What is Cost Assignment?

Share This...

Cost assignment.

Cost assignment is the process of associating costs with cost objects, such as products, services, departments, or projects. It encompasses the identification, measurement, and allocation of both direct and indirect costs to ensure a comprehensive understanding of the resources consumed by various cost objects within an organization. Cost assignment is a crucial aspect of cost accounting and management accounting, as it helps organizations make informed decisions about pricing, resource allocation, budgeting, and performance evaluation.

There are two main components of cost assignment:

- Direct cost assignment: Direct costs are those costs that can be specifically traced or identified with a particular cost object. Examples of direct costs include direct materials, such as raw materials used in manufacturing a product, and direct labor, such as the wages paid to workers directly involved in producing a product or providing a service. Direct cost assignment involves linking these costs directly to the relevant cost objects, typically through invoices, timesheets, or other documentation.

- Indirect cost assignment (Cost allocation): Indirect costs, also known as overhead or shared costs, are those costs that cannot be directly traced to a specific cost object or are not economically feasible to trace directly. Examples of indirect costs include rent, utilities, depreciation, insurance, and administrative expenses. Since indirect costs cannot be assigned directly to cost objects, organizations use various cost allocation methods to distribute these costs in a systematic and rational manner. Some common cost allocation methods include direct allocation, step-down allocation, reciprocal allocation, and activity-based costing (ABC).

In summary, cost assignment is the process of associating both direct and indirect costs with cost objects, such as products, services, departments, or projects. It plays a critical role in cost accounting and management accounting by providing organizations with the necessary information to make informed decisions about pricing, resource allocation, budgeting, and performance evaluation.

Example of Cost Assignment

Let’s consider an example of cost assignment at a bakery called “BreadHeaven” that produces two types of bread: white bread and whole wheat bread.

BreadHeaven incurs various direct and indirect costs to produce the bread. Here’s how the company would assign these costs to the two types of bread:

- Direct cost assignment:

Direct costs can be specifically traced to each type of bread. In this case, the direct costs include:

- Direct materials: BreadHeaven purchases flour, yeast, salt, and other ingredients required to make the bread. The cost of these ingredients can be directly traced to each type of bread.

- Direct labor: BreadHeaven employs bakers who are directly involved in making the bread. The wages paid to these bakers can be directly traced to each type of bread based on the time spent working on each bread type.

For example, if BreadHeaven spent $2,000 on direct materials and $1,500 on direct labor for white bread, and $3,000 on direct materials and $2,500 on direct labor for whole wheat bread, these costs would be directly assigned to each bread type.

- Indirect cost assignment (Cost allocation):

Indirect costs, such as rent, utilities, equipment maintenance, and administrative expenses, cannot be directly traced to each type of bread. BreadHeaven uses a cost allocation method to assign these costs to the two types of bread.

Suppose the total indirect costs for the month are $6,000. BreadHeaven decides to use the number of loaves produced as the allocation base , as it believes that indirect costs are driven by the production volume. During the month, the bakery produces 3,000 loaves of white bread and 2,000 loaves of whole wheat bread, totaling 5,000 loaves.

The allocation rate per loaf is:

Allocation Rate = Total Indirect Costs / Total Loaves Allocation Rate = $6,000 / 5,000 loaves = $1.20 per loaf

BreadHeaven allocates the indirect costs to each type of bread using the allocation rate and the number of loaves produced:

- White bread: 3,000 loaves × $1.20 per loaf = $3,600

- Whole wheat bread: 2,000 loaves × $1.20 per loaf = $2,400

After completing the cost assignment, BreadHeaven can determine the total costs for each type of bread:

- White bread: $2,000 (direct materials) + $1,500 (direct labor) + $3,600 (indirect costs) = $7,100

- Whole wheat bread: $3,000 (direct materials) + $2,500 (direct labor) + $2,400 (indirect costs) = $7,900

By assigning both direct and indirect costs to each type of bread, BreadHeaven gains a better understanding of the full cost of producing each bread type, which can inform pricing decisions, resource allocation, and performance evaluation.

Other Posts You'll Like...

Where Do Interest and Dividends Go on the Statement of Cash Flows?

REG CPA Practice Questions Explained: How to Deduct Real Estate and Other Taxes

What Are the Required Disclosures for the Statement of Cash Flows?

Are Non-Cash Transactions on the Statement of Cash Flows?

Indirect vs Direct Method of Statement of Cash Flows

What’s the Purpose of the Statement of Cash Flows?

Helpful links.

- Learn to Study "Strategically"

- How to Pass a Failed CPA Exam

- Samples of SFCPA Study Tools

- SuperfastCPA Podcast

Helicopter Pilot to CPA: How Chase Passed His CPA Exams

How Josh Passed His CPA Exams Using Shorter Study Sessions

The Changes That Helped Marc Pass His CPA Exams After Failing 6 Times

The CPA Study Tweaks Gabi Used to Pass Her CPA Exams

How Skylar Went From a Psychology Major to Becoming a CPA

How Dalton Is Passing Exams by Making His CPA Study a Lifestyle

Want to pass as fast as possible, ( and avoid failing sections ), watch one of our free "study hacks" trainings for a free walkthrough of the superfastcpa study methods that have helped so many candidates pass their sections faster and avoid failing scores....

Make Your Study Process Easier and more effective with SuperfastCPA

Take Your CPA Exams with Confidence

- Free "Study Hacks" Training

- SuperfastCPA PRO Course

- SuperfastCPA Review Notes

- SuperfastCPA Audio Notes

- SuperfastCPA Quizzes

Get Started

- Free "Study Hacks Training"

- Read Reviews of SuperfastCPA

- Busy Candidate's Guide to Passing

- Subscribe to the Podcast

- Purchase Now

- Nate's Story

- Interviews with SFCPA Customers

- Our Study Methods

- SuperfastCPA Reviews

- CPA Score Release Dates

- The "Best" CPA Review Course

- Do You Really Need the CPA License?

- 7 Habits of Successful Candidates

- "Deep Work" & CPA Study

- Cost Classifications

- Relevant Cost of Material

- Manufacturing Overhead Costs

- Conversion Costs

- Quality Costs

- Revenue Expenditure

- Product Cost vs Period Cost

- Direct Costs and Indirect Costs

- Prime Costs and Conversion Costs

- Relevant vs Irrelevant Costs

- Avoidable and Unavoidable Costs

- Cost Allocation

- Joint Products

- Accounting for Joint Costs

- Service Department Cost Allocation

- Repeated Distribution Method

- Simultaneous Equation Method

- Specific Order of Closing Method

- Direct Allocation Method

Cost allocation is the process by which the indirect costs are distributed among different cost objects such as a project, a department, a branch, a customer, etc. It involves identifying the cost object, identifying and accumulating the costs that are incurred and assigning them to the cost object on some reasonable basis.

Cost allocation is important for both pricing and planning and control decisions. If costs are not accurately calculated, a business might never know which products are making money and which ones are losing money. If cost are mis-allocated, a business may be charging wrong price to its customers and/or it might be wasting resources on products that are wrongly categorized as profitable.

Cost allocation is a sub-process of cost assignment , which is the overall process of finding total cost of a cost object. Cost assignment involves both cost tracing and cost allocation. Cost tracing encompasses finding direct costs of a cost object while the cost allocation is concerned with indirect cost charge.

Steps in cost allocation process

Typical cost allocation mechanism involves:

- Identifying the object to which the costs have to be assigned,

- Accumulating the costs in different pools,

- Identifying the most appropriate basis/method for allocating the cost.

Cost object

A cost object is an item for which a business need to separately estimate cost.

Examples of cost object include a branch, a product line, a service line, a customer, a department, a brand, a project, etc.

A cost pool is the account head in which costs are accumulated for further assignment to cost objects.

Examples of cost pools include factory rent, insurance, machine maintenance cost, factory fuel, etc. Selection of cost pool depends on the cost allocation base used. For example if a company uses just one allocation base say direct labor hours, it might use a broad cost pool such as fixed manufacturing overheads. However, if it uses more specific cost allocation bases, for example labor hours, machine hours, etc. it might define narrower cost pools.

Cost driver

A cost driver is any variable that ‘drives’ some cost. If increase or decrease in a variable causes an increase or decrease is a cost that variable is a cost driver for that cost.

Examples of cost driver include:

- Number of payments processed can be a good cost driver for salaries of Accounts Payable section of accounting department,

- Number of purchase orders can be a good cost driver for cost of purchasing department,

- Number of invoices sent can be a good cost driver for cost of billing department,

- Number of units shipped can be a good cost driver for cost of distribution department, etc.

While direct costs are easily traced to cost objects, indirect costs are allocated using some systematic approach.

Cost allocation base

Cost allocation base is the variable that is used for allocating/assigning costs in different cost pools to different cost objects. A good cost allocation base is something which is an appropriate cost driver for a particular cost pool.

T2F is a university café owned an operated by a student. While it has plans for expansion it currently offers two products: (a) tea & coffee and (b) shakes. It employs 2 people: Mr. A, who looks after tea & coffee and Mr. B who prepares and serves shakes & desserts.

Its costs for the first quarter are as follows:

Total tea and coffee sales and shakes sales were $50,000 & $60,000 respectively. Number of customers who ordered tea or coffee were 10,000 while those ordering shakes were 8,000.

The owner is interested in finding out which product performed better.

Salaries of Mr. A & B and direct materials consumed are direct costs which do not need any allocation. They are traced directly to the products. The rest of the costs are indirect costs and need some basis for allocation.

Cost objects in this situation are the products: hot beverages (i.e. tea & coffee) & shakes. Cost pools include rent, electricity, music, internet and wi-fi subscription and magazines.

Appropriate cost drivers for the indirect costs are as follows:

Since number of customers is a good cost driver for almost all the costs, the costs can be accumulated together to form one cost pool called manufacturing overheads. This would simply the cost allocation.

Total manufacturing overheads for the first quarter are $19,700. Total number of customers who ordered either product are 18,000. This gives us a cost allocation base of $1.1 per customer ($19,700/18,000).

