changing environmental conditions must be quantified.

Long term durability of joints in severe environments has been recognized as one of the obstacles to the widespread application of adhesive, specially for aerospace, marine, and offshore structure which exposed to severe environmental conditions. Composite structure absorbs more moisture through the atmospheric condition during its service period, but we could not neglect the moisture absorbed by an individual components such as composite laminate, adhesive before bonding process. The moisture absorbs before bonding called pre-bond moisture and after the bonding term as post-bond moisture. In subsequent sections, both pre-bond and post-bond moisture are described individually in details.

Pre-bond moisture

Pre-bond moisture issue is very important for joints formed between polymeric-composite substrates as it directly influences on the performance of adhesive joints. There are several potential sources of pre-bond moisture in composite substrates such as: during the manufacturing process, CFRP panel undergoes several treatment procedures like wet abrasion, water break test, transportation of CFRP panel from one place to another, storing the laminate for longer periods in freezer and exposing to environmental conditions during composite repair in field etc. [ 44 , 47 , 150 , 151 ].

There are limited studies [ 4 , 34 , 41 , 44 , 47 ] reported on the pre-bond moisture effect on the mechanical properties of the bonded joints and most of them found the decrease in strength when the moisture is present in the composite. Parker et al. [ 41 ] studied the effect of composite pre-bond moisture and found a reduction in single lap-shear joint strength. Voiding, plasticization of the adhesive, and a reduction in interfacial adhesion are the possible causes for the reduction in strength [ 41 , 152 , 153 ].

An increase in the pre-bond moisture of the composite substrate yielded an increase in void content of the joint further support for higher degradation [ 41 ]. Drying the composite substrates and curing the bonded joints under isostatic pressure was found to prevent the occurrence of voids [ 44 , 47 , 154 ]. Most of the entrapped air could be evacuated prior to cure for the method using a textured adhesive film. These air evacuation strategies reduced the bondline void and exhibited a higher strength of repair bonded joints [ 39 , 63 ]. Previous work on BMI adhesives suggested that void reduction was also possible if vacuum was removed at the adhesive flow temperature and small positive pressure was maintained during cure [ 155 ].

A small amount of pre-bond moisture (below 0.5% w/w) appears to have a positive or no/little effect on the strength of the repaired joint, but as the moisture level increases, the repair strength falls [ 4 ]. However, pre-bond moisture of about 1.3% would cause a 20% loss in the tensile strength of the joint, whereas the flexural strength of the joints was not affected. For example, the flexural strength of repairs of XAS/913 parent panels with XAS/913 (using BSL 312/5 adhesive) appeared to be only weakly dependent on the pre-bond moisture level up to 1.3%. There was a slight decline in strength with moisture content up to a moisture content of around 1.2% or 1.3%, after which the decrease becomes far more rapid. It is clear that if the composite content small percentage of moisture (0.5% w/w) then complete drying before repair is not always necessary. Generally, the moisture levels usually found in composite components in service are typically 0.8% w/w. Research is needed to establish whether the effect of pre-bond moisture is always detrimental or whether a small percentage of moisture in the composite is acceptable.

Extending the drying time of the substrate cause an improvement on the composite bonded strength and fracture toughness of the joint although not fully recovered [ 44 , 154 ]. Thus, this is one of the areas that need a further attention. In addition to that fatigue behavior is still not well developed under the effect of pre-bond moisture. Thus, these are the areas that need a further attention. It is needed to elaborate this results in more fraction of moisture and provide a significant explanation for this. Nevertheless, it is necessary to have more experimental studies in order to justify or set the proper process parameter which link up the relationship between pre-bond moisture and bonded joint strength.

Post-bond moisture

The moisture absorption of the composite structures are mainly depends on the exposure condition such as: humidity, temperature, wind, UV radiation, thermal cycling, water and the exposure time. Moisture can ingress into the joint through diffusion into the bulk adhesive, composite laminate and wicking along the interface or capillary action into cracks and voids.

Several researchers [ 41 , 46 , 124 , 139 , 156 , 157 ] reported the reduction of bonded joint strength with effect of post-bond moisture. Weakening of bonding between the fiber and matrix and softening of matrix are the possible causes for the reduction in strength [ 124 , 139 , 156 , 157 ]. The strength reduction rate depends on the exposure time, exposure condition, type of adhesive material and adhered, which ultimately lead to final moisture content in the bonded joints. Jeoung et al. [ 158 ] noticed an increase in the failure strength (21%) compared to the dry joint at a moisture content of 1%. However, when the moisture content increased to 2.1% and 2.5%, the joint strength significantly decreased. It is believed that the composite joint strength increased at low moisture content due to the prevention of delamination by the compressive stress created between the plies of the adherend. The extent of the loss is dependent on the adhesive: adhesives cured at 175 °C give joints with lower strength losses than do adhesives cured at 120 °C [ 44 , 157 ]. Drying is the best suited treatment to recover the strength, However the full recovery was not achieved [ 34 ]. Drying at high temperature could improve the strength up to certain extent but blistering and some crack on the composite surface occur. Therefore, behavior of specific bonded systems exposed to various environments should be taken into account in durability design.

The performance of the composite bonded joints in the presence of moisture mainly depends on how particular adhesive and composite laminate behave when it’s subjected to the same moisture. In addition to that interface between adhesive-adherend and bonding manufacturing process such as co-curing, co-bonding, etc. also plays an important role [ 159 ]. So, complete performance data of the adhesive and the composite laminate should be in hand in the presence of moisture before selection for composite bonded joints.

- Hygrothermal

The combined effect of moisture and temperature is more severe than the adverse effect of each individual condition (temperature and moisture). Generally, moisture sensitivity (moisture absorption, desorption, and saturation) is more effective when the structure is exposed to elevated temperature.

