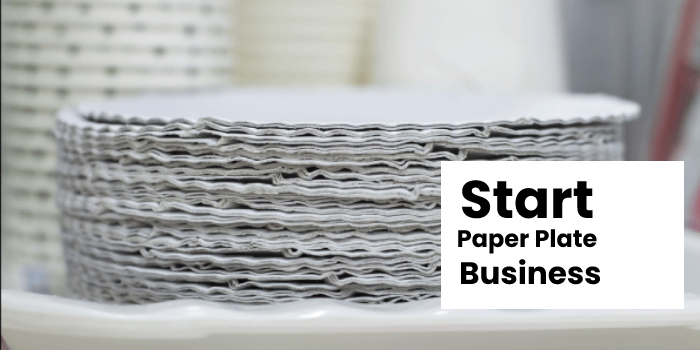

How to Start a Profitable Paper Plate Manufacturing Business

Do you want to start a paper plate-making business at home? If YES, find here a detailed plan guide to start a disposable paper manufacturing business with market potential, business licensing, machinery, manufacturing process, and required raw materials.

Any individual can start this business on a small, medium, and large-scale basis. However, depending on your investment capacity, you must plan the business size. From the same unit, you can produce disposable bowls and glasses also. Additionally, you can start this business on both a part-time and full-time basis.

Related: Profitable Paper Business Ideas

Generally, this type of disposable plate comes with special quality paper reinforced with polythene sheets to make it leakproof. Some of the majorly used papers are millboard, greyboard, kraft paper, greaseproof paper, and other papers. In most cases, these plates come in either white or printed.

Mostly, these are used in family functions and corporate gatherings. In most cases, people use to serve snacks, cakes, pastries, bakery items fruits, sweets, etc.

Table of Contents

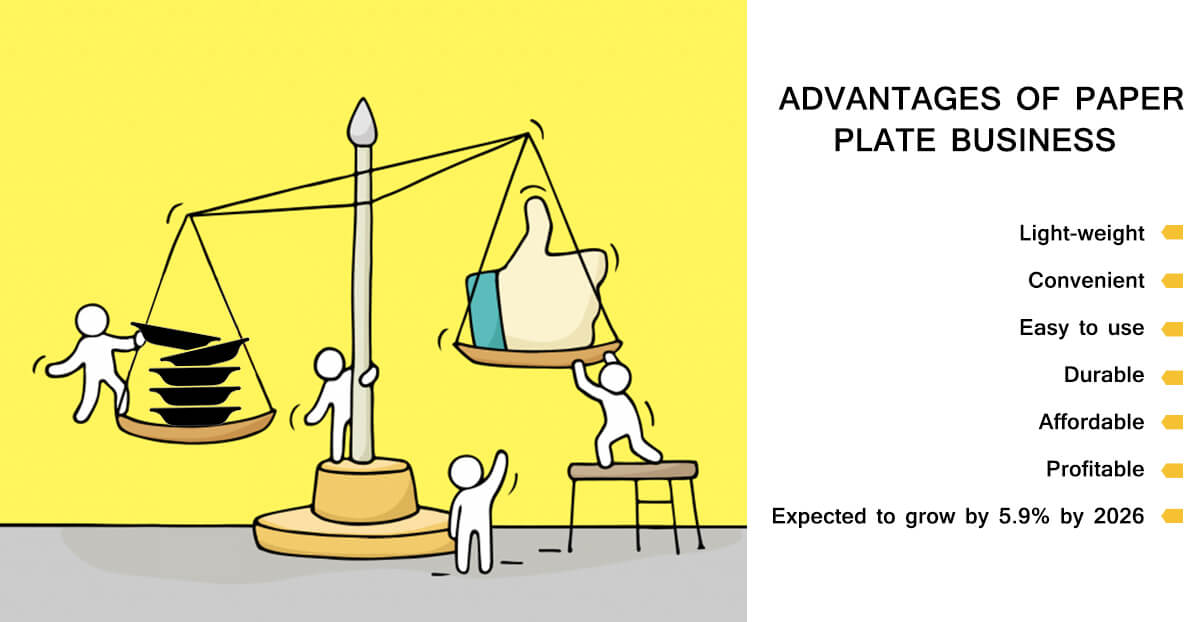

Is Paper Plate Making Profitable?

Disposable paper plates have an urban as well as a rural market. People use these items mostly for social functions, religious gatherings, parties, marriages, outings, sweet shops, caterers, etc.

The products have many advantages and are hence preferred as compared to standard utensils/crockery for serving eatables. Additionally, because of their disposable nature, they save a lot of labor as far as the cleaning/drying of utensils is concerned.

Furthermore, these are easily transportable and easy to handle. Further, people use these items in marriages, birthday parties, and other family functions on a regular basis. Also, sweet shops and small eateries are the major consumers of this item. Hence, we can conclude starting a disposable paper plate-making business is a highly profitable and lucrative opportunity for entrepreneurs.

Here are the Steps to Start Paper Plate Manufacturing Business

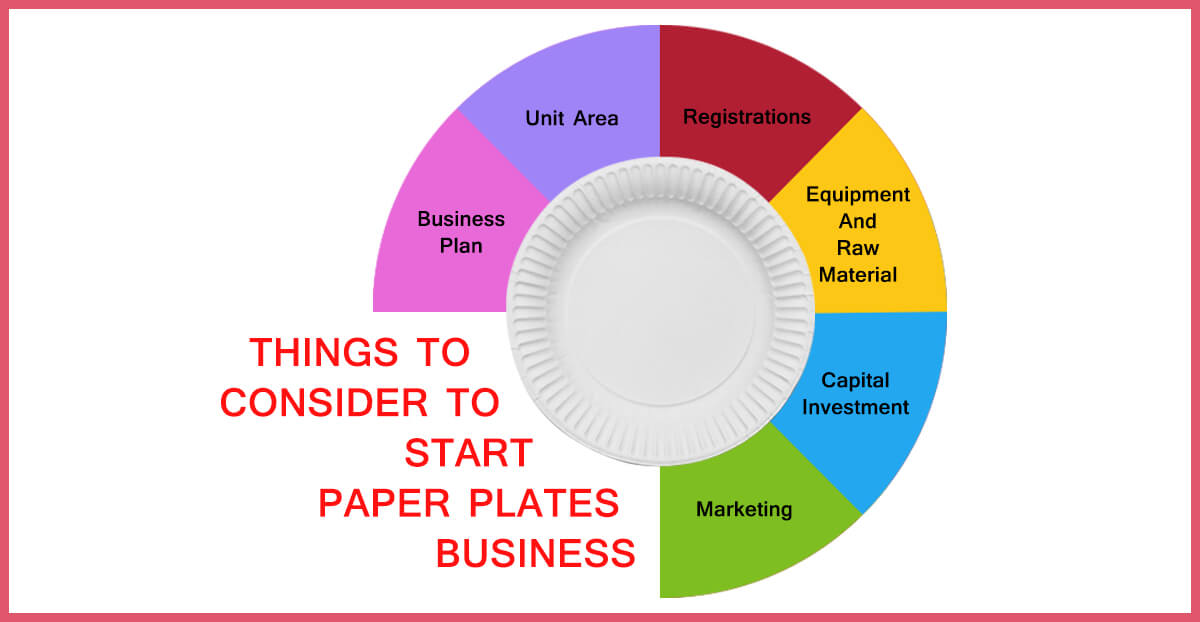

1. create a business plan.

In starting this business, you must craft a business plan first. And to understand the industry, you must conduct a market survey prior. Identify the different types of plates that have regular demand in the market. Understand the design, thickness, color, etc. Identify the established manufacturers and know their market policy. These all will help you in crafting a business plan rightfully.

In writing the business plan, mention your business goal, mission, vision, and what type of organization you want to build. For a small or tiny operation, you can open the business as a proprietorship company.

2. Arrange Business Capital

Generally, disposable paper plate-making business demands moderate capital investment. However, starting the business at home eliminates the cost of securing a space. Additionally, it helps you to work from the comfort of your home.