A detailed cost assignment is as follows:

Manufacturing overheads allocated to Tea & Cofee = $1.1×10,000

Manufacturing overheads allocated to Shakes = $1.1×8,000

by Irfanullah Jan, ACCA and last modified on Jul 22, 2020

Related Topics

- Cost Behavior

All Chapters in Accounting

- Intl. Financial Reporting Standards

- Introduction

- Accounting Principles

- Business Combinations

- Accounting Cycle

- Financial Statements

- Non-Current Assets

- Fixed Assets

- Investments

- Revenue Recognition

- Current Assets

- Receivables

- Inventories

- Shareholders' Equity

- Liability Accounts

- Accounting for Taxes

- Employee Benefits

- Accounting for Partnerships

- Financial Ratios

- Cost Accounting Systems

- CVP Analysis

- Relevant Costing

- Capital Budgeting

- Master Budget

- Inventory Management

- Cash Management

- Standard Costing

Current Chapter

XPLAIND.com is a free educational website; of students, by students, and for students. You are welcome to learn a range of topics from accounting, economics, finance and more. We hope you like the work that has been done, and if you have any suggestions, your feedback is highly valuable. Let's connect!

Copyright © 2010-2024 XPLAIND.com

Our Recommendations

- Best Small Business Loans for 2024

- Businessloans.com Review

- Biz2Credit Review

- SBG Funding Review

- Rapid Finance Review

- 26 Great Business Ideas for Entrepreneurs

- Startup Costs: How Much Cash Will You Need?

- How to Get a Bank Loan for Your Small Business

- Articles of Incorporation: What New Business Owners Should Know

- How to Choose the Best Legal Structure for Your Business

Small Business Resources

- Business Ideas

- Business Plans

- Startup Basics

- Startup Funding

- Franchising

- Success Stories

- Entrepreneurs

- The Best Credit Card Processors of 2024

- Clover Credit Card Processing Review

- Merchant One Review

- Stax Review

- How to Conduct a Market Analysis for Your Business

- Local Marketing Strategies for Success

- Tips for Hiring a Marketing Company

- Benefits of CRM Systems

- 10 Employee Recruitment Strategies for Success

- Sales & Marketing

- Social Media

- Best Business Phone Systems of 2024

- The Best PEOs of 2024

- RingCentral Review

- Nextiva Review

- Ooma Review

- Guide to Developing a Training Program for New Employees

- How Does 401(k) Matching Work for Employers?

- Why You Need to Create a Fantastic Workplace Culture

- 16 Cool Job Perks That Keep Employees Happy

- 7 Project Management Styles

- Women in Business

- Personal Growth

- Best Accounting Software and Invoice Generators of 2024

- Best Payroll Services for 2024

- Best POS Systems for 2024

- Best CRM Software of 2024

- Best Call Centers and Answering Services for Busineses for 2024

- Salesforce vs. HubSpot: Which CRM Is Right for Your Business?

- Rippling vs Gusto: An In-Depth Comparison

- RingCentral vs. Ooma Comparison

- Choosing a Business Phone System: A Buyer’s Guide

- Equipment Leasing: A Guide for Business Owners

- HR Solutions

- Financial Solutions

- Marketing Solutions

- Security Solutions

- Retail Solutions

- SMB Solutions

Online only.

What Is Cost Allocation?

Table of Contents

For your business to make money, you must charge prices that not only cover your expenses, but also provide a profit. Cost allocation is the process of identifying and assigning costs to the cost objects in your business, such as products, a project, or even an entire department or individual company branch.

While a detailed cost allocation report may not be vital for extremely small businesses, such as a teen’s lawn service, more complex businesses require the process of cost allocation to ensure profitability and productivity.

In short, if you can assign a cost to any part of your business, it’s considered a cost object.

What is cost allocation?

Cost allocation is the method business owners use to calculate profitability for the purpose of financial reporting . To ensure the business’s finances are on track, costs are separated, or allocated, into different categories based on the area of the business they impact.

For instance, cost allocation for a small clothing boutique would include the costs of materials, shipping and marketing. Calculating these costs consistently would help the store owner ensure that profits from sales are higher than the costs of owning and running the store. If not, the owner could easily pinpoint where to raise prices or cut expenses .

For a larger company, this process would be applied to each department or individual location. Many companies use cost allocation to determine which areas receive bonuses annually.

Regardless of your business size, you’ll want to review and choose the best accounting software to help this process run as smoothly as possible.

Types of costs

In the boutique example above, the process of cost allocation is pretty simple. For larger businesses, however, many more costs are involved. These costs break down into seven categories.

- Direct costs: These expenses are directly related to a product or service. In your business’s financial statements, these costs can be linked to items sold. For a small clothing store, this might include the cost of inventory.

- Direct labor: This cost category includes expenses directly related to the employee production of items or services your business sells. Direct labor costs include payroll for employees involved in making the items your business sells.

- Direct materials: As the name suggests, this category includes costs related to the resources used to manufacture a finished product. Direct materials include fabric to make clothing, or the glass used in building tables.

- Indirect costs: These expenses are not directly related to a product or service, but necessary to create the product or service. Indirect costs include payroll for those who work in operations. It also lists costs for materials you use in such small quantities that their costs are easy to overlook.

- Manufacturing overhead: This category includes warehouse costs, and any other expenses directly related to manufacturing the products sold. Manufacturing overhead costs include payroll for warehouse managers, as well as warehouse expenses such as rent and utilities.

- Overhead costs: These include expenses that support the company as a whole but are not directly related to production. Some examples of overhead costs are marketing, operations and utilities for a storefront.

- Product costs: Also called “manufacturing costs” or “total costs,” this category includes expenses for making or acquiring the product you sell. All manufacturing overhead costs are also listed in this category.

Example of cost allocation

To better explain the process of cost allocation and why it’s necessary for businesses, let’s look at an example.

Dave owns a business that manufactures eyeglasses. In January, Dave’s overhead costs totaled $5,000. In the same month, he produced 3,000 eyeglasses with $2 in direct labor per product. Direct materials for each pair of eyeglasses totaled $5.

Here’s what cost allocation would look like for Dave:

Overhead: $5,000 ÷ $3,000 = $1.66 per pair

Direct costs:

- Direct materials: $5 per pair

- Direct labor: $2 per pair

- Overhead: $1.66 per pair

- Total cost: $8.66 per pair

As you can see, without cost allocation, Dave would not have made a profit from his sales. Larger companies would apply this same process to each department and product to ensure sufficient sales goals. [Read related article: How to Set Achievable Business Goals ]

How to allocate costs

Cost objects vary by business type. The cost allocation process, however, consists of the same steps regardless of what your company produces.

1. Identify cost objects.

To begin allocating costs, you’ll need to list the cost objects of your business. Remember that anything within your business that generates an expense is a cost object. Review each product line, project and department to ensure you’ve gathered all cost objects.

2. Create a cost pool.

Next, gather a detailed list of all business costs. It’s a good idea to categorize the costs based on the reason for each amount. Categories should cover utilities, insurance , square footage and any other expenses your business incurs.

3. Allocate costs.

Now that you’ve listed cost objects and created a cost pool, you’re ready to allocate costs. As demonstrated in the example above, add up the costs of each cost object. At a glance, your report should justify all expenses related to your business. If costs don’t add up correctly, use the list to determine where you can make adjustments to get back on track.

What is cost allocation used for?

Cost allocation is used for many reasons, both externally and internally. Reports created by this process are great resources for making business decisions , monitoring productivity and justifying expenses.

External reports are usually calculated based on generally accepted accounting principles (GAAP) . Under GAAP, expenses can only be reported in financial statements during the time period the associated revenue is earned. For this reason, overhead costs are divided and allocated to individual inventory items. When the inventory is sold, the overhead is expensed as a portion of the cost of goods sold (COGS) .

Internal financial data, on the other hand, is usually reported using activity-based costing (ABC). This method assigns all products to the overhead expenses they caused. This process may not include all overhead costs related to operations and manufacturing.

Cost allocation reports show which cost objects incur the most expenses for your business and which products or departments are most profitable. These findings can be a great resource to pair with employee monitoring software when evaluating productivity. If you determine that a cost object is not as profitable as it should be, you should do further evaluations on productivity. If another cost object is found to exceed expectations, you can use the report to find staff members who deserve recognition for their contributions to the company.

Recognition is one of the best ways to keep employees motivated .

What is a cost driver?

A cost driver is a variable that can change the costs related to a business activity. The number of invoices issued, the number of employee hours worked, and the total of purchase orders are all examples of cost drivers in cost accounting .

While cost objects are related to the specific process or product incurring the costs, a cost driver sheds light on the reason for the incurred cost amounts. These items can take different forms – including fixed costs, such as the initial fees during the startup phase . Cost drivers give a bird’s-eye view of the entire company and how each department operates.

It’s common for only one cost driver to be used with very small businesses , since they are focused on using minimal reporting to estimate overhead costs.

Benefits of cost allocation

- It simplifies decision-making. Cost allocation gives you a detailed overview of how your business expenses are used. From this perspective, you can determine which products and services are profitable, and which departments are most productive.

- It assists in staff evaluation. You can also use cost allocation to assess the performance of different departments. If a department is not profitable, the staff productivity may need improvement. Cost allocation can also be an indicator of departments that exceed expectations and deserve recognition. Awards and recognition are a great way to motivate staff and, in turn, increase productivity. [Read related article: Best Business Productivity Apps ]

Even if you operate a very small business, it’s a great idea to learn the process of cost allocation, especially if you anticipate expansion in the future. Since the method can be complex, it’s ideal to use accounting software as an aid. Whether you choose to start allocating costs on your own with software or hire a professional accountant , it’s a process no business owner can afford to overlook.

Building Better Businesses

Insights on business strategy and culture, right to your inbox. Part of the business.com network.

Workflow Solutions

FloQast Close

FloQast Reconciliation Management

FloQast Variance Analysis

FloQast Analyze

FloQast Compliance Management

FloQast Ops

FloQast ReMind

Finance and Accounting Operations Platform

Platform Overview

AI and Machine Learning

Scalability

Trust & Security

Integrations

FloVerse Community

FloQast Studios

FloQast Blog

Controller Manifesto

FloQademy - Join / Sign In

Charting the Future of Accounting eBook

Your next step: navigating the future amidst changes and challenges

Chief Accounting Officer

Accounting Manager

Compliance Manager

Internal Audit Manager

By Workflow

Financial Close

Account Reconciliations

Audit Findings

Controls and Risk Management

SOX Compliance

Audit Readiness

Oracle NetSuite

Sage Intacct

FloQast Connect API

By Platform

The IPO Playbook for Finance & Accounting Teams

An at-a-glance guide to going public

Success Stories

Video Testimonials

PulteGroup Constructs Faster Close and Team Productivity with FloQast

Learn how FloQast helped PulteGroup reduce paper consumption, speed up its monthly Close, and streamline compliance reporting.