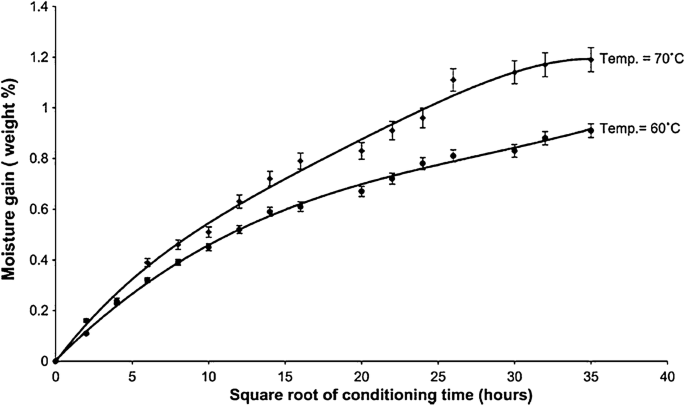

Composite usually absorbs more water at high temperature and this is a common way to accelerate water absorption. It is clear from the Fig. 13 that the higher the temperature, the higher the moisture uptake rate and higher the saturation capacity [ 52 ]. Mijovic and Weinstein [ 160 ] found that absorbed water induced depression of glass transition temperature, T g in a Gr/Ep composite was strongly dependent on the temperature during the water absorption process. The magnitude of the reduction in T g under saturated conditions reflects the degree of resin plasticisation and water/resin interactions occurring in the material [ 125 ]. This effect is usually reversible when water is removed but exposure to high temperature can produce irreversible effects, which are attributed to the chemical degradation of the matrix and attack on the fiber/matrix interface [ 161 , 162 ]. The glass transition temperature under dry and saturated conditions is a critical property for composites as the maximum service temperature depends on it.

Moisture absorption kinetics of carbon/epoxy composites at 60 °C temperature and 95% RH, and at 70 °C temperature and 95% RH [ 52 ]

The mechanical performance of composite material is influenced by the hygrothermal effect. High temperature and absorbed moisture cause expansion and plasticization of the matrix and degradation of the fiber/matrix interfaces, which change residual stresses, elastic moduli and the critical stresses for damage such as transverse cracking and delamination [ 147 ]. The possible causes for the reduction in strength are the adverse effect of a higher degree of thermal stress at the higher temperature, matrix plasticization due to moisture and temperature, swelling and induced internal stresses, cracking/crazing due to both osmosis [ 163 , 164 , 165 , 166 , 167 , 168 ].

Adhesive (epoxy resin) usually absorbs more moisture as compared to the composite laminate and composite structure, but it absorbs even more at a particular temperature (elevated). The absorbed water molecules in an epoxy can exist in either the free or bound states [ 115 , 169 , 170 ]. Free water molecules act as a plasticizer, strongly reducing T g and the modulus of elasticity [ 171 ]. Usually, when the material is exposed in a hygrothermal environment the T g decreases and, therefore, the service temperature of the material changes. This modification in T g reflects the degree of resin plasticization and water/resin interactions occurring in the material [ 151 ]. Not only temperature and moisture but also exposure time and exposing temperature also decide the variation of glass transition temperature of epoxy resin [ 172 , 173 ]. Hence selection of adhesive material and its glass transition temperature should be notified before the application [ 158 ].

Limited research was carried out on hygrothermal effect on the bonded joints strength. Most of the researchers [ 41 , 157 , 158 , 174 ] reported the reduction in strength of ageing specimen (joints) at elevated temperature. However the strength of the pre-saturated joint up to 1.0% of the moisture content increase in both room and elevated temperature conditions. A decrease in strength was observed in the case of higher temperature and longer exposure time to humidity. The tensile strength and ILSS decrease when the material has been exposed to moisture and tested at elevated temperature. But, no significant difference was reported for strength in between autoclave and vacuum-cured materials. This result supports the feasibility of scarf joint repairs with pre-cured or cocured patches under vacuum curing conditions in field-level facilities. Therefore, repairs with vacuum pre-cured or vacuum co-cured patches requiring less equipments seem to be a serious potential alternative to the composite patch repair requiring autoclave conditions which might be only available at depot level maintenance centers [ 96 ].

To summarize, the individual effect of moisture and temperature on the mechanical properties of adhesive material and joints is well understood, but there is a still a lack if systematic ageing conditions to clearly identify the combined effect of each environmental parameter.

Finite element method

An increasing complexity in geometry and material non-linearity of composite repair bonded joints makes difficult to obtain an overall governing equation. In addition to that, incorporation of the environmental parameters i.e. moisture and temperature in the analysis makes more complex the mathematical formulations. However, the experiments are often time consuming and costly. Therefore, the finite element analysis can be employed to overcome the limitations of the analytical methods.

Several researchers [ 6 , 10 , 11 , 13 , 175 , 176 , 177 , 178 ] successfully used finite element and analytical tools to perform a broad geometric and material parametric studies to optimise the parameters for maximum repair joint performance. Figure 14 shows the main geometrical parameters such as scarf angle, number of steps, patch thickness, adhesive thickness, overlap length, doubler plate, stacking sequence etc. of scarf and stepped lap repair joint. Selection of failure criterion is an important parameter for finite element analysis of the composite bonded joints. For linear elastic analysis, peal stress and shear stress value were considered as a failure criterion performance (quality indicator), where the adhesive behavior assumed to be elastic. When the adhesive behaviour became non-linear, the maximum shear strain of the adhesive layers was used to assess the joint strength. One problem with the allowable stress or allowable strain criterion is the mesh dependent singularity at the tip of the crack (geometric singularity), as well as the singularity at the intersection of each ply and the adhesive (stiffness mismatch) [ 17 , 179 ].

