Open Access is an initiative that aims to make scientific research freely available to all. To date our community has made over 100 million downloads. It’s based on principles of collaboration, unobstructed discovery, and, most importantly, scientific progression. As PhD students, we found it difficult to access the research we needed, so we decided to create a new Open Access publisher that levels the playing field for scientists across the world. How? By making research easy to access, and puts the academic needs of the researchers before the business interests of publishers.

We are a community of more than 103,000 authors and editors from 3,291 institutions spanning 160 countries, including Nobel Prize winners and some of the world’s most-cited researchers. Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too.

Brief introduction to this section that descibes Open Access especially from an IntechOpen perspective

Want to get in touch? Contact our London head office or media team here

Our team is growing all the time, so we’re always on the lookout for smart people who want to help us reshape the world of scientific publishing.

Home > Books > Pipeline Engineering - Design, Failure, and Management

Review on the Stability of the Nanofluids

Submitted: 06 July 2022 Reviewed: 17 August 2022 Published: 27 October 2022

DOI: 10.5772/intechopen.107154

Cite this chapter

There are two ways to cite this chapter:

From the Edited Volume

Pipeline Engineering - Design, Failure, and Management

Edited by Sayeed Rushd and Mohamed Anwar Ismail

To purchase hard copies of this book, please contact the representative in India: CBS Publishers & Distributors Pvt. Ltd. www.cbspd.com | [email protected]

Chapter metrics overview

216 Chapter Downloads

Impact of this chapter

Total Chapter Downloads on intechopen.com

Total Chapter Views on intechopen.com

Both mono and hybrid nanofluids, the engineered colloidal mixture made of the base fluid and nanoparticles, have shown many interesting properties and become a high potential next-generation heat transfer fluid in various engineering applications. The present review focuses on improving the stability of the nanofluids. For this, the present review briefly summarizes the impact of nanofluid preparation on the stability of various nanofluids and described in the following classification; (a) Nanofluid constituent, (b) Nanomaterial synthesis, and (c) Nanofluid synthesis techniques which are well-grouped and thoroughly discussed. Physical mechanisms for heat transfer enhancement using nanofluids are explored as well. Most of the studies reveal that there are significant improvements in the stability of the nanofluids. Hence, there is an excellent opportunity to use stabled nanofluids in various engineering applications. Finally, some useful recommendations are also provided.

- nanomaterial synthesis

Author Information

Sumit kumar singh *.

- Department of Mechanical Engineering, Indian Institute of Technology (B.H.U.), Varanasi, India

*Address all correspondence to: [email protected]

1. Introduction

Nanofluids are engineered by dispersing nanoparticles, having average sizes below 100 nm, in conventional heat transfer fluids. Proper and stable dispersion of even a negligible fraction of particles in nanofluids can offer significant enhancement in the heat transfer properties. Various types of nanoparticles like metals, metal oxides, alloys, allotropes of carbon, ceramics, phase change materials, and metal carbides are being used for preparing nanofluids. In addition to nanofluids, hybrid nanofluids have also gained attention recently due to significant improvement in heat transfer characteristics and stability may be caused by the synergistic effect of hybridization. Heat exchangers that use tubes or pipes often have a circular, rectangular, or elliptical cross-section and are easier to design. Tubular heat exchangers are fairly prevalent in pipeline engineering applications. These heat exchangers might be built to handle fluids under high pressure or to handle pressure differentials between cold and hot fluids. Double-pipe and shell-tube heat exchangers are additional categories that apply to these heat exchangers. Modifying the fluids’ characteristics can also increase the heat exchange rate of a heat exchanger. Due to the fact that stable nanofluids have significantly improved heat transfer characteristics, particularly in terms of thermal conductivity, slip mechanisms, and the nanofin effect, they may be employed in tubular heat exchangers to increase energy efficiency. For preparing mono or hybrid nanofluids, the two-step method is generally used where firstly different nanoparticles or nanocomposites are prepared. Then they are mixed in the base fluid through magnetic or mechanical stirring. After that, the solution is sonicated and then characterized using different techniques to assure the proper (homogeneous) mixing and stability of the hybrid nanofluids. Both mono and hybrid nanofluids are thus prepared to provide improved heat transfer characteristics due to an increase in thermal conductivity, Brownian motion, proper dispersion, agglomeration, solid/liquid interface layering, thermophoresis, the improved thermal network between the solid nanoparticle and fluid molecules, nanofin and nanoporous effects at the heat transfer surface. The reason behind this improvement can be summarized as: (i) More heat transfer surface between nanoparticles and fluid, (ii) Collision between the nanoparticles, (iii) Increment in the thermal conductivity due to the interactive effect of different nanoparticles, and (iv) Proper dispersion of the nanoparticles in the base fluid, creating micro turbulences. Therefore, in hybrid nanofluids, both nanoparticles compromise their properties and provide better thermo-physical, chemical, and rheological properties within the low cost that makes it preferable over nanofluids for different applications. Stability is the main key factor for the performance of nanofluids in various engineering applications. All the thermo-physical properties of nanofluid are dependent on its stability. The unstability of nanofluid can inhibit its performance in several applications such as heat exchangers, chemical industry applications, enhanced oil recovery etc. The unstability of nanofluid is caused due to the propensity of nanoparticles to form a cluster in the fluid. The nanofluids may be broadly categorized into three groups based on the nanoparticle composition, namely: (i) mono-nanofluids (made from one type of nanoparticles), (ii) hybrid nanofluids containing different nanoparticles, and (iii) hybrid nanofluids consisting one solid covered by a layer of another solid (composite nanoparticles).

The current review emphasizes the impact of nanofluid preparation on the stability of various nanofluids and is described in the following classification; (a) Nanofluid constituent, (b) Nanomaterial synthesis, and (c) Nanofluid synthesis techniques.

2. Literature review

The available literature on the preparation, characterization, and stability of mono/hybrid nanofluids are discussed in three sections. In all section, it summarizes the impact of nanofluid preparation on the stability of various nanofluids and described in the following classification; (a) Nanofluid constituent, (b) Nanomaterial synthesis, and (c) Nanofluid synthesis techniques. Exclusive reviews on the heat transfer, pressure drop characteristics, and energy performance of both double-tube and shell-tube heat exchangers using nanofluids are presented in the third and fourth sections.

2.1 Impact of nanofluid preparation

There are two main approaches to synthesize nanofluids: the single-step method and the two-step method. In the one-step method, nanofluid is prepared directly by dispersing nanoparticles in the base fluid without the requirement of numerous steps such as particle drying, storage, etc. Using this method, the stability of nanofluid exhibits most superior compared to the two-step method. But this technique is not beneficial for large scale because of its high production cost. Therefore, the two-step method is the more effective and generally common method of nanofluid preparation. The foremost disadvantage of this process is the control of particle agglomeration tendency. The common application of wide ultrasonication and stirring is the most frequently used method to control agglomeration. Several forces such as Van der Waal attractive force, gravitational force, buoyancy force, and electrostatic repulsive force are acted which lead to destabilization and form sediments. The Van der Waal attractive force and gravitational force work against the stability of any colloidal suspension. Stability is the main key factor for the performance of nanofluids in various engineering applications. All the thermo-physical properties of nanofluid are dependent on its stability. The unstability of nanofluid can inhibit its performance in several applications such as heat exchangers, chemical industry applications, enhanced oil recovery etc. The unstability of nanofluid is caused due to the propensity of nanoparticles to form a cluster in the fluid. For considering a stable nanofluid, agglomeration propensity has to be removed. Some stability evaluation methods are used in literature i.e., sedimentation and centrifugation method, zeta potential measurement, spectral absorbance and transmittance measurement, and dynamic light scattering. Numerous efforts have been made to prepare long-time stable and homogenous nanofluids using various techniques. The current review emphasizes the impact of nanofluid preparation on the stability of various nanofluids and is described in the following classification; (a) Nanofluid constituent, (b) Nanomaterial synthesis, and (c) Nanofluid synthesis techniques.

2.1.1 Nanofluid constituent

2.1.1.1 nanomaterial type.