Closing Collaboration in a Multinational Accounting Team: How Emma Improved Team Collaboration and Internal Controls Together with FloQast

Emma's 70-person geographically distributed accounting team improved internal controls and streamlined the audit thanks to FloQast.

Qualys Modernizes SOX Compliance and Improves the Annual Audit with FloQast

Read how in just a matter of weeks, Qualys leveraged FloQast to standardize the close process and organize controls and documentation for a more simplified SOX compliance.

Partner Program

Become a Partner

Take Your Business to the Next Level

FloQast’s suite of easy-to-use and quick-to-deploy solutions enhance the way accounting teams already work. Learn how a FloQast partnership will further enhance the value you provide to your clients.

All Resources

Checklists & Templates

Customer Video Testimonials

Whitepapers

Customer Success Stories

Month-End Close Checklist

SOX RCM Template

Leverage best practices to build a SOX RCM that focuses on what’s most important for SOX compliance.

Customer Success Management

Customer Success

Global Community

Request Support

Earn Free CPE with FloQademy

FloQademy, FloQast’s learning portal, provides over 100+ hours of free CPE, on-demand, 24/7, and is open to everyone.

The FloQast Advantage

Initiatives

Diversity, Inclusion, & Community

Contact FloQast

Get In Touch

FloQast raises $100M at a $1.6B valuation

The Series E round was led by ICONIQ Growth to supercharge FloQast's global expansion and Innovation with Artificial Intelligence.

What is Cost Allocation? Definition & Process

Jul 16, 2020 Michael Whitmire

Working with the former accountants now working at FloQast, we decided to take a look at some of the pillars of the accounting professions.

The key to running a profitable enterprise of any kind is making sure that your prices are high enough to cover all your costs — and leave at least a bit for profit. For a really simple business — like the proverbial lemonade stand that almost every kid ran — that’s pretty simple. Your costs are what you (or your parents) paid for lemons and sugar. But what if it’s a more complex business? Then you might need to brush up on cost accounting, and learn about allocation accounting . Let’s walk through this using the hypothetical company, Lisa’s Luscious Lemonade.

What is cost allocation ?

The cost allocation definition is best described as the process of assigning costs to the things that benefit from those costs or to cost centers . For Lisa’s Luscious Lemonade, a cost center can be as granular as each jug of lemonade that’s produced, or as broad as the manufacturing plant in Houston.

Let’s assume that the owner, Lisa, needs to know the cost of a jug of lemonade. The total cost to create that jug of lemonade isn’t just the costs of the water, lemons, sugar and the jug itself, but also includes all the allocated costs to make it.

Let’s start by defining some terms…

Direct costs are costs that can be traced directly to the product or service itself. For manufacturers, these consist of direct materials and direct labor. They appear in the financial statements as part of the cost of goods sold .

Direct materials are those that become an integral part of the finished product. This will be the costs of the water, sugar, lemons, the plastic jug, and the label.

Direct labor includes the labor costs that can be easily traced to the production of those finished products. Direct labor for that jug will be the payroll for the workers on the production line.

Indirect costs are the costs that can’t be easily traced to a product or service but are clearly required for making whatever an enterprise sells. This includes materials that are used in such insignificant quantities that it’s not worth tracing them to finished products, and labor for employees who work in the factory, but not on the production line.

Overhead costs encompass all the costs that support the enterprise that can’t be directly linked to making the items that are sold. This includes indirect costs , as well as selling, marketing, administration, and facility costs.

Manufacturing overhead includes the overhead costs that are directly related to making the products for sale. This includes the electricity, rent, and utilities for the factory and salaries of supervisors on the factory floor.

Product costs are all the costs in making or acquiring the product for sale. These are also known as manufacturing costs or total costs . This includes direct labor, direct materials, and allocated manufacturing overhead.

What is the process?

The first step in any cost allocation system is to identify the cost objects to which costs need to be allocated. Here, our cost objec t is a jug of lemonade. For a more complex organization, the cost object could be a product line, a department, or a branch.

Direct costs are the simplest to allocate. Last month, Lisa’s Luscious Lemonades produced 50,000 gallons of lemonade and had the following direct costs:

Total costs Cost per gallon Direct materials $142,500 $2.85 Direct labor $37,500 $.75

How are costs allocated?

Allocating overhead costs is a bit more complex. First, the overhead costs are split between manufacturing costs and non-manufacturing costs. Some of this is pretty straightforward: the factory floor supervisor’s salary is clearly a manufacturing cost, and the sales manager’s salary is a non-manufacturing cost. But what about the cost of human resources or other service departments that serve all parts of the organization? Or facilities costs, which might include the rent for the building, insurance, utilities, janitorial services, and general building maintenance?

Human resources and other services costs might be logically split based on the headcount of the manufacturing versus non-manufacturing parts of the business. Facilities costs might be split based on the square footage of the manufacturing space versus the administrative offices. Electricity usage might be allocated on the basis of square footage or machine hours , depending on the situation.

Let’s say that for Lisa’s Luscious Lemonades, after we split the overhead between manufacturing and non-manufacturing costs, we have the following annual manufacturing overhead costs :

Supervisor salary $84,000 Indirect costs $95,000 Facility costs $150,000 Human resources $54,000 Depreciation $65,000 Electricity $74,000 Total manufacturing overhead $522,000

In a perfect world, it would be possible to keep an accurate running total of all overhead costs so that management would have detailed and accurate cost information. However, in practice, a predetermined overhead rate is used to allocate overhead using an allocation base .

This overhead rate is determined by dividing the total estimated manufacturing overhead by the estimated total units in the allocation base . At the end of the year or quarter, the allocated costs are reconciled to actual costs.

Ideally, the allocation base should be a cost driver that causes those overhead costs . For manufacturers, direct labor hours or machine-hours are commonly used. Since Lisa only makes one product — gallon jugs of lemonade — the simplest cost driver is the number of jugs produced in a year.

If we estimate that 600,000 gallons of lemonade are produced in a year, then the overhead rate will be $522,000 / 600,000 = $.87 per gallon.

Our final cost to produce a gallon of Lisa’s Luscious Lemonade is as follows:

Direct materials $2.85 Direct labor $0.75 Manufacturing overhead $0.87 Total cost $4.47

What is cost allocation used for?

Cost allocation is used for both external reporting and internally for decision making. Under generally accepted accounting principles (GAAP), the matching principle requires that expenses be reported in the financial statements in the same period that the related revenue is earned.

This means that manufacturing overhead costs cannot be expensed in the period incurred, but must be allocated to inventory items, where those costs remain until the inventory is sold, when overhead is finally expensed as part of the cost of goods sold. For Lisa’s Luscious Lemonade, that means that every time a jug of lemonade is produced, another $4.47 goes into inventory. When a jug is sold, $4.47 goes to the cost of goods sold.

However, for internal decision-making, the cost allocation systems used for GAAP financials aren’t always helpful. Cost accountants often use activity-based costing , or ABC, in parallel with the cost allocation system used for external financial reporting .

In ABC, products are assigned all of the overhead costs that they can reasonably be assumed to have caused. This may include some — but not all — of the manufacturing overhead costs , as well as operating expenses that aren’t typically assigned to products under the costing systems used for GAAP.

AutoRec to keep you sane

Whatever cost accounting method you use, it’s going to require spreadsheets that you have to reconcile to the GL. Combine that with the other reconciliations you have to do to close out the books, and like Lisa’s controller, you might be ready to jump into a vat of lemonade to drown your sorrows.

Enter FloQast AutoRec. Rather than spend hours every month reconciling accounts, AutoRec leverages AI to match one-to-one, one-to-many, or many-to-many transactions in minutes. Simple set up means you can start using it in minutes because you don’t need to create or maintain rules. Try it out, and see how much time you can save this month.

Ready to find out more about how FloQast can help you tame the beast of the close?

Michael Whitmire

As CEO and Co-Founder, Mike leads FloQast’s corporate vision, strategy and execution. Prior to founding FloQast, he managed the accounting team at Cornerstone OnDemand, a SaaS company in Los Angeles. He began his career at Ernst & Young in Los Angeles where he performed public company audits, opening balance sheet audits, cash to GAAP restatements, compilation reviews, international reporting, merger and acquisition audits and SOX compliance testing. He holds a Bachelor’s degree in Accounting from Syracuse University.

Related Blog Articles

Report: Accountants Want Financial Transformation, but Lack of Fulfillment and Confidence Stand in the Way

Study: Compliance and Controls Processes Are Struggling

Report: Analyzing Accountants’ Relationship with Technology as Stressor in the Workplace – and at Home

404 Not found

- school Campus Bookshelves

- menu_book Bookshelves

- perm_media Learning Objects

- login Login

- how_to_reg Request Instructor Account

- hub Instructor Commons

- Download Page (PDF)

- Download Full Book (PDF)

- Periodic Table

- Physics Constants

- Scientific Calculator

- Reference & Cite

- Tools expand_more

- Readability

selected template will load here

This action is not available.

2.6: Process Costing (FIFO Method)

- Last updated

- Save as PDF

- Page ID 65679

Another acceptable method for determining unit cost under process costing is the first-in, first-out (FIFO) cost method. Under the FIFO method, we assume any units that were not completed last period (beginning work in process) are finished before anything else is started. The following table shows the differences between the weighted average method and the FIFO cost method:

We will look at each item individually as we discuss the steps of process costing. Under either method, weighted average or FIFO, process costing consists of 5 steps:

Physical Flow of Units

- Equivalent Units

Cost per Equivalent Unit

- Assign Costs to Units Completed and Ending Work in Process Inventory

Reconcile Costs

The physical flow of units is as follows under the weighted average method:

This is altered just slightly under the FIFO method as we must separate the items in units completed into Units Completed from beginning work in process and Units started and completed this period since under FIFO, we must finish anything from beginning work in process before we start something new. Under the FIFO, we the physical flow of units would be documented as:

Just as in the weighted average method, the 2 Total Units figures must agree!