Design parameters of a scarf repair, b stepped lap repair

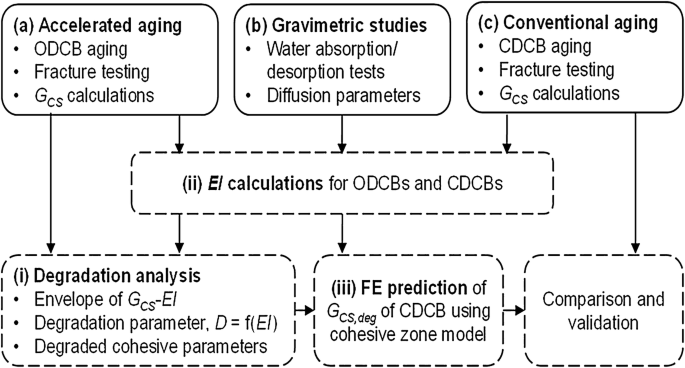

Recently, a cohesive zone model (CZM) modelling methodology has been shown to be a versatile approach to predict the durability of adhesively bonded joints exposed to humid environments [ 68 , 164 , 180 , 181 , 182 , 183 ]. The accurate prediction of failure behaviour should be correctly implemented using a traction–separation law which includes triangular, trapezoidal and exponential shape [ 184 , 185 ]. The parameters that principally define the traction–separation response are the cohesive fracture energy and the critical traction of the adhesive in each fracture mode. A proper selection of traction–separation law behavior is important. For example, a trapezoidal law predict more accurate for temperature variation in the joint [ 68 , 183 ]. As the moisture concentration adversely influences the cohesive properties, moisture-dependent cohesive properties are required to accurately predict the failure behavior of a saturated or unsaturated adhesively bonded joint using the cohesive zone approach.

Incorporation of fracture data from the ageing test into a fracture prediction methodology to enable the prediction of real closed joints is a real issue and time taking also, hence it is essential to use testing techniques that accelerate the ageing. To accelerate the ageing the open-faced method has shown a great promise in significantly reducing the time and cost of fracture tests. However, the challenge is how to incorporate the fracture data from accelerated ageing test into a fracture prediction methodology to enable the prediction of real closed joints. Ameli et al. [ 186 ] successfully assessed the applicability of the open-faced technique to predict the durability of closed double cantilever beam (CDCB) specimens. A framework for the assessment of the applicability of the open faced technique to the prediction of the durability of closed DCB (CDCB) joints is shown in Fig. 15 [ 187 ]. The significance of this framework is the ability to remarkably reduce the exposure time by using the open-faced technique and to incorporate the spatial variation of degradation in the closed joint with the aid of the 3D finite element model [ 187 ].

Framework for the FE prediction and validation of fracture toughness in environmentally degraded closed adhesive joints [ 187 ]

The lifetime of bonded joints is difficult to model accurately and their long term performance cannot easily and reliably be predicted, especially under the combined effect of an aggressive environment and mechanical loading. In addition to that, incorporation of manufacturing process of the bonded repair on its stress state in cohesive zone model is needed, as this parameters shows positive response on bonded repair performance. The problem of durability of adhesive joints to hostile environments has become the main challenge for researchers in this area. This mechanism can however be included by defining the delamination strength for the composite with a mode dependent CZM parameters.

Conclusions

Important concerns are critically expressed here regarding the environmental variants (moisture, temperature, humidity etc.) on mechanical performance of composite repair bonded joints. In recent years, many developments have been made by researchers to improve the environmental resistance of the composite structures such as new advanced composite and adhesive material, curing method, manufacturing bonded joints method, etc. Hence, there is strong need for improving the current composite repair subjected to environmental issues such as moisture, temperature etc. for reliable and repeatable repairs. In this review, several scientific challenges and opportunities have been identified in order to develop more durable and cost-effective composite bonded repair technologies with short repair cycle:

There is no generalised trend with respect to the effect of moisture and temperature on the bonded joint as it depends on a number of factors: such as curing temperature, curing method, adhesive and composite laminate material. Hence, an urgent need to assess and evaluate the behavior of advanced composite laminate and adhesive material under high and low temperature as well under different moisture conditions in order to utilize the full capability of the material for bonded repair joints. Advanced structural adhesives and composite material, could offer opportunities to enhance strength and long-term durability of bonded repairs.

Time required to fabricate bonded repair mainly depends on drying of composite before repair bonding and curing the same repair joints, could significantly influence the associated economical aspects. The material system that can cured at low temperature with short cycle but should have higher glass transition temperature could be a good for bonded repairs. A complete drying of composite is in current practice of composite repair, but it is not necessary always as deduced by researchers. So curing at low temperature and not complete drying, both help to reduce the repair time which impact on huge economical aspect.

Performance of composite repair can be improved by implementing new methods: such as curing by vacuum method which produce a good quality repair with low bondline void as similar to the autoclave curing method, manufacturing by co-bonded method joints, which absorb less moisture compare to the co-cured bonded joints method. There is need to work on this aspect and plan for more tests and confirm assurance for the better composite repair bonded joints.

The available studies focusing on the effect of moisture and temperature on the mechanical behavior of adhesively bonded joints still have considerable differences in terms of the adherend and adhesive material properties, the material processing methods, adhesive curing temperature and specimen configurations. Thus it is important to have the pre-knowledge (such as curing temperature, glass transition temperature, moisture absorption–desorption limit, swelling, thermal expansion, etc.) of the adhesive and composite behavior at the specified temperature and moisture level over which structure will expose during service period for the best used of material to obtained a better composite repair joints.

Limited studies were carried out on the effect of hygrothermal (moisture and temperature) on the composite bonded joints and it is highly demand for this study as the combined effect is more sever than individual condition.

Aerospace industry demand for lower frequency of repair and maintenance of the composite structure and this can be possible by introducing the self healing materials which can help to improve the durability of the structure. Also composite bonded structure should easily disbond without damaging the structure, then it can be used for reuse and recycle. Both these aspect should be implemented in the current scenario in order to reduce the frequency of the maintenance and easily separate without damaging the parent structure at the time of repair.

Finite element method is well developed numerical tool and used to optimise the geometry and material parameter of repair joint for better performance of the structure. Failure criterion of the composite bonded joints and incorporation of moisture and temperature parameter is the main constraint in scarf and stepped lap joints. Cohesive zone model successfully incorporate the environmental issue on the bonded joints and analyse the joints under the influence of moisture and temperature. Still long term durability is a major concern, as it is difficult to predict accurate environmental behavior of the joints. Open face specimen technique introduced accelerated ageing which help to reduce the exposure time. Open face technique offer opportunities for developing accurate prediction of joint behavior for long term using cohesive zone modeling to any adhesive system that exhibits nonuniform degradation.