Apart from the space, the business demands investment for procuring the machinery and raw materials. You also need to hire manpower and arrange other necessary resources. Hence, a financial calculation is necessary and you must include this in the business plan. Besides using your own fund, you can apply for a loan from the banks.

Also, do not forget to apply for a credit card to meet small-time business expenses.

3. Registration & Licenses

Even, if you start the business from home, check the licensing issues from the Govt. agency of your state. It is mandatory. It also depends on the manufacturing process and the raw materials you are using.

Register your business with a suitable organization form. Check the upcoming tax liabilities of your startup.

Generally, you will need to obtain a Trade License from the local authority. And if you operate from a factory premise, then you will need to apply for a Factory license.

In India, you will need to apply for a GST Number.

4. Paper Plate Manufacturing Unit Setup

If you don’t have enough space at home to start the business, you will need to secure a location for setting up the unit. Before finalizing, check the water resource and electricity connection. Contact the machinery supplier to get a floor plan for the installation of the machinery.

It will help you to plan accordingly. Determine specific spaces for raw material storage, operation area, and finished goods storage. In addition to that, you will need to have an admin area for preparing the bills, etc.

5. Paper Plate Making Machinery

The major plant and machinery consist following macies.

- Double-die press with dies.

- Electrically operated.

- Bag sealing machine

- Weighing scales.

Besides this, you will need to have furniture and fixture for the overall unit operation.

6. Raw Materials

The basic raw materials for the unit are good-quality scrap paper & polyethylene sheets. Packing the unit will require polythene bags and hessian sacks. The cut to size paper is readily available in two varieties. These are thick and thin.

7. Paper Plate Manufacturing Process

The process of manufacturing is not very complicated. Basically, you can produce the product by using the specific die. First of all, cut the paper and the polyethylene sheets previously according to the size. Also, you can procure a specific size of the paper depending on your specific requirements.

Then, mount the specific die on the press and start heating to the desired temperature. Place the two layers of paper and the polythene sheets in between the male-female die parts. Then, apply the pressure so that the product takes shape.

Remove the formed product and set the another. The machine is an ordinary press with one fixed platform and another moving plunger. The movement of the plunger is through the hydraulic mechanism.

Finally, collect the formed products and trim the edges to give them a proper shape. Pack the plates and stock them for dispatch.

8. Cost of Starting a Paper Plate Manufacturing Business

The cost of starting a paper plate manufacturing business will depend on several factors. It includes location, machinery and equipment, legal fees, raw materials, labor cost, etc.

On average, the cost of starting a small-scale paper plate manufacturing business in India will be around Rs. 5-10 lacs (approximately $6,800 – $13,600 USD).

However, the cost can go up from INR 50 to Rs. 1 Cr. for large-scale setups.

9. Develop a Distribution Network

Retail distribution is the most proven way of promoting this type of item. Additionally, you must concentrate on institutional selling. Talk to the event planners and small caterers in your area. Also, you can offer introductory discounts. Moreover, you must have a solid marketing plan to make your paper plate-making business a great success.

10. Promote Your Paper Plate Making Business

Paper plates are not new products. So, people are already aware of these items. Additionally, there is already a huge demand in the market. However, you must have a marketing plan for your product promotion.

In the present day, going online is a must. Create a website and promote your products through social media platforms.

Next What Business Research Team

The Editorial Staff at NextWhatBusiness is a team of Business Consultants having years of experience in small and medium-scale businesses.

- Products Tissue machine Mask Making Machine Disposable Cap Making Machine Shoes Cover Making Machine Bouffant Cap Making Machine Plastic Tub Cover Making Machine Sleeves Making Machine Disposable Medical Cloth Making Machine Glove Making Machine Dust-proof Cover Making Machine Ultrasonic Sewing Machine

- About Us Company Profile Team Picture R & D and Results

- Tissue machine

- Mask Making Machine

- Disposable Cap Making Machine

- Shoes Cover Making Machine

- Bouffant Cap Making Machine

- Plastic Tub Cover Making Machine

- Sleeves Making Machine

- Disposable Medical Cloth Making Machine

- Glove Making Machine

- Dust-proof Cover Making Machine

- Ultrasonic Sewing Machine

- Company Profile

- Team Picture

- R & D and Results

Home > News

How to Start Paper Plate Business: Investment, Profit Margin, and Marketing

A paper plate business involves manufacturing plates that were made out of paper for serving food. They were considered an economical alternative to plastic plates.

The demand for eco-friendly products such as paper plates has suddenly increased.

If you are looking to capture this moment by starting your own paper plate making business, then this is the right time for you.

Moreover, it is a proven low investment business with a good profit margin.

Resources Required to Start A Paper Plate Business

To start a paper plate business, you need to have some basic amenities such as land, machinery, raw materials, and labor.

On top of that, you need a good amount of money to start this business. Most of the people might not have lakhs of rupees initially to buy all those things and many approach banks for loans.

To sanction the loan amount, we need to submit a project report. So, all these things are covered in this topic.

Land or Building for Rent

You don’t require huge land for starting a paper plate manufacturing business. A room with 250 – 500 sq ft is good enough.

This can easily fit your machine and have enough space for storing raw material and cardboard boxes for packing.

Land Requirement: 250 – 500 square feet

Note:- it is better to choose a place within the radius of markets, shops, hotels, and business for easy transportation and marketing. Also make sure to check important documents, licenses, and permission available for the place you rent.

Current Supply

Electricity is important for running your paper plate making machine.

Before you choose a place to start the business, look at whether the location has a good power supply or not.

Most paper machines require a voltage of 220-240v to run effectively. Some high-end paper plate machines may even require 440V.

So, make sure that the building you choose to set up the manufacturing unit has the required current supply.

Also note, frequent power cuts or constant voltage fluctuations can damage your paper machine.

Raw Material

The price of paper material required for manufacturing plates depends on various factors such as GSM, size, type, and quality.

These raw materials are available as rolls or sheets.

There are different types of raw materials used in making paper plates such as kraft paper, sitting plate, and lamination sheets.

Kraft paper is available in a range of 70 GSM to 200 GSM.

Sitting plates are available between 70 GSM – 140 GSM.

Purchasing sitting plates directly from paper mills is the best option as you will get them for the lowest price.

Film paper or lamination paper is used on the sitting plate.

There are different types of film designs available in the market.

Next is coating material, some paper materials are single sided PE coated and some others are double-sided. A Double-sided PE coated paper costs more than single sided one.

Paper Plate Machine

A paper plate machine is the most important requirement for manufacturing process.

The price of the machine depends on its capacity, model (automatic or semi-automatic), features (Single Die or Double die), and power consumption.

It requires 2-3 workers to run the business decently. You can either put them in a single shift or different shifts. You also don’t have to worry about training them because, the process just need some basic skills to learn.

If you can tell them general instructions and show them how to operate the machine, it’s fairly enough.

Preparing a Project Report for Paper Plate Business

Lets now get in to submitting a brief project report.

Project report is essential for getting a loan from the bank. Basing upon the report you submit. Banks will decide how much loan they can provide for starting a paper plate manufacturing unit.

So, you must know every aspect of this report or consult a professional who can guide you in preparing a project report for your business.

Things Covered in a Project Report.

Details of Manufacturing Unit and the Founder

In this report, you provide the details about your paper plate manufacturing unit and yourself (founder).

Basically, you provide an overview of your company and details about yourself and any experiences in running such type of business in the past and its related documents.

Technical Feasibility Report

Technical feasibility is the second most important aspect of your project report. Basically, a feasibility report helps you to determine the possibilities of starting your business.

In a feasibility report, you will brief the current situation of your business in the market and explain the machinery, raw materials, and resources required for starting this business.

And then, explain what is the scope of your business and how you can compete with the market.

Details of the Location – Land or Building

A detailed explanation of the manufacturing location, land, or building must be included in your project report.

It is important that you check all the necessary amenities such as water connection, proper electrical wiring, and transportation facility are available in the desired location.