Equivalent Units of Production

Under the FIFO method, we will calculate equivalent units for 3 things: Units completed from beginning work in process, units started and completed this period and units remaining in ending work in process. This video will discuss the differences between the Weighted Average and FIFO methods for equivalent units (if you are comfortable with the weighted average method, skip to minute 4:06 to begin the discussion on the FIFO method).

A YouTube element has been excluded from this version of the text. You can view it online here: http://pb.libretexts.org/ma/?p=78

Equivalent units for the period will be calculated as follows under FIFO ( keep in mind, you may have different percent complete for materials, labor and overhead ):

- Units from beginning work in process: you want to complete this units, so how much MORE effort will be needed to finish these units. You will calculate this as beginning work in process units x (100% – given % complete) to calculate the amount of additional work necessary to make the unit 100% complete.

- Units started and completed this period: take the units x 100% complete since they were started and completed they have received all of their materials, labor and overhead and will not receive any more since they are finished.

- Units in Ending work in process: just like with the weighted average method, we will take the ending work in process units x a given % complete.

To illustrate the computation of equivalent units under the FIFO method, assume the following facts (for simplicity we are using just one percent complete for materials, labor and overhead):

The physical flow of units would be (calculate units started and completed as units started 10,000 – units in ending work in process 5,000):

The equivalent production for the period would be:

Under the weighted average method, we use beginning work in process costs AND costs added this period. Under the FIFO method, we will only use the costs added this period. This video will explain the differences between the two approaches.

The formula we will use for calculating cost per equivalent unit under the FIFO Method is:

Assign Costs

When we assign costs to units completed and transferred and units remaining in ending work in process under the FIFO method, we need the following items:

- Costs from beginning work in process: these were the costs we started the period with or the unfinished items from the previous period ( no calculation required — just bring over the costs from beginning work in process ). Remember, under FIFO, these are finished first so their costs must be passed along to completed units.

- Costs to complete beginning work in process: you will take the Equivalent units calculated for completing beginning work in process x the cost per equivalent unit. You will do this for materials, labor and overhead (or for conversion costs which is the both direct labor and overhead).

- Costs of units started and completed: you will take the equivalent units calculated for units started and completed x the cost per equivalent unit for materials, labor and overhead (or conversion).

- The sum of these 3 will be the cost of units completed and transferred which is also known as cost of goods manufactured. This amount is transferred to the next department or to finished goods and out of work in process for the units completed this period.

- Cost of units remaining in ending work in process: you will take the ending work in process equivalent units x the cost per equivalent unit for materials, labor and overhead (or conversion) just as we did under the weighed average method. This amount rolls over to be the next period’s beginning work in process inventory.

This video will provide a demonstration of cost assignment under the FIFO method.

Finally, something is the same under FIFO and Weighted Average.

We want to make sure that we have assigned all the costs from beginning work in process and costs incurred or added this period to units completed and transferred and ending work in process inventory.

First, we need to know our total costs for the period (or total costs to account for) by adding beginning work in process costs to the costs incurred or added this period. Then, we compare the total to the cost assignment in step 4 for units completed and transferred and ending work in process to get total units accounted for. Both totals should agree.

The cost reconciliation would be:

In the next page, we will do a demonstration problem of the FIFO method for process costing.

Contributors and Attributions

- Equivalent Units. Authored by : Linda Williams. License : All Rights Reserved . License Terms : Standard YouTube License

- Cost Per Equivalent Unit-- FIFO Method vs. Weighted-average Method . Authored by : Education Unlocked. Located at : https://youtu.be/P_Nwchc_pcs . License : All Rights Reserved . License Terms : Standard YouTube License

- Cost Per Equivalent Unit, FIFO Method, Part 2 (Applying Costs) . Authored by : Education Unlocked. Located at : https://youtu.be/y1TLRSL9Yjo . License : All Rights Reserved . License Terms : Standard YouTube License