Abbreviations

glass transition temperature

cured in place

glass fiber reinforced polymer

carbon fiber reinforced polymer

polymer matrix composites

fiber reinforced polymer

coefficient of thermal expansion

relative humidity

fracture toughness under mode I loading

cohesive zone model

matrix deformation

fiber bridging

fiber fracture

fiber-matrix interfacial debonding

Finn SR, He Y-F, Springer GS, Lee H-J. Compressive strength of damaged and repaired composite plates. J Compos Mater. 1992;16(12):1797–825.

Google Scholar

Myhre SH, Labor JD. Repair of advanced composite structures. J Aircraft. 1981;18(7):546–52.

Article Google Scholar

Markatos DN, Tserpes KI, Rau E, Markus S, Ehrhart B, Pantelakis S. The effects of manufacturing-induced and in-service related bonding quality reduction on the mode-I fracture toughness of composite bonded joints for aeronautical use. Compos Part B Eng. 2013;45(1):556–64.

Article CAS Google Scholar

Robson J, Matthews F, Kinloch A. The bonded repair of fibre composites: effect of composite moisture content. Compos Sci Technol. 1994;52:235–46.

Cheng P, Gong X-J, Hearn D, Aivazzadeh S. Tensile behaviour of patch-repaired CFRP laminates. Compos Struct. 2011;93(2):582–9.

Hu FZ, Soutis C. Strength prediction of patch-repaired CFRP laminates loaded in compression. Compos Sci Technol. 2000;60:1103–14.

Asp L. The effect of moisture and temperature on the interlaminar delamination toughness of carbon/epoxy composites. Compos Sci Technol. 1998;58:967–77.

Akay M, Kong S, Stanely A. Influence of moisture on the thermal and mechanical properties of autoclaved and oven cured Kevlar-49/epoxy laminates. Compos Sci Technol. 1997;57:565–71.

Nugroho AM, Ahmad MH, Ossen DR. A preliminary study of thermal comfort in Malaysia’s single storey terraced houses. J Asian Archit Build Eng. 2002;6:176–82.

Bendemra H, Compston P, Crothers PJ. Optimisation study of tapered scarf and stepped-lap joints in composite repair patches. Compos Struct. 2015;130:1–8.

Breitzman TD, Iarve EV, Cook BM, Schoeppner GA, Lipton RP. Optimization of a composite scarf repair patch under tensile loading. Compos Part A Appl S. 2009;40(12):1921–30.

Coelho SRM, Reis PNB, Ferreira JAM, Pereira AM. Effects of external patch configuration on repaired composite laminates subjected to multi-impacts. Compos Struct. 2017;168:259–65.

Gong X-J, Cheng P, Aivazzadeh S, Xiao X. Design and optimization of bonded patch repairs of laminated composite structures. Compos Struct. 2015;123:292–300.

Jefferson Andrew J, Arumugam V. Effect of patch hybridization on the tensile behavior of patch repaired glass/epoxy composite laminates using acoustic emission monitoring. Int J Adhes Adhes. 2017;74:155–66.

Jefferson Andrew J, Srinivasan SM, Arockiarajan A. The role of adhesively bonded super hybrid external patches on the impact and post-impact response of repaired glass/epoxy composite laminates. Compos Struct. 2018;184:848–59.

Liu B, Xu F, Feng W, Yan R, Xie W. Experiment and design methods of composite scarf repair for primary-load bearing structures. Compos Part A Appl S. 2016;88:27–38.

Wang CH, Gunnion AJ. On the design methodology of scarf repairs to composite laminates. Compos Sci and Technol. 2008;68(1):35–46.

Abdel Wahab MM. Fatigue in adhesively bonded joints: a review. ISRN Mater Sci. 2012;2012:1–25.

Banea MD, da Silva LFM. Adhesively bonded joints in composite materials: an overview. Proc Inst Mech Eng L. 2009;223(1):1–18.

Budhe S, Banea MD, de Barros S, da Silva LFM. An updated review of adhesively bonded joints in composite materials. Int J Adhes Adhes. 2017;72:30–42.

Chaves FJP, da Silva LFM, de Moura MFSF, Dillard DA, Esteves VHC. Fracture mechanics tests in adhesively bonded joints: a literature review. J Adhes. 2014;90:955–92.

Heshmati M, Haghani R, Al-Emrani M. Environmental durability of adhesively bonded FRP/steel joints in civil engineering applications: state of the art. Compos Part B Eng. 2015;81:259–75.

Banea MD, da Silva LFM, Campilho RDSG. The effect of adhesive thickness on the mechanical behavior of a structural polyurethane adhesive. J Adhes. 2015;91:331–46.

da Silva LFM, Carbas RJC, Critchlow GW, Figueiredo MAV, Brown K. Effect of material, geometry, surface treatment and environment on the shear strength of single lap joints. Int J Adhes Adhes. 2009;29(6):621–32.

Meneghetti G, Quaresimin M, Ricotta M. Influence of the interface ply orientation on the fatigue behaviour of bonded joints in composite materials. Int J Fatigue. 2010;32(1):82–93.

Mokhtari M, Madani K, Belhouari M, Touzain S, Feaugas X, Ratwani M. Effects of composite adherend properties on stresses in double lap bonded joints. Mater Des. 2013;44:633–9.

Moradi A, Carrère N, Leguillon D, Martin E, Cognard JY. Strength prediction of bonded assemblies using a coupled criterion under elastic assumptions: effect of material and geometrical parameters. Int J Adhes Adhes. 2013;47:73–82.

Song M-G, Kweon J-H, Choi J-H, Byun J-H, Song M-H, Shin S-J, Lee T-J. Effect of manufacturing methods on the shear strength of composite single-lap bonded joints. Compos Struct. 2010;92(9):2194–202.