If you find you are lacking any important amenities, you can approach a professional, and ask them whether you get any finance for the money spent on the construction of such amenities.

Also, make sure you have obtained all the necessary documents and permission to set up your business in that area.

Details about the Manufacturing Process

You have to present the details of your manufacturing process, what type of raw materials you are going to use, and other details such as the number of days your unit will operate, and its production capacity.

Financial Details of your Project

You have to provide the entire financial details of your project such as the amount spent on equipment, raw material, machinery, labor, building, marketing, and other expenses.

Overall all such details need to be mentioned in a detailed table-wise manner in order for the banks to properly estimate how much loan they can sanction to you.

Getting Registration, Documents, and Other Licenses

To start any business, you need to obtain certain licenses and they depend on various things such as type of business, number of workers, sector, and place of the business.

Some of the most common licenses and registrations include company registration, GST, Udyam registration, Shop and Establishment Act licenses, or such things.

Depending upon your manufacturing capacity and investment capital. You need to check which one is applicable to you.

How to Select Paper plate Making Machine

You need to consider several things before investing money on a quality paper plate machine. Because this is the costliest equipment of your business and a onetime purchase.

Things to consider before buying a paper plate making machine.

Generally, if you have a low requirement and only makes normal paper plates such as 7-inch size or 4-inch bowl type paper plates, you can choose the one within 45,000 price.

If you need a high-speed paper plate making machine with advanced features, then you may have to spend a lot of money on it.

This type of equipment is best suited for making large thali plates.

Single Die Vs Double Die Vs Multiple Die

In a paper plate making machine, Die is a pressing tool that applies high pressure on the paper material to turn it into a plate.

The price of the paper plate machine highly depends upon the no of dies. Machines with Double and Triple die cost more than a single die. More number of dies means more number of plates produced per hour.

Automatic and Semi-automatic machine

The third step in selecting a paper plate machine is to choose whether you need an automatic one or semi automatic one.

Fully Automatic paper plate machine

In a fully automatic machine, you just need to place the paper roll on dedicated rollers and load the sitting plates in the compartment.

Once you switch on the machine it will automatically drag the paper roll and press them on to the sitting plate releasing a fully completed paper plate within no time

Best suited for – Already who have existing business with large market supply

Semi-automatic paper plate machine

In a semi-automatic model, you must load the paper material manually on to the press. Once the pressing is finished you need to take out the paper plate and load the next one

Best suited for – This type of machine is good for those who are new to this business, low investment, and a small market network.

Production capacity

Production capacity is the number of plates produced per hour and it varies depending up on the Number of Dies, Size of the plate, Motor power.

Some machines can produce 1500 to 2000 pieces per hour. Whereas some machines can produce up to 5000 pieces per hour. Depending upon your budget and demand choose the best one for your business.

Paper Plate Machine with Buy Back Agreement.

Some paper plate machine manufacturers or traders provide buy-back agreement. This means if you are not satisfied with their product or in any circumstances if want to return the machine. the seller will be ready to take it and give back some money. However, keep in mind buy back agreements have certain limitations that you need to be aware of.

Manufacturing plan for paper plates

Once you have gathered all the information about machinery and raw material, you must create a ground plan on how to manufacture paper plates.

This generally depends upon four things.

Market demand

Type of paper plates that you are making

Market Demand

The first thing you must consider before starting full-scale manufacturing is to know whether anyone buys from you.

To do so, approach shops, canteens, street vendors, and catering businesses, or such and show some free samples. If they like them you can make a contract and start manufacturing plates accordingly.

You need a good amount of cash to meet your daily and monthly expenses such as traveling, buying raw materials, daily wages, and other miscellaneous things.

So, depending upon your budget, plan your production process.

The production capacity of your machine depends upon the number of plates it can produce per hour.

If your machine capacity is 1500 plates per hour, then it can produce 12,000 paper plates per 8 hours. If it is a double die model, it can double the production to 24,000.

Basing upon market demands, budget and season plan your production capacity.

Types of Paper plates

Paper plates are available in different sizes, Quality and Shape. Some are very small and light weight. These are mostly used for serving samosa, pani puri and other snack items. They are mostly available in 4 inch to 7-inch size.

While some other paper plates are thick and durable that can hold the food firmly. These types of plates are generally used for serving thali and tiffins. They are available in 10 to14-inch sizes.

Before you decide to manufacture a certain variety, ask the local vendors whether they would purchase or not. At the same time try to choose the ones that have continuous demand in the market.

Marketing and Selling of Paper plates

Once you have finished manufacturing of paper plates you have to sell them in the market. Paper plates have huge demand almost all over India. So, don’t have to worry about market.

However, keep in mind, selling paper plates is quite a challenging task.

Because there are already several people who do this type of business and they sell at a very low-profit margin and have a large network in the market.

But don’t get depressed. You can do several things to grow your business such as

Selling your paper plates at a reasonable price than your competitors.

Get in touch with new shop keepers.

Provide free samples and ask the buyers to try them for a few days.

Build connections with small catering businesses

Use WhatsApp to take orders. This is the simple and fastest way you can contact easily.

In some gated community apartments, you will mostly have some shops located. Approach the president or respective head of the apartment and tell them about your service. So, when there is a function or party going on in their community they will contact you

Get in touch with function hall owners and give your visiting card so that in future purposes if they require a bulk order for a function or marriage or any such occasion they may contact you.

Paper Plate Profit Margin Estimation

In paper plates business, profit highly depends on three things Quality, Budget and Marketing power.

Quality is the most essential requirement in this business. if you provide good quality paper plates at a reasonable price you will have better chances of getting more customers.

Sometimes your paper plates might get damaged during transportation or packing. if your paper plates lack the quality the buyer would bargain you to reduce the paper price which you may end up in less profit.

Let’s, look at the Budget, on average It would require approximately 5 Lakh to 10 Lakh INR. to run a paper plate business decently. This includes machinery cost, salaries to workers, current bills, water bills, transportation, registration, marketing, and other extra costs.

If you have a high budget, you can buy expensive automatic machinery in the first place. This will save labor costs as most of the automatic models just need a person to supervise the machine. However, these machines would cost you around 1,25,000 to 180,000 INR and GST plus extra tax.

On other hand, if you buy a machine with normal cost starting with 60,000 INR and keep 2-3 workers you have to give monthly or hourly wages. So, choose which one is perfect for you.

In the same way, if you have more budget you can buy different raw materials and produce different varieties of paper plates which you can sell it to different types of customers and get good results.

If you are only making a single variety of paper plates with normal quality and selling them with a medium profit margin then you can expect satisfactory results.

The no.one factor for making a successful paper plate business depends on how well you are marketing them. To be frank without marketing you cannot expect good profit.

You need to supply your paper plates to a large network of shops, canteens, hotels and other events to expect good return of investment.

One of the best suggestions is to sell as much as paper plates during Festivals or Marriage seasons. Because the demand for paper plates is especially high during these occasions.

Also, keep in mind, not to completely rely on marketing your paper plates only in famous centers, rather approach other areas too. Because popular centers in the city will have great competition.

So, instead of wasting your time there, you can travel to other places and make new deals.

Also, utilize the festive seasons or marriage seasons effectively. If you can get 10-20 orders for marriage or functions with at least 200 – 300 members capacity, you can easily sell up to 2000 – 6000 paper plates in one go.

Previous Eco-friendly take-out and everything you need to know about take-out food containers

Next What is flexible packaging?

Paper Plate Making Business Plan & Profit Margin in India

Paper Plates are alternatives of steel, glass and ceramic material that we often use in our daily lives. Paper plates are basically not used on the first place but are used as an alternatives or for specific use. In India, paper plates hold great prominence because of their large scale usage. If you are planning to start paper plate making business then this is absolutely right time to kick start your business. This industry is growing in rapid rate in India and profit margin in the manufacturing of plate is also very high.

In this article, you will learn about following important points:-

- how to start your own paper plate manufacturing unit in India?