principlesofaccounting.com

Cost Allocation To Completed Units And Units In Process

- Goals Achievement

- Fill in the Blanks

- Multiple Choice

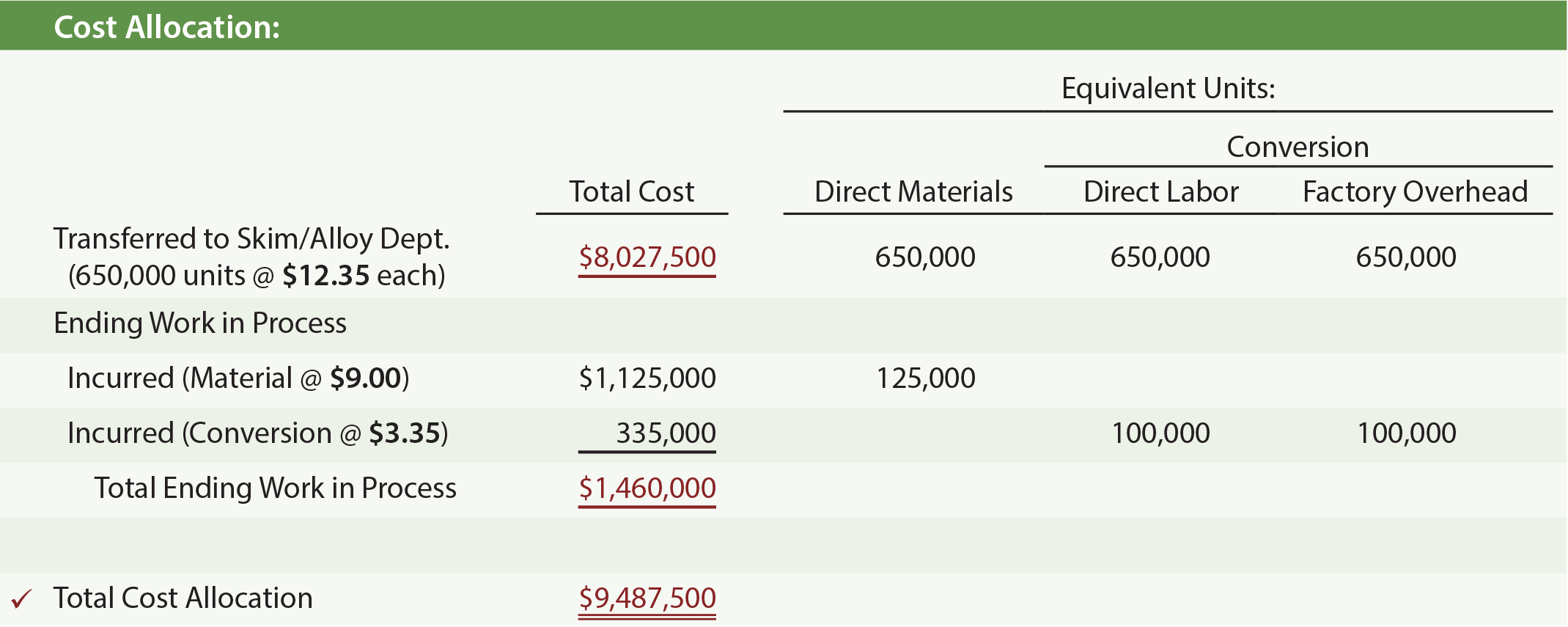

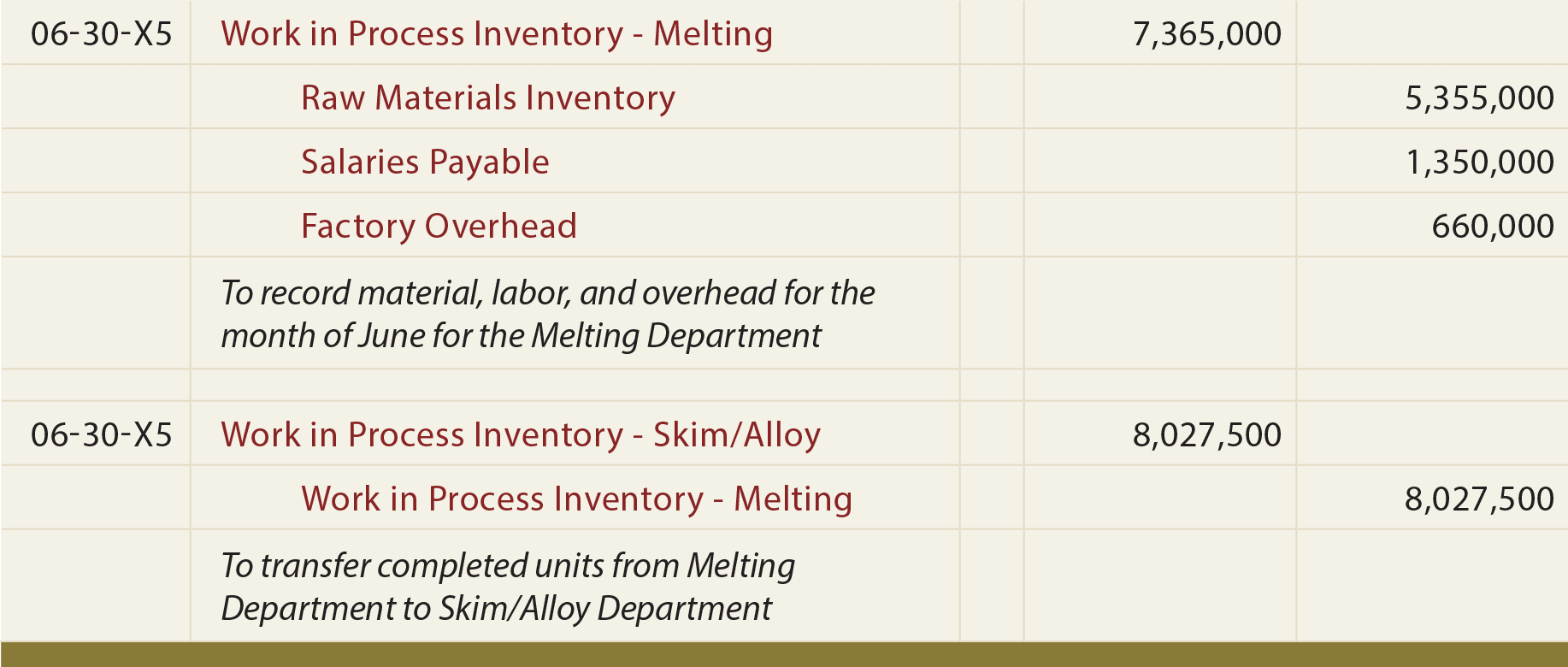

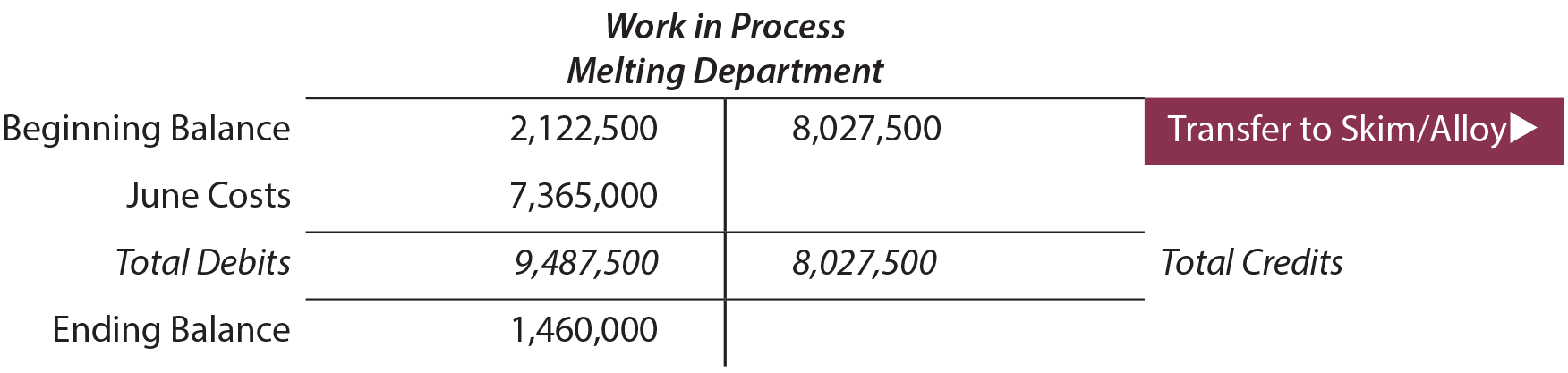

The cost per equivalent unit calculations are used to allocate cost incurred between a department’s completed production and the units in ending work in process. Carefully examine the following schedule to see that the cost assigned to completed units totals $8,027,500. The ending work in process is $1,460,000, determined as 125,000 equivalent units at $9.00 each, plus 100,000 equivalent units of conversion at $3.35 each.

Note that a check mark is placed beside the total cost allocation ($9,487,500 = $8,027,500 + $1,460,000) as a reminder that this schedule must allocate the entire cost incurred within the Melting Department.

Cost Of Production Report

The preceding schedules are combined into a single cost of production report as shown below. A similar report would be prepared for each department.

These reports are used for many management purposes, such as inventory control, efficiency studies, incentive pay plans, and the like. They also provide the basis for the following entries that are needed to update the ledger accounts for the inventory cost allocations.

Analysis of Cost Flow

The journal entries, along with the beginning work in process of $2,122,500, result in an ending work in process of $1,460,000.

The following T-account portrays the cost flow through the Work in Process account of the Melting Department:

Added Processes

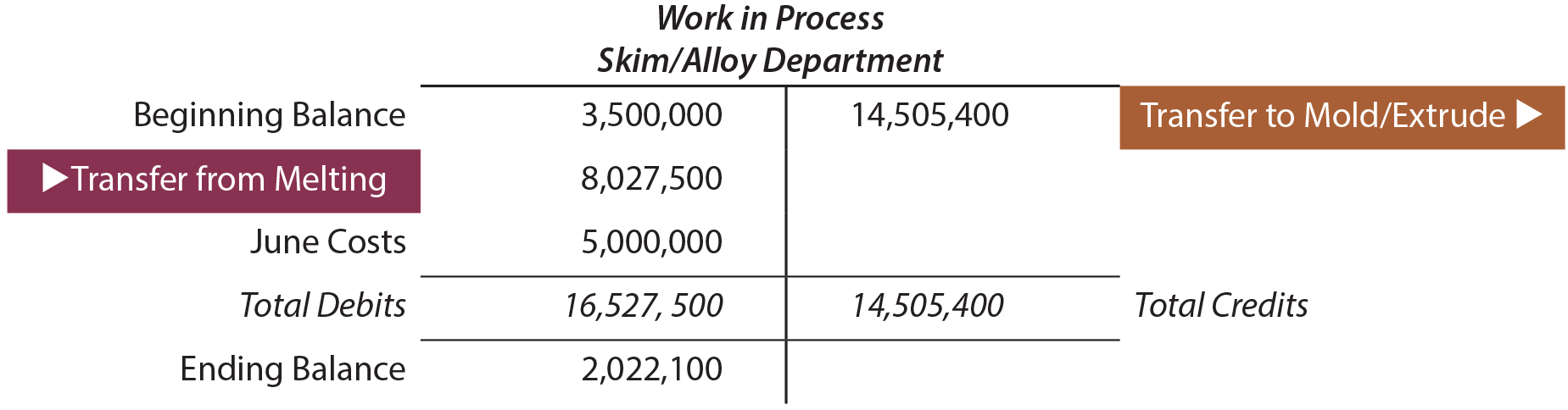

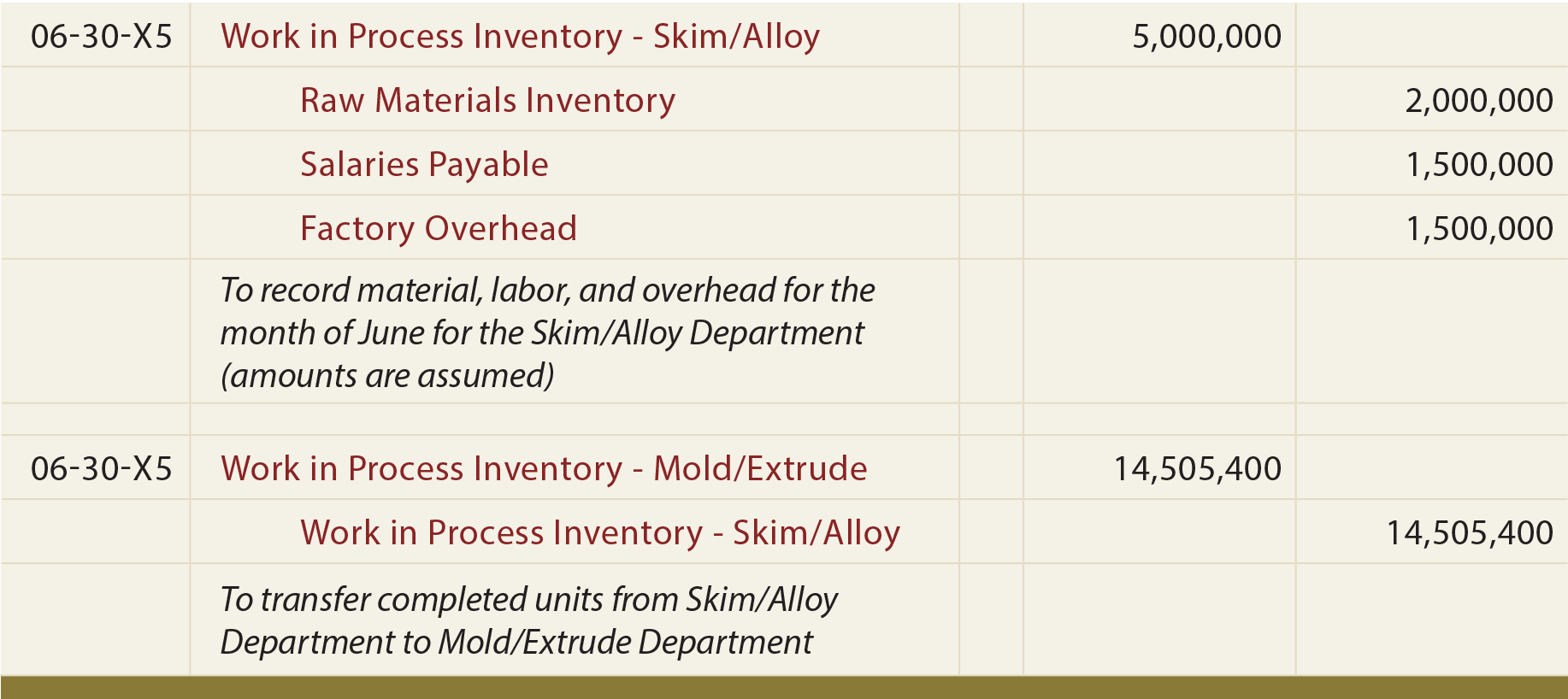

It is important to notice that the journal entry to transfer $8,027,500 out of the Melting Department (credit) is offset with an increase in the Work in Process of the Skim/Alloy Department (debit).