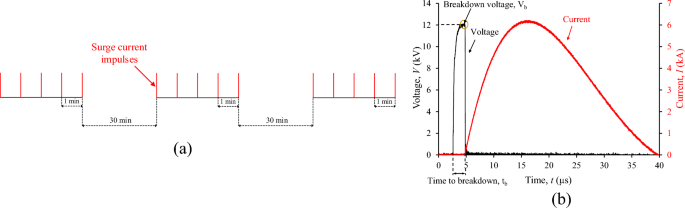

There are several types of nanofluids: metallic nanofluids (Al, Ag, Cu, Fe, Au), metal oxide nanofluids (Al 2 O 3 , CuO, Fe 3 O 4 , SiO 2 , TiO 2 , ZnO, etc.), and non-metallic nanofluids (SiC, TiC, graphite, diamond, SWCNT/MWCNT, graphene, etc.). Several studies on the impact of the nanofluid constituents on its stability are shown in Table 1 . Xu et al. [ 4 ] prepared hybrid nanofluids with nanoparticles of different masses added with a small amount of SDBS and PEG into DW and observed that 25% Al 2 O 3 + 75% TiO 2 hybrid nanofluid shows good suspension stability. The zeta potential value for the 25% Al 2 O 3 + 75% TiO 2 hybrid nanofluid is found 42.6 mV indicating high stability. Zeta potential means electrostatic repulsion force between nanoparticles and base fluid. High repulsion force indicates high stability of nanofluid, whereby 30mV is generally considered as a benchmark for a stable nanofluid and excellent nanofluid stability may exceed 60 mV. Some studies investigated the impact of functionalizing the nanoparticles surface which reduces aggregation and improves dispersion. Said et al. [ 5 ] studied the stability of Carbon nanofiber (CNF), Functionalized Carbon nanofiber (F-CNF), Reduced graphene oxide (rGO), and F-CNF/rGO nanofluids. The results indicated that hybrid (FCNF/rGO) nanofluid shows higher stability than as compared to CNF, F-CNF, and rGO nanofluids. Also, the sample of CNF almost completely sedimented on 2nd day as shown in the Figure 1 . It is due to the low charge density on the surface of the CNF nanoparticle which leads to the tendency of agglomeration. Said et al. [ 15 ] used acid treatment of CNF to examine the stability. The zeta potential of 0.02 vol. % F-CNF nanofluid was −42.9 and − 41.8 mV after 2 and 90 days which indicates that the stability was improved while the zeta potential of CNF was −16.3 and − 15.5 mV, indicating a relatively unstable dispersion. One way to achieve long-term stability is to adjust the nanofluid pH, away from the isoelectric point (IEP). Thus, IEP differs from one sample to another. These values were prepared in acidic and alkaline ranges using HCl and NaOH solutions and adjusted by pH meter. Kazemi et al. [ 6 ] used two different nanoparticles (GnP, SiO 2 ) with the same base fluid (water) as well as different pH values (3,6,9, and 12) to study the stability of the nanofluids. The results found that SiO 2 /Water nanofluids have good stability at all pH values, especially for samples with pH >3 and GnP/water achieve better stability at higher pH values. Akhgar and Toghraie [ 9 ] examined the stability of water-based MWCNT and TiO 2 nanofluid at different pH (3, 6,9, and 12). The results observed that the nanofluid containing water/TiO 2 with pH = 9 had more stability than the rest of the samples. On the other hand, MWCNT particles are not dispersed in water and are not stable in any pH without any surfactant. Kazemi et al. [ 21 ] compared the stability of three types of nanofluids, G/Water, SiO 2 /Water, and G-SiO 2 /Water and found that SiO 2 /Water nanofluid shows excellent stability at all pH values while G/Water sustainability is poor in lower pH value. Due to better stability in higher pH values, the CMC surfactant can be used to increase pH by creating a negative charge surface for graphene nanoparticles and developing functional groups. Siddiqui et al. [ 8 ] performed a stability study with metal (Cu), oxide (Al 2 O 3 ), and meta-oxide Cu- Al 2 O 3 ) nanofluid containing the same base fluid (DI water). Al 2 O 3 nanofluid exhibits better stability between 0 and 6 h followed by good stability with little particle settling between 6 and 240 h. Cu nanofluid shows poor dispersion stability after 1 hour of preparation. In case of hybrid nanofluid, nanofluid with optimum mixing ratio exhibits relatively better stability. Muthoka et al. [ 14 ] used PCM-DI water as the base fluid and two different nanoparticles (MgO and MWCNT) to examine the stability. They observed that the stability of MgO and 24 wt% base fluid without surfactant showed poor stability after only 24 h while the functionalized MWCNT nanofluid showed no separation after 24 h. Also, it was concluded that the stability of the nanofluid at low temperatures is increased by the use of surfactant. Alawi et al. [ 16 ] synthesized PEG-GnP, PEG-TGr, Al 2 O 3, and SiO 2 water-based nanofluids. They observed the dispersion stabilities of carbon-based nanofluids and metallic oxides nanofluids for 30days, and the results showed the higher dispersibility of the PEG-GnP, PEG-TGr nanofluids in an aqueous media with very low sedimentation. Akbari and Saidi [ 17 ] observed TiO 2 /DW nanofluid shows good stability as compared to GnP/DW nanofluid. Since graphene is an inherently hydrophobic material and the stability of graphene/water nanofluid is not favorable without any surfactants. Boroomandpour et al. [ 22 ] studied the stability of ternary hybrid nanofluids containing MWCNT-TiO 2 -ZnO/DW-EG (80:20) as well as binary and mono nanofluids. They found that all nanofluids have good stability up to 48 h after fabrication and the addition of CTAB surfactant lead to better stability.

Synopsis of the investigations about the impact of the nanofluid constituents on its stability.

Photographs of vials showing the stability of nanofluids for: (a) 1 st day, (b) 2nd day, (c) 30 days, (d) 45 days, (e) 60 days, and (f)180 days [ 5 ].

From the literature reviews on the preparation of nanofluids with different particles, it is found that the stability of water mono/hybrid nanofluid is strongly dependent on the particle shape and size. It is found that the propensity of aggregation is increased with the reduction in particle size and isoelectric point (pH value) decreases with the decrease in particle size. Therefore, the agglomeration process moves toward lesser pH value. The cylindrical-shaped particles sediment faster than spherical and platelet-shaped particles. High aspect ratio nanoparticles are more susceptible to agglomeration.

2.1.1.2 Surfactant type

Addition of different surfactants such as: Anionic (Sodium Dodecyl Sulfate (SDS), Sodium Dodecyl Benzene Sulfonate (SDBS)), Cationic (Cetyltrimethylammonum Bromide (CTAB)), Non-ionic (Span 80, Tween 20) and polymer (Polyvinyl Pyrrolidone (PVP), Poly Vinyl Alcohol (PVA), Gum Arabic (GA)) during nanofluid preparation is an additional way of controlling particle aggregation. A negatively charged suspension may be obtained by using anionic surfactants (SDC, SDS, and SDBS) while a cationic surfactant (CTAB) may contribute a positive charge. The augmentation in stability will achieve by the coating of surfactant on nanoparticles, which leads to a dominating electrostatic repulsion over the van der Waals force and thus prevent nanoparticles from agglomerating. Also, the stability of the nanofluid can be improved by decreasing the sedimentation velocity of the nanoparticles. According to Stokes law, the sedimentation velocity can be reduced by using nanoparticles with smaller diameters. However, when the nanoparticles diameter decreases, the surface energy will be increased which leads increase possibility of agglomeration. The best way to suppress the agglomeration without disturbing the sedimentation velocity is the usage of surfactants. While surfactant addition is an active way to improve the stability of the nanofluids but surfactants may lead to cause some problems. Surfactants may contaminate the heat transfer media. Surfactants may produce foams while heating and cooling are regular processes in heat exchange systems. Additionally, surfactant molecules attributed to the surfaces of nanoparticles might increase the thermal resistance between the nanoparticles and the base fluid, which may hinder the augmentation of the thermal conductivity.

Xian et al. [ 1 ] used three different surfactants, i.e., SDS, CTAB, and SDBS to stabilize the COOH-TiO 2 hybrid nanofluid. They observed that COOH-TiO 2 hybrid nanofluid with CTAB surfactant exhibited the best surfactant to stabilize this hybrid nanofluid. The visual inspection of sedimentation of nanofluids with different surfactants after 40 days is shown in Figure 2 . Almanassra et al. [ 2 ] compared the effect of different types of surfactants on the stability of CNT/water nanofluids. They investigated with three types of surfactants namely, GA, PVP, and SDS and found that the nanofluids with GA as well as PVP surfactants were more stable for more than 6 months. Gum Arabic can be a promising surfactant for stabilizing the CNT in water-based nanofluids. Cacua et al. [ 3 ] found Al 2 O 3 nanofluid with SDBS at 1 CMC and CTAB at 0.5 CMC were the most stable and unstable nanofluids, respectively. Anionic SDBS provides high repulsive forces between nanoparticles. Ouikhalfan et al. [ 7 ] prepared surface-modified TiO 2 nanofluid with two different surfactants (SDS and CTAB). The quick sedimentation was found in non-treated TiO 2 nanofluid after 24 hours of the preparation as shown in Figure 3 . TiO 2 nanofluid with CTAB showed better stability up to several days while the nanofluid with SDS surfactant shows less but overall better dispersion compared to nanofluid with non-treated TiO 2 . Choi et al. [ 10 ] studied the effect of various surfactants as well as the temperature on the stability of water-based MWCNT nanofluid. They prepared nanofluid with four different surfactants, i.e., SDBS, CTAB, SDS, and TX-100 between the temperatures 10°C–80°C. It was observed that for short-term time period (3 h), nanofluids prepared with SDBS, CTAB, and TX-100 show better stability while for long-term time period (1 month), the SDBS and TX-100 nanofluids have the highest suspension stability. On the account of temperature, TX-100, CTAB, and SDS are not suitable surfactants for nanofluids operating from 10 to 85°C. Das et al. [ 11 ] found TiO 2 (Anatase) with SDS and CTAB show excellent stabilization (stable for exceeding 12 h and 24 h) as compared with nanofluid with SDS and acetic acid surfactant. Kuang et al. [ 13 ] prepared nanofluids by dispersing three nanoparticles (i.e., SiOx, Al 2 O 3 , and TiO 2 ) and five different chemical agents i.e., oleic acid (OA), polyacrylic acid (PAA), a cationic, an anionic, and a nonionic surfactant) in base brine solutions. Nanofluids made with the anionic surfactant made the surface slightly more water wet. The results revealed that SiO x nanofluids exhibit stability in all cases while Al 2 O 3 + PAA and Al 2 O 3 + cationic surfactant show the most stability. In case of TiO 2 nanofluid, TiO 2 + PAA show the most stability among all surfactants. Cacua et al. [ 18 ] used UV–vis spectroscopy to examine the stability of Al 2 O 3 with two different surfactants (SDBS and CTAB). The outcome reveals that the nanofluid with SDBS at 1 CMC and that with CTAB at 0.5 CMC achieved the lowest and highest absorbance variation, respectively. Low absorbance variation over time indicates high nanofluid stability. Etedali et al. [ 19 ] investigated the stability of SiO 2 nanofluids with different surfactants, i.e., SLS, CTAB, and Ps 20 through the Zeta potentials test. The results of the Zeta-potential test found that the maximum surface charge for the nanofluids with SLS, CTAB, and Ps20 surfactants were − 87.4, 74.2, and − 97.9, respectively, confirming the stability conditions.