- what are the machines required and cost of machines?

- Manufacturing process and plant setup

- Profit margin in manufacturing of paper plates

- Cost estimation ROI(Return on Investment)

Usage of Paper Plates (Business Opportunity)

Paper plates are basically used in two categories. The first category belongs to domestic usage and the second category belongs to commercial use. The first category usage amounts to use for domestic purpose, marriage, event, function, picnic and travel purpose. Most of us use paper plates in marriages as the best way to serve the most without worrying about cleaning or loss of item. It is also very convenient, light and affordable.

On the other hand we have the commercial use. Commercial use is linked to street shops that offer eateries, street hawkers and their likes. This part consumes the most manufactured paper plates as the demand is regular and huge.

Paper Plate Making Business Plan

If you planning to open up a manufacturing center for paper plates then you need to draw up a comprehensive and well though business plan because this market is already grown up. Your plan should not only be limited to its manufacturing but also to its supply and returns. Here we will discuss how you can open a paper plate manufacturing plant.

Requirements for opening a Paper Plate Manufacturing Plant

There’s not much required to open a paper plate manufacturing business what you need is some basic requirements which are mentioned below.

- Land: Yes you need a land where you can set up your manufacturing plant. The land must be at a place which has basic amenities so that you don’t find much trouble. The size of the land isn’t the big issue because a 100 sq. feet land will also work.

- Water: Water is an important part in paper plate manufacturing business because while doing so one needs a constant water supply. This can also be seen as disadvantage because the water requirement here is quite huge.

- Electricity: Electricity is something as essential as water. You need proper power supply to run your paper machine along with water pump and other electronics. The power supply should be constant and proper with required standard voltage so that your machine works well.

- Raw Material: It would be better that you get the raw material directly as papers or paper rolls. Because manufacturing paper requires lots of resources, money and time. You can get lots of paper from local scrap shops which may sell you those papers at a very minimal rate per kg. A quintal or 1000 kg of paper can easily be brought at Rs 5000 to 7000.

- Manufacturing Machine: A manufacturing machines varies with price. Most common variation comes in number of generation of paper plates per hour. Some machine generate 1000-2000 pieces per hour while some do 4000-7000 pieces per hour. Also the design, quality and type of machines varies. One normal machine will cost you around Rs 75, 000 to Rs 500, 000.

- Labor: You may need at least two more people along with you if you are also involved in manufacturing. This may not be much costly but you need to give them proper training in initial days.

Feasibility Analysis of Paper Manufacturing Plan

A feasibility analysis is necessary aspect that should always be conducted where you are going to do something brief with a respected amount of capital. Setting up a manufacturing center requires a decent amount of capital, time, raw material, resources and man power. It would be better for you to conduct such feasibility test that will give you a comprehensive report. Here is some aspects of feasibility analysis.

Requirement of Resources

The basic requirement for opening a manufacturing center is a decent size of land. It should definitely be built as per the requirement. You can also open this in your house with only one machine. Second requirement will be paper work related to the business that includes registration, taxation, required permissions, etc. The third important point is a proper connection of water supply and power. Your place of manufacturing should be at place that has all basic amenities. Other requirements are raw materials, machine and labor.

Investment Required

Though most of the people open their plant in their own land or house instead of buying a separate land because it is quite costly. Building up that place will at least required few lakhs of rupees. Other than that your basic investment will be in machine. This will cost around Rs 75, 000 to Rs 500, 000. Raw material, power supply, water, taxation, labor will cost you around Rs 10 lakhs a minimum. It may go up to Rs 15 lakh which you must try to minimize as much as possible.

Other Possible Issues Related with the Business

Paper work and proper permission : You should be prompt with these issues of taking proper permission from the authorities. Paper work like proper electric connection, water supply connection, registration of your business, registration in GST and many others.

Arrangement of Capital : Though many of us won’t have that much of money to invest in this business at a go. We definitely need some sources from where we can arrange these funds. The better option would be to go for a bank loan. The Indian government recently launched a scheme known as MUDRA Yojna where it is offering loan of Rs 50, 000 to 10 lakhs for those who want to start a small business. You can go up with your plan and papers and get a loan.

Market for the Business : It is the most necessary aspect of the business where you need to have a proper market for selling up your product. Make a network with local vendors, shopkeepers and wholesalers who sell such items. Make a deal with them based on supply and rate. Your market should focus where you can sell your product at a good price.

Paper Plate Manufacturing

Paper plate manufacturing should focus on three different perspective. The first perspective should be the total amount of manufacturing per day. A normal machine manufactures a minimum of 2000 plates per hour so if you make it work for eight hours it will give you 16000 plates. You should consider having two machines in case one of your machines stops to work you may continue with the other. If both are working then you may have greater manufacturing and then greater supply.

The second perspective is the shape and size of the plate. Though machine remains the same but there are different shapes and sizes that are fitted to manufacture such plates. You can do an analysis in the market for the requirements and based on it you can manufacture them. Make sure what you manufacture has some good demand so that you get a constant order. The last perspective is the quality of product.

There are different types of paper plates. Some of them are extremely light while some of them are light weight yet durable. The last category is the most advanced and durable plate that is thick and holds the best quality. You should try all of them based on requirements. Some shopkeepers use the lowest quality while some use the best. You can figure it out while consulting the shopkeepers.

Return on Investment:

Your profit depends first on your investment. If you have a good investment then your return for the first time may not sound good but if your investment is low then you may be comfortable with the return. Apart from manufacturing, the return in this business also depends on the market. You need to have a proper network where you can supply your product.

This network should be wide so that you can get different prices for your product. Your aim should be supplying product directly to the user. Shopkeepers in cities demand quality paper plates where the cost is high. You can sell your product to them so that you get the best returns. Cost of transportation also will be an add up but if you get a good price then it can be managed.

The return of this business is satisfactory because the raw material that is paper is quite cheap and a kg of paper will create good amount of plates. These plates per dozen or hundred piece cost decent amount. If you are able to sell 10, 000 to 50, 000 plates a day then your result will be very much satisfactory or else you have to build your business and work hard to achieve the target. One other important aspect is the cost of manufacturing that should be controlled to the best. If that’s done then you can easily maximize your return.

A paper plate making business is a business that creates paper plates. This can be done through a variety of methods, such as using a machine to create the plates or by hand. The business may also sell other paper products, such as cups and napkins.

There are a few benefits to starting a paper plate making business. One is that the startup costs are relatively low. You will need to purchase a paper plate making machine, which can be found for a few hundred dollars online, and you will need to purchase paper and other supplies. Another benefit is that paper plate making is a relatively easy business to operate. You can make the plates in your home or in a small workshop, and there is minimal packaging and shipping involved. Finally, paper plate making is a sustainable business. Paper plates can be made from recycled paper, and they can be composted or recycled after use.

A paper plate making business plan should include an executive summary, a market analysis, a description of the product or service, a marketing plan, a financial plan, and a management plan.

1. Research the paper plate market and decide what type of plates you will sell. 2. Find a manufacturer of paper plates who can produce the plates to your specifications. 3. Negotiate a price with the manufacturer and order a minimum quantity of plates. 4. Find a supplier of paper plate raw materials, such as pulp and wax. 5. Set up a production line for your paper plates.

The cost of starting a paper plate making business can vary depending on the size and scale of the operation. A small business may be able to start up for as little as a few thousand dollars, while a larger operation may require tens of thousands of dollars in initial investment.

The main markets for paper plate making businesses are businesses that require disposable plates, such as restaurants, catering companies, and event planners.

The common challenges faced by paper plate making businesses are high raw material costs, competition from plastic products, and seasonal demand.

Similar Posts

Starting Paper Bag Making – High Profit Margin Business Plan With Investment

How to Get Your Product Manufactured with Less Stress?

Starting A Packaging Material Manufacturing Unit – Business Plan Sample

Why is Water Jet Cutting Crucial for Aerospace Businesses?