Viana G, Costa M, Banea MD, da Silva LFM. A review on the temperature and moisture degradation of adhesive joints. Proc Inst Mech Eng L. 2016;231(5):488–501.

Banea MD, da Silva LFM, Campilho RDSG, Sato C. Smart Adhesive joints: an overview of recent developments. J Adhes. 2014;90(1):16–40.

Kumar S, Sridhar I. Special issue on ‘mechanics of composite adhesive joints and repairs. J Adhes Sci Technol. 2017;31(19–20):2089–91.

Pimenta S, Pinho ST. Recycling carbon fibre reinforced polymers for structural applications: technology review and market outlook. Waste Manage. 2011;31(2):378–92.

Katnam KB, da Silva LFM. Special issue on primary bonded repairs in composite structures. J Adhes. 2014;91(1–2):1–3.

Armstrong K. Effects of absorbed water in CFRP composites on adhesive bonding. Int J Adhes Adhes. 1996;16:21–8.

Kohli DK. Improved 121 °C curing epoxy film adhesive force composite bonding and repair applications: FM300-2 adhesive system. Int J Adhes Adhes. 1999;19:231–42.

Wang J, Zhou Z, Vodicka R, Chiu WK. Selection of patch and adhesive materials for helicopter battle damage repair applications. Compos Struct. 2009;91(3):278–85.

Choi HS, Jang YH. Bondline strength evaluation of cocure/precured honeycomb sandwich structures under aircraft hygro and repair environments. Compos Part A Appl S. 2010;41(9):1138–47.

Hayes-Griss JM, Gunnion AJ, Afaghi Khatibi A. Damage tolerance investigation of high-performance scarf joints with bondline flaws under various environmental, geometrical and support conditions. Compos Part A Appl S. 2016;84:246–55.

Préau M, Hubert P. Processing of co-bonded scarf repairs: void reduction strategies and influence on strength recovery. Compos Part A Appl S. 2016;84:236–45.

Chong HM, Liu SL, Subramanian AS, Ng SP, Tay SW, Wang SQ, Feih S. Out-of-autoclave scarf repair of interlayer toughened carbon fibre composites using double vacuum debulking of patch. Compos Part A Appl S. 2018;107:224–34.

Parker B. Some effects of absorbed water in CFRP composites on adhesive bonding. Compos Struct. 1986;6:123–39.

Kassapoglou C, Rangelov K, Rangelov S. Repair of composites: design choices leading to lower life-cycle cost. Appl Compos Mater. 2017;24(4):945–63.

Armstrong KB, Cole W, Bevan WG. Care and repair of advanced composites. London: SAE International; 2005.

Parker B. The effect of composite pre-bond moisture on adhesive-bonded CFRP-CFRP joint. Composites. 1983;14(3):226–32.

Bowditch MR. The durability of adhesive joints in the presence of water. Int J Adhes Adhes. 1996;16:73–9.

Charalambides MN, Hardouin R, Kinloch AJ, Matthews FL. Adhesively-bonded repairs to fibre-composite materials I: experimental. Compos Part A Appl S. 1998;29A:1371–81.

Blackman BRK, Johnsen BB, Kinloch AJ, Teo WS. The effects of pre-bond moisture on the fracture behaviour of adhesively-bonded composite joints. J Adhes. 2008;84(3):256–76.

Guermazi N, Tarjem AB, Ksouri I, Ayedi HF. On the durability of FRP composites for aircraft structures in hygrothermal conditioning. Compos Part B Eng. 2016;85:294–304.

Ameli A, Papini M, Spelt JK. Hygrothermal degradation of two rubber-toughened epoxy adhesives: application of open-faced fracture tests. Int J Adhes Adhes. 2011;31(1):9–19.

Loh WK, Crocombe AD, Abdel Wahab MM, Ashcroft IA. Modelling anomalous moisture uptake, swelling and thermal characteristics of a rubber toughened epoxy adhesive. Int J Adhes Adhes. 2005;25(1):1–12.

Pavlidou S, Papaspyrides CD. The effect of hygrothermal history on water sorption and interlaminar shear strength of glass/polyester composites with different interfacial strength. Compos Part A Appl S. 2003;34(11):1117–24.

Ray BC. Temperature effect during humid ageing on interfaces of glass and carbon fibers reinforced epoxy composites. J Colloid Interf Sci. 2006;298(1):111–7.

Zhang Y, Adams RD, da Silva LFM. Absorption and glass transition temperature of adhesives exposed to water and toluene. Int J Adhes Adhes. 2014;50:85–92.

Banea MD, da Silva LFM. The effect of temperature on the mechanical properties of adhesives for the automotive industry. Proc Inst Mech Eng L. 2010;224(2):51–62.

Ashcroft IA, Hughes DJ, Shaw SJ. Mode I fracture of epoxy bonded composite joints: 1. Quasi-static loading. Int J Adhes Adhes. 2001;21:87–99.

Jia Z, Hui D, Yuan G, Lair J, Lau KT, Xu F. Mechanical properties of an epoxy-based adhesive under high strain rate loadings at low temperature environment. Compos Part B Eng. 2016;105:132–7.

da Silva LFM, Adams RD. Measurement of the mechanical properties of structural adhesives in tension and shear over a wide range of temperatures. J Adhes Sci Technol. 2004;19:109–41.

Banea MD, de Sousa FSM, da Silva LFM, Campilho RDSG, de Pereira AMB. Effects of temperature and loading rate on the mechanical properties of a high temperature epoxy adhesive. J Adhes Sci Technol. 2011;25(18):2461–74.

Frassine R, Rink M, Pavan A. Viscoelastic effects on the interlaminar fracture behavior of thermoplastic matrix composites: II. Rate and temperature dependence in unidirectional peek/carbon-fiber lamiantes. Compos Sci Technol. 1996;56:1253–60.

Adams RD, Coppendale J, Mallick V, AI-Hamdan H. The effect of temperature on the strength of adhesive joints. Int J Adhes Adhes. 1992;12:185–90.