Visual inspection of sedimentation of nanofluids with different surfactants and ultra-sonication time after 40 days. [ 1 ].

Sediment photograph capturing of the nanofluid with (1) nontreated TiO 2 , (2) CTAB-treated TiO 2 nanofluid, and (3) SDS-treated TiO 2 nanofluid [ 7 ].

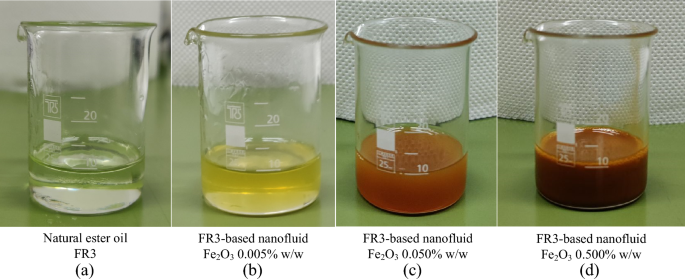

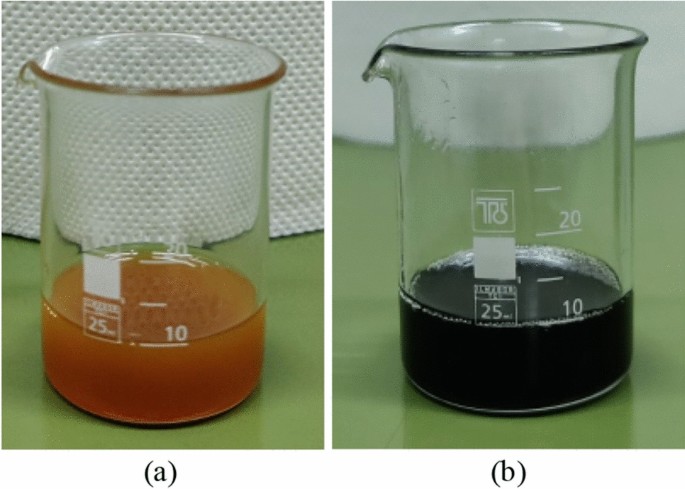

2.1.1.3 Base fluid type

Gao et al. [ 12 ] prepared GNP nanofluid with three different base fluids namely, EG, DW, and EG/DW and reported that the stability of nanofluid with EG base fluid is better than that of DW-based nanofluid. Figure 1 shows the visual observation of GNP nanofluid with different base fluids. Giwa et al. [ 20 ] used two-step method to prepare Al 2 O 3 -Fe 2 O 3 hybrid nanofluid with two type of base fluid viz., DW and EG/DW. SDS and NaDBS were used as a surfactant. Using UV-visible spectrophotometer, they found DW-based Al 2 O 3 -Fe 2 O 3 were relatively more stable than the EG–DW Al 2 O 3 -Fe 2 O 3 hybrid nanofluid. The absorbance value of the DW-based Al 2 O 3 -Fe 2 O 3 displayed better horizontal straight lines than those of the EG–DW Al 2 O 3 -Fe 2 O 3.

2.2 Nanomaterial synthesis

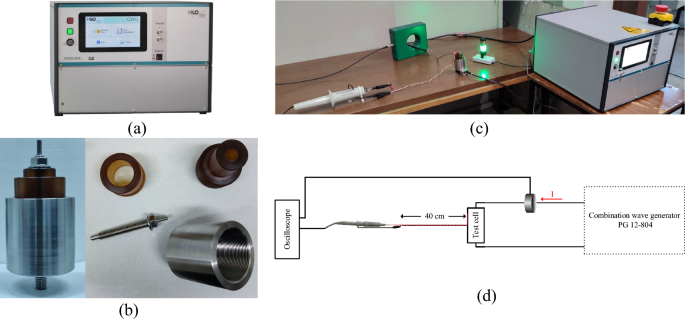

Ding et al. [ 23 ] prepared the functionalized graphene (ESfG) by adding the graphite powder into the milling jar with steel balls of smaller diameter and the system was filled with SO 3 gas. After removing metallic impurities, the samples were then freeze-dried for 36 hours at −120°C to yield black powder as the final ESfG. The prepared ESfG was stable for several months in water. The sulfonic-acid groups can bond with carbon atoms at the edge of graphite which tends to enhance the stability of ESfG water-based nanofluids. Gul and Firdous [ 24 ] synthesized the graphene oxide nanosheet by the oxidation of graphite using the Hummers method as shown in Figure 4 . In this method the graphite powder was mixed with NaNO 3 , H 2 SO 4, and KMnO 4 and stirred in an ice bath for about 30 min. Finally, the mixture was sonicated and added H 2 O 2 and HCl to quench the reaction and get light yellow graphite oxide. The results found that the highly dispersible nature of GO in water which is fruitful for the preparation of GO nanofluid for multipurpose applications. Li et al. [ 25 ] introduced the β-cyclodextrin(β-CD) onto the surface of MWCNTs by a simple chemical synthesis method. It was found that the introduction of β-CD onto the surface of MWCNTs exhibited better stability of nanofluids. The possibility of aggregation between CD-CNTs is significantly decreased due to the Vander Waals force or steric interrupts between β-CD. Rahimi et al. [ 26 ] treated the hydrophilization of MWCNTs with different concentrated acids. They added the raw MWCNTs into the mixture of H 2 SO 4 and HNO 3 and the mixture was refluxed for 3 hours. The acid-treated MWCNTs were obtained after washing with DI water and dried for 4 hours. Acid-treated MWCNTs suspensions display good stability in water. This is due to the generation of hydroxyl groups on nanotube surfaces. Vozniakovskii et al. [ 27 ] synthesized a hybrid nanomaterial composed of nanodiamonds-multi-walled carbon nanotubes (DND-CNT) using a catalyst chemical vapor deposition (CCVD) method. The results showed that DND-CNT hybrid suspension was stable up to 100 hours while the initial DND began to precipitate after 1 hour. The stability of DND-CNT hybrid particles in water is explained by the opening of a previously closed surface covered with groups with a labile proton, which ensures the stability of the particles of the hybrid material in water.

Synthetic route of graphene oxide by hummers method [ 24 ].

2.3 Nanofluid synthesis technique

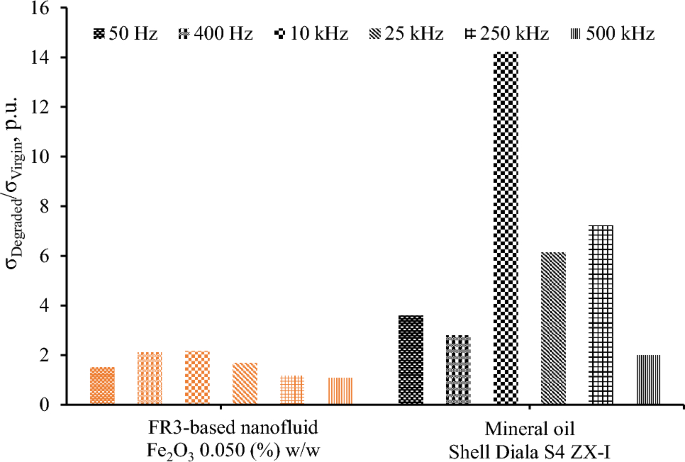

Numerous nanofluid stabilization techniques are used for reducing the cluster size of nanoparticles i.e. ultrasonic vibration and ball milling etc. The role of ultrasonication is to break the nanoparticle cluster and create a homogenous mixture. Ultrasonic vibration can be employed in two ways; (a) indirect method (ultrasonic bath), and (b) direct method (probe sonicator). Among these two methods, the probe sonicator offers better results in terms of breaking the particle cluster and lowering the average cluster size. Several studies on the impact of the nanofluid synthesis technique on its stability are shown in Table 2 . Asadi et al. [ 28 ] used two-step method to prepare TiO 2 -CuO hybrid nanofluid. They applied a magnetic stirrer for 1 hour in order to distribute the nanomaterial in the base fluid. Moreover, for breaking the clusters and uniformly distributing the nanoparticles in the base fluid, a probed ultrasonic device was applied for 1 hour. The DLS results ensured the nanoparticles exist in the base fluid, and the phenomenon of agglomeration did not happen. Chen et al. [ 29 ] investigated the impact of sonication time on the stability of the Al 2 O 3 /liquid paraffin nanofluid. They used two-step method with varying the magnetic stirrer time from 10 to 40 minutes and sonication time from 1 to 4 hours. It was found that nanofluids prepared using shorter sonication times show stability for a minimum of 1 month. When increase in sonication time, it breaks the bond between the nano additives and the surfactant which leads to be unstable. Asadi et al. [ 30 ] varied the sonication time from 10 to 80 minutes to measure the stability of MWCNT/water nanofluid. They reported that after the 30th day, the samples subjected to 10, 20, 40, and 60 minutes of ultrasonication showed good stability while the samples subjected to longer time ultrasonication showed the amount of sedimentation leads to having agglomerated particles. Ranjbarzadeh et al. [ 31 ] used magnetic stirrer for 1 hour to mix the SiO 2 nanoparticles in the base fluid and then sonicated for 60 minutes. By visual observation, the result found that no sediments were formed after 6 months. Aberoumand and Jafarimoghaddam [ 32 ] prepared Ag-WO 3 /Transformer oil nanofluid using the first step method. They applied Electrical Explosion Wire (EEW) to prepare the nanofluid. The Zeta potential of applied nanofluids in three different concentrations of 1%, 2%, and 4% was measured. The results indicate the excellent stability of applied hybrid nanofluids. Using the same EEW method, Aberoumand et al. [ 34 ] prepared Ag/water nanofluid and found that with EEW method, the nanofluid maintained their stability for a long time. Dalkılıç et al. [ 33 ] prepared CNT-SiO 2 /DW using two-step methods and the mixture was sonicated for 3 hours. It was found that the sedimentation was not observed up to 48 hours. The raw CNT particles showed poor dispersion stability in the base fluid. SiO 2 particles support and increase the stability of CNTs particles in water. Tests showed that CNT particles exhibit less stability in water without SiO 2 particles and surfactants. Kakavandi and Akbari [ 35 ] used DLS test to examine the distribution of the MWCNT and SiC nanoparticles in the hybrid nanofluids. The results indicated acceptable stability of nanofluids. The hybrid nanofluid was magnetically stirred for 1 hour and then sonicated for 45 minutes. Keyvani et al. [ 36 ] used Ce 2 O/EG nanofluid to examine the stability. The nanofluid was stirred and then exposed to ultrasonic waves for 2 and 7 hours, respectively. The sedimentation of particles was found after 2 weeks. Nanofluid with a higher concentration of particles, nanoparticles led to agglomerate; therefore, the stability of the nanofluid weakened. It was also reported that the stability of the prepared nanofluid with a lower volume fraction of nanoparticles was stable for a longer period of time compared to the nanofluids with a higher volume fraction [ 39 ].