The Increasing Role Of Technology In Manufacturing

Agarbatti Making – Rs 1 Lakh/month Profit – Business Plan

How to Start a Paper Plate Making Business

By: Author Tony Martins Ajaero

Home » Business ideas » Manufacturing Industry

Do you want to start a paper plate making business? If YES, here is a complete guide to starting a paper plate making business with NO money and no experience . First and foremost, paper plates are accessories used in serving food items. At picnics or a finger food party, the role of paper plates can never be overemphasized. Its size and lightweight has made it attractive and a must for events. These plates are available in a wide range of designs and sizes to meet the needs and preferences of consumers.

This is why establishing and running your own paper plate business is an amazing way of earning extra income. With the growing demand coupled with the low supply of paper plates, now is the perfect time to start and run this business successfully.

But before you start your own paper plate making business, you need to take a look at the market and its needs in relation with the international market. Indeed there are huge demands for paper-made products owing to environmental concerns that made government authorities to ban plastic plates and cups.

You can leverage this growing market and start a paper plate making business which is a clean opportunity for you to have a self-standing career.

18 Steps to Starting a Paper Plate Making Business in the United States

1. understand the industry.

Reports have it that the market for paper plates is globally fragmented into types of materials, end use, and regions. On the basis of material type, the global market is segregated into plastic, polyethylene terephthalate, low-density polyethylene, polypropylene, and high-density polyethylene.

The plastics segment is further sub-segregated into molded fiber, paper and paperboard, and plastic. On the basis of end use, the market is categorized into restaurants, birthday parties and other occasions, theatres, food retail outlets, and others.

Based on the geographical regions, the market is diversified into North America, Asia Pacific, Eastern Europe, the Middle East & Africa, Western Europe, and Latin America.

It’s important to note that paper plates are manufactured by the producers of food packaging materials. Experts believe that the food packaging industry holds a good market share. Indeed paper is available in very big quantities and have low cost, therefore growing the demand for paper plates.

We also believe that the change in lifestyle of people in developing regions and the consumption of ready to eat snacks have greatly affected the paper plate market positively. But then, the availability of alternatives such as trays for serving the food limits the growth of the paper plate market.

Reports have also shown that the massive growth in the food servicing industry in North America is the key trend that is driving the paper plate market; while the market growth in Western Europe is also good due to the change in the lifestyle of the people.

Experts believe that the paper plate market will grow at a moderate rate in Eastern Europe in the coming years. As Latin America and Asia Pacific regions are densely populated regions, the market is expected to grow at a rapid rate. In the Middle East and Africa, the market share for paper plate is small but is slowly growing.

2. Conduct Market Research and Feasibility Studies

- Demographics and Psychographics

Just like we stated above, understanding the market demand for paper plates in your anticipated market is very important before choosing any business niche. Higher comfort is the main reason behind the increasing demand of paper plates. It is very easy to dispose of them and no need of cleaning and washing.

These plates will always be used in different occasions like picnics or any kind of ceremony or event where food or snacks will be distributed to people. Also since they are daily usable items and are disposed of immediately, this product is continuously in demand.

Research has shown that paper plates are widely used in eateries like canteens, restaurants, sweet and snack corners and have a great market with event organizers. In this business, you will get a steady market demand for your paper plates as with the increasing population; the need for the paper plates is also growing by a huge margin.

With the help of your marketing skills, you can have an agreement with different canteens and restaurants or event organizers to have a permanent customer base. We also believe you can lure them with attractive pricing or other gifts or schemes depending on the market requirement and individual choice.

3. Decide What Niche to Concentrate On

When starting your paper plate making business, you will have to decide who you are trying to sell to. You need to find your niche and decide how you will differentiate yourself from other paper plate manufacturers out there.

This is why deciding on a niche is part of the crucial decisions you have to make. If you specialize in a certain type of plate, your business name will be synonymous with the sort of plates you produce. Niches may include:

- Making custom made paper plates

- Making gift paper plates

- Making green paper plates

- Creating paper plates used for designs etc.

The Level of Competition in the Industry

Reports have it that the US paper plates market reached US$ 104 billion in 2016. Indeed the ever growing food service sector has led the United States to become one of the largest markets for paper cups and plates worldwide.

We believe that paper cups and plates are most times covered with plastic resin to increase their durability, making them liquid resistant and preventing them from soaking the moisture and becoming soggy. This is why they are extensively used to dispense beverages such as tea, coffee, soup, etc. But then paper disposables such as cups and plates do not need cleaning, and therefore can be discarded easily after use.

Due to modernization, hectic lifestyle and surging income levels, industry clients prefer to use disposables instead of reusable utensils to save time and effort, therefore encouraging the growth of the paper plates market.

The market is expected to reach a value of US$ 119 billion by 2022, growing at a CAGR of more than 2% between 2017 and 2022. Analysis has shown that food retail outlets are hindered by the challenge of serving customers at a faster rate along with keeping service cost at low levels.

We believe that this need to serve food to customers and at the same time maintain hygiene levels has led to the use of disposable paper plates. Research has it that paper plates and cups are widely used by restaurants, food joints, fast food retailers, etc.

Plastic plate manufacturers are supplying eco-friendly or paper made plates in order to address the issue of disposability of plastics. Paper plates are manufactured from paper pulp or recycled material which is very cheap and easily available.

4. Know the Major Competitors in the Industry

- Ningbo Yinzhou Realpack Products Co., Ltd.

- Eco-Products, Inc.

- Guangdong Huasheng Meto Green Tech Stock Limited

- Yiwu Green Paper Work Factory

- Biopac India Corporation Limited

- Ecoware Solutions Pvt. Ltd.

- Sabert Corporation

- Huhtamaki Group

- Hangzhou Lvyang Paper Products Co., Ltd.

- Xiamen Bioleader Environmental Protection Technology Co., Ltd.

Economic Analysis

Paper plates over the years has gained very huge acceptance over plastic plates. Also the ban of plastic usage all over the world has made paper plate business attractive to new entrepreneurs.

Industry statistics has shown that plates have a huge demand in parties and functions all over the world. Paper plates are generally made from millboard, grey board, Kraft paper, greaseproof paper. Nowadays demand for paper plates has increased drastically both in urban and rural areas.

Have it in mind that writing a detailed business plan for your paper plate making business and acting in accordance with it will ensure the smooth running of your business. The document should highlight your financial requirements, business goals, competitive environment; marketing strategies you will use to attract your target audience, the resources needed for the business and so on.

Also note that you can employ a professional in the field to do that for you, but if you have adequate knowledge about it, then no harm is done. Paper plate demands are mainly originating from IT concerns, educational institutes, industrial canteens, food canteens, roadside café and eateries, coffee shops, fast food centers, supermarkets and event organizers.

We also believe that the massive growth in demand, high employability, recycling of waste paper, production of paper plates of different designs and sizes are the strengths of the paper industry and as a result, this industry is having huge growth potential which would lead to socio-economic development, huge demands, good output recyclability, innovative creations of new items and emergence of fresh ancillary industry like packaging and transportation.

5. Decide Whether to Buy a Franchise or Start from Scratch

Note that the advantage of buying a paper plate making business franchise instead of starting a new business from the scratch is quite encouraging. But then buying a franchise isn’t necessarily a bed of roses.

Thoroughly evaluating the factors involved with buying a franchise, you will understand that you also need to do your research even before deciding to commit yourself. You also need to make sure the business is the right fit for your personal and professional goals.

If you think the business rhymes with your life goals, the assistance of a business broker will help all the pieces of the process to fall in place and you might just become an owner of a Paper plate making business without much stress. Facts have shown that your main goal of growing your business is more achievable if you become a franchisee instead of starting from the scratch.

- Always research the history of the franchise

- Decide if it’s the best of you

- Hope for the Best But Plan for the Worst

- Negotiate for a Good Price

6. Know the Possible Threats and Challenges You Will Face

This business has its own problems and pitfalls. The alterations in economic and technological environment along with the regulatory framework have affected the industry to a great extent.