The Skim/Alloy Department’s T-account for June might look something like this (amounts are assumed):

The corresponding journal entries for the Skim/Alloy Department for June are as follows:

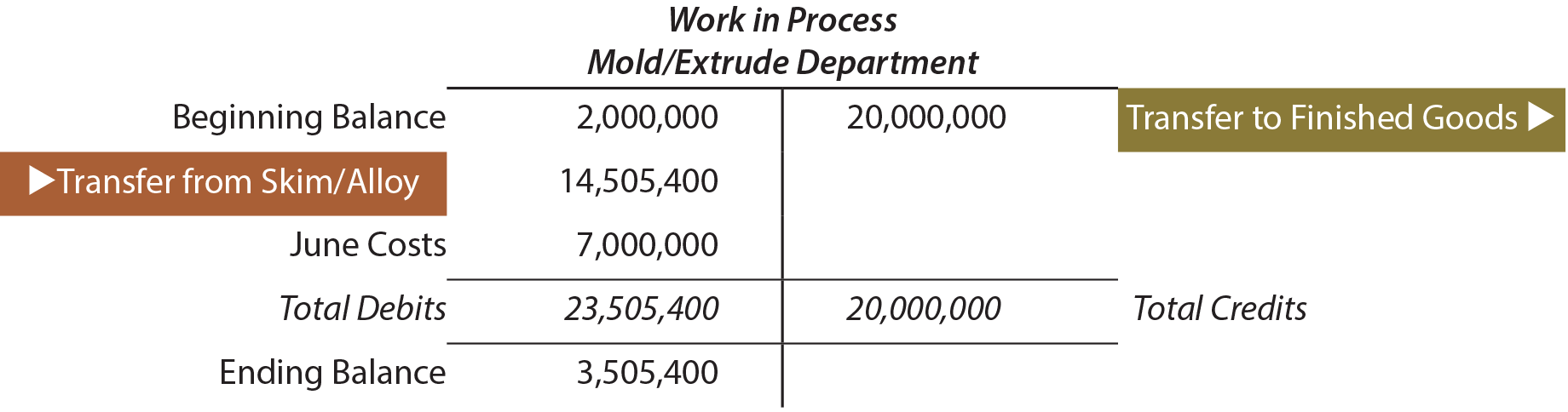

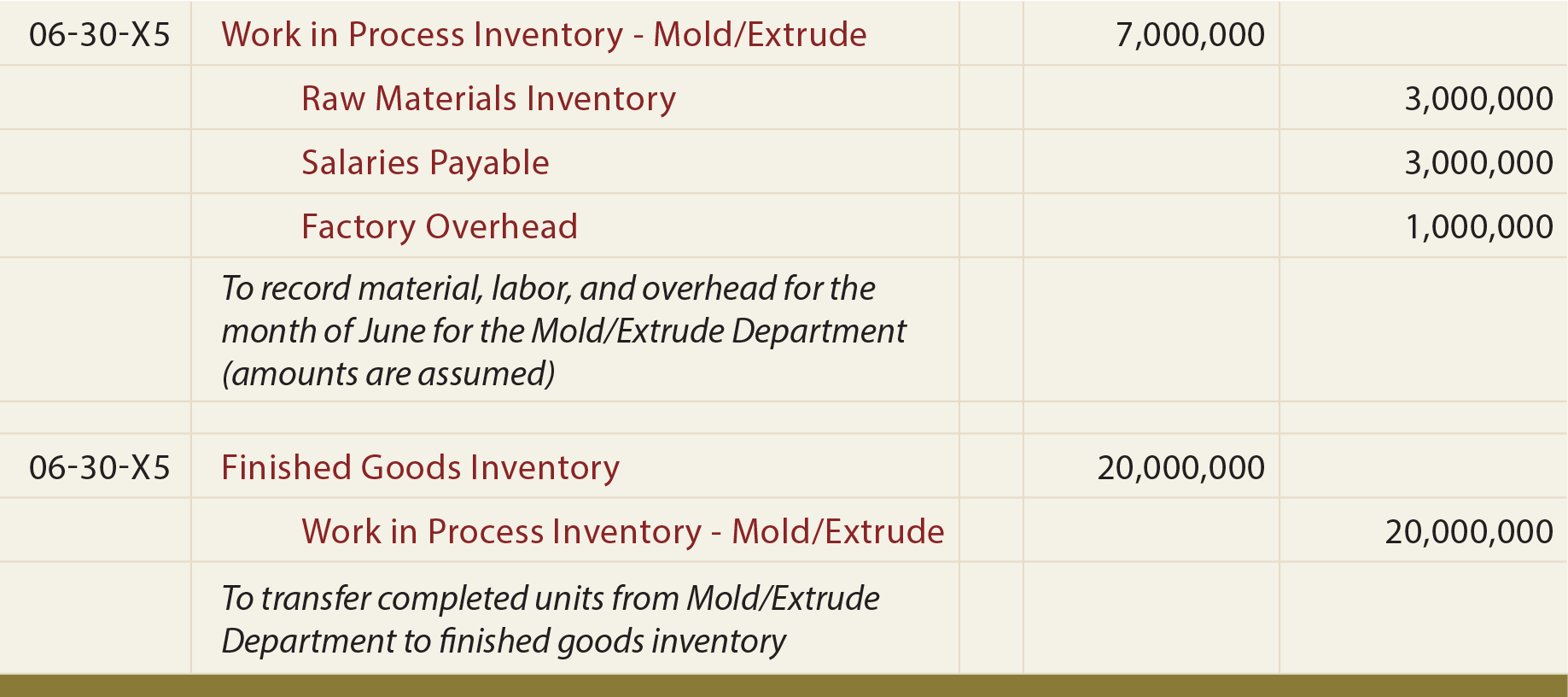

Assume the Mold/Extrude Department has the following T-account and related entries.

The costs transferred from the Mold/Extrude unit go to the finished goods inventory since this is the final process.

As noted within the journal entry descriptions, all costs for each department were assumed. But, overhead is not in direct proportion to salaries payable for each department. This is not unexpected as there is no requirement that overhead be applied at the same rate, or on the same basis, in different departments.

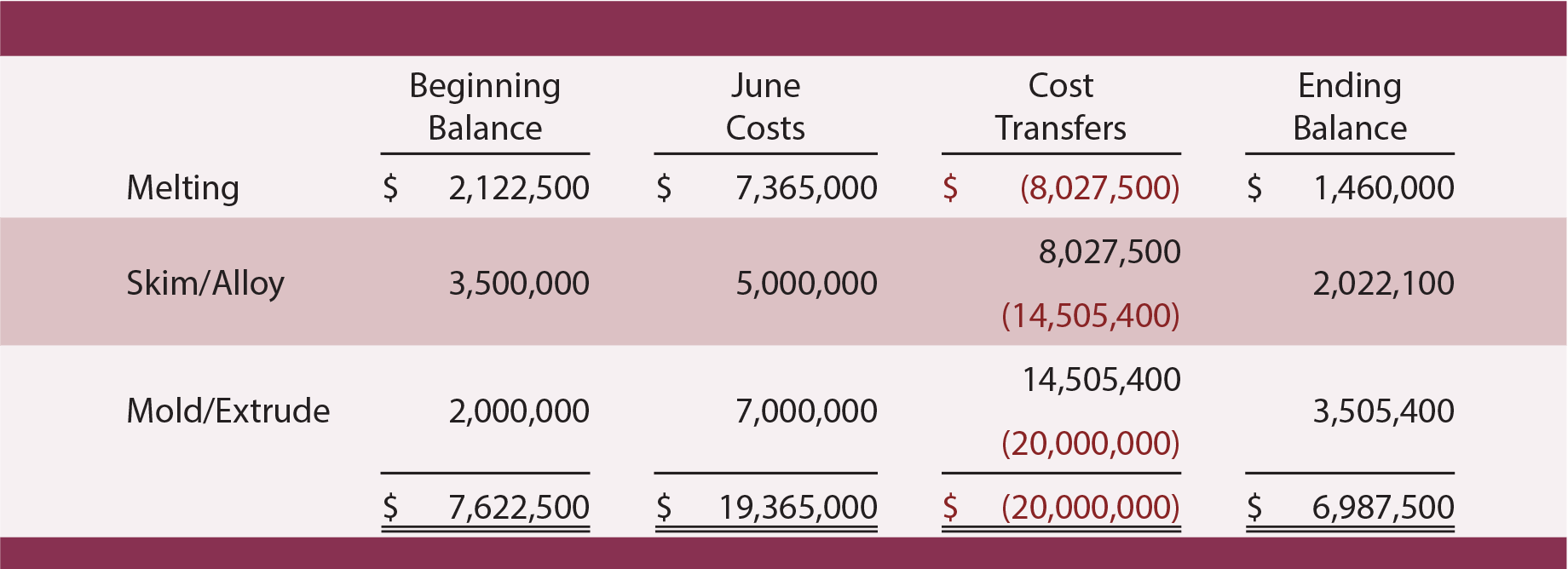

Overall Review

The schedule below shows that Navarro incurred $19,365,000 in costs and transferred $20,000,000 to finished goods. Total work in process inventory declined by $635,000. This is verified by comparing the beginning and ending work in process balances ($7,622,500 – $6,987,500 = $635,000). Navarro’s balance sheet at June 30 would include $6,987,500 as work in process inventory.

Chapter 3: Process Cost System

3.5 process costing (fifo method).

Another acceptable method for determining unit cost under process costing is the first-in, first-out (FIFO) cost method. Under the FIFO method, we assume any units that were not completed last period (beginning work in process) are finished before anything else is started. The following table shows the differences between the weighted average method and the FIFO cost method:

We will look at each item individually as we discuss the steps of process costing. Under either method, weighted average or FIFO, process costing consists of 5 steps:

- Physical Flow of Units

- Equivalent Units

- Cost per Equivalent Unit

- Assign Costs to Units Completed and Ending Work in Process Inventory

- Reconcile Costs

Physical Flow of Units

The physical flow of units is as follows under the weighted average method:

This is altered just slightly under the FIFO method as we must separate the items in units completed into Units Completed from beginning work in process and Units started and completed this period since under FIFO, we must finish anything from beginning work in process before we start something new. Under the FIFO, we the physical flow of units would be documented as:

Just as in the weighted average method, the 2 Total Units figures must agree!

Equivalent Units of Production

Under the FIFO method, we will calculate equivalent units for 3 things: Units completed from beginning work in process, units started and completed this period and units remaining in ending work in process. This video will discuss the differences between the Weighted Average and FIFO methods for equivalent units (if you are comfortable with the weighted average method, skip to minute 4:06 to begin the discussion on the FIFO method).

Equivalent units for the period will be calculated as follows under FIFO ( keep in mind, you may have different percent complete for materials, labor and overhead ):

- Units from beginning work in process: you want to complete this units, so how much MORE effort will be needed to finish these units. You will calculate this as beginning work in process units x (100% – given % complete) to calculate the amount of additional work necessary to make the unit 100% complete.

- Units started and completed this period: take the units x 100% complete since they were started and completed they have received all of their materials, labor and overhead and will not receive any more since they are finished.

- Units in Ending work in process: just like with the weighted average method, we will take the ending work in process units x a given % complete.