Reis JML, Pacheco LJ, da Costa Mattos HS. Influence of the temperature and strain rate on the tensile behavior of post-consumer recycled high-density polyethylene. Polym Test. 2013;32(8):1576–81.

Banea MD, da Silva LFM, Campilho RDSG. Effect of temperature on tensile strength and mode I fracture toughness of a high temperature epoxy adhesive. J Adhes Sci Technol. 2012;26(7):939–53.

CAS Google Scholar

Rider AN, Wang CH, Chang P. Bonded repairs for carbon/BMI composite at high operating temperatures. Compos Compos Part A Appl S. 2010;41(7):902–12.

Banea MD, da Silva LFM, Campilho RDSG. Mode II fracture toughness of adhesively bonded joints as a function of temperature: experimental and numerical study. J Adhes. 2012;88:534–51.

Banea MD, da Silva LFM, Campilho RDSG. Effect of temperature on the shear strength of aluminium single-lap bonded joints for high temperature applications. J Adhes Sci Technol. 2014;28(14–15):1367–81.

Lapique F, Redford K. Curing effects on viscosity and mechanical properties of a commercial epoxy resin adhesive. Int J Adhes Adhes. 2002;22:337–46.

Sánchez Cebrián A, Basler R, Klunker F, Zogg M. Acceleration of the curing process of a paste adhesive for aerospace applications considering cure dependent void formations. Int J Adhes Adhes. 2014;48:51–8.

Fernandes RL, de Moura MFSF, Moreira RDF. Effect of temperature on pure modes I and II fracture behavior of composite bonded joints. Compos Part B Eng. 2016;96:35–44.

Antunes DM, Infante V, Reis A. Mechanical characterization and experimental performance of an aerospace adhesive. Eng Fail Anal. 2016;69:43–56.

Marques EAS, da Silva LFM, Flaviani M. Testing and simulation of mixed adhesive joints for aerospace applications. Compos Part B Eng. 2015;74:123–30.

Banea MD, da Silva LFM, Campilho RDSG. Mode I fracture toughness of adhesively bonded joints as a function of temperature: experimental and numerical study. Int J Adhes Adhes. 2011;31(5):273–9.

Banea MD, da Silva LFM, Campilho RDSG. Temperature dependence of the fracture toughness of adhesively bonded joints. J Adhes Sci Technol. 2010;24:2011–26.

Brewis DM, Comyn J, Shalash RJA. The effect of moisture and temperature on the properties of an epoxidepolyamide adhesive in relation to its performance in single lap joints. Int J Adhes Adhes. 1982;2(4):215–22.

Ou Y, Zhu D, Zhang H, Huang L, Yao Y, Li G, Mobasher B. Mechanical characterization of the tensile properties of glass fiber and its reinforced polymer (GFRP) composite under varying strain rates and temperatures. Polymers. 2016;8(5):1–16.

Eftekhari M, Fatemi A. Tensile behavior of thermoplastic composites including temperature, moisture, and hygrothermal effects. Polym Test. 2016;51:151–64.

Mortazavian S, Fatemi A. Tensile and fatigue behaviors of polymers for automotive applications. Materialwiss Werkst. 2015;46(2):204–13.

De Monte M, Moosbrugger E, Quaresimin M. Influence of temperature and thickness on the off-axis behaviour of short glass fibre reinforced polyamide 6.6—Quasi-static loading. Compos Part A Appl S. 2010;41(7):859–71.

Ou Y, Zhu D. Tensile behavior of glass fiber reinforced composite at different strain rates and temperatures. Constr Build Mater. 2015;96:648–56.

Reis JML, Coelho JLV, Monteiro AH, da Costa Mattos HS. Tensile behavior of glass/epoxy laminates at varying strain rates and temperatures. Compos Part B Eng. 2012;43(4):2041–6.

Robert M, Benmokrane B. Behavior of GFRP reinforcing bars subjected to extreme temperatures. J Compos Constr. 2010;14(4):353–60.

Nardone F, Di Ludovico M, De Caso y Basalo FJ, Prota A, Nanni A. Tensile behavior of epoxy based FRP composites under extreme service conditions. Compos Part B Eng. 2012;43(3):1468–74.

Di Ludovico M, Piscitelli F, Prota A, Lavorgna M, Mensitieri G, Manfredi G. Improved mechanical properties of CFRP laminates at elevated temperatures and freeze–thaw cycling. Constr Build Mater. 2012;31:273–83.

Takeda N, Ogihara S. In situ observation and probablistic prediction of microscopic failure processes in CFRP cross-ply laminates. Compos Sci Technol. 1994;52:183–95.

Bechel VT, Camping JD, Kim RY. Cryogenic/elevated temperature cycling induced leakage paths in PMCs. Compos Part B Eng. 2005;36(2):171–82.

Timmerman JF, Tillman MS, Hayes BS, Seferis JC. Matrix and fiber infuences on the cryogenic microcracking of carbon fiber/epoxy composites. Compos Part A Appl S. 2002;33:323–9.

Schutz JB. Properties of composite materials for cryogenic applications. Cryogenics. 1998;38:3–12.

Dutta PK, Hui D. Low-temperature and freeze–thaw durability of thick composites. Compos Part B Eng. 1996;27B:371–9.

Etches J, Potter K, Weaver P, Bond I. Environmental effects on thermally induced multistability in unsymmetric composite laminates. Compos Part A Appl S. 2009;40(8):1240–7.

Reed RP, Golda M. Cryogenic properties of unidirectional composites. Cryogenics. 1994;34:909–28.

Sethi S, Ray BC. Mechanical behavior of polymer composites at cryogenic temperatures. In: Kalia SFS, editor. Polymers at cryogenic temperatures. Berlin: Springer; 2013.

Drzal LT, Rich MJ, Lloyd PF. Adhesion of graphite fibers to epoxy matrices: I. The role of fiber surface treatment. J Adhes. 2006;16:1–30.