The availability of raw materials, power, paper and cellulose raw materials has hindered the access to the proper technology that can convert these raw stuff into high grade pulp. Also the need for water used in production poses a serious challenge in this business.

Recently, the most coveted raw material for the industry is depleting at a fast rate and has already started giving alarming signals at some areas across the country. Also the paper plates industry is also affected by energy shortage like power and coal and the industry is energy intensive. Other challenges or barriers to starting this business may include;

- Purchasing Supplies And Equipment

- Hiring staff

- Market services

- Selecting a niche

- Researching about the industry

- Naming your business

- Setting up your workplace

7. Choose the Most Suitable Legal Entity (LLC, C Corp, S Corp)

When making this decision for your business, just bear it in mind that you have two options- sole proprietorship and the LLC. This is why to hugely understand the tax liabilities for each; it is quite beneficial if you get hold of the definitions.

A sole proprietor business structure is a company with a single owner. This structure is used by three-quarters of all businesses. The owner is in control of the company and has the simplest initial setup. A limited liability corporation, or LLC, is often formed for partnerships when the business has grown significantly. The LLC creates more options for growth and tax advantages.

Indeed a lot of entrepreneurs would want to establish their business as an LLC than a sole proprietorship because of liability issues, but have it in mind that it takes money to prepare the articles of incorporation.

Payment options need to be considered, a bookkeeping system has to be in place, and this all takes additional money that takes away from the funding necessary to purchase the materials to make the products.

8. Choose a Catchy Business Name from the ideas Below

- Flashy paper plates

- Pressing Events

- Warship plates

- Paper press

- The Gallery Collection

- Paper plates cottage

- The Papery Of Princeton

- Funny paper plates

- Brickwell plates

- Plates Factory

- Heaven paper plates

- Smart paper plates

- Paper plates Galore

- Carlton Paper plates

- Glass Cinderella paper plates

- Paper plate making Shop

9. Discuss With an Agent to Know the Best Insurance Policies for You

It’s very important that you cover yourself as a paper business owner from potential lawsuits by getting business insurance. Even before you purchase insurance, you need to categorically outline your business risks and decide how to avoid those risks. Note that not all of your risks as a business owner can be covered simply by getting a basic insurance policy.

We suggest that you first know what your risks are before you set out to protect yourself. This is why we suggest you consult with an attorney or even an insurance professional. Risk in the Paper plate making business can be overwhelming but listed below are the basic insurance policies you will need.

Professional Liability Insurance

This insurance which is also known as Errors and Omissions insurance or E&O insurance provides coverage in the event that a business is held legally liable for damages which are cause by your improper advice or negligence.

Commercial Auto Insurance

Being an entrepreneur, you need the same kinds of insurance coverage for your business car as you do for your personal cars– liability, collision and comprehensive, medical payments (known as personal injury protection in some states) and coverage for uninsured motorists.

General Liability Insurance

This insurance protects your business against claims for bodily injury and property damage. Adding property coverage to a General Liability policy is often referred to as a Business Owner Policy or BOP insurance. The BOP insurance has many levels and facets. General Liability protects your small business from injury or damage caused by your employees or injury to 3rd parties while on your premises.

Workers compensation insurance

This insurance covers the medical and lost wage costs (similar to disability) when an employee suffers a work-related injury or illness.

10. Protect your Intellectual Property With Trademark, Copyrights, Patents

Indeed copyright is an automatic right, but then the way you protect your designs rests solely on you. We can all agree that creating and designing a product is hard work. It will sure hurt if after taking so much time striving to bring your idea to life, then you discover your design or promotional copy is stolen. Imitation is not the most sincere form of flattery; it’s a drastic reduction on your gross income and your ability to support yourself.

Licensing or mass producing your work is one very great way to make money but there are a lot of issues you need to consider when licensing your design. For instance, will you receive artist credit?

What method of payment will you be getting– a flat fee for the design or royalties based upon sales? What about any non-compete clauses? You should be wise and alert wen dotting the contract to make sure you’re not actually losing money by licensing your product.

A lot of paper plate making businesses will be better served by copyrighting their work. However, this is a complex subject that is best discussed with your attorney should you think you may benefit from seeking a design patent.

You need to understand that the most crucial part of copyrights for your paper plate making business is that they protect the written word. Your ideas and designs aren’t protected by the copyright law, although the way in which they are expressed may be – thus the importance of protecting your written word.

A trademark is a unique symbol, word, or phrase that identifies your product. Two symbols designate a trademark. One is ™ and the other is an R inside a circle ®. You should formal formally to register your trademark with the U.S. Patent and Trademark Office (USPTO).

11. Get the Necessary Legal Documents You Need to Operate

Every business needs legal documents to do business in a particular environment. It doesn’t depend on what you make or sell, or if you make a profit or not. A lot of licenses may be necessary, but is still depends on your location and what you are offering. This is why the prime step is to find out if you need a business license.

If you plan on operating your paper plate making business as a home-based business and live within city limits, the best place to check is with your city business license office. You can also check with your county business license office. If you need to get a business license, you also need to check for zoning issues.

We also suggest that you contact your local government to know about those requirements, and to make sure you have all the proper forms. Also, try paying the proper taxes. Apply to the IRS for a tax identification number, which you will use on the many tax-filing forms your new business will need.

You should also purchase financial software. Strive to meet all the mandatory and necessary legal obligations and visit the respective authorities to obtain necessary documents. If you do this and comply with all the necessary laws, then you can proceed to the next thing you are expected to do before kick starting a paper plate making business.

12. Raise the Needed Startup Capital

To start a paper plate making business, you need to have startup capital at hand or it will be very hard to launch your business successfully. It does not necessarily mean that you must have the exact capital needed to kick start your business. You can raise capital from family members and friends, or better still, apply for a loan from financial institutions with your business plan.

We believe there are several new government schemes out there where you can get loan to set up your paper plate business without any collateral. But then to ask for a loan from any financial institutions, you need to file a well-written business plan of your paper plate making business. You can get business finance from…

- Personal savings

- Credit card caveats

- Partnership

- Crowdfunding

- Family and friends

13. Choose a Suitable Location for your Business

Most individuals are neglecting this business because they assume they need a huge garage or workspace to start making paper plates. But have it in mind that you can successfully set up a small hobbyist paper plate making shop in any space, even in an apartment.

First you need to consider the demographics and Psychographics of the proposed location , you need to decide if your targeted audience are close to you and you can reach them. Then there are raw material considerations, competition, good road network, brand affinity and networking. However, choosing the suitable business location is very critical to the success of your business.

If you plan on starting big, you will need a factory and not a retail counter for selling paper plates and location would not be of prime significance. It is better to set up the factory in the outskirts of the city or in particular industrial zones where price of land is not quite high.

But we suggest you have your manufacturing unit close to your intended consumers and suppliers of raw materials. All you would need is a covered area of approximately 500 square meters with uninterrupted power connectivity to run all the electrical machines. The location should be such that you can effortlessly attract, source and eventually recruit workers for your plant.

14. Hire Employees for your Technical and Manpower Needs

We believe you don’t need to have specific skills or knowledge before staring up this lucrative business. The paper plate making business is not completely dependent on manual operation.

The manufacturing process of paper plates is not at all labour-intensive and you would be able to run the entire factory with the help of one production manager, one skilled labourer and one unskilled labourer.

But then it’s best to estimate the manpower on both managerial and administrative role needed on the basis of the capacity of the plant while you do rest of the works. Tools needed to start the business include;

- Paper plate making machine

- Raw Materials

The Service Delivery process of the Business

There are three stages involved in the process of making paper plates. The very first stage takes care of carving out the design and pattern of the plate and the encircling area is tapered in the second stage while in the third and final stage, the paper plate is pre-heated and the sides are rimmed and curled to make the process complete.

Raw materials

Paper plate businesses need raw items in the form of bottom reel, printed PE paper and packing material. There are a lot of manufacturers of automatic machinery of paper plates across the United States and you can surely get something to meet your requirements within your budget.