To illustrate the computation of equivalent units under the FIFO method, assume the following facts (for simplicity we are using just one percent complete for materials, labor and overhead):

The physical flow of units would be (calculate units started and completed as units started 10,000 – units in ending work in process 5,000):

The equivalent production for the period would be:

Cost per Equivalent Unit

Under the weighted average method, we use beginning work in process costs AND costs added this period. Under the FIFO method, we will only use the costs added this period. This video will explain the differences between the two approaches.

The formula we will use for calculating cost per equivalent unit under the FIFO Method is:

Assign Costs

When we assign costs to units completed and transferred and units remaining in ending work in process under the FIFO method, we need the following items:

- Costs from beginning work in process: these were the costs we started the period with or the unfinished items from the previous period ( no calculation required — just bring over the costs from beginning work in process ). Remember, under FIFO, these are finished first so their costs must be passed along to completed units.

- Costs to complete beginning work in process: you will take the Equivalent units calculated for completing beginning work in process x the cost per equivalent unit. You will do this for materials, labor and overhead (or for conversion costs which is the both direct labor and overhead).

- Costs of units started and completed: you will take the equivalent units calculated for units started and completed x the cost per equivalent unit for materials, labor and overhead (or conversion).

- The sum of these 3 will be the cost of units completed and transferred which is also known as cost of goods manufactured. This amount is transferred to the next department or to finished goods and out of work in process for the units completed this period.

- Cost of units remaining in ending work in process: you will take the ending work in process equivalent units x the cost per equivalent unit for materials, labor and overhead (or conversion) just as we did under the weighed average method. This amount rolls over to be the next period’s beginning work in process inventory.

This video will provide a demonstration of cost assignment under the FIFO method.

Reconcile Costs

Finally, something is the same under FIFO and Weighted Average.

We want to make sure that we have assigned all the costs from beginning work in process and costs incurred or added this period to units completed and transferred and ending work in process inventory.

First, we need to know our total costs for the period (or total costs to account for) by adding beginning work in process costs to the costs incurred or added this period. Then, we compare the total to the cost assignment in step 4 for units completed and transferred and ending work in process to get total units accounted for. Both totals should agree.

The cost reconciliation would be:

In the next page, we will do a demonstration problem of the FIFO method for process costing.

- Equivalent Units. Authored by : Linda Williams. License : All Rights Reserved . License Terms : Standard YouTube License

- Cost Per Equivalent Unit-- FIFO Method vs. Weighted-average Method . Authored by : Education Unlocked. Located at : https://youtu.be/P_Nwchc_pcs . License : All Rights Reserved . License Terms : Standard YouTube License

- Cost Per Equivalent Unit, FIFO Method, Part 2 (Applying Costs) . Authored by : Education Unlocked. Located at : https://youtu.be/y1TLRSL9Yjo . License : All Rights Reserved . License Terms : Standard YouTube License

Understanding Cost Objects – What They Are and Why They Matter

Businesses must clearly understand their costs as they strive to make informed financial decisions. One tool that companies use to track and manage their costs is cost objects.

But what exactly is a cost object, and how is it used in accounting and finance? In this blog post, we will explore the definition of cost objects, common types used in business and finance, and their role in cost accounting.

We will also answer frequently asked questions, including who assigns costs to cost objects and why we assign them. We will also discuss the challenges businesses may face when assigning costs and provide examples of cost objects used in the manufacturing industry.

Finally, we will explore techniques for allocating costs to cost objects and discuss how the size of a business can impact its use. By the end of this post, you will have a comprehensive understanding of cost objects and their importance in managing business finances.

What Is a Cost Object and How Is It Defined in Accounting and Finance? – Understanding Cost Objects

In accounting and finance, a cost object consumes resources or generates costs within a business or organization. It can be a product, service, project, department, customer, or any other entity that requires resources and generates costs.

A cost object can help identify the costs associated with producing a particular product or service, performing a specific activity, or serving a typical customer. This information can then be used to make more informed decisions about pricing, resource allocation, and process improvements .

For example, each bike would be a cost object in a manufacturing company that produces bicycles. The costs associated with producing each bicycle, such as materials, labor, and overhead expenses, would be tracked and assigned to that cost object.

This information can then be used to determine the true cost of each bicycle and make more informed decisions about pricing, production processes, and resource allocation.

In service-based businesses, cost objects can be more challenging to identify. For example, each project or client could be a cost object in a consulting firm. The costs associated with each project or client, such as labor and travel expenses, would be tracked and assigned to that cost object.

There are two types of cost objects: direct and indirect. Direct cost objects can be traced to a particular product, service, or activity. Indirect cost objects are not easily traced back to a particular product, service, or activity but consume resources and generate costs.

It is essential to accurately assign costs to cost objects to make more informed decisions about pricing, resource allocation, and process improvements. Failure to accurately assign costs to cost objects can lead to inaccurate pricing decisions, inefficient use of resources, and ultimately lower profits.

What Are Some Common Types of Cost Objects Used in Business and Finance? – Understanding Cost Objects

In business and finance, everyday cost objects are used to identify and track costs associated with producing goods or services, providing customer support, and managing operations. These cost objects help businesses understand the true costs of their activities and make informed decisions about pricing, resource allocation, and process improvements.

Output Cost – Types of Cost Objects Used in Business and Finance

One common type of cost object is the output cost. This refers to the cost of producing a good or providing a service that will be sold for a profit. It includes materials, labor, and overhead expenses directly associated with the production process. By accurately identifying and tracking output costs, businesses can determine the true cost of their products or services and make informed pricing decisions that maximize profits.

Operational Cost – Types of Cost Objects Used in Business and Finance

Another common type of cost object is operational cost. This includes departmental, functional, event, and customer-specific costs associated with managing and operating a business.

For example, the operational cost of an event management company would include all expenses related to planning and executing events, such as venue rentals, catering, and marketing expenses. By tracking operational costs, businesses can identify areas where they can improve efficiency and reduce costs while maintaining a high service level.

Business Relationship Cost – Types of Cost Objects Used in Business and Finance

Business relationship costs are another type of cost object. These costs refer to the money spent promoting or maintaining relationships with customers, suppliers, and other business partners.

For example, licensing fees, trade association dues, and customer freebies are all examples of business-related costs. These costs are significant because they help businesses establish and maintain strong relationships with their partners, which can lead to increased revenue and long-term success.

In addition to these types of cost objects, businesses may use many other objects to track costs and make informed decisions.

For example, customer acquisition costs, which refer to acquiring new customers, can be useful for businesses looking to expand their customer base. Similarly, employee-related costs, such as salaries , benefits, and training expenses, can be tracked as a cost object to help businesses understand the true cost of their workforce.

What Is an Example of a Cost Object in Business? – Understanding Cost Objects

An example of a cost object in business could be a product line or a specific service. Let’s consider the scenario of a company that manufactures and sells three different types of smartphones – basic, mid-range, and premium. In this case, each product line is a cost object, and the company can track the costs associated with each line separately.

The company can identify and track the costs associated with each cost object to determine the cost of producing each smartphone model. For example, the cost of materials, labor, and overhead for producing each smartphone can be tracked separately for each product line .

This information can be used to make informed pricing decisions, as the company can determine the actual cost of each product and adjust the price accordingly to maximize profitability.

In addition to pricing decisions, cost objects can help identify areas where costs can be reduced or efficiency can be improved. For example, suppose the company identifies that the cost of producing the mid-range smartphone is higher than expected.

In that case, they can analyze the costs associated with that product line to identify areas where costs can be reduced. This may include identifying cheaper materials or streamlining the production process.

Another scenario where cost objects can be helpful is in customer profitability analysis. By tracking the costs associated with each customer, businesses can identify which customers are the most profitable and which are not. This information can be used to make informed decisions about customer acquisition and retention strategies.

Who Typically Assigns Costs to Cost Objects Within an Organization? – Understanding Cost Objects

In an organization, the process of assigning costs to cost objects is typically performed by various individuals or departments, depending on the size and complexity of the organization. The following list outlines some of the key stakeholders involved in the cost assignment process:

1. Management Accountants – Who Typically Assigns Costs to Cost Objects Within an Organization?

Management accountants are responsible for analyzing and reporting on the organization’s financial performance. They often play a key role in assigning costs to cost objects, as they deeply understand the organization’s financial systems and processes.

2. Production Managers – Who Typically Assigns Costs to Cost Objects Within an Organization?

Production managers are responsible for overseeing the production process and ensuring that it runs smoothly and efficiently. They may assign costs to cost objects related to the production process, such as the cost of raw materials, labor, and equipment.

3. Sales and Marketing Managers – Who Typically Assigns Costs to Cost Objects Within an Organization?

Sales and marketing managers promote the organization’s products or services and generate revenue. They may assign costs to cost objects related to sales and marketing activities, such as advertising and promotions.

4. Purchasing Managers – Who Typically Assigns Costs to Cost Objects Within an Organization?

Purchasing managers are responsible for sourcing and procuring the materials and supplies needed for the organization’s operations. They may assign costs to cost objects related to the procurement process, such as raw materials and shipping costs.

5. IT Managers – Who Typically Assigns Costs to Cost Objects Within an Organization?

IT managers are responsible for overseeing the organization’s technology systems and infrastructure. They may assign costs to cost objects related to IT expenses, such as software licenses and hardware maintenance.

6. Human Resources Managers – Who Typically Assigns Costs to Cost Objects Within an Organization?

Human resources managers are responsible for managing the organization’s workforce. They may assign costs to cost objects related to employee compensation, benefits, and training.

7. Financial Controllers – Who Typically Assigns Costs to Cost Objects Within an Organization?

Financial controllers are responsible for managing the organization’s financial systems and processes. They may assign costs to cost objects related to overhead expenses, such as rent, utilities, and insurance.

8. Operations Managers – Who Typically Assigns Costs to Cost Objects Within an Organization?

Operations managers are responsible for overseeing the day-to-day operations of the organization. They may assign costs to cost objects related to operational expenses, such as supplies and equipment maintenance.

In addition to these stakeholders, other individuals or departments may be involved in the cost assignment process, depending on the specific needs and requirements of the organization. For example, a large manufacturing company may have a dedicated cost accounting team responsible for assigning costs to cost objects and analyzing the organization’s financial performance.

How Are Cost Objects Used in Cost Accounting to Help Businesses Manage Their Costs? – Understanding Cost Objects

Cost accounting is a branch of accounting that focuses on measuring, analyzing, and reporting the costs associated with producing goods or providing services.