Bockenheimer C, Fata D, Possart W. New aspects of aging in epoxy networks. II. Hydrothermal aging. J Appl Polym Sci. 2004;91:369–77.

Chwala S. Characterization and modeling of the effect of environmental degradation on flexural strength of carbob/epoxy composites. Dissertation, University of Alabama, Canada; 2009.

Birger S, Moshonov A, Kenig S. The effects of thermal and hygrothermal ageing on the failure mechanisms of graphite-fabric epoxy composites subjected to flexural loading. Composites. 1989;24:341–8.

Sousa JM, Correia JR, Firmo JP, Cabral-Fonseca S, Gonilha J. Effects of thermal cycles on adhesively bonded joints between pultruded GFRP adherends. Compos Struct. 2018. https://doi.org/10.1016/j.compstruct.2018.02.081 .

Elaldi F, Elaldi P. A study on curing processes and environmental effects for rapid composite repair. J Reinf Plast Compos. 2011;30(9):749–55.

Zhang Y, Vassilopoulos AP, Keller T. Effects of low and high temperatures on tensile behavior of adhesively-bonded GFRP joints. Compos Struct. 2010;92(7):1631–9.

Razak SNA, Othman AR, Sheng LW. Effect of temperature on the strength properties of adhesively single-lap bonded joint for composite laminates. Mater Mind. 2014;1:4–6.

Grammatikos SA, Jones RG, Evernden M, Correia JR. Thermal cycling effects on the durability of a pultruded GFRP material for off-shore civil engineering structures. Compos Struct. 2016;153:297–310.

Sousa JM, Correia JR, Cabral-Fonseca S, Diogo AC. Effects of thermal cycles on the mechanical response of pultruded GFRP profiles used in civil engineering applications. Compos Struct. 2014;116:720–31.

Humfeld RG, Dillard DA. Residual stress development in adhesive joints subjected to thermal cycling. J Adhes. 1998;65:277–306.

Coronado P, Argüelles A, Viña J, Mollón V, Viña I. Influence of temperature on a carbon–fibre epoxy composite subjected to static and fatigue loading under mode-I delamination. Int J Solid Struct. 2012;49(21):2934–40.

Davidson BD, Kumar M, Soffa MA. Influence of mode ratio and hygrothermal condition on the delamination toughness of a thermoplastic particulate interlayered carbon/epoxy composite. Compos Part A Appl S. 2009;40(1):67–79.

Melcher RJ, Johnson WS. Mode I fracture toughness of an adhesively bonded composite–composite joint in a cryogenic environment. Compos Sci Technol. 2007;67(3–4):501–6.

Hutapea P, Yuan FG. The effect of thermal aging on the Mode-I interlaminar fracture behavior of a high-temperature IM7/LaRC-RP46 composite. Compos Sci Technol. 1999;59:1271–86.

Cowley KD, Beaumont PWR. The interlaminar and intralaminar fracture toughness of carbon-fiber/polymer composites: the effect of temperature. Compos Sci Technol. 1997;97:1433–44.

Garg A, Ishai O. Hygrothermal influence on delamiantion behavior of graphite/epoxy laminates. Eng Fract Mech. 1985;22:413–27.

Thunga M, Lio WY, Akinc M, Kessler MR. Adhesive repair of bismaleimide/carbon fiber composites with bisphenol E cyanate ester. Compos Sci Technol. 2011;71(2):239–45.

Ashcroft IA, Hughes DJ, Shaw SJ, Wahab MA, Crocombe A. ffect of temperature on the quasi-static strength and fatigue resistance of bonded composite double lap joints. J Adhes. 2001;75:61–88.

Kim KY, Ye L. Interlaminar fracture toughness of CF/PEI composites at elevated temperatures: roles of matrix toughness and fiber/matrix adhesion. Compos Part A Appl S. 2004;35:477–87.

Russell AJ, Street KN. Moisture and temperature effects on the mixed-mode delamination fracture of unidirectional graphite/epoxy: delamination and debonding of materials. Philadelphia: American Society for Testing and Materials; 1985. p. 349–70.

Hashemi S, Kinloch AJ, Williams JG. The effects of geometry, rate and temperature on the mode I, mode II and mixed-mode I/II interlaminar fracture of carbon-fibre/poly(ether-ether ketone) composites. J Compos Mater. 1990;24:918–39.

Lin YC, Chen X. Moisture sorption–desorption–resorption characteristics and its effect on the mechanical behavior of the epoxy system. Polymer. 2005;46(25):11994–2003.

Adamson MJ. Thermal expansion and swelling of cured epoxy resin used in graphite/epoxy composite materials. J Mater Sci. 1980;15:1736–45.

Popineau S, Rondeau-Mouro C, Sulpice-Gaillet C, Shanahan MER. Free/bound water absorption in an epoxy adhesive. Polymer. 2005;46(24):10733–40.

Moy P, Karasz FE. Epoxy-water interactions. Polym Eng Sci. 1980;20:315–9.

Xiang ZD, Jones FR. Effects of water on a graphite/epoxy composite. In: International conference on composite materials ICCM-9; Zaragoza: Woodhead Publishing Ltd.; 1993. p. 601.

Bordes M, Davies P, Cognard JY, Sohier L, Sauvant-Moynot V, Galy J. Prediction of long term strength of adhesively bonded steel/epoxy joints in sea water. Int J Adhes Adhes. 2009;29(6):595–608.

Heshmati M, Haghani R, Al-Emrani M. Effects of moisture on the long-term performance of adhesively bonded FRP/steel joints used in bridges. Compos Part B Eng. 2016;92:447–62.

Hua Y, Crocombe AD, Wahab MA, Ashcroft IA. Continuum damage modelling of environmental degradation in joints bonded with EA9321 epoxy adhesive. Int J Adhes Adhes. 2008;28(6):302–13.

Lettieri M, Frigione M. Effects of humid environment on thermal and mechanical properties of a cold-curing structural epoxy adhesive. Constr Build Mater. 2012;30:753–60.