Also note that you will have to look for reputed suppliers who can get you the raw materials in good time and extend the credit term if needed and you should also have to negotiate better pricing with the suppliers by promising timely payment. Also ensure that the raw materials are of top quality so that you don’t have to compromise the quality of your manufactured products.

Paper plate manufacturing process

Making and designing paper plates is not as complicated because you can make plates of varying shapes and sizes with the aid of specific die. The paper along with the polythene sheets need to be previously cut for proper sizing and you may even buy these materials pre-cut as per your requirements. The particular die has to be mounted on the press and the die is then heated to the needed temperature.

Then both the layers of paper as well as polythene sheets are placed properly in between the respective die parts and application of pressure aids the product to take its needed shape. After that, the product ultimately formed is removed for you to load another set.

Afterwards, the bulk of manufactured products are collected and the edges are trimmed and rippled to give it the desired shape and appearance. Then they are packed in a set and dispatched for delivery. The general production capacity of a regular paper plate manufacturing unit is 30,000 to 40,000 in a day per each press on two shifts.

15. Write a Marketing Plan Packed With ideas & Strategies

As a new entrant in this lucrative industry, you are expected to have a solid value proposition for creating a viable market for your business. This is why you will have to segregate the different targeted groups of consumers, their special attributes etc., so that you can scheme distinct marketing strategies for every customer segment.

To make known your identity, you may consider venturing into an agreement with consumers where you may sell the paper plates at a relatively lower cost. Immediately your target group of consumers is assured of the quality and competitive pricing of your products, you may raise the price.

We also suggest that you ensure that the quality of your manufactured products is top rate as it is very important to the success of your business.

Staffing Expertise

A lot of entrepreneurs believe that in-house staffing is attractive because it can be performed by current employees and can give them more control over the process, which is indeed true.

So don’t you neglect or overlook the need to enlist the assistance of external marketing professionals. In addition to delivering a better overall outcome, marketing firms brings an optimistic perspective to your strategy and key messaging.

Make use of the Contests concept

Leveraging this concept does not guarantee high income and revenue, but it can be a strategic component of a comprehensive marketing plan. However, a contest is not a no-risk marketing option. Poor execution can dampen your struggle to improve your business’s market presence.

Making use of Multichannel Marketing Strategies

We believe that making use of multichannel marketing strategies can make your business grow higher and reach more customers. Customers now engage with brands in different ways, which is the more why brands need to show diversity in the channels they employ to connect with customers.

It is very much possible for a paper plate making business to channel a part of its resources towards marketing channels to maintain a noticeable presence in the marketplace. So consider including print ads, flyers, and even online marketing tactics in your marketing plan. Also note that the acquisition of a reliable mailing list from considerable and proven providers can aid your business.

16. Develop Iron-clad Competitive Strategies to Help You Win

You have to understand the competitive landscape that you might face in this business and where your new business will fit in. It’s also important that you understand that competition is natural in business and it shouldn’t be discouraged. You just need to sit up and devise ways to win your business competitors, and this ways may include:

- Use Your Printer’s Bulletin Board

- Teach a class once in a while or speak to a group

- Submit your paper plates to reps

- Help other people make money

- Invent a new kind of paper plates

- Write and publish an article

- Contact Trade Publications

- Offer raffle donation

17. Brainstorm Possible Ways to Retain Clients & Customers

Customers returning is a blessing every business should be working towards and praying for. Have it in mind that a customer with an awesome story to tell or an awesome product to show will definitely attract ten new ones. Ways to increase customer retention and make your brand super lucrative may include;

- Know your customers

- Try display advertising retargeting your customers

- Work together and implement loyalty programs

- Satisfy your customers

- Stay in contact

- Attend to dissatisfied customers

- Make them feel wanted

- Educate customers

18. Develop Strategies to Boost Brand Awareness and Create a Corporate Identity

The essence of having brand awareness is to make sure people know you are selling paper plates for them to patronize it. It’s your sole responsibility as an entrepreneur to boost your brand awareness and create a corporate identity for your business. Ways to do that may include:

- Leverage the social media

- Go directly to event organisers and shops to sell your products and create a sustainable supply chain

- Create a website to sell your paper plates online

- Using an online store like Etsy or eBay, make sure you are familiar with the kind of users that populate these sites, and whether or not they fit into your target audience.

Related Posts:

- How to Start a Foam Production Business

- How to Start a Construction Nail Manufacturing Business

- How to Start a Boat Manufacturing Business

- How to Start an Electric Bulb Manufacturing Business

- How to Start a Wood Chip Manufacturing Business

A Plate of Success: Basic Steps For A Paper Plate Business

Indian functions are often a grandiose affair with various dishes being served and the humble paper plate is very much an integral part of these functions. With the move by several states and the Indian Railways to ban single-use plastic, paper plates have been the go-to for many.

Setting up a paper plate business is profitable as the investment barrier is low, and it has a good profit margin.

Guidelines for Setting Up Your Paper Plate Business:

Individuals with an aptitude for business can start a paper plate business on a scale that applies to them. The scale of the business depends on your investment capacity.

The raw material for paper plates is mainly special quality paper reinforced with polythene sheets to make it leakproof. Some commonly used papers are greyboard, millboard, kraft paper, greaseproof paper, etc.

A paper plate business can thrive during festive and wedding seasons as they help save manual labour required to wash plastic dishes and are cheap in bulk.

How Profitable is a Paper Plate Business?

Both rural and urban markets demand disposable paper plates, as many retail food outlets use them. A paper plate business can explore diverse industries like catering and institutional consumers for large business volumes.

Steps to Get Started on Your Paper Plate Business:

Formulate a business plan.

While initiating a business endeavour, the first and most crucial step would be to draw up a business plan. The initial steps include conducting market surveys to identify the kinds of plates in demand, the designs, colours, and thickness.

Evaluate the competition to grasp why they are successful, what they are doing right, and where there is room for improvement. Also, mention details like the business scale, the amount you are looking to invest, the ROI and output you are targeting etc.

Organise Working Capital:

The paper plate business doesn’t place too many demands on initial funding. The basic requirements for this business would be appropriate space, machinery and raw materials procuring. Hiring sufficient and skilled labour also needs to be considered.

You can also check this out Bag Profits With Paper Bag Business

Apply for Requisite Permits:

It is mandatory to obtain the requisite permits according to the prevailing laws. The standard requirements are a Trade Licence entitling you to carry out commercial activities and a Factory Licence if required. You will also need to register with the GST department, which will assign you a GST Number.

Plan for the Initial Investment:

The bulk of the initial investment will be for procuring machinery and raw materials, and the machinery may set you back up by Rs 5 Lakh. The rest of the expenses are variable depending on the quality of raw material, the skill level of the hired labour, etc.

Have a Distribution Network:

Identifying retailers to stock your product is ideal to ensure it reaches the end consumer. Apart from this, getting in touch with event planners, caterers, large corporate firms, etc., are a surefire way of maintaining sustained sales and income.

Conclusion:

This summarises the basic information required for setting up a paper plate business in India. Be sure to conduct in-depth research before starting this venture.

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Related Posts

Sustainable Fashion Threads: A Revolution for Tomorrow

E-commerce Giants: Dominance in the Digital Marketplace

Get the best stories on the Newsletter

- Business Ideas

- Grow Your Business

- Online Business

- Internet Marketing

- Use Of Cookie

Starting a Food Truck Business in New Zealand – Procedure, Permits…

Starting a new business abroad: is it worth it, starting a pool cleaning business – profitable business plan sample, 15 profitable business ideas & opportunities in south africa for 2024, the most profitable food franchise for sale to invest in, 10 situations when your business should consult an employment attorney, top tips for success as a new e-commerce firm, partnering with an amazon fba prep centre: what to look for…, bolstering every aspect of your digital presence, 8 ways plastic injection molding is transforming industries , the business of smiles: how dentistry meets entrepreneurship, peter’s success: navigating nyc’s vacation rental business legally, how artificial intelligence is changing appraisal management and how to adapt, starting a small business in australia – an overview, five aspects of the business landscape to consider, 5 new online business trends for 2024, andrew’s inspiring blogging success: from passion to prosperity, 5 ways to make money from home right now, success in e-book publishing business: a journey from dream to reality, secret tips on selecting a niche for blogging and affiliate marketing, seo tactics tailored for the hospitality industry, marketing the unique: strategies for promoting boutique hotels in a competitive…, 4 ways to optimize underperforming email campaigns, how to create product descriptions that convert, the power of establishing trust through e-commerce website design, paper plate making business plan & profit margin in india.