Synopsis of the investigations about the impact of the nanofluid synthesis technique on its stability.

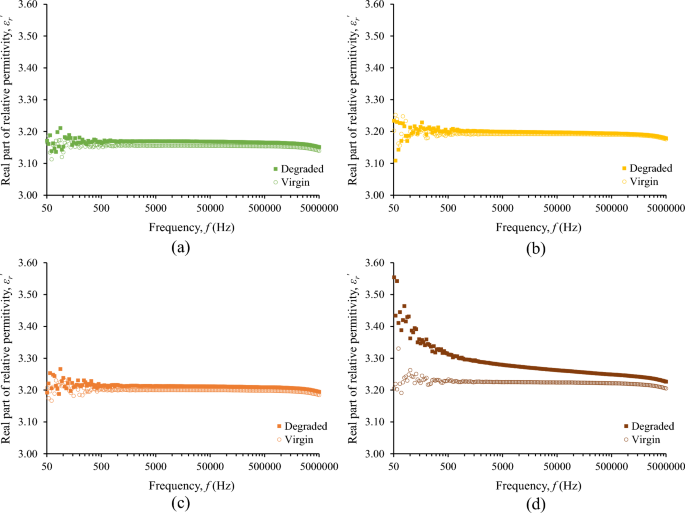

Liu et al. [ 37 ] prepared rGO by the reduction of graphene oxide with L-ascorbic acid as a reductant in an aqueous solution. To prepare rGO, the graphene oxide solution was dispersed in DI water and ultrasonicated for 1 hour. NH 3 -water was then added to control the pH to 10 with sonication for 30 minutes. L-ascorbic acid was added and the mixture was maintained at 95°C for 3 hours for the completion of the reaction. The rGO solution was filtered to obtain rGO on the filter paper. Finally, rGO nanofluids were prepared by sonicating the filtered powder in a certain amount of DI water. The whole process is shown in Figure 5 . The rGO nanofluids exhibited good stability for 10 day without the addition of other dispersants. Ranjbarzadeh et al. [ 38 ] conducted a test to study of pH effects on the stability in acid and alkaline spectrums for GO-SiO 2 /Water hybrid nanofluids. The results observed that the nanofluid, due to the presence of functional groups on the surface of its nanoparticles, shows acceptable stability in all spectrums; however, in the long term, nanofluids with pH > 7 showed better stability. Zeng and Xuan [ 40 ] sonicated the MWCNT-SiO 2 /Ag binary nanofluids for 1 hour and reported that the stability of the binary nanofluid sustained the dispersion stability for 7 days. Gulzar et al. [ 41 ] dispersed hybrid nanopowder (Al 2 O 3 -TiO 2 ) in Therminol-55 oil and the mixture was subjected to high shear stirring at 2500 rpm using a magnetic stirrer for 4 hours. The mixture was then sonicated for 2 hours using a high energy probe sonicator. Oleic acid was used as a surfactant as of better miscibility with Therminol-55 oil. They observed that the value of zeta potential declines with the rise in concentration which may cause agglomeration adequately after a long time. The surfactant which changes the surface charge and increases the repulsive forces between the nanoparticles also contributes to improved stability. Same way, Alarifi et al. [ 42 ] used magnetic stirring for 2 hours and sonicated for 1 hour to prepare a long-term stable MWCNT-TiO 2 /oil nanofluid. The stability of the prepared hybrid nanofluid was observed over 14 days and no sedimentation was found. Akram et al. [ 43 ] checked the stability of CGNP–water nanofluid by zeta potential at different pH values. They prepared this nanofluid after the sonication for 60 minutes and observed that the CGNP nanofluid had high negative values (− 4.42 mV to −49.5 mV) within the pH variations from 1.84 to 10.55. The zeta potential values for the CGNP nanofluids are far from the isoelectric point (i.e., point of zero charges), which indicates that this pH range (2.8–10.55) results in strong electric repulsion forces. Sharafeldin and Grof [ 44 ] did sonication of WO 3 /water nanofluid continuously for about 75 minutes to break the agglomeration between the nanoparticles which leads to well disperse the particles into water. The mean zeta potential value for WO 3 /water nanofluid was −43.12 and a little decrease in the values was observed over the period of 7 days. MWCNT nanofluids suffer from low dispersion and short-time stability which inhibit their practical application. Chen et al. [ 45 ] used a novel method, i.e., a one-pot method by stirred media mill technique. In this method, raw MWCNTs nanoparticles were treated by ball milling to change their morphology, length, and specific surface first. After centrifuging, dry nanoparticles were purified by acid treatment to improve their dispersion in the solution. Thus, the resulting powder was dispersed again in base fluids by ultrasonication and meanwhile, surfactant was added to improve dispersion. The results showed that the milling-treated MWCNT nanofluid exhibited better stability as compared to raw MWCNT and Acid treated MWCNT nanofluid. Ali et al. [ 46 ] investigated the stability of dispersed Al nanoparticles in base fluid (water) prepared by the conventional and the controlled bath temperature two-step methods. The sonication process was taken the same for 4 hours in the range of 10–60°C. The results revealed that the sedimentation behavior of the nanofluids prepared through the controlled bath temperatures of less than 30°C was of dispersed sedimentation type, while those produced by the conventional method and the fixed temperatures of 30°C and higher were of flocculated sedimentation type. Furthermore, increasing the controlled sonication temperature led to an increase in the settling process of the sediments. Also, the rise in nanoparticle concentration was seen to reduce the variation in sedimentation height ratio between the fixed temperature samples. A comparison between the two preparation methods was shown that the 30°C nanofluids had better short- and long-term stability than the conventionally produced suspensions. Mahbubul et al. [ 47 ] varied the sonication time from 1 to 5 hours to study the effect of sonication time on the stability of the 0.5 vol% Al 2 O 3 nanofluids. They observed that with low sonication time or no sonication, the sedimentation rate is higher. It can be concluded that longer ultrasonication reduces the sedimentation of nanoparticles and hence, increases the stability of nanofluids. Mahyari et al. [ 48 ] used probe-type ultrasonicator to achieve the stability of GO-SiC/water-EG hybrid nanofluid. DLS test results with different patterns approved acceptable stability of the nanofluid. Chen et al. [ 49 ] prepared the saline water based magnetic MWCNT nanofluids at different mass concentration from 0 to 0.04 wt% by two-step method. A mechanical stirrer was used at 500 rpm continuously for 30 minutes to mix nanoparticles and water and then the mixture was sonicated thoroughly for 2 hours. Magnetic MWCNTs nanofluids showed high stability in 1000 ppm saline water, and when the solution salinity increased, the original colloidal structure would be destroyed by charge ion. Therefore, the salt-resisting surfactant was added to reinforce the double-layer repulsion and remained the system stable. Okonkwo et al. [ 50 ] prepared the Al 2 O 3 -Fe/Water using two-step methods and measured the stability of nanofluid through the Zeta potential test. Hybrid nanofluid was found significantly more stable at pH values of 12 when compared at any other pH value. Terueal et al. [ 51 ] performed using the liquid phase exfoliation technique starting with bulk MoSe 2 to prepare stable nanofluids. Triton X-100 was used as a surfactant. The suspension underwent sonication in an ultrasound bath for 4 hours with two different frequencies: 80 kHz and 130 kHz. The samples were then centrifuged at 1000 rpm for 10 minutes and again at 4000 rpm for 10 minutes. The results showed that the nanofluid prepared with the frequency of 80 kHz and 130 kHz show the highest extinction coefficient values after 30 days. Higher extinction coefficient values mean the highest amount of nanomaterial in suspension. Li et al. [ 52 ] analyzed the stability of SiO 2 -oleic acid/liquid paraffin nanofluid through the Zeta potential test. The nanofluid was prepared with two-step methods (magnetic stirrer for 30 minute and then sonicated for 1 hour). It was found that the large numbers of SiO 2 nano-sized particles possess maximum value for the total count at values less than −40 mV indicating high stability of SiO2 nano-sized particles in liquid paraffin. Geng et al. [ 53 ] used the DLS test to study the stability of ZnO-MWCNT/Oil nanofluid and found that the nanoparticles are in the nanoscale after the preparation of nano-oil. Li et al. [ 54 ] produced SiO 2 /EG nanofluids by the two-step method with a mass fraction of 0.005–5%. The zeta potential value of the nanofluid was found −56.28 mV and claimed that the nanofluid is stable. Greater the number of particles with a smaller diameter, the higher the probability of stability. Nanofluid cluster formation may lead to the larger diameter of the nanoparticles. As the number of clusters increases, the fluid stability will decrease.