Zafar A, Bertocco F, Schjødt-Thomsen J, Rauhe JC. Investigation of the long term effects of moisture on carbon fibre and epoxy matrix composites. Compos Sci Technol. 2012;72(6):656–66.

Oudad W, Madani K, Bachir Bouiadjra B, Belhouari M, Cohendoz S, Touzain S, Feaugas X. Effect of humidity absorption by the adhesive on the performances of bonded composite repairs in aircraft structures. Compos Part B Eng. 2012;43(8):3419–24.

Sugiman S, Crocombe AD, Aschroft IA. Experimental and numerical investigation of the static response of environmentally aged adhesively bonded joints. Int J Adhes Adhes. 2013;40:224–37.

Zhou J, Lucas JP. Hygrothermal effects of epoxy resin. Part II: variations of glass transition temperature. Polymer. 1999;40:5513–22.

LaPlante G, Lee-Sullivan P. Moisture effects on FM300 structural film adhesive: stress relaxation, fracture toughness, and dynamic mechanical analysis. J Appl Polym Sci. 2005;95(5):1285–94.

Xiao GZ, Shanahan MER. Swelling of DGEBA/DDA epoxy resin during hygrothermal ageing. Polymer. 1998;39:3253–60.

Fernández-García M, Chiang MYM. Effect of hygrothermal aging history on sorption process, swelling, and glass transition temperature in a particle-filled epoxy-based adhesive. J Appl Polym Sci. 2002;84:1581–91.

Tsenoglou CJ, Pavlidou S, Papaspyrides CD. Evaluation of interfacial relaxation due to water absorption in fiber–polymer composites. Compos Sci Technol. 2006;66(15):2855–64.

Srivastava VK. Influence of water immersion on mechanical properties of quasi-isotropic glass fibre reinforced epoxy vinylester resin composites. Mater Sci Eng. 1999;A263:56–63.

Marom G. The role of water transport in composite materials. In: Comyn J, editor. Polymer permeability. New York: Elsevier; 1986. p. 341–73.

Giuseppe DA, Lees R. Effect of water immersion on the interlaminar and flexural performance of low cost liquid resin infused carbon fabric composites. Compos Part B Eng. 2012;43(3):1368–73.

Thomason JL. The interface region in glass fibre-reinforced epoxy resin composites: 2, water absorption, voids and the interface. Composites. 1995;26:477–85.

Zhou J, Lucas JP. The effect of a water environment on anomalous absorption behavior in graphite/epox composites. Compos Sci Technol. 1995;53:57–64.

Bao L-R, Yee AF, Lee CYC. Moisture absorption and hygrothermal aging in a bismaleimide resin. Polymer. 2001;42:327–7333.

Apicella A, Nicolais L, Astarita G, Drioli E. Hygrothermal history dependence of moisture sorption kinetics in epoxy resins. Polym Eng Sci. 1981;21(1):18–22.

Chaichanawong J, Thongchuea C, Areerat S. Effect of moisture on the mechanical properties of glass fiber reinforced polyamide composites. Adv Powder Technol. 2016;27(3):898–902.

Kootsookos A, Mouritz AP. Seawater durability of glass- and carbon-polymer composites. Compos Sci Technol. 2004;64(10–11):1503–11.

Selzer R, Friedrich K. Mechanical properties and failure behaviour of carbon fibre-reinforced polymer composites under the influence of moisture. Compos Part A Appl S. 1997;28A:594–604.

Liao K, Schultheisz CR, Hunston DL. Effects of environmental aging on the properties of pultruded GFRP. Compos Part B Eng. 1999;30:485–93.

Morii T, Ikuta N, Kiyosum K, Hamada H. Weight-change analysis of the interphase in hygrothermally aged FRP: consideration of debonding. Compos Sci Technol. 1997;57:985–90.

Weitsman YJ, Guo Y-J. A correlation between fluid-induced damage and anomalous fluid sorption in polymeric composites. Compos Sci Technol. 2002;62:889–908.

Mohd Ishak ZA, Ariffin A, Senawi R. Effects of hygrothermal aging and a silane coupling agent on the tensile properties of injection molded short glass fiber reinforced poly(butylene terephthalate) composites. Eur Polym J. 2001;37:1635–47.

DiBenedetto AT. Tailoring of interfaces in glass fiber reinforced polymer composites: a review. Mater Sci Eng. 2001;A302:74–82.

Ibrahim G, Casari P, Jacquemin F, Freour S, Clement A, Celino A, Khalil K. Moisture diffusion in composites tubes: characterization and identification of microstructure-properties relationship. J Compos Mater. 2018;52(8):1073–88.

Wan YZ, Wang YL, Huang Y, Zhou FG, He BM, Chen GC, Han KY. Moisture sorption and mechanical degradation of VARTMed three-dimensional braided carbon–epoxy composites. Compos Sci Technol. 2005;65(7–8):1237–43.

Ogi K, Kim HS, Maruyama T, Takao Y. The influence of hygrothermal conditions on the damage processes in quasi-isotropic carbon/epoxy laminates. Compos Sci Technol. 1999;59:2375–82.

Ray BC. Effects of changing environment and loading speed on mechanical behavior of FRP composites. J Reinf Plast Compos. 2006;25(12):1227–40.

Bao L-R, Yee AF. Effect of temperature on moisture absorption in a bismaleimide resin and its carbon fiber composites. Polymer. 2002;43:3987–97.

Dodiuk H, Drori L, Miller J. Preconditioning of epoxy film adhesives for bond strength improvement. Int J Adhes Adhes. 1984;4:169–70.

Dodiuk H, Drori L, Miller J. The effect of moisture content in epoxy film adhesives on their performance. II. T-peel and 105 °C lap shear strength. J Adhes. 2006;19:1–13.

Myhre SH, Labor JD, Aker SC. Moisture problems in advanced composite structural repair. Composites. 1982;13:289–97.

Sage GN, Tiu WP. The effect of glue line voids and inclusions on the fatigue strength of bonded joints in composites. Composites. 1982;13:228–32.