In the realm of small-scale entrepreneurship, the paper plate making business in India has emerged as a lucrative opportunity. This narrative delves into the inspiring story of Prasad, who transformed this idea into a successful business reality. His journey is not just a tale of business acumen but also a guide for aspiring entrepreneurs, particularly highlighting the paper plate business profit margin.

This article, infused with Prasad’s insights, aims to guide aspiring entrepreneurs on how to start a paper plate making business and understand the paper plate business profit margin.

The Initial Steps

Raw material and investment.

Prasad began with an understanding of the foundational needs of this business. He calculated that the monthly requirement of raw materials would cost around 5,00,000 INR, comprising essential items like bottom reel, printed PE paper, and packing material. He then invested in automatic machinery, which cost about 8,50,000 INR, and dyes priced at 1,50,000 INR. This initial investment was critical in establishing his paper plate making business.

The Manufacturing Process Unveiled

Prasad shares his insights into the manufacturing process, broken down into simple steps for easy understanding:

- Material Preparation : He started by selecting the right dies for different shapes and sizes, ensuring the paper and polythene sheets were pre-cut to the desired dimensions.

- Die Setup and Heating : Each selected die was mounted on the press and heated to the appropriate temperature.

- Layering and Molding : Carefully placing the paper and polythene layers between the die parts, Prasad applied pressure to mold the product into its shape.

- Extraction and Resetting : Post-molding, each product was removed, and the machine was reset for the next batch.

- Finishing Touches : The bulk of products underwent trimming and detailing to achieve the final desired appearance.

- Packing and Dispatch : The final step involved packaging the plates in sets and dispatching them for sale.

Prasad’s unit boasted a production capacity of 30,000 to 40,000 plates per day, running two shifts for about 300 days annually.

Crafting the Blueprint of Success

The roadmap to success.

- In-Depth Market Analysis : Prasad began by researching the demand for paper plates in various markets.

- Strategic Financial Planning : He allocated a budget for raw materials, machinery, and operational expenses.

- Machinery Acquisition : Investing in efficient machinery was a priority for long-term business sustainability.

- Securing Quality Raw Materials : Establishing reliable supplier relationships was crucial for consistent quality.

- Location and Setup : Prasad chose an accessible location for his unit, adhering to all business regulations.

- Streamlining Production : He focused on efficient manufacturing processes for optimal output.

- Ensuring Quality Standards : Quality control was paramount to maintain product standards.

- Effective Marketing Strategies : Prasad developed innovative marketing tactics to reach potential clients.

- Building a Distribution Network : A robust distribution network ensured timely delivery of products.

- Financial Oversight : Careful monitoring of expenses and revenues helped understand the paper plate business profit margin.

Marketing Paper Plate Business

How to market paper plate business

- Develop a Business Plan : Before starting your paper plate business, create a plan that outlines your goals, products, services, budget and target market. It should also estimate your projected expenses and revenue.

- Design a Logo and Website : Create a logo and website to market your paper plate business. Make sure your logo is memorable and get the word out by giving away free promotional items with your logo.

- Networking : Attend local networking events to meet potential customers. Make sure you have plenty of business cards and literature ready to hand out.

- Targeted Advertising : Identify your target market and decide the best way to reach out to it. This might include advertising in specialized publications, distributing fliers and tap into social media accounts.

- Bulk Selling : Start out by offering lower priced items such as paper plates for bulk packages. Reach out to caterers, wedding planners and supermarkets who may need supplies.

- Promotions : Offer discounts and promotions to promote your paper plates. You can also create contests to encourage people to buy more plates.

- Follow up : Make sure you follow up with customers after they make a purchase. Send thank you emails or special offers to reward them for their loyalty.

Prospects and Scope of Paper Plate Business

The untapped potential.

Understanding the prospects and scope of the paper plate business is crucial. In India, the increasing demand for eco-friendly and convenient tableware drives the market. Factors contributing to this growth include:

- Environmental Awareness : Shift towards sustainable products.

- Urbanization and Lifestyle Changes : Greater need for disposable tableware in urban areas.

- Catering to Diverse Markets : From local eateries to large events, the demand spans a wide range.

Prasad’s venture thrived by tapping into these market dynamics. He emphasizes that the paper plate business profit margin is attractive due to low production costs and high demand.

Prasad’s success in the paper plate making business exemplifies the vast potential in this sector. His story is an inspiration, demonstrating how strategic planning, understanding the market, and commitment can lead to a prosperous business. The paper plate making business in India, with its growing demand and environmental appeal, offers a fertile ground for entrepreneurs, and Prasad’s journey is a testament to this lucrative opportunity.

RELATED ARTICLES MORE FROM AUTHOR

Starting a food truck business in new zealand – procedure, permits & license, achieving diversity in the tech workspace.

I want to start the work of make disposal plates, cup, etc

I want to paper cap, plates etc….

hi can i meet u .

Can u give more details regarding making paper plates etc.

Did you start paper plates business

yes iam Start paper plates business

dear sir, i want to start the buisness of paper plate making so tell me do’s and dont do’s

Sir I want to start paper plates and disposal glass plz tell me how can I get raw materials and machinery

I can help you , I have this business.

I want to start this business

i want to start this business at my home can this posible if it is so how can i do that, can you reply me on my mail id i need your assistance . my mail id is [email protected]

Hello Micky can I get your number.

Dona. 4″ paper plate

sir, we intend to start the manufacturing venture on disposable articles- all type of raw material , all the range. can you help us project report, profitability, machines, raw material etc.

Plz give me ur no

Sir how much profit u gain

How much profit can get

I wish to start this business in my home .But I have not so much capital..Can u assist me please…My mail id is mentioned below [email protected]

hi micky can u give me ur no or email [email protected] i want to talk to u.

call me Mohtaran my number 9943005774 i like to start

i also want your mobile no for more information about the business ….

Hi cal me i want to start bussines 8699028497

I went start paper business at my home so plz help ma sir

Hello Micky

Hello Micky I want to start this. Give me ideas and brief knowledge of this .

I want to start this business, Please provide your number. my number is 9999901385.

Sir ,can you tell me what is the cost of row materials and machine?? And how many plates can be manufacture from 1 kg of row material??.. sir plz give me any rply

dear sir.I’m interesting in paper cup. but i think the machine price is way too high. I am a designer and educated person but please give ideas about eco freindly, quality, marketing and profit detail.

Thanks. P.D.Could you tell me if i can start with hand made cup and then switch for a machine

dear sir, i want to start this type business and how i can arrange finance for this business . I am a technical educated person but please give ideas about marketing and profit detail.

I want to start paper plate making business, pls help me wr can I get raw materials and also suppliers.

you can get raw materials an machine. to know details call +917337404789

hi pratyush myself Piyush after done with my master from azim premji university I am working with NGO in MP named sps ( samaj pragati sahyog ) in different livelihood activities through more than 2000 SHG. as have been working with more than 100 SHG ( self help.group all the members are women) want to intervane some livelihood interventation like that if possible inform me in more basic detail regarding this. on my mail [email protected]

hi,Mr Pratyush …

what time you are free i want talk to you regarding this business.

Sir What is the cost of machine and row materials per kg??

Sir I want to start paper plates and disposal glass plz tell me how can I get raw materials and machinery and (+) points and (-) points details tell me sir

Sir i want to start paper plate bussiness pl tell me how can i get raw material& machinery ,how much selling.and positive& negetive point plz details tell me sir