Schematic graph of rGO nanofluids preparation.

3. Conclusion

From the literature, it can be concluded that the stability of suspension of nanoparticles in the base fluid is improved when the nanofluid is synthesized by the one-step method as compared to the two-step method but the preparation of nanofluids by one-step method is difficult and expensive relative than two-step method. The literature also reveals that with low sonication time or no sonication, the sedimentation rate is higher. It can be concluded that longer ultrasonication reduces sedimentation of nanoparticles and hence, increases the stability of nanofluids. There are major tasks, which need to be focused on for selection of mono/hybrid nanofluids and their fabrication process, the stability of hybrid nanofluids. The stabilized nanofluids and their characteristics can increase the heat exchange rate of heat exchangers which are generally used in pipeline engineering. In order to help newcomers and researchers in this field recognize the potential research gap, this review study seeks to provide the latest research and development on stable nanofluids and their applications in pipeline engineering. Due to the lack of understanding of the mechanism of nanofluid at the atomic level, many experimental studies are needed to consider several important issues such as particle migration, agglomeration, and stability.

- 1. Xian HW, Sidik NAC, Saidur R. Impact of different surfactants and ultrasonication time on the stability and thermophysical properties of hybrid nanofluids. International Communications in Heat and Mass Transfer. 2020; 110 :104389

- 2. Almanassra IW, Manasrah AD, Al-Mubaiyedh UA, Al-Ansari T, Malaibari ZO, Atieh MA. An experimental study on stability and thermal conductivity of water/CNTs nanofluids using different surfactants: A comparison study. Journal of Molecular Liquids. 2019; 19 :30397-30396

- 3. Cacua K, Buitrago-Sierra R, Pabon E, Gallego A, Zapata C, Herrera B. Nanofluids stability effect on a thermosyphon thermal performance. International Journal of Thermal Sciences. 2020; 153 :106347

- 4. Xu Q, Liu L, Feng J, Qiao L, Yu C, Shi W, et al. A comparative investigation on the effect of different nanofluids on the thermal performance of two-phase closed thermosyphon. International Journal of Heat and Mass Transfer. 2020; 149 :119189

- 5. Said Z, Abdelkareem MA, Rezk H, Nassef AM, Atwany HZ. Stability, thermophysical and electrical properties of synthesized carbon nanofiber and reduced-graphene oxide-based nanofluids and their hybrid along with fuzzy modeling approach. Powder Technology. 2020; 364 :795-809

- 6. Kazemi I, Sefid M, Afrand M. A novel comparative experimental study on rheological behavior of mono & hybrid nanofluids concerned graphene and silica nano-powders: Characterization, stability and viscosity measurements. Powder Technology. 2020; 366 :216-229

- 7. Ouikhalfan M, Labihi A, Belaqziz M, Chehouani H, Benhamou B, Sarı A, et al. Stability and thermal conductivity enhancement of aqueous nanofluid based on surfactant-modified TiO2. Journal of Dispersion Science and Technology. 2020; 41 :374-382

- 8. Siddiqui F, Tso C, Chan K, Fu S, Chao CY. On trade-off for dispersion stability and thermal transport of Cu-Al2O3 hybrid nanofluid for various mixing ratios. International Journal of Heat and Mass Transfer. 2019; 132 :1200-1216

- 9. Akhgar A, Toghraie D. An experimental study on the stability and thermal conductivity of water-ethylene glycol/TiO2-MWCNTs hybrid nanofluid: Developing a new correlation. Powder Technology. 2018; 338 :806-818

- 10. Choi TJ, Jang SP, Kedzierski M. Effect of surfactants on the stability and solar thermal absorption characteristics of water-based nanofluids with multi-walled carbon nanotubes. International Journal of Heat and Mass Transfer. 2018; 122 :483-490

- 11. Das PK, Mallik AK, Ganguly R, Santra AK. Stability and thermophysical measurements of TiO2 (anatase) nanofluids with different surfactants. Journal of Molecular Liquids. 2018; 254 :98-107

- 12. Gao Y, Wang H, Sasmito AP, Mujumdar AS. Measurement and modeling of thermal conductivity of graphene nanoplatelet water and ethylene glycol base nanofluids. International Journal of Heat and Mass Transfer. 2018; 123 :97-109

- 13. Kuang W, Saraji S, Piri M. A systematic experimental investigation on the synergistic effects of aqueous nanofluids on interfacial properties and their implications for enhanced oil recovery. Fuel. 2018; 220 :849-870

- 14. Muthoka MJ, Xuelai Z, Xioafeng X. Experimental investigation on supercooling, thermal conductivity and stability of nanofluid based composite phase change material. Journal of Energy Storage. 2018; 17 :47-55

- 15. Said Z, Allagui A, Abdelkareem MA, Alawadhi H, Elsaid K. Acid-functionalized carbon nanofibers for high stability, thermoelectrical and electrochemical properties of nanofluids. Journal of Colloid and Interface Science. 2018; 18 :30190-30195

- 16. Alawi OA, Mallah AR, Kazi SN, Sidik NAC, Najafi G. Thermophysical properties and stability of carbon nanostructures and metallic oxides nanofluids. Journal of Thermal Analysis and Calorimetry. 2019; 135 :1545-1562

- 17. Akbari A, Saidi MH. Experimental investigation of nanofluid stability on thermal performance and flow regimes in pulsating heat pipe. Journal of Thermal Analysis and Calorimetry. 2019; 135 :1835-1847

- 18. Cacua K, Ordoñez F, Zapata C, Herrera B, Pabón E, Buitrago-Sierra R. Surfactant concentration and pH effects on the zeta potential values of alumina nanofluids to inspect stability. Colloids and Surfaces, A: Physicochemical and Engineering Aspects. 2019; 583 :123960

- 19. Etedali S, Afrand M, Abdollahi A. Effect of different surfactants on the pool boiling heat transfer of SiO2/deionized water nanofluid on a copper surface. International Journal of Thermal Sciences. 2019; 145 :105977

- 20. Giwa SO, Sharifpur M, Goodarzi M, Alsulami H, Meyer JP. Influence of base fluid, temperature, and concentration on the thermophysical properties of hybrid nanofluids of alumina–ferrofluid: Experimental data, modeling through enhanced ANN, ANFIS, and curve fitting. Journal of Thermal Analysis and Calorimetry. 2020; 6 :4149-4167

- 21. Kazemi I, Sefid M, Afrand M. Improving the thermal conductivity of water by adding mono & hybrid nano-additives containing graphene and silica: A comparative experimental study. International Communications in Heat and Mass Transfer. 2020; 116 :104648

- 22. Boroomandpour A, Toghraie D, Hashemian M. A comprehensive experimental investigation of thermal conductivity of a ternary hybrid nanofluid containing MWCNTs- titania-zinc oxide/water water ethylene (80:20) as well as binary and mono nanofluids. Synthetic Metals. 2020; 268 :116501

- 23. Ding J, Zhao H, Yu H. Graphene nanofluids based on one-step exfoliation and edge-functionalization. Carbon. 2021; 171 :29-35

- 24. Gul T, Firdous K. The experimental study to examine the stable dispersion of the graphene nanoparticles and to look at the GO–H2O nanofluid flow between two rotating disks. Applied Nanoscience. 2018; 8 :1711-1727

- 25. Li X, Zou C, Chen W, Lei X. Experimental investigationof β-cyclodextrinmodified carbon nanotubesnanofluids for solar energy systems: Stability, optical properties and thermal conductivity. Solar Energy Materials & Solar Cells. 2016; 157 :572-579

- 26. Rahimi K, Riahi S, Abbasi M. Effect of host fluid and hydrophilicity of multi-walled carbon nanotubes on stability and CO2 absorption of amine-based and water-based nanofluids. Journal of Environmental Chemical Engineering. 2019; 19 :30703

- 27. Vozniakovskii AA, Kol’tsova TS, Voznyakovskii AP, Kumskov AL, Kidalov SV. Powder hybrid nanomaterial: Detonation nanodiamonds – Carbon nanotubes and its stable reversible water nanofluids. Journal of Colloid and Interface Science. 2020; 565 :305-314

- 28. Asadi A, Alarifi IM, Foong LK. An experimental study on characterization, stability and dynamic viscosity of CuO-TiO2/water hybrid nanofluid. Journal of Molecular Liquids. 2020; 307 :112987

- 29. Chen Z, Shahsavar A, Al-Rashed AA, Afrand M. The impact of sonication and stirring durations on the thermal conductivity of alumina-liquid paraffin nanofluid: An experimental assessment. Powder Technology. 2020; 360 :1134-1142

- 30. Asadi A, Alarifid IM, Ali V, Nguyen HM. An experimental investigation on the effects of ultrasonication time on stability and thermal conductivity of MWCNT-water nanofluid: Finding the optimum ultrasonication time. Ultrasonics Sonochemistry. 2019; 58 :104639

- 31. Ranjbarzadeh R, Kazerouni AM, Bakhtiari R, Asadi A, Afrand M. An experimental study on stability and thermal conductivity of water/silica nanofluid: Eco-friendly production of nanoparticles. Journal of Cleaner Production. 2018; 18 :32938

- 32. Aberoumand S, Jafarimoghaddam A. Tungsten (III) oxide (WO3) – Silver/transformer oil hybrid nanofluid: Preparation, stability, thermal conductivity and dielectric strength. Alexandria Engineering Journal. 2018; 57 :169-174

- 33. Dalkılıç AS, Yalçın G, Küçükyıldırım BO, Öztuna S, Eker AA, Jumpholkul C, et al. Experimental study on the thermal conductivity of water-based CNT-SiO2 hybrid nanofluids. International Communications in Heat and Mass Transfer. 2018; 99 :18-25

- 34. Aberoumand S, Ghamari S, Shabani B. Energy and exergy analysis of a photovoltaic thermal (PV/T) system using nanofluids: An experimental study. Solar Energy. 2018; 165 :167-177

- 35. Kakavandi A, Akbari M. Experimental investigation of thermal conductivity of nanofluids containing of hybrid nanoparticles suspended in binary base fluids and propose a new correlation. International Journal of Heat and Mass Transfer. 2018; 124 :742-751

- 36. Keyvani M, Afrand M, Toghraie D, Reiszadeh M. An experimental study on the thermal conductivity of cerium oxide/ethylene glycol nanofluid: Developing a new correlation. Journal of Molecular Liquids. 2018; 2018 :30794

- 37. Liu X, Wang X, Huang J, Cheng G, He Y. Volumetric solar steam generation enhanced by reduced graphene oxide nanofluid. Applied Energy. 2018; 220 :302-312

- 38. Ranjbarzadeh R, Akhgar A, Musivand S, Afrand M. Effects of graphene oxide’silicon oxide hybrid nanomaterials on rheological behavior of water at various time durations and temperatures: Synthesis, preparation and stability. Powder Technology. 2018; 2018 :30406

- 39. Sharafeldin M, Gróf G. Experimental investigation of flat plate solar collector using CeO2-water nanofluid. Energy Conversion and Management. 2018; 155 :32-41

- 40. Zeng J, Xuan Y. Enhanced solar thermal conversion and thermal conduction of MWCNT-SiO2/Ag binary nanofluids. Applied Energy. 2018; 212 :809-819

- 41. Gulzar O, Qayoum A, Gupta R. Experimental study on stability and rheological behavior of hybrid Al2O3-TiO2 Therminol-55 nanofluids for concentrating solar collectors. Powder Technology. 2019; 352 :436-444

- 42. Alarifi IM, Alkouh AB, Ali V, Nguyen HM, Asadi A. On the rheological properties of MWCNT-TiO2/oil hybrid nanofluid: An experimental investigation on the effects of shear rate, temperature, and solid concentration of nanoparticles. Powder Technology. 2019; 355 :157-162

- 43. Akram N, Sadri R, Kazi SN, Ahmed SM, Zubir MNM, Ridha M, et al. An experimental investigation on the performance of a flat-plate solar collector using eco-friendly treated graphene nanoplatelets–water nanofluids. Journal of Thermal Analysis and Calorimetry. 2019; 138 :609-621

- 44. Sharafeldin M, Grof G. Efficiency of evacuated tube solar collector using WO3/Water nanofluid. Renewable Energy. 2019; 134 :453-460

- 45. Chen W, Zou C, Li X. Application of large-scale prepared MWCNTs nanofluids in solar energy system as volumetric solar absorber. Solar Energy Materials and Solar Cells. 2019; 200 :109931

- 46. Ali N, Teixeira JA, Addali A. Aluminum nanofluids stability: A comparison between the conventional two-step fabrication approach and the controlled sonication bath temperature method. Journal of Nanomaterials. 2019:3930572, https://doi.org/10.1155/2019/3930572

- 47. Mahbubul I, Elcioglu E, Amalina M, Saidur R. Stability, thermophysical properties and performance assessment of alumina–water nanofluid with emphasis on ultrasonication and storage period. Powder Technology. 2019; 345 :668-675

- 48. Mahyari AA, Karimipour A, Afrand M. Effects of dispersed added Graphene Oxide-Silicon Carbide nanoparticles to present a statistical formulation for the mixture thermal properties. Physica A. 2019; 521 :98-112

- 49. Chen W, Zou C, Li X, Liang H. Application of recoverable carbon nanotube nanofluids in solar desalination system: An experimental investigation. Desalination. 2019; 451 :92-101

- 50. Okonkwo EC, Wole-Osho I, Kavaz D, Abid M. Comparison of experimental and theoretical methods of obtaining the thermal properties of alumina/iron mono and hybrid nanofluids. Journal of Molecular Liquids. 2019; 292 :111377

- 51. Teruel M, Aguilar T, Martínez-Merino P, Carrillo-Berdugo I, Gallardo-Bernal JJ, Gómez-Villarejo R, et al. 2D MoSe2-based nanofluids prepared by liquid phase exfoliation for heat transfer applications in concentrating solar power. Solar Energy Materials and Solar Cells. 2019; 200 :109972

- 52. Li Z, Asadi S, Karimipour A, Abdollahi A, Tlili I. Experimental study of temperature and mass fraction effects on thermal conductivity and dynamic viscosity of SiO 2 -oleic acid/liquid paraffin nanofluid. International Communications in Heat and Mass Transfer. 2020; 110 :104436

- 53. Geng Y, Al-Rashed AAAA, Mahmoudi B, Alsagri AS, Shahsavar A, Alebizadehsardari P. Characterization of the nanoparticles, the stability analysis and the evaluation of a new hybrid nano-oil thermal conductivity. Journal of Thermal Analysis and Calorimetry. 2020; 139 :1553-1564

- 54. Li Y, Kalbasi R, Nguyen Q, Afrand M. Effects of sonication duration and nanoparticles concentration on thermal conductivity of silica-ethylene glycol nanofluid under different temperatures: An experimental study. Powder Technology. 2020; 367 :464-473

© 2022 The Author(s). Licensee IntechOpen. This chapter is distributed under the terms of the Creative Commons Attribution 3.0 License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Continue reading from the same book

Pipeline engineering.

Edited by Sayeed Rushd

Published: 01 March 2023

By Satoru Hashimoto

66 downloads

By Mohamed Mohamed Azzam

360 downloads

By Milad Rezvani Rad and Andre McDonald

162 downloads

- Open access

- Published: 20 May 2015

Performance evaluation of nanofluids in solar energy: a review of the recent literature

- Navid Bozorgan 1 &

- Maryam Shafahi 2

Micro and Nano Systems Letters volume 3 , Article number: 5 ( 2015 ) Cite this article

20k Accesses

66 Citations

1 Altmetric

Metrics details

Utilizing nanofluid as an absorber fluid is an effective approach to enhance heat transfer in solar devices. The purpose of this review is to summarize the research done on the nanofluids’ applications in solar thermal engineering systems in recent years. This review article provides comprehensive information for the design of a solar thermal system working at the optimum conditions. This paper identifies the opportunities for future research as well.

Introduction

Energy is an important entity for the economic development of any country. On the other hand, fossil fuels meeting a great portion of the energy demand are scarce and their availability is decreasing continously. Nowadays, solar systems play an important role in the production of energy from renewable sources by converting solar radiation into useful heat or electricity. Considering the environmental protection and great uncertainty over future energy supplies, solar energy is a better alternative energy form in spite of its its slightly higher operation costs. Heat transfer enhancement in solar devices is one of the significant issues in energy saving and compact designs. One of the effictive methods is to replace the working fluid with nanofluids as a novel strategy to improve heat transfer characteristics of the fluid. More recently reserachers have become interested in the use of nanofluids in collectors, water heaters, solar cooling systems, solar cells, solar stills, solar absorption refrigeration systems, and a combination of different solar devices due to higher thermal conductivity of nanofluids and the radiative properties of nanoparticle. How to select suitable nanofluids in solar applications is a key issue. The effectiveness of nanofluids as absorber fluids in a solar device strongly depends on the type of nanoparticles and base fluid, volume fraction of nanoparticles, radiative properties of nanofluids, temperature of the liquid, size and shape of the nanoparticles, pH values, and stability of the nanofluids [ 1 ]. It was found that only a few review papers have discussed the capability of nanofluids to enhance the performance of solar systems [ 2 - 5 ].This paper compiles recent research in this field and identifies many issues that are open or even not commenced to investigate. It is authors’ hope that this review will be useful to determine the effectiveness of nanofluids in solar applications.

Literature review of recent years

Using nanofluids in solar collectors, role of nanoparticles.

Gan et al. [ 6 ] experimently showed that the radiation absorption of Al 2 O 3 nanofluids is less than Aluminuim nanofluids. For nanofluids with Al 2 O 3 particles, the situation is different because of the different optical properties of Al 2 O 3 . The weak radiation absorption of Al 2 O 3 nanoparticles will not result in significant localized convective heat transfer from the particles to the base fluids. The use of Al 2 O 3 /water nanofluid as coolant was simulated for a silicon solar cell using the finite element method by Elmir et al. [ 7 ]. They considered the solar panel as an inclined cavity with a slope of 30°. Application of nanofluids increased the average Nusselt number and rate of cooling. They reported 27% enhancement in the heat transfer rate for 10% alumina nanofluid at Re = 5.

Luo et al. [ 8 ] simulated the performance of a DAC solar collector with nanofluids using a 2D model by solving the radiative transport equations of particulate media and combining conduction and convection heat transfer equations. The nanofluid flows horizontally from right to left in a steady-state solar collector covered with a glass plate. A solar radiation simulator is used to validate their model. They prepared nanofluids by dispersing and oscillating TiO 2 , Al 2 O 3 , Ag, Cu, SiO 2 , graphite nanoparticles, and carbon nanotubes into Texatherm oil. Their results show that the use of nanofluid in solar collector can improve the outlet temperature and efficiency. They also found that the efficiency of most nanofluids are similar and larger than that of oil, except for TiO 2 .

Rahman et al. [ 9 ] performed a numerical study for a triangular shape solar collector with nanofluids by Galerkin weighted residual finite element method for a wide range of Grashof numbers (Gr). The corrugated bottom is kept at a constant high temperature and the side walls of the triangular enclosure are kept at a low temperature as seen in Figure 1 . It is assumed that both fluid phase and nanoparticles are in thermal equilibrium and there is no slip between them. Nanofluid is Newtonian and incompressible, and flow is laminar and unsteady. Constant thermophysical properties are considered for the nanofluid except for the density variation in the buoyancy forces determined by using the Boussinesq approximation. Nevertheless, they have not mentioned the particle’s diameters. The authors concluded that high value of both Gr and solid volume fraction confirms better heat transfer through convection and conduction. Results showed 24.28% improvement for Gr = 10 6 at 10% volume fraction of copper particles. For lower values of Gr number, conduction is the primary mode of heat transfer for any value of solid volume fractions. The results showed that the convective heat transfer performance is better when the solid volume fraction is kept at 0.05 or 0.08. This study also showed that cu-water nanofluid is the best nanofluid for the augmentation of heat transfer.

(a) Schematic of the triangular shape collector (b) 3D view of a solar thermal collector filled with nanofluid [ 9 ].

Faizal et al. [ 10 ] investigated the thermal performance of nanofluid solar collector and its contribution size reduction to estimate the cost saving. Their findings indicated that efficiency of solar collector with nanofluids is calculated by the function of working fluid density, specific heat and mass flow rates. The results confirmed that higher density and lower specific heat of nanofluids offers higher thermal efficiency than water and can reduce the solar collector area about 25.6%, 21.6%, 22.1% and 21.5% for CuO, SiO 2 , TiO 2 and Al 2 O 3 nanofluids as seen in Figure 2 . Hence, it will reduce the weight, energy and cost to manufacture the collector. The average value of 220 MJ embodied energy can be saved for each collector, 2.4 years payback period can be achieved and around 170 kg less CO 2 emissions will be the result of using nanofluid based solar collector compared to a conventional one. Environmental damage cost is also lower with the nanofluid based solar collector.

Percentage of size reduction for solar collector by applying different nanofluids.

Parvin et al. [ 11 ] numerically investigated the effects of the nanoparticle volume fraction (ϕ = 0%, 1%, 3%, 5% and 7%) and the Reynolds number (Re = 200, 400, 600, 800 and 1000) on the temperature distribution, rate of entropy generation, and collector efficiency. The working fluid was incompressible Cu-water nanofluid under a laminar regime. Their findings were as follows: a) Increasing the particles concentration raises the fluid viscosity and decreases the Reynolds number and consequently decreases heat transfer. b) It is important to find the optimum volume fraction of nanoparticle for each application. c) The collector efficiency can be enhanced nearly 2 times by using Ag-water and Cu-water nanofluids with concentration of 3% as seen in Figure 3 d) The entropy generation is enhanced up to ϕ = 3% as seen in Figure 3 . After this level, adding more nanoparticles makes no changes in mean entropy generation.

Collector efficiency (η), mean entropy generation (S) and Bejan number (Be) at various concentrations.

Ladjevardi et al. [ 12 ] numerically studied the effects of using nanofluid on the performance of a solar collector as seen in Figure 4 considering the different diameter and volume fractions of graphite nanoparticles. They observed that in the infrared domain, the water optical characteristics are dominant while in the UV and visible ranges extinction coefficients are dependent on nanoparticle volume fractions. The extinction coefficient is calculated from the absorption and scattering efficiencies in this research. Their numerical results showed that nanofluid collector thermal efficiency increases about 88% compared with the one in pure water collector with the inlet temperature of 313 K. It also can be increased to 227% with the inlet temperature of 333 K.

Schematic of volumetric solar collector.

Filho et al. [ 13 ] studied silver nanoparticles as direct sunlight absorbers for solar thermal applications. Their results showed that the maximum stored thermal energy increases by 52%, 93% and 144% for silver particle concentration of 1.62, 3.25 and 6.5 ppm respectively due to the good photothermal conversion properties of silver nanoparticles. They also observed that the influence of particle concentration on the specific absorption rate (SAR) is only discernable at the initial heating period. It was concluded that reduction in the SAR at higher particle loadings (65 and 650 ppm) might be the result of: (i) The formation of agglomerates and reduction in the intensity of the sunlight into the fluid due to the deposited particles on the surface, (ii) The difference in the absorption efficiency of each particle at different fluid depth, (iii) The heat leak through radiation may become strengthened as the particle concentration exceeds a certain value as seen in Figures 5 , 6 and 7 .

Experimental system: (a) a schematic illustration and (b) a snapshot of the system under direct sunlight on top of a roof.

Comparison of the ratio of stored thermal energy at different concentrations (where b and u refer to thermocouples located at the bottom and upper positions respectively).

Specific absorption rate of silver nanoparticles (where b and u refer to thermocouples located at the bottom and upper positions respectively).

Karami et al. [ 14 ] experimentally showed that aqueous suspension based alkaline functionalized carbon nanotubes (f-CNT), 10 nm in diameter and 5-10 μm in length, has good stability as an absorber fluid in low-temperature Direct Absorption Solar Collector (DASC). The reason is associated with the hydrophilic nature of carboxylate groups. f-CNT considerably reduces the transmittance and enhances the thermal conductivity as seen in Figure 8 . They recommended the use of this kind of nanofluids to absorb the light directly. In this study, f-CNTs was dispersed into the water by an ultrasonic instrument with the volume fractions less than 150 ppm. Higher concentrations produced a black solution which light was not able to pass through it.

Thermal conductivity of f-CNT/water NFs in ambient temperature and 60°C.

Said et al. [ 15 ] found that nanofluids with single wall carbon nanotubes (SWCNTs) in a flat plate solar collector showed the minimum entropy generation compared to the nanofluids prepared by suspending Al 2 O 3 , TiO 2 and SiO 2 nanoparticles in the same base fluid as seen in Figure 9 . They attributed the decrease of the entropy generation to the increase in heat flux on the absorber plate due to the nanoparticles addition. Ultrasonicator and high pressure homogenizer (capacity of up to 2000 bar) is used to disperse the nanoparticles into the water. It was observed the SWCNTs nanofluids could reduce the entropy generation by 4.34% and enhance the heat transfer coefficient by 15.33%. It also had a small penalty in the pumping power by 1.2%.

Change of entropy generation with volume fraction.

Tang et al. [ 16 ] prepared the carbon nanotube/PEG/SiO 2 composites with high thermal conductivity from multiwall carbon nanotubes (MWCNTs), poly (ethylene glycol) (PEG) and inorganic SiO 2 . These composites had higher thermal conductivity than traditional phase-change materials (PCMs) because of the high thermal conductivity of MWCNTs. Their results clearly showed that PEG/ SiO 2 /MWCNT composites can effectively improve the efficiency of solar energy applications.

Saidur et al. [ 17 ] investigated the effects of different parameters on the efficiency of a low-temperature nanofluid-based direct absorption solar collector (DAC) with water and aluminum nanoparticles. One big advantage of using low-temperature systems is that solar collectors can be relatively simple and inexpensive. Additionally, there are a number of working fluids suitable to low-temperature operation. Commonly used base liquids are water, oil, and ethylene glycol. They accounted for the effects of absorption and scattering within the nanofluid to evaluate the intensity distribution within the nanofluid by the radiative transfer equation (RTE). In order to calculate the spectral extinction coefficient of the nanofluid that is sum of scattering coefficient and absorption coefficient, they investigated the optical properties of the based fluid and nanoparticles separately. Their results revealed that Aluminum/water nanofluid with 1% volume fraction improves the solar absorption considerably. They found that the effect of particle size on the optical properties of nanofluid is minimal, but in order to have Rayleigh scattering the size of nanoparticles should be less than 20 nm. They also found that the extinction coefficient is linearly proportionate to volume fraction.

Sokhansefat et al. [ 18 ] numerically investigated the heat transfer enhancement for Al 2 O 3 /synthetic oil nanofluid with concentrations up to 5% in a parabolic trough collector tube at different operational temperatures as seen in Figure 10 . Nanofluid enhanced convective heat transfer coefficient as seen in Figure 11 .

Schematic diagram of the parabolic trough collector and absorber tube.

Mean convective heat transfer coefficient vs.particle concentration at the operational temperatures of 300,400 and 500 K.

Nasrin et al. [ 19 ] performed a numerical study to investigate the influence of Prandtl number on the flow, temperature fields, convective and radiated heat transfer rates, mean bulk temperature of the fluids and average velocity field in a solar with water- Al 2 O 3 nanofluid collector as seen in Figure 12 . The results showed that with increasing Pr from 1.73 to 6.62, the convective heat transfer enhances about 26% and 18% for nanofluid and base fluid respectively whereas the radiation enhances by 8%.

Schematic diagram of the solar collector.

Role of base fluid

Colangelo et al. [ 20 ] experimently showed that the thermal conductivity improvement of the nanofluids with diathermic oil is greater than that with water in high temperature applications such as solar collectores. They observed that the thermal conductivity reduced with increasing the size of nanoparticles.

Hordy et al. [ 21 ] made four different nanofluids by dispersing plasma functionalized multi-walled carbon nanotubes (MWCNTs) in water, ethylene glycol, propylene glycol and Therminol VP-1 heat transfer fluids with the aid of an ultrasonic bath. They examined both the long-term and high-temperature stability of CNT nanofluids for use in direct solar absorption. In this work plasma treatment applied to modify the surface of the MWCNTs to improve their dispersion property within the base fluid. This study reported a quantitative demonstration of the high temperature and long-term stability of ethylene glycol and propylene glycol-based MWCNT nanofluids for solar thermal collectors.

Said et al. [ 22 ] experimentlly investigated the thermal conductivity, viscosity and pressure drop of water, ethylene glycol (EG) and EG + H2O (60:40)-based Al2O3 (13 nm) nanofluids prepared by using ultrasonic dispersion method in the operating temperature range of 25°C to 80°C at low range concentrations of 0.05% to 0.1% for. They observed that deviation of experimental values from estimated values of thermal conductivity of Al 2 O 3 /water nanofluids is considerably high but the experimental values of Al 2 O 3 /EG nanofluids are nearly similar to those of the model calculation as seen in Figure 13 . Their results showd that nanofluids pressure drop at a low concentration flowing in a solar collector is slightly higher than the base fluid.

Thermal conductivity of Al2O3/EG (a) and Al2O3/water (b) nanofluids at different volume fractions and at 25°C.

Liu et al. [ 23 ] experimentally investigated the feasibility of using the graphene (GE)-dispersed nanofluids based on the ionic liquid 1-hexyl-3-methylimidazolium tetrafluoroborate ([HMIM] BF 4 ) in high-temperature heat transfer systems (such as solar collectors). Ionic liquids (ILs) are a group of molten salts with a melting below 100°C as well as a wide liquid temperature range from room temperature to a maximum temperature of 459°C. ILs have excellent thermophysical properties such as good thermal and chemical stability, high density and heat capacity and negligible vapor pressure. In this work, authors showed how to improve the performance of ILs for solar thermal systems. They observed 15.2%-22.9% enhancement in thermal conductivity using 0.06% graphene in the temperature range from 25 to 200°C as seen in Figure 14 . Their results showed that GE is a better nanoadditive for nanofluids than other carbon materials and metal nanoparticles.

Thermal conductivity of [HMIM]BF4 and the GE-dispersed Ionanofluids as a function of temperature.

Variation of specific heat capacity with temperature for the pure and the different nanoparticle concentration of Hitec nanofluid.

The authors attributed this reduction to the self-lubrication characteristic of GE. In addition, the results obtained from the thermogravimetric analysis showed the high thermal stability of GE/BF 4 nanofluids. Their measurements showed that this novel class of nanofluids is very suitable for high temperature applications such as solar collectors.

Ho et al. [ 24 ] found the optimal concentration of alumina nanoparticles in doped molten Hitec (a nitrate salt) by maximizing its specific heat capacity. High-temperature molten salt typically has a high heat capacity and is effective as a working fluid for concentrating solar power (CSP) systems. Their findings are as follows: 1- The addition of less than 2% Al 2 O 3 nanoparticles significantly increases the specific heat of Hitec metal at low temperatures as seen in Figure 15 , 2- For the volume fractions less than or equal to 0.5%, adding Al 2 O 3 nanoparticles has a negative effect on the specific heat in temperature of 335°C, 3- At all temperatures, a concentration of 0.063 wt.% provides the maximum enhancement of specific heat about 19.9%, 4- The scanning electron microscopic (SEM) images show that, even at a relatively low concentration, nanoparticles aggregate as clusters with the size of 0.2 to 0.6 μm in the grain boundaries of Hitec, 5- The findings of this study suggest that the concentration that yields favorable uniform dispersion and optimal pattern of particles or clusters may maximize the specific heat. The simplified model of the solid-fluid interfacial area demonstrates that interfacial area is maximal at a concentration of 0.023 wt.%. As the nanoparticle concentration increases above 0.023 wt. %, the formed clusters become larger and the interfacial area density between the solid clusters and the base fluid decreases which may reduce the increase in specific heat capacity. According to the results obtained from this study, the maximum enhancement of the specific heat capacity occurs at concentration of 0.063 wt.% instead of 0.023 wt.%. Indeed, some agglomeration of nanoparticles forming submicrometer clusters may be the best for the enhancement of specific heat capacity. However, the total interfacial area at concentration of 0.063 wt. % was slightly less than its value at concentration of 0.023 wt. %.

Role of surfactants

Singh et al. [ 25 ] added Cu to commercial solar heat transfer fluids (Therminol 59 (TH59) and Therminol 66 (TH66)) by the combination of temperature and ultrasonic ripening processes. They stated that surfactant selection has an important role in preparing stable nanofluids. Choosing the right surfactant is mainly dependent on the properties of the base fluids and particles. For example, silicon oxide nanoparticles were successfully dispersed in TH66 using benzalkonium chloride (BAC, Acros Organics) as a surfactant but the use of BAC surfactant with Cu nanoparticles did not provide sufficient stability of suspension due to the lack of specific interaction between the nanoparticles and the surfactant molecules. The bi-layer arrangement of surfactant molecules should provide good adhesion to the nanoparticle surface and miscibility with the aromatic solvent. In this work, authors used a combination of oleic acid and BAC and a mixture of octadecyl thiol (ODT) and BAC surfactants to disperse Cu nanoparticles in TH66 and TH59, respectively. They observed that 3D Cu nanoparticle agglomerates do not break by conventional sonication with ultrasound gun without temperature ripening. They showed that a sonication time of about 4 h leads to the effective breakup of Cu agglomerates into individual grains at a 120°C. They also concluded that Cu/TH66 nanofluids appear to be more stable than the Cu/TH59 nanofluids because of the higher dynamic viscosity.

Yousefi et al. [ 26 , 27 ] studied the effect of Al 2 O 3 (15 nm) and MWCNT (10-30 nm) water nanofluid on the efficiency of a flat plate solar collector experimentally. The weight fractions of the nanoparticles were 0.2% and 0.4%, and the experiments were performed with and without Triton X-100 as surfactant. Their findings showed that the surfactant presence in the nanofluid extremely affects solar collector’s efficiency.

Lenert et al. [ 28 ] presented a combined modeling and experimental study to optimize the performance of a cylindrical nano-fluid volumetric receiver. They concluded that the efficiency is more than 35% when nanofluid volumetric receivers are coupled to a power cycle and optimized with respect to the optical thickness and solar exposure time. This study provides an important perspective in the use of nanofluids as volumetric receivers in concentrated solar applications. In this work, 28 nm carbon-coated cobalt (C-Co) nanoparticles dispersed and suspended in Therminol VP-1 after 30 min in a sonication bath without any surfactant.

Role of the pH

Yousefi et al. [ 29 ] investigated the effect of pH of MWCNT-H2O nanofluid on the efficiency of a flat-plate solar collector as seen in Figure 16 . The experiments were carried out using 0.2 wt% MWCNT (10-30 nm) with various pH values (3.5, 6.5 and 9.5) and with Triton X-100 as an additive. They found that increasing or decreasing the pH with respect to the pH of the isoelectric point (IEP) would enhance the positive effect of nanofluids on the efficiency of the solar collector. The collector efficiency enhanced while the differences between the pH of nanofluids and that of isoelectric increased. As the nanofluids become more acidic (lower pH value), more charges are accumulated on the particle surface, leading to lower agglomeration of nanoparticles in the suspension. Consequently, the effective thermal conductivity of the nanofluid increases. In addition, with the increase in pH of the nanofluid, the surface charge of the CNT increases leading to the increase in thermal conductivity and stability of nanofluid.

The efficiency of the flat-plate solar collector with MWCNT nanofluid as base fluid at three pH values as compared with water in0.0333 kg/s mass flow rate.

Using nanofluids in photovoltaic/thermal (PV/T) system

Sardarabadi et al. [ 30 ] performed experiments to study the effects of using SiO2/water nanofluid as a coolant on the thermal and electrical efficiencies of a photovoltaic thermal (PV/T) system. A flat plate solar collector was attached to a PV panel. The tilt angle of the collector was set at a constant value of 32° to maximize the solar collecting area. It was observed that by adding a thermal collector to a PV system, the total exergy for the three cases with pure water, 1% silica/water nanofluid and 3% silica/water nanofluid increased by 19.36%, 22.61% and 24.31%, respectively as seen in Figure 17 . Thermal efficiency of the PV/T collector for the two cases of 1 and 3 wt% of silica/water nanofluid increased 7.6% and 12.8%, respectively.

Exergetic efficiency of the system for the three cases with pure water (a), 1% silica/water nanofluid (b) and 3% silica/water nanofluid (c) during the daily experiment.

Karami et al. [ 31 ] experimentlly investigated the cooling performance of water based Boehmite (AlOOH. xH 2 O) nanofluid in a hybrid photovoltaic (PV) cell. The PV cell is mono-crystalline silicon. Results showed that the nanofluid performed better than water and the average PV surface temperature decreased from 62.29°C to 32.5°C as seen in Figure 18 . They reported that the electrical efficiency falls as the concentration of the nanofluid rises beyond a certain level. The authors attributed this reduction to the high surface activity of nanoparticles and their tendency to agglomeration/clustering at high particle loadings. Table 1 summarizes the results of nanofluids influence on different solar thermal applications

Variation of the average temperatures of the PV surface at various flow rates for water and three different concentrations of nanofluid.

Using nanofluids in solar stills

Kabeel et al. [ 32 ] investigated a small unit for water desalination coupled with nano-fluid-based (Cu/water) solar collector as a heat source as seen in Figure 19 . The system consists of a solar water heater (flat plate solar collector), a mixing tank and a flashing chamber plus a helical heat exchanger and a condenser. The desalination process is based on the evaporation of sea water under a very low pressure (vacuum). The evaporated water is then condensed to obtain fresh water. The simulation results showed that the nanoparticle concentration is an important factor on increasing the fresh water production and decreasing cost. Authors reported that the water cost can be decreased from 16.43 to 11.68 $/m 3 at ϕ = 5% as seen in Figure 20 .

Schematic diagram of single stage flash (SSF) system.

Variations in system productivity and water cost as a function of nano-particle volume fraction.

Kabeel et al. [ 33 ] used Al 2 O 3 nanoparticles with water inside a single basin solar still. Their results showed that using nanofluids improves the solar still water productivity by about 116% and 76% with and without operating the vacuum fan. The authors attributed this increment to the increase of evaporation rate inside the still. Utilizing nanofluid increases the rate of evaporation. In addition, due to this vacuum inside the still the evaporation rate increases further and the productivity increases compared with the still working at atmospheric conditions.

Using nanofluids in solar pond