One of the key concepts in cost accounting is the use of cost objects, which are specific items, products, or activities to which costs can be attributed.

Cost objects are used to help businesses manage their costs in several ways, as outlined below:

1. Cost Control – How Are Cost Objects Used in Cost Accounting

Cost objects help businesses control costs by identifying the specific items or activities driving their expenses. By assigning costs to specific cost objects, businesses can track their expenses more accurately and identify areas where they may be overspending.

For example, a manufacturing company may use cost objects to track the costs of producing each product in its line. This can help them identify the most profitable products needing reevaluation or discontinued.

2. Cost Analysis – How Are Cost Objects Used in Cost Accounting

Cost objects also help businesses analyze costs and make informed decisions about managing them. By analyzing the costs associated with specific cost objects, companies can identify trends, patterns, and areas for improvement.

For example, a service-based company may use cost objects to track the costs associated with each client or project. This can help them identify which clients or projects are the most profitable and which may cost them money.

3. Cost Planning – How Are Cost Objects Used in Cost Accounting

Cost objects help businesses plan for their costs and make informed pricing, budgeting, and resource allocation decisions.

By understanding the costs associated with specific cost objects, businesses can make more accurate projections about their future expenses and revenues. For example, a construction company may use cost objects to track the costs associated with each phase of a building project. This can help them create more accurate project estimates and avoid cost overruns.

4. Cost Reduction – How Are Cost Objects Used in Cost Accounting

Cost objects help businesses reduce their costs by identifying areas where they may be able to streamline their operations or reduce waste.

By analyzing the costs associated with specific cost objects, businesses can identify opportunities for cost reduction and implement strategies to improve their efficiency. For example, a retail store may use cost objects to track the costs associated with each product line. This can help them identify the most profitable products that may tie up valuable resources.

5. Cost Allocation – How Are Cost Objects Used in Cost Accounting

Cost objects help businesses allocate their costs to the appropriate departments, products, or services. By assigning costs to specific cost objects, businesses can ensure that their expenses are accurately allocated and reported.

This can help them make more informed decisions about resource allocation and pricing. For example, a hospital may use cost objects to track the costs associated with each patient. This can help them allocate costs to the appropriate departments and ensure their expenses are accurately reported to insurance providers and regulatory agencies.

When Would It Be Appropriate to Use a Project as a Cost Object? – Understanding Cost Objects

Using a project as a cost object can be appropriate in several situations, as outlined below:

1. Project Cost Control – When Would It Be Appropriate to Use a Project as a Cost Object?

By using a project as a cost object, businesses can control their costs more effectively by tracking the expenses associated with a specific project.

This can help them identify areas where they may be overspending and take corrective action before it is too late. For example, a construction company may use a project as a cost object to track the costs associated with building a new office building. This can help them monitor their expenses and ensure they stay within budget.

2. Project Cost Analysis – When Would It Be Appropriate to Use a Project as a Cost Object?

Using a project as a cost object can also help businesses analyze their costs and make informed decisions about future projects.

By analyzing the costs associated with a specific project, businesses can identify areas to reduce costs or improve their efficiency. For example, a software development company may use a project as a cost object to track the costs of developing a new app. This can help them identify areas where they may be able to streamline their development process and reduce costs.

3. Project Cost Planning – When Would It Be Appropriate to Use a Project as a Cost Object?

Using a project as a cost object can help businesses plan for their costs more effectively by providing a detailed breakdown of the expenses associated with a specific project.

This can help businesses make more accurate projections about their expenses and revenues. For example, a marketing agency may use a project as a cost object to track the costs associated with developing a new advertising campaign. This can help them create more accurate project estimates and avoid cost overruns.

4. Project Cost Reduction – When Would It Be Appropriate to Use a Project as a Cost Object?

By using a project as a cost object, businesses can identify areas where they may be able to reduce costs and improve their efficiency. This can help them achieve their goals more effectively and with fewer resources.

For example, a manufacturing company may use a project as a cost object to track the costs associated with developing a new product line. This can help them identify areas where they may be able to reduce costs and improve their manufacturing processes.

5. Project Cost Allocation – When Would It Be Appropriate to Use a Project as a Cost Object?

Using a project as a cost object can help businesses allocate their costs more accurately to the appropriate departments or products. By tracking the expenses associated with a specific project, businesses can ensure that their costs are allocated correctly and reported accurately.

For example, a consulting firm may use a project as a cost object to tracking the costs associated with a specific client engagement. This can help them allocate costs to the appropriate departments and ensure that their expenses are accurately reported.

Who Benefits the Most From Using Cost Objects to Track Expenses in a Business?

Below are some of the stakeholders that can benefit the most from using cost objects to track expenses in a business:

1. Management – Who Benefits the Most From Using Cost Objects?

One of the primary beneficiaries of using cost objects to track expenses is management. By better understanding where money is spent within a company, management can make more informed decisions about where to allocate resources, which projects to pursue, and which expenses to cut. Cost objects can also help management identify areas where efficiency and costs can be improved.

2. Accountants – Who Benefits the Most From Using Cost Objects?

Accountants also benefit from using cost objects to track expenses in a business. Cost objects provide a more accurate picture of where money is being spent, which helps accountants create more accurate financial statements. This can help them comply with financial reporting requirements, such as GAAP or IFRS, and provide stakeholders with a clear view of the company’s financial health.

3. Sales and Marketing – Who Benefits the Most From Using Cost Objects?

Sales and marketing teams can benefit from using cost objects to track expenses by understanding the cost of acquiring new customers or generating new leads. Using cost objects, they can see how much money is spent on specific campaigns or initiatives and make informed decisions about where to invest their resources.

4. Operations – Who Benefits the Most From Using Cost Objects?

Operations teams can benefit from using cost objects to track expenses by identifying areas where efficiency can be improved. By understanding the cost of specific processes or activities, operations teams can find ways to streamline operations and reduce costs.

5. Investors – Who Benefits the Most From Using Cost Objects?

Investors can benefit from using cost objects to track expenses in a business by having a better understanding of how the company is using its resources. This can help them make informed decisions about whether or not to invest in a company and can provide insight into the company’s long-term financial health.

6. Customers – Who Benefits the Most From Using Cost Objects?

While not traditional stakeholders, customers can indirectly benefit from using cost objects to track expenses in a business. By better understanding where money is being spent, companies can potentially reduce their costs and offer products or services at a lower price point. This can ultimately benefit customers by providing them with more affordable options.

What Are Some Challenges Businesses May Face When Assigning Costs to Cost Objects? – Understanding Cost Objects

Assigning costs to cost objects can be challenging for businesses, mainly when numerous cost objects are involved or when the costs are not easily attributable to a specific object. Below are some of the common challenges businesses may face when assigning costs to cost objects:

1. Identifying Cost Objects – Challenges Businesses May Face

One of the biggest challenges businesses face when assigning costs to cost objects is identifying the appropriate cost objects. It can be challenging to determine which costs should be assigned to which cost objects, mainly if many cost objects are involved or if the costs are not easily attributable to a specific object.

2. Allocating Indirect Costs – Challenges Businesses May Face

Another challenge businesses face when assigning costs to cost objects is allocating indirect costs. Indirect costs, such as overhead or administrative expenses, can be difficult to allocate to specific cost objects. Businesses may need to use allocation methods, such as activity-based costing, to allocate indirect costs to cost objects.

3. Choosing the Right Allocation Method – Challenges Businesses May Face

Businesses may face challenges in choosing the right allocation method when assigning costs to cost objects. Several different allocation methods are available, each with advantages and disadvantages. Choosing the correct method can be challenging and may require careful consideration of the specific circumstances and goals of the business.

4. Ensuring Accuracy – Challenges Businesses May Face

Assigning costs to cost objects requires accuracy to ensure the resulting data is reliable and valuable. However, achieving accuracy can be difficult, mainly if the data is incomplete or inaccurate. Businesses may need to implement procedures to ensure data accuracy in cost allocation.

5. Updating Cost Object Data – Challenges Businesses May Face

Cost objects may change over time, challenging businesses when assigning costs. For example, if a product line is discontinued, the costs associated with that product line may need to be allocated to a different cost object. Businesses must ensure that they regularly update cost object data to reflect changes in the industry.

6. Ensuring Consistency – Challenges Businesses May Face

Consistency in cost allocation is important to ensure the resulting data is comparable over time. However, achieving consistency can be challenging, mainly if the business uses different allocation methods or cost objects over time. Companies may need to implement procedures to ensure that cost allocation is consistent over time.

7. Dealing with Complexity – Challenges Businesses May Face

Some businesses may have complex operations, making assigning costs to cost objects challenging. For example, assigning costs to cost objects can become complex if a business operates in multiple locations or has multiple product lines. Businesses may need sophisticated cost allocation methods or software to handle this complexity.

When Should a Business Consider Creating a New Cost Object? – Understanding Cost Objects

There may be situations where a business needs to create a new cost object to manage costs better.

Below are some scenarios where a business should consider creating a new cost object:

1. Introducing a New Product or Service – When Should a Business Consider Creating a New Cost Object?

When a business introduces a new product or service, creating a new cost object may be appropriate to track the costs associated with that product or service. This can help the business to determine the profitability of the new offering and to identify opportunities to reduce costs.

2. Expanding into a New Market or Region – When Should a Business Consider Creating a New Cost Object?

If a business expands into a new market or region, it may need to create a new cost object to track the costs associated with that market or region. This can help the business determine whether the expansion is profitable and identify opportunities to reduce costs in the new market or region.

3. Undertaking a Large Project – When Should a Business Consider Creating a New Cost Object?

When a business undertakes a large project, such as building a new factory or launching a new marketing campaign, it may be appropriate to create a new cost object to track the costs associated with the project. This can help the business determine the project’s total cost and identify opportunities to reduce costs.

4. Tracking Costs for a Specific Customer – When Should a Business Consider Creating a New Cost Object?

Sometimes, a business may want to track costs associated with a specific customer, particularly if that customer represents a significant portion of the business’s revenue. Creating a new cost object for the customer can help the business determine the customer’s profitability and identify opportunities to reduce costs associated with serving that customer.

5. Managing Costs for a Specific Department – When Should a Business Consider Creating a New Cost